Polymer Engineered Diffusers®

- Square, Circular, and Line Scatter Shapes

- Design Wavelength: 400 nm - 700 nm

- Transmission: 90%

- Unmounted and Mounted Ø1" Diffusers Available

ED1-C20-MD

20° Circle Pattern, Mounted

ED1-C20

20° Circle Pattern, Unmounted

Line Pattern

Square Pattern

Circle Pattern

OVERVIEW

| Diffuser Selection Guide | |||

|---|---|---|---|

| Ground Glass Diffusers | |||

| Type | Material | Mounting, Coating | Operating Wavelength |

| Standard Diffusers | N-BK7 Substrate | Unmounted, Uncoated | 350 nm - 2.0 μm |

| Unmounted, AR Coated | 350 nm - 700 nm 650 nm - 1050 nm |

||

| Mounted, Uncoated | 350 nm - 2.0 µm | ||

| UVFS Substrate | Unmounted, Uncoated | 185 nm - 2.0 µm | |

| Diffuse Reflectors | N-BK7 Substrate | Unmounted, UV-Enhanced Aluminum Coated |

250 nm - 450 nm |

| Unmounted, Protected Silver Coated | 450 nm - 20 µm | ||

| Unmounted, Protected Gold Coated | 800 nm - 20 µm | ||

| Alignment Disks | |||

| Engineered Diffusers | |||

| Type | Material | Mounting, Coating | Operating Wavelength |

| Glass Diffusers | UVFS Substrate | Unmounted and Mounted, Uncoated | 400 nm - 700 nm |

| Polymer Diffusers | ZEONOR Substrate | Unmounted and Mounted, Uncoated | 400 nm - 700 nm |

| Diffuser Kits | |||

Features

- Ø1" Diffusers

- Input Illumination Homogenized to Circle, Square, or Line Pattern Profiles

- ZEONOR Polymer Substrate

- Design Wavelength Range from 400 - 700 nm

- 90% Transmission Efficiency from 380 nm - 1100 nm

- Available Unmounted or Mounted

- Ideal for Low-Power Applications

Thorlabs offers Polymer Engineered Diffusers®*, which provide non-Gaussian intensity distributions in square, circular, and line distribution patterns (see the Graphs tab). Over their design wavelength, these diffusers have a square or circular distribution pattern with a 20° or 50° divergence angle, while the line distribution has a 0.4° x 100° divergence; typical diffusers do not offer this advanced level of light control.

These cost-effective engineered diffusers are made from injection molded ZEONOR polymer and have 90% transmission efficiency from 380 nm - 1100 nm. They are ideal for low-power applications and are designed for use with Ø0.5 mm or larger beams; smaller beams should be expanded prior to the diffuser. For high-power applications or applications requiring UV transmission, Thorlabs offers UV Fused Silica Engineered Diffusers.

Our polymer engineered diffusers are available unmounted or mounted. The mounted Ø1" diffusers come in an engraved SM1-threaded (1.035"-40) mount, as shown at the top of the webpage. The mount provides quick identification and helps protect the diffusers from fingerprints and other contamination. SM1 threading is particularly useful when building

Please see the Technology tab for more information on the technology and fabrication of our Engineered Diffusers.

*Engineered Diffusers® is a registered trademark of VIAVI Solutions, Inc.

SPECS

| Common Specifications | |

|---|---|

| Material | Injection Molded ZEONOR |

| Design Wavelengtha | 400 - 700 nm (Achromatic) |

| Transmission Spectruma | 380 - 1100 nm |

| Diffuser Diameter | Ø25.4 mm (Ø1") |

| Diffuser Thickness | 1.5 mm (0.06") |

| Incident Beam Size | ≥0.5 mm |

| Index of Refraction | 1.53 |

| Item # | Pattern | Divergencea | Transmission Efficiency | ||

|---|---|---|---|---|---|

| Flat Intensity Regionb | 50% of Max Intensityc | 10% of Max Intensityd | |||

| ED1-C20(-MD) | Circle | 20° | 27° | 36° | 90% |

| ED1-C50(-MD) | Circle | 50° | 60° | 70° | 90% |

| ED1-S20(-MD) | Square | 20° | 27° | 36° | 90% |

| ED1-S50(-MD) | Square | 50° | 60° | 70° | 90% |

| ED1-L4100(-MD) | Line | 100° | 105° | 115° | 90% |

TECHNOLOGY

Click to Enlarge

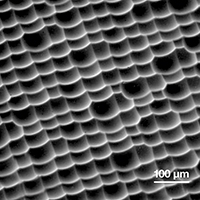

Figure 814B SEM Picture of Engineered Diffuser for Display Brightness Enhancement

Click to Enlarge

Figure 814A SEM Picture of Engineered Diffuser for Projection Screens

Engineered Diffuser® Technology

Thorlabs' Engineered Diffusers provide advanced beam shaping that leads to significant performance enhancements for applications as diverse as lithographic systems, outdoor lighting, displays, backlighting, display brightness enhancement, and projection screens.

Homogeneous diffusers made of, for example, ground glass, opal glass, or holographic elements, consist of repeating, uniform surface patterns across the entire clear aperture that provide only limited control over the shape and intensity profile of the illuminated area, causing the incident light to be used inefficiently. In addition, holographic diffusers are usually limited to monochromatic applications using coherent light. On the other hand, Engineered Diffusers consist of differing, individually manipulated microlens units that provide broadband compatibility and excellent control over the light distribution and beam profile.

Each microlens unit that forms the diffuser is individually specified with respect to its surface profile and location in the array. At the same time, to ensure that the diffuser is stable against variations in the input beam's intensity profile and usable in the visible and IR, the distribution of microlenses is randomized according to probability distribution functions chosen to implement the desired beam shaping functions. The randomized location of the mircrolenses prevents the formation of diffraction artifacts and zero-order bright spots while also making the diffuser relatively insensitive to variations in the input beam intensity profile or the frequency of the light, which results in a diffuser that works equally well with monochromatic or broadband light. While the specifications for Engineered Diffusers are given at the design wavelength, deviating from that wavelength will only result in a slight variation of the divergence angle of the transmitted light owing to their achromatic properties; as a result, they can be used to mix light from RGB LED arrays into a transmitted light distribution, with a controlled color temperature, divergence, intensity distribution, and shape. In this manner, Engineered Diffusers retain the best properties of both random and deterministic diffusers.

Click to Enlarge

Figure 814C Diagram of Mastering Process

Fabrication

The master microlens array is produced by a laser writing system developed by VIAVI Solutions, Inc. This system exposes a thick layer of photoresist point-by-point in a raster scan mode, as shown in Figure 814C. By modulating the intensity of the laser beam as it is scanned, the degree to which the photoresist is exposed can be varied. A deeply textured, engineered surface is the result, as shown in the SEM images of the surface topography in Figures 814A and 814B.

Comparison to Other Diffuser Technologies

Other common diffuser types include prismatic glass integrating bars, ground glass, opal glass, holographic diffusers, and diffractive diffusers. Prismatic glass integrating bars, though sometimes used in high-end systems, are expensive and occupy a great deal of precious space. Ground and opal glass scatter light equally in all directions but with a low degree of control. In addition, efficiency is generally poor with these simple diffusers. Holographic diffusers are an improvement on these technologies and enable limited production of light distribution patterns, but only offer Gaussian-like intensity profiles and circular or elliptical patterns. In terms of general beam shaping capability, diffractive elements can shape an input beam arbitrarily. However, they are confined to narrow diffusion angles, highly sensitive to wavelength, and cannot eliminate zero-order bright spots collinear with the incident beam. In contrast, Engineered Diffusers provide high transmission efficiencies and the ability to control the divergence angle, spatial distribution, and intensity profile of the diffused light over a broad wavelength range.

Custom Solutions

In a particularly challenging application of this technology, an ideal projection screen was designed. For this application, the divergence angle in one direction was large (120° FWHM), while in the other it was narrow (40° FWHM). In addition, the near-field distribution of focal spots was controlled and the speckle pattern commonly associated with coherent light sources was avoided, all while maintaining the resolution of the projection. Please contact Tech Sales for custom Engineered Diffusers to fit your application.

GRAPHS

Introduction

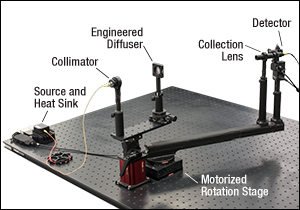

These Polymer Engineered Diffusers® are designed to create non-Gaussian intensity distributions in circular or square beam profiles that diverge from the plane of incidence. Figures 4.1, 4.3, 4.5, 4.7, and 4.9 are the theoretical approximations of the intensity through the center of the diverging beam profile when illuminating the engineered diffusers with a 633 nm collimated beam. Figures 4.2, 4.4, 4.6, and 4.8 contain data compiled from independent tests with laser wavelengths of 488 nm, 637 nm, 785 nm, and 1064 nm to demonstrate the change in output profile with wavelength. The highlighted region of each graph denotes the divergence angle of the engineered diffuser. At the bottom of this tab is a description of the laboratory setup and procedure used to collect these data and the results.

Circular Pattern Diffusers Transmitted Intensity Plots

|

|

Click to Enlarge Click to EnlargeFigure 4.2 Experimental Data for ED1-C20 Raw Data |

Click to Enlarge Click to EnlargeFigure 4.3 Theoretical Data for ED1-C50 |

Click to Enlarge Click to EnlargeFigure 4.4 Experimental Data for ED1-C50 Raw Data |

Square Pattern Diffusers Transmitted Intensity Plots

Click to Enlarge Click to EnlargeFigure 4.5 Theoretical Data for ED1-S20 |

Click to Enlarge Click to EnlargeFigure 4.6 Experimental Data for ED1-S20 Raw Data |

Click to Enlarge Click to EnlargeFigure 4.7 Theoretical Data for ED1-S50 |

Click to Enlarge Click to EnlargeFigure 4.8 Experimental Data for ED1-S50 Raw Data |

Line Pattern Diffuser Transmitted Intensity Plot

Click to Enlarge

Figure 4.9 Theoretical Data for ED1-L4100

Click to Enlarge

| Light Preparation | ||||

|---|---|---|---|---|

| Wavelength (nm) | 488 | 637 | 785 | 1064 |

| Source | LP488-SF20 | LP637-SF70 | LP785-SF100 | DBR1064S |

| Heat Sink | LDM9LP | LM14S2 | ||

| Collimator | TC06FC-543 | TC06FC-633 | TC06APC-780 | TC06APC-1064 |

Procedure

Four wavelengths of light were chosen for study: 488 nm, 637 nm, 785 nm, and 1064 nm. These were prepared using the equipment in Figure 4.10 (a full list of all parts used can be found in the figure caption). The optical path was approximately 35 cm above the surface of the breadboard; it began when fiber-coupled light sources were collimated with triplet collimators, using a design wavelength as close to the source wavelength as possible. In free space, the beams were incident upon one of the Polymer Engineered Diffusers. The exiting divergent profile was isolated and focused by an LA1304 plano-convex lens attached to an SM05L20 lens tube. The signal was sampled every 0.5° by a SM05PD1A photodiode. This assembly was mounted on the end of an XT34-500 rail. The opposite end of the rail was mounted to a previous-generation NR360Sa rotation stage centered with the engineered diffuser under test in order to sweep the detector and lens assembly through the center of the profile, as illustrated in Figure 4.11, and plot normalized intensity versus output angle. The distance between the diffuser and the detector was approximately 43 cm. The output angle was defined with respect to the original optical axis when the diffuser was not within the path. In order to control for ambient light, a 1 kHz sine wave was used to modulate the drive current applied to the laser diode and the signal was acquired with a lock-in amplifier. A LabVIEW program was written to control the setup and acquire the data.

Experimental Limitations

Only one of each Item # was testedb. Stability may have been compromised by the experiment being performed on a PBG11113c breadboard without any isolation. Only the middle of each diffuse shape was measured, so variances in other areas of the shape are possible, including the corners of the square profiles.

Results

It was found that there was little variance in diffuse beam profile with respect to wavelength across the middle of each beam profile. Figures 4.1, 4.3, 4.5, 4.7, and 4.9 include the theoretical estimations of intensity across the width of the resulting beam profile. Figures 4.2, 4.4, 4.6, and 4.8 contain data compiled from independent tests with various laser wavelengths to verify the theoretical models.

| Item # | Theoretical | Experimental | Raw Data | |

|---|---|---|---|---|

| Circular Patterns | ED1-C20 | Click Here | ||

| ED1-C50 | Click Here | |||

| Square Patterns | ED1-S20 | Click Here | ||

| ED1-S50 | Click Here | |||

| Line Pattern | ED1-L4100 | Not Available | Not Available |

Click to Enlarge

Figure 4.11 Detector Path Through Diffuse Profiles

Ø1" Unmounted Polymer Engineered Diffusers®

- Ø1" Engineered Diffusers®

- ZEONOR Polymer Substrate

- Circle, Square, or Line Pattern Diffusers

Unmounted optics are ideal for applications that are tight on space or that need added mounting flexibility. These Ø1" Unmounted Polymer Engineered Diffusers are commonly used in SM1-threaded (1.035"-40) lens tubes. The optic should be oriented so that incident light hits the engineered surface first.

Part Number | Description | Price | Availability |

|---|---|---|---|

ED1-C20 | Ø1" Unmounted Polymer Engineered Diffuser, 20° Circle Pattern | $152.54 | Today |

ED1-C50 | Ø1" Unmounted Polymer Engineered Diffuser, 50° Circle Pattern | $152.54 | Today |

ED1-S20 | Ø1" Unmounted Polymer Engineered Diffuser, 20° Square Pattern | $152.54 | Today |

ED1-S50 | Ø1" Unmounted Polymer Engineered Diffuser, 50° Square Pattern | $152.54 | Today |

ED1-L4100 | Ø1" Unmounted Polymer Engineered Diffuser, 0.4° x 100° Line Pattern | $152.54 | Today |

Ø1" Mounted Polymer Engineered Diffusers®

- Ø1" Engineered Diffusers® in SM1-Threaded Mounts

- ZEONOR Polymer Substrate

- Circle, Square, or Line Pattern Diffusers

These Mounted Engineered Diffusers are the same as their unmounted counterparts, but are set in an engraved mount with internal SM1-threading (1.035"-40). Mounted optics have the advantage that they are easy to identify and the optics are recessed in the mount so that they are better protected from contamination than unmounted optics. The optic should be oriented so that incident light hits the engineered surface first; when the optic is placed in its mount, this surface will face the retaining ring.

Part Number | Description | Price | Availability |

|---|---|---|---|

ED1-C20-MD | Ø1" SM1-Mounted Polymer Engineered Diffuser, 20° Circle Pattern | $169.06 | Today |

ED1-C50-MD | Ø1" SM1-Mounted Polymer Engineered Diffuser, 50° Circle Pattern | $169.06 | Lead Time |

ED1-S20-MD | Ø1" SM1-Mounted Polymer Engineered Diffuser, 20° Square Pattern | $169.06 | In Stock Overseas |

ED1-S50-MD | Ø1" SM1-Mounted Polymer Engineered Diffuser, 50° Square Pattern | $169.06 | In Stock Overseas |

ED1-L4100-MD | Ø1" SM1-Mounted Polymer Engineered Diffuser, 0.4° x 100° Line Pattern | $169.06 | Today |

Mounted Polymer Engineered Diffuser® Kit

| Table G3.1 EDK01 Contents | |

|---|---|

| Item # | Description |

| ED1-C20-MD | Ø1" SM1-Mounted Polymer Engineered Diffuser, 20° Circle Pattern |

| ED1-C50-MD | Ø1" SM1-Mounted Polymer Engineered Diffuser, 50° Circle Pattern |

| ED1-S20-MD | Ø1" SM1-Mounted Polymer Engineered Diffuser, 20° Square Pattern |

| ED1-S50-MD | Ø1" SM1-Mounted Polymer Engineered Diffuser, 50° Square Pattern |

| ED1-L4100-MD | Ø1" SM1-Mounted Polymer Engineered Diffuser, 0.4° x 100° Line Pattern |

| - | Labeled Storage Box |

- Ø1" Engineered Diffusers® in SM1-Threaded Mounts

- ZEONOR Polymer Substrate

- Kit Includes Five Diffusers and a Storage Box

The EDK01 Polymer Engineered Diffuser® Kit includes five Ø1" mounted diffusers and a labeled storage box. These SM1-threaded mounts are engraved with the item number and a brief item description. Please see Table G3.1 for the contents of this diffuser kit.

Part Number | Description | Price | Availability |

|---|---|---|---|

EDK01 | Ø1" SM1-Mounted Polymer Engineered Diffuser Kit, 5 Pieces | $851.63 | Today |

Click to Enlarge

Click to Enlarge