Fiber Polishing Supplies

- Silicon Dioxide, Diamond, Calcined Alumina, Aluminum Oxide, or Silicon Carbide Lapping Film

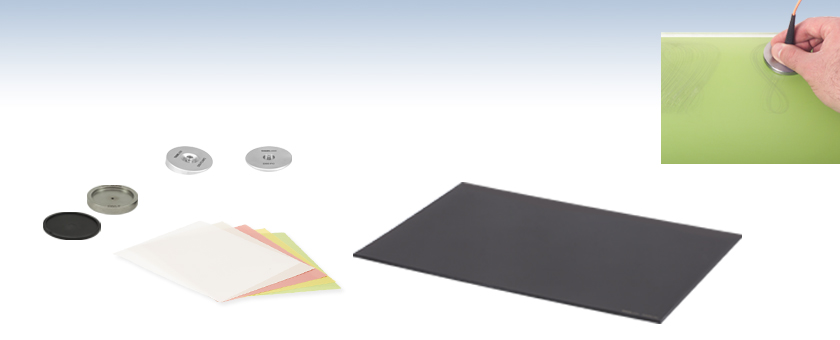

- Polishing Pucks for 5 Different Connector or Ferrule Types

- Glass Polishing Plate and Rubber Polishing Pad

D50-F

Ferrule Polishing Puck and Jig

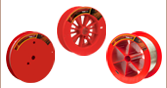

D50-FC/APC

Polishing Disk

D50-FC

Polishing Disk

NRS913A

Rubber Polishing Pad for Polishing Sheets

Polishing/Lapping Sheets

For Ceramic Ferrules, 0.01 μm to 30 μm Grit

Polishing a Fiber using a Puck and Polishing Sheet

Please Wait

Thorlabs offers a family of products to assist customers who would like to terminate their bare fiber, including fiber polishing film for use with ceramic or stainless steel ferrules, polishing pucks, polishing plates, and termination kits. We also offer instructions on how to polish a connector, including how to glue and cleave the fiber. A color manual can be purchased below, or it can be downloaded here for free. The components sold here are also available in kits, sold at the bottom of the page.

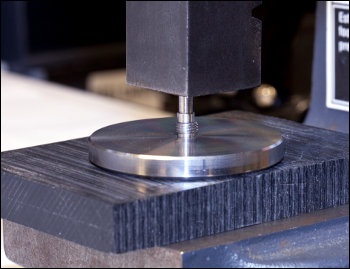

Calibrating the D50-SMA

Included with the D50-SMA is the D50-A calibration pin. To use this calibration pin, you will need an arbor press and a flat surface as a reference. Using the arbor press, press the calibration pin into the center hole of the puck. This will press the threaded part of the polishing puck into the flat disc until the end of the calibration pin is level with the bottom surface of the puck. This will ensure that the fiber is polished to the correct height in the SMA ferrule.

| Posted Comments: | |

Thomas Dzelzainis

(posted 2024-07-10 16:57:16.06) Hi,

The 0.01 um polishing sheets, LFCF2, don't seem to be available on science warehouse. I was wondering if you could add them.

Many thanks,

Tom. cdolbashian

(posted 2024-07-12 02:25:23.0) Thank you for reaching out to us with this inquiry. To our knowledge, "science warehouse" is not an official distributor of Thorlabs components. Perhaps I am misunderstanding something, however, and I have reached out to you directly for clarification. allan bereczki

(posted 2023-12-11 07:50:30.803) Hello,

Is it posssible to use D50-SMA to polish a 600 µm free standing SMA 906 fiber? ksosnowski

(posted 2023-12-18 10:52:30.0) Hello Allan, thanks for reaching out to us! With an air-gapped SMA ferrule like our high power SMA cables, using these polishing pucks could introduce cracking due to the ferrule geometry. Unfortunately the polishing process from our high power cable series is proprietary. I have reached out directly to discuss this application further. 艾 传韡

(posted 2023-11-08 17:59:32.153) 想咨询一下,光纤抛光纸可以用来打磨镜片吗?想用这个去除镀银反射棱镜上的镀层,不知道现不现实 cdolbashian

(posted 2023-11-16 02:50:12.0) Thank you for reaching out to us with your inquiry. I have contacted you directly to inquire about your application. Perhaps there is another solution instead of sanding off the protective layer on the mirror coating. Mohan Wang

(posted 2023-06-13 09:50:58.147) Hi, I have been using D50-F extensively to polish our customized fiber, which is extremely helpful, especially as our fibers come in different diameters. Because we are also using a mechanical splice, I am wondering if there could be a 7 degree angled D50-F version. We are definitely happy to buy one if such design would be available. Best wishes, Mohan cdolbashian

(posted 2023-06-21 10:50:59.0) Thank you for reaching out to us with this inquiry! There may be some difficulty in making a well-toleranced 7° polishing puck as a custom item for you. I have reached out to you directly to ask a bit more about your application, and how we can assist with it. Rene Reimann

(posted 2022-12-07 15:53:49.83) Hello,

the manual is quite good, however, there seems to be an error on p. 22, where the 6 µm polishing step is described. In the current description it is unclear when the 6 µm polishing step is finished. The manual states "Inspect the end face with the fiber scope (FS201) until it looks like Figure 24." Unfortunately Figure 24 does not show an image of a fiber end face under a fiber scope.

It would be nice to either add the right picture and change the text slightly (the current Figure 24 is correctly referred in a different context) or to describe in the text when the 6 µm polishing step is finished. jgreschler

(posted 2022-12-07 03:37:15.0) Thank you for pointing this out! Our technical marketing team has been made aware of this and will make changes to the manual pending review. peter frank

(posted 2022-07-12 15:34:10.217) do polyurethane pads need to be conditioned before polishing the substrate? jgreschler

(posted 2022-07-22 04:10:13.0) Thank you for reaching out to Thorlabs. All the instructions required to add a connector and polish a fiber can be found in our FN96A manual, which is available for download as a PDF from our website. I have reached out to you directly to provide a copy. Qiang Bian

(posted 2021-07-28 12:46:56.64) Is it possible to use diamond sheets to polish the endface of sapphire fiber? YLohia

(posted 2021-08-05 01:22:59.0) Thank you for contacting Thorlabs. Unfortunately, we have not attempted to use these diamond sheets to polish sapphire fibers so we cannot guarantee the performance level, but we would expect these to be useful for such applications. w.r.browne

(posted 2018-04-15 11:13:45.993) I bought the polishing kits but the puks are too narrow for any of the fibres i have from thorlabs- seems a bit of a cheat and the manual is not clear either as to which pucks i actually need for the steel sma and FC terminated fibres

some proper advice would be appreciated YLohia

(posted 2018-04-18 01:52:09.0) Hello, thank you for contacting Thorlabs. From our discussion, it looks like you ordered the TUK05 kit, which is meant for ceramic ferrules and comes with pucks for FC/PC and FC/APC connectors. The fiber you have (M68L01) requires the D50-SMA puck, which is not included in that kit. We have updated certain specs regarding tolerances and connector compatibility to be more clear on the website. pdeslandes

(posted 2016-05-23 12:12:28.54) Hello,

I would like to know the tolerance of the angle on the D50-FC/APC. The product polishes ferrules with an angle of 8° and i owuld like to know the tolerance on that angle (the drawing doesn't state any tolerance).

have a nice day

regards

Dr. Pierre DESLANDES, CTO, Moria Lase besembeson

(posted 2016-05-25 11:40:24.0) Response from Bweh at Thorlabs USA: We are currently reviewing our internal drawing for this part and I will communicate this to you via email. g.h.p.ebberink

(posted 2016-03-08 14:10:20.36) Using this manual I have created many SM patch cords and longer cables. Now I was asked to create a PM cable. Is there a "trick" to align the panda fiber to the key of a FC/APC connector? besembeson

(posted 2016-03-10 02:14:14.0) Response from Bweh at Thorlabs USA: We provide the components that you can do it yourself if you know a process that will meet your application requirements but unfortunately we don't disclose our method to achieve the specifications for our PM fibers as the setup is complex and proprietary. user

(posted 2015-06-01 17:51:42.393) Hello, We have bought a fiber polishing set to polish damaged (already conectorized, polraziation maintaining) fibers. However, we find that the fiber tip does not stick out from the polishing disc and thus cannot be polished. How can one use this polishing set to polish damaged fiber tips? Kind regards besembeson

(posted 2015-08-28 12:13:19.0) Response from Bweh at Thorlabs USA: We have the part number TUK05 that is typically used for such applications. The manual is found here: http://www.thorlabs.us/thorcat/TTN/TUK05-Manual.pdf.

You can contact us at techsupport@thorlabs.com to discuss this further since we don't have your contact information. bdada

(posted 2012-02-14 13:44:00.0) Response from Buki at Thorlabs to avle:

Thank you for participating in our feedback forum. We do not currently have a Solidworks model for our polishing discs but I will look into this further and contact you shortly with more information on when we can provide one. avle

(posted 2012-02-14 02:08:48.0) do you have a solidworks cad model for this?

thanks! lmorgus

(posted 2011-09-26 15:51:00.0) Response from Laurie at Thorlabs to the anonymous poster: Thank you for your suggestion to add some linkage to our fiber inspection tools, most notably the SMA gauge. We have added a related items link at the top of the page in response to your suggestion. We hope this helps to make it easier to find other products you may be interested in purchasing when shopping for fiber polishing supplies. user

(posted 2011-09-26 12:25:54.0) Please add the SMA gauge to this page. bdada

(posted 2011-08-24 14:07:00.0) Response from Buki at Thorlabs:

Thank you for your feedback. There is a calibration pin included with the D50-SMA. Please use an Arbor Press to press the pin down to the bottom of the puck and make sure there is room for the pin to extend the bottom of the puck. Then flip the puck on a solid surface and press the pin down. You can then remove the pin.

We will add this information to our website. Please contact TechSupport@thorlabs.com if you have additional questions. bs

(posted 2011-08-24 15:59:10.0) How can I recalibrate the D50-SMA? Tyler

(posted 2008-10-03 08:40:31.0) A response from Thorlabs to vincent.gosling: After some discussion with the engineers in the fiber business unit we are sending you a new polishing disc just incase the one you have doesnt meet specifications. Some burnt connectors can be repaired by polishing with a diamond polish, however, if the damage is too severe, it may be necessary to replace the connector. Thorlabs provides reconnectorization services, simply contact our technical support department for a quotation. Thank you for contacting us and if the new disk doesn’t solve your problem, please let us know. vincent.gosling

(posted 2008-10-01 06:10:24.0) My company recently purchased a polishing kit to repair a "burnt" fc/apc. Unfortunately the fibre doesnt sit proud of the polishing disc and therefore doesnt polish. Could you tell me whether there is another technique to repair fibres or , (as I expect) to confirm if it is beyond repair (without replacing the connector).

Any information would be greatly appreciated.

Many thanks

Vince Gosling |

Thorlabs offers lapping (polishing) sheets to polish a connector after the fiber has been epoxied into the ceramic ferrule. Polishing or Lapping Film is composed of tiny particles glued to a substrate. By moving the connector over the polishing film, excess material is removed and the fiber end is polished. Different grades of polishing film are used in successive polishing cycles. Each polishing cycle uses a finer grit paper.

Our diamond sheets have tiny diamond particles glued to a substrate of polyester with resin. We highly recommend a five step polishing process: the first four steps using diamond sheets in four different grit sizes of 30 µm, 6 µm, 3 µm, and 1 µm, and the fifth using our final polishing sheets which have a grit size of 0.01 µm. To use, drop distilled water onto the sheet and polish in a figure-eight motion using an appropriate polishing puck (sold below).

Our Final Polishing Sheets (Item # LFCF2), which eliminate the need for slurry, are designed to be used as the last step in the fiber polishing process. These sheets are made by coating polyester film with precision-grade silicon dioxide. These sheets produce an excellent surface finish with minimal scratches and offer no binder contamination on the optical fiber during polishing.

We recommend using these sheets over the less expensive aluminum oxide, silicon carbide, or calcined alumina sheets when polishing ceramic or zirconia ferrules because they do not cause undercutting when polishing the connector like silicon carbide can. Undercutting occurs when the fiber material is removed more quickly than the ferrule material creating a dip just above the fiber. When the connector is mated to another connector, instead of obtaining a glass-to-glass interface, the air gap created by the undercutting causes a glass-air-glass interface and excess loss, which is undesirable.

Despite the higher upfront cost per sheet, each area of the sheet can be used up to 20 times instead of once, compared to the aluminum oxide, silicon carbide, and calcined alumina sheets featured below. This greatly increases its value. These 6” x 6” sheets should be used with our glass polishing plates and rubber mats (see below).

Note: The diamond and final polishing films are sold in packages of 5.

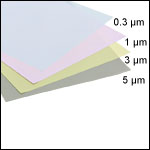

Thorlabs offers aluminum oxide, silicon carbide, and calcined alumina lapping/polishing sheets to polish a connector after the fiber has been epoxied into the ferrule. Lapping sheets are like sandpaper for optical connectors. Tiny aluminum oxide, silicon carbide, or calcined alumina particles are glued to a substrate of polyester with a non-pressure-sensitive adhesive. As we highly recommend a four step polishing process when using these sheets, we offer our sheets in four different grit sizes: 5 µm grit using silicon carbide, 1 and 3 µm grits using aluminum oxide, and 0.3 µm grit using calcined alumina.

Typically, each area of each sheet can only be used once to polish a single connector. Care should be taken when polishing your connector as these sheets can cause undercutting especially with ceramic or zirconia ferrules. Undercutting occurs when the fiber material is removed quicker than the ferrule material creating a dip just above the fiber. When the connector is mated to another connector, instead of getting a good glass-to-glass interface, the air gap created by the undercutting causes a glass-air-glass interface and undesirable excess loss.

These 11” x 9” sheets should be used with our glass polishing plates and rubber mats (see below).

Note: All polishing/lapping sheets for stainless steel ferrules are sold in packages of 10.

In order to hold the fiber connector securely and to maintain the proper angle, a Manual Fiber Polishing Puck can be used. The puck makes easier holding the connector against the polishing film and ensures an even polish. We offer polishing discs for six different connector types. Please note that discs are specific to the type of connector and are not interchangeable. Please verify connector type and size prior to purchase.

FC/PC and SC/PC Connector Polishing Disc

This polishing disc will accommodate both flat and pre-radiused connectors. This polishing disc accepts IEC standard Ø2.499 ± 0.0005 mm PC-style ferrules.

FC/APC Connector Polishing Disc

This polishing disc is designed to polish ferrules at 8° while securing the connector key in the proper orientation with respect to the polish angle. This polishing disc accepts IEC standard Ø2.499 ± 0.0005 mm PC-style ferrules.

SMA Connector Polishing Disc

This polishing disc will accommodate both SMA905 and SMA906 connectors. Each disc is factory set to produce the correct ferrule length after polishing is complete. The D50-SMA polishing disc can be recalibrated using our D50-A calibration pin, which is included with the D50-SMA polishing disc. For information on the recalibration procedure, please view the D50-SMA Calibration tab above. This polishing disc accepts IEC standard Ø3.17 +0.002/-0.004 mm SMA905 ferrules.

ST®*/PC or LC®/PC Connector Polishing Disc

These polishing discs are designed to allow the ST/PC (D50-ST) or LC/PC (D50-LC) connector to float. This design allows the polishing of both flat and pre-radiused connectors. The D50-LC polishing disc accepts Ø1.249 ± 0.0005 mm LC-style ferrules, while the D50-ST polishing disc accepts IEC standard Ø2.499 ± 0.0005 mm PC-style ferrules.

*ST® is a registered trademark of Lucent Technologies, Inc.

Click to Enlarge

D50-F Polishing Puck in Jig with Secured Ferrule

Thorlabs’ bare ferrule polishing pucks provide a convenient and secure platform to evenly polish bare ferrules. Each puck includes a jig that is used to set the depth of the ferrule and a setscrew that firmly holds the ferrule in the puck. To use, simply place the puck on the jig, drop the ferrule into place, and tighten down the setscrew with the included 0.050" hex key (see image to the right). The puck will ensure that the ferrule is held perpendicular to the polishing surface while allowing the user to polish by holding the puck instead of the ferrule. During the polishing process, it may be necessary to return the puck to the jig in order to reset the proper depth. This simple yet practical device alleviates concerns of damaging or breaking the fiber while polishing the ferrule.

We offer the D50-F polishing puck for FC/PC and SC/PC ferrules and the D50-L for LC/PC ferrules.

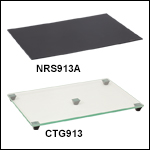

Click to Enlarge

Polishing Pad on Glass Polishing Plate

Glass Polishing Plate

Polishing of fiber optic connectors requires a flat, hard surface. The glass plate is produced from safety glass with all edges and corners rounded. Rubber feet help to ensure the plate will not mar the work surface and keep the plate from sliding. These 5 feet, located at the four corners and center of the plate, raise the top of the glass to a height of 0.5" (12.7 mm).

Polishing Pad

This solid silicone polishing pad (50 Durometer) is required when polishing PC-style pre-radiused connectors. When used with our glass polishing plate, as shown in the photo to the right, the pad helps to maintain the radius of the connector tip during polishing. This pad is 8.75" x 13" (222.3 mm x 330.2 mm) and 0.12" (3.1 mm) thick uncompressed.

Guide to Connectorization and Polishing of Optical Fibers

The FN96A Polishing and Connectorization Guide contains easy-to-follow, step-by-step instructions that show the reader how to properly cleave a fiber, assemble a cable and connector, and polish the connector. A color manual can be purchased below, or it can be downloaded here in PDF format for free.

- Includes All Tools and Supplies to Connectorize an Optical Fiber (Optical Fiber and Connectors Not Included)

- Kits for FC/PC, FC/APC, or SMA Connectors

Thorlabs' Fiber Optic Termination / Connectorization Kits contain all of the materials for your connectorization needs with the exceptions of the single mode or multimode connectors and the optical fiber, which need to be purchased separately. The CK01 is an SMA Connectorization Tool Kit, the CK03 is an FC/PC Connectorization Tool Kit, and the CK05 is an FC/APC Connectorization Tool Kit. The CK03 and CK05 kits include a Rubber Polishing Pad (50 Durometer) that is used to produce PC (radiused) polishes.

We recommend our fiber optic disposal unit (FTDU, sold separately) to properly dispose of all cleaved fiber scraps, epoxy, and syringes.

To view the SDS documents for the F112 epoxy included in these kits, click on the red Docs icons below. Please note that the epoxy included in these kits is classified as a dangerous good in some countries. Depending on the delivery location, this item may need to be shipped separately from the rest of your order at an additional charge. Please contact our sales department if there are questions or concerns when placing an order for these kits.

| Connectorization Kit Components | |||||

|---|---|---|---|---|---|

| Item # | Description | Qty. | Item # | Description | Qty. |

| FN96A | Step-by-Step Instructions | 1 | MS403-10 | 10 Epoxy Syringes | 1 |

| CT042 | Crimp Toola | 1 | FT030 | Furcation Tubing (2 m) | 1 |

| CTG913 | Glass Polishing Plate | 1 | F112 | Epoxy | 10 |

| FS201 | 200X Fiber Scope | 1 | T06S13 | Fiber Stripper (Cladding/Coating: 125 µm / 250 µm) |

1 |

| BFG1 | Bare Fiber Gripper | 1 | FTS4 | Three-Holed Furcation Tubing Stripper | 1 |

| S90R | Ruby Fiber Scribe | 1 | KW32 | Kim Wipes (280 Sheet Box) | 1 |

| - | Wash Bottleb | 1 | T186 | Kevlar Cutting Shears | 1 |

| CK01 Only | |||||

| LF03P | 0.3 µm Grit Polishing Film | 10 Sheets | LF3P | 3 µm Grit Polishing Film | 10 Sheets |

| LF1P | 1 µm Grit Polishing Film | 10 Sheets | LF5P | 5 µm Grit Polishing Film | 10 Sheets |

| D50-SMA | SMA Polishing Puck | 1 | - | - | - |

| CK03 and CK05 | |||||

| LFCFc | 0.02 µm Final Lapping Film | 5 Sheets | LF6D | 6 µm Grit Lapping Film | 5 Sheets |

| LF1D | 1 µm Grit Lapping Film | 5 Sheets | LF30D | 30 µm Grit Lapping Film | 5 Sheets |

| LF3D | 3 µm Grit Lapping Film | 5 Sheets | NRS913A | Rubber Polishing Pad | 1 |

| CK03 Only | CK05 Only | ||||

| D50-FC | FC/PC Polishing Puck | 1 | D50-FC/APC | FC/APC Polishing Puck | 1 |

| Touch-Up Polishing Kit Components | |||||

|---|---|---|---|---|---|

| Item # | Description | Qty. | Item # | Description | Qty. |

| - | Step-by-Step Instructions | 1 | FCC-7020 | Fiber Cleaning Tape | 1 |

| D50-FC | FC/PC Polishing Puck | 1 | LF1D | 1 µm Grit Lapping Film | 5 Sheets |

| D50-FC/APC | FC/APC Polishing Puck | 1 | LFCFc | Final Lapping Film | 5 Sheets |

| - | 30 mL Dropper Bottle for Distilled Water |

1 | - | Polishing Pada | 1 |

| - | 30 mL Dropper Bottle for Isopropanol |

1 | - | Carrying Caseb | 1 |

Click to Enlarge

We Recommend Using the FS201 Fiber Inspection Scope with the TUK05 Kit

- Repair Fiber Optic Connectors with Scratched End Faces

- Compatible with FC/PC and FC/APC Connectors with Ceramic Ferrules

- Repair Approximately 20 Connector End Faces with the Included Lapping Film

A fiber optic connector end face is an optical-quality surface that needs to be free of dirt and scratches for optimal performance. When cleaning the end face is not effective, Thorlabs' TUK05 Touch-Up Polishing Kit allows worn fiber connector end faces to be repaired by polishing out the scratches.

The kit includes polishing supplies and complete repair instructions, all housed in a convenient carrying case. The kit has components compatible with FC/PC and FC/APC ceramic ferrule connectors and has enough polishing film to repair approximately 20 connector end faces.

Connectors can generally be repolished 10 times before reconnectorization is necessary. For replacement of worn or marred connectors, contact Thorlabs' tech support for assistance.

Kit Expansion Options

We strongly recommend using a fiber inspection scope such as the FS201 with this kit. To repair different connector types, additional polishing pucks can be purchased separately. Our aluminum oxide polishing film can be used with this kit to polish steel ferrule connectors, and rougher grits of diamond lapping film can be used to repair deeply scratched connectors (see the User's Manual for details).

The carrying case included with the TUK05 has extra storage slots for the FS201 microscope, two extra polishing pucks, and one extra dropper bottle as well as space for additional lapping film. The scope itself includes batteries and fiber adapters compatible with FC/PC, FC/APC, ST®*/PC, SC/PC, SMA905 and SMA90 connectors. For more information about the FS201, see the full web presentation. The case has removable foam inserts (see photo to the left) for reuse or storage of other components.

*ST® is a registered trademark of Lucent Technologies, Inc.

Products Home

Products Home

Zoom

Zoom

Polishing Supplies

Polishing Supplies