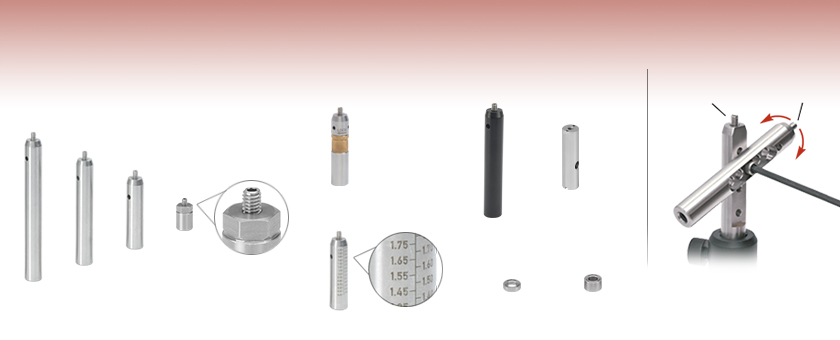

Optical Posts: Ø1/2" and Ø12 mm

- Precision Ground Stainless Steel or Aluminum Posts

- 8-32 (M4) and 1/4"-20 (M6) Threaded or #8 (M4) Counterbored

- Ø1/2" and Ø12 mm Outer Diameter Posts Available

- Vacuum-Compatible and Low-Reflectivity Posts Available

TR4

TR3

TR2

PLS-H2

Vacuum

Compatible

TRT2

0.25" (6.4 mm)

Vertical Translation

TR2E

Engraved Graduations

TR3T

TR3C

Application Idea

TRA3

Hard Coat

Aluminum

Stainless Steel Posts

TH075

Hex Top Post

TR8M

TR3M

Post Spacers (Shims)

Optical Construction Posts for Complex Optomechanical Assemblies

Please Wait

Click to Enlarge

Features

- Precision-Ground Posts with 1/2" (12.7 mm) or 12 mm Diameters

- Options with 8-32 (M4) Removable Setscrew, 8-32 (M4) Tap, or #8 (M4) Counterbores

- Top Threaded Posts Feature 1/4"-20 (M6) Bottom Thread

- Ø12 mm Metric Posts for Japanese Optomechanics (See -JP Item Numbers Below)

- Three Material Options Available

- Standard Posts (303 Stainless Steel)

- Vacuum-Compatible Posts (303 & 304L Stainless Steel)

- Non-Magnetic, Low-Reflectivity Posts (Aluminum with Anodized Hard Coat)

- Available in a Variety of Lengths Ranging from 0.60" to 12" (15 mm to 300 mm for Metric Posts)

- Posts Available with Hex Tops Instead of Side-Located Bores

- Graduated Posts Available to Aid in Optic Alignment

- Post Spacers (Shims) to Achieve Intermediate Post Heights

- All Included Setscrews are Double-Ended (Except with Vacuum-Compatible Posts)

Thorlabs’ Ø1/2" and Ø12 mm Optical Posts are a basic building block required in most rigid constructions and come in a wide range of post lengths ranging from 0.60" to 12" (15 mm to 300 mm for metric posts). Our precision-ground stainless steel posts are fabricated from 303 stainless steel (304L for vacuum-compatible posts) and are compatible with our Ø1/2" post holders and construction accessories. Additionally, we offer non-magnetic Ø1/2" aluminum posts that feature a black anodized hard coating to provide a lower reflectivity in the UV and visible spectral ranges, suitable for applications sensitive to magnetic fields or reflections (see the Anodization Classes tab for more information).

All of these posts, with the exception of the vacuum compatible posts, come with double-ended removable setscrews.

Along with our standard posts, Thorlabs also manufactures specialty posts for a wide variety of applications. These options include our Ø1/2" posts with hex tops, Ø1/2" graduated posts, Ø1/2" translating optical posts that are ideal for quick, stable height adjustment of a mounted component, and Ø1/2" optical construction posts for mounting in custom configurations.

The posts with top-located setscrews or taps feature a bottom-located 1/4"-20 (M6) tapped hole, providing compatibility with virtually all of our optic mounts. The 8-32 (M4) tapped hole provides additional flexibility by allowing 8-32 (M4) cap screws to be used with our universal mounts. All our posts, except the translating posts and the hex top posts, feