Polarizing Fiber Tutorial

Single Mode Fiber

Coiled Polarizing Fiber

Aligned

Polarizing-Maintaining

Fiber

Unpolarized Light

Splicing Area

Splicing Area

Polarized Light

Polarized Light

Please Wait

PZ Fiber Overview

Polarizing (PZ) fiber (i.e., Zing™ fiber) is a specialty optical fiber that will guide only one polarization direction, thus polarizing light that is propagated through the fiber. This form of single-polarization transmission carries several benefits over single mode (SM) or polarization-maintaining (PM) fiber. While PM fiber maintains the polarization direction that is aligned with the birefringence axis, cross talk occurs since the PM fiber is capable of guiding any polarization direction. SM fiber can be stressed to induce birefringence (see manual fiber polarization controllers), which causes the fiber to behave much like a wave plate. While the polarization axis can be manipulated in this case, the SM fiber does not polarize the light.

In contrast, PZ fiber guides only one polarization direction; all other directions are unguided. As a result, PZ fibers will polarize the light guided through it, creating excellent suppression of unguided polarization directions. While in-line polarizers can provide between 20 and 30 dB suppression of unwanted polarization directions, PZ fibers can realize ≥30 dB suppression at the design wavelength. Additionally, by stressing the fiber, the polarization window can be manipulated and the user can realize suppression of over 35 dB. Because stress on a PZ fiber can alter its operation, "deployment" of the fiber becomes an essential quality. Deployment refers to how the fiber is laid out, whether it is straight, coiled, or randomly piled.

Using PZ Fiber

It is important to note that the deployment of the PZ fiber is key to its performance. Our PZ fiber has a very wide polarizing window, the width and center wavelength of which depends on how the fiber is deployed (see the Graphs Tab). In nominal usage of the fiber around its design wavelength, the PZ fiber will polarize for any deployment. For other usage, however, the user should ensure that the deployment shifts the polarization window such that the window overlaps the source. This method works best with a narrow linewidth souce such as a laser. For broadband sources, the PZ fiber needs to be coiled appropriately such that the width and center wavelength of the polarization window can overlap the source.

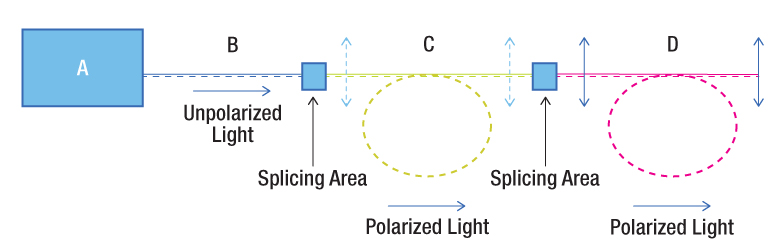

It is advantageous to use a depolarizer at the input of the PZ fiber because it ensures the light is evenly polarized, avoiding power variations that can occur with all types of polarizers. The depolarizer can be made from two sections of PM fiber spliced at 45° (length will depend on the source). In this system, the PZ fiber is also typically coupled to the depolarized output at 45° to take full advantage of the depolarizing effect (Note: If using patch cables, one termination should be rotated 45° relative to the other where the depolarizer fiber meets the PZ fiber, by offsetting the key in either fiber at 45°). When the input light to the PZ fiber is depolarized, the light incident upon the fast and slow axes of the PZ fiber is equal, resulting in consistent 3 dB rejection and stable output power. The figure below shows an example system for using our polarizing fibers with an unpolarized light source. The chart below the figure lists the components in the system for each of our PZ fibers.

| Fiber | A | B | C | D |

|---|---|---|---|---|

| HB830Z | 830 nm Laser Source |

SM800 Fiber | Coiled HB830Z Fiber | Aligned PM780-HP Fiber |

| HB1060Z | 1060 nm Laser Source |

SM980 Fiber | Coiled HB1060Z Fiber | Aligned PM980-XP Fiber |

| HB1550Z | 1550 nm Laser Source |

SMF-28-J9, CCC1310-J9, 1550BHP, or 1310BHP Fiber |

Coiled HB1550Z Fiber | Aligned PM1550-XP Fiber |

Coiling our PZ fiber to smaller diameters will create a narrower polarization window and blueshift the center wavelength. Coiling the PZ fiber can result in a better polarization extinction ratio, although it can lead to greater loss. If loss is too high, the coil is too tight; conversely, if the polarization extinction ratio is too low, the coil is not tight enough. For example, to achieve an extinction ratio of 35 dB with our HB1060Z PZ Fiber, 2 m of fiber is coiled into Ø5 cm loops. The diagram above demonstrates how this is implemented. Unpolarized light was sent into the PZ fiber, which is coiled to produce the desired effect. The PZ fiber was then spliced into a PM fiber, which goes out to the system. For additional performance stability, it is recommended to use 3 - 5 m of HB1060Z fiber or 4 - 10 m of HB830Z and HB1550Z. However, due to the high birefringence of the PZ fiber, the polarization window will still be broad, giving the user a wide variety of packaging and deployment options.

| Posted Comments: | |

| No Comments Posted |

Products Home

Products Home

Single Mode Polarizing Fiber

Single Mode Polarizing Fiber