Fiber-Optic Cleaver and Scribes

- Manual Fiber Cleaver for Consistent 0.5° Cleaves

- Ruby Scribe and Carbide Scribe for Cleaving Excess Fiber

- Ceramic Scribe for Cleaving Polyimide- or TECS-Coated Large-Core Fiber

- Disposal Unit for Cleaved Fiber

S90R

Ruby Fiber Scribe

Close-Up View

FTDU

Disposal Unit

CSW12-5

Ceramic Fiber Scribe

(Pack of 5)

CLV150

Manual Fiber Cleaver

OVERVIEW

Thorlabs offers the CLV150 manual cleaver, the S90R ruby-tipped scribe, the S90C carbide-tipped scribe, and CSW12-5 ceramic scribe as solutions for easy, manual cleaving of fibers. The CLV150 manual cleaver with sliding blade provides quality, repeatable cleaves needed for fusion splicing of fiber optics. The CSW12-5 ceramic scribes are optimal for scoring and cleaving hard-coated and large-core fiber. The S90R ruby-tipped wedge scribe and the S90C carbide-tipped scribe can be used for easy scribing of excess fiber from ferrules in the connectorization process. The S90C in particular is adept at cleaving metal coated fiber. The FTDU provides a simple safe solution for disposing of all cleaved fiber ends. We recommend using such a disposal unit to protect against injuries caused by fiber shards. In addition, Thorlabs offers a variety of complementary products and tools for fiber termination.

CLEAVING GUIDE

If you would like more information about tips, tricks, and other methods we often use in the lab, we recommend our other Video Insights. In addition, our webinars provide practical and theoretical introductions to our different products.

Cleave Fibers Using a Hand-Held Scribe

The S90R, S90C, and CSW12-5 scribes are convenient, easy-to-use tools for scoring or cleaving fiber. They are used extensively when connectorizing or polishing fibers. Below we provide a simple step-by-step description on the most common usages for these scribes. For more detailed information on connectorization or polishing of fibers, please refer to the FN96A connectorization guide.

The Video Insight at right describes an approach for achieving an optical-quality end face using the S90R and a multimode fiber with a 400 μm core. Also demonstrated are a couple of techniques for inspecting the end face for information about its quality.

Fiber Scoring

Scoring is a technique for cleaving a fiber that utilizes a scribe to make a small cut in the fiber (i.e., a score) that becomes a stress point for cleaving. Below are descriptions on how to use the S90R ruby scribe, the S90C carbide scribe, and the CSW12-5 ceramic scribe.

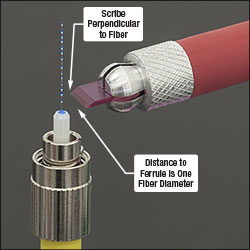

For the S90R and S90C, the cutting edge of the scribe must be held perpendicularly to the protruding fiber. Figure 1 shows a fiber, protruding from a connector, undergoing scoring by a ruby scribe. The CSW12-5 ceramic scribe should be held at a 45° angle to the fiber so that the straight edge (i.e., any edge on the un-engraved side) is in contact with the fiber. As shown in Figure 2, this will result in the engraved side facing upwards. The engraved metric scale on the CSW12-5 can used to ensure repeatable cuts.

While restraining the fiber, gently drag the scribe across the fiber at the desired location. Different optical fiber types will require different amounts of scoring. It will not take a lot of force to score the fiber, and the fiber should not break during scoring. If the fiber does break during scoring, it may produce a jagged edge that cannot be polished correctly; hence, care must be taken to prevent breakage during scoring. Over time, as the cutting edge progressively deteriorates, more pressure will be needed to score the fiber; keep in mind that undue pressure can lead to poor cuts. Once a fiber has been scored, it can be easily cleaved. From the scored side of the fiber, gently squeeze the fiber tip and pull straight away from the rest of the fiber (see Figure 4). Avoid bending or flexing the fiber. This should be all the force necessary to create a clean cleave. Multimode fibers may require slightly more force due to their larger core diameter.

Fiber Cleaving

Cleaving a fiber is a technique that is very similar to scoring. After preparing a fiber for cleaving, clean the bare fiber using a lint-free wipe moistened with isopropyl alcohol. Once clean, tape one end of the fiber to a bench or work station; leave about 6 mm between the edge of the table and tape. Figure 3 shows a fiber cable prepped for cleaving. When using this technique, it helps to secure the free end of the fiber to a support in order to help prevent against breaking the fiber on the edge of the table. Even the weight from a short section of fiber can be enough to cause the fiber to break.

To start the cleave, pull the fiber taut and keep tension in the fiber as you cleave. Bring the scribe toward the fiber at a 45° angle for the ceramic scribe (see figure 2) or at a perpendicular angle for the ruby and carbide scribes (see figure 3). It's important to keep the proper amount of pressure on the scribe during this process. If too much pressure is applied to the scribe, the fiber will break, resulting in a jagged end, which may not be able to be polished correctly. Too little pressure and the fiber will not score enough to cleave cleanly. After the fiber has been scored, place a drop of water on the cleave site. Then apply pressure to the taped end of the fiber and, like with the scoring above, pull the fiber straight back until you cleave the fiber (see figure 4). Try to avoid any bending or flexing of the fiber, as this could affect the cleave.

The end of the fiber may be inspected with an eye loupe or microscope. A good cleave will be flat across the fiber and perpendicular to the optic axis. There should be no 'tag' (i.e., protrusion) from the edge of the fiber. The region where the initial scribe was made may be visible. It should be less than 5% of the core diameter. If the cleave is not acceptable, repeat the cleaving process.

Click to Enlarge

Figure 1: Hold the ruby scribe perpendicular to the fiber.

Click to Enlarge

Figure 2: Hold the ceramic scribe at a 45° angle to the fiber.

Click to Enlarge

Figure 3: Ensure the fiber is secured and taut when cleaving or scoring.

Click to Enlarge

Figure 4: Pull the fiber straight back until the fiber is cleaved to ensure a clean break. Do not twist or bend the fiber.

Manual Fiber Cleaver

Click to Enlarge

The cleaving blade can be rotated to expose new, unused edges.

Click to Enlarge

CLV150 Cleaver with Lid and Fiber Clip Open

- Precision Engineered to Produce Flat Cleaves with ±0.5° Tolerance

- For Use with Standard Ø125 µm Cladding and Ø250 or Ø900 µm Buffers and Ø3 mm Ribbon Cable (Compatible with Ø110 - 200 µm Cladding)

- Push to Cleave with Auto-Return Mechanism

- Rotatable Blade Position with 24 Marked Indices, Rated for 48k Cleaves

- Mechanical Design Allows for Easy, Precise Blade Replacement

- Removable Waste Bin for Fiber Scrap

- Replacement Blade Available Separately

The CLV150 Fiber Cleaver features a sliding blade that produces consistent flat cleaves within ±0.5° and is equipped with a multi-channel fiber holder that is compatible with Ø250 µm and Ø900 µm jacketed fibers as well as Ø3.0 mm fiber ribbon cables. This cleaver offers simple two-step operation and automatic blade return when the lid is lifted after the cleave process. An attached waste bin holds fiber remnants. The blade can be rotated to expose unused edges, as illustrated in the photo to the right. Each CLVB blade is rated for up to 48k cleaves (2k per labelled blade position).

This cleaver is similar to the cleavers included with the ARC150 Arc Splicer Kit, which includes two cleavers with removable transfer clips for use with the splicer. The CLV150 standalone cleaver includes a multi-purpose clip which can be removed for compatibility with the FHC series transfer clips included with the ARC150 kit.

Part Number | Description | Price | Availability |

|---|---|---|---|

CLV150 | Manual Fiber Cleaver with Clip for Ø125 µm Cladding Fiber | $663.00 | Lead Time |

CLVB | Replacement Blade for Manual Fiber Cleaver | $102.00 | Today |

Ceramic Fiber Scribes

Click for Details

Click for DetailsThe CSW12-5 has Straight and Micro-Serrated Edges

- Durable 1" x 2" x 0.03" Aluminum Oxide (Al2O3) for Longterm Use

- Capable of Scoring Optical Fiber with Polyimide, TECS, or Polymer Coatings

- Engraved Metric Scale for Measuring Short Fiber Lengths Quickly

- Convenient for Quickly Cleaving Optogenetics Cannula to Desired Length

- Sold in Packs of 5

These Ceramic Fiber Optic Scribes have four straight edges for scoring fiber optics and four micro-serrated edges for glass-lined metal capillary and stainless steel hypodermic needle stock. Its hard ceramic (98% Al2O3) edges are capable of cleaving polyimide-, TECS-, or polymer-coated optical fiber. These scribes feature a large surface area for secure handling, are suitable for small or large core fibers, and have an engraved metric scale that can be used for quick and repeatable measurements. These ceramic scribes are autoclavable for applications that require sterile procedures.

The straight edge is any edge on the un-engraved side, and the serrated edge is any edge on the engraved side. The edges can also be distinguished by running your fingernail along each edge; the straight edge will feel smooth, whereas the serrated edge will be noticeably rough. See the diagram to the right for details. The CSW12-5 scribes are designed for longterm use but will eventually dull. When all four sides of the scribe become dull, discard and replace with a fresh scribe. This will help to minimize adding undue force onto the fiber due to a dull edge.

For information on scoring fiber with the ceramic fiber scribe, please see our Cleaving Guide tab above.

Part Number | Description | Price | Availability |

|---|---|---|---|

CSW12-5 | Ceramic Fiber Optic Scribes, 5 Pack | $52.41 | Today |

Ruby Fiber Scribe

- 30°, Single Bevel, Ruby Tip

- 5.2 mm to 5.5 mm Long Contact Area Aids Cleaving of Large-Core Fiber

- Cleave Bare Fiber to Produce Optical Quality Surfaces

- Scribe Excess Fiber from the Connector Ferrule in Preparation for Polishing

This Ruby Fiber Scribe has a 30°, single bevel, ruby blade with a 5.2 mm to 5.5 mm long contact area. The blade is reversible, which doubles the life of the scribe (see below for details). However, replacement blades are not available. The soft, non-slip grip provides precise control during scribing. The scribe is approximately 5" long from end to end. Each scribe comes with a clear safety cap to protect the blade from damage when not in use.

Blade Reversal

To reverse the blade, unscrew the knurled end of the scribe and pull it slightly out of the handle. This releases the blade mount. Push the knurled end back into the handle. The blade and its mount will be pushed away from the handle allowing the blade to be removed, flipped, and reinserted. While holding the blade and mount in the handle, screw the knurled end back in, securing the blade.

For information on scoring and cleaving fiber with the Ruby Fiber Scribe, please see our Scribe Guide tab above.

Part Number | Description | Price | Availability |

|---|---|---|---|

S90R | Ruby DualScribe Fiber Optic Scribe | $61.48 | Today |

Carbide Fiber Scribe

Click to Enlarge

Click to EnlargeCarbide Fiber Scribe has a Reversible Blade with 30° Bevel

- 30°, Single Bevel, Carbide Tip

- Capable of Scoring Optical Fiber with Aluminum Coatings

- 5.2 mm to 5.5 mm Long Contact Area Aids Cleaving of Large-Core Fiber

- Cleave Bare Fiber to Produce Optical Quality Surfaces

- Scribe Excess Fiber from the Connector Ferrule in Preparation for Polishing

This Carbide Fiber Scribe has a 30°, single bevel, carbide blade with a 5.2 mm to 5.5 mm long contact area. The blade is reversible, which doubles the life of the scribe (see below for details). However, replacement blades are not available. The soft, non-slip grip provides precise control during scribing. The scribe is approximately 5" long from end to end. Each scribe comes with a clear safety cap to protect the blade from damage when not in use. Carbide blades typically last two to three times longer than ruby or sapphire blades, and are recommended for use with metal-coated fibers.

Blade Reversal

To reverse the blade, unscrew the knurled end of the scribe and pull it slightly out of the handle. This releases the blade mount. Push the knurled end back into the handle. The blade and its mount will be pushed away from the handle allowing the blade to be removed, flipped, and reinserted. While holding the blade and mount in the handle, screw the knurled end back in, securing the blade.

For information on scoring and cleaving fiber with a scribe, please see our Scribe Guide tab above.

Part Number | Description | Price | Availability |

|---|---|---|---|

S90C | Carbide DualScribe Fiber Optic Scribe | $82.33 | Today |

Fiber Optic Disposal Unit

- Safe Solution for Disposing of Cleaved Fiber Ends

- One Circular and One Rectangular Covered Hole in Lid

- Dimensions (L x W x H): 2.75" x 2.75" x 6" (6.99 cm x 6.99 cm x 15.24 cm)

- Disposable: Do Not Reuse

The FTDU offers a safe solution for disposal of cleaved fiber ends, epoxy and syringes, and other sharp objects. This high-density polyethylene (HDPE) bottle features a translucent lid with one circular and one rectangular hole in it (see the photo to the right). Both of these holes have individual covers that snap closed to keep the contents inside the unit. Tabs on the side of the lid hold the covers open for hands-free use. The two hole covers are connected by a plastic tab. Cut, or pull, the covers apart to use the holes separately.

To use, insert sharps into one of the holes in the lid. Do not remove the lid itself from the unit. Use the "Contents" space on the label to clearly indicate what is inside. To protect against spills, keep the holes covered when not inserting sharps. When it is full, securely cover both holes in the lid by inserting the tab on the cover into the slot in the lid and dispose of the canister according to the contents. Do not fill the sharps container past the indicated "Full" line on the label. Do not reuse this unit; it is a one-time-use container only.

Part Number | Description | Price | Availability |

|---|---|---|---|

FTDU | Fiber Optic Disposal Unit | $8.74 | Today |

Click to Enlarge

Click to Enlarge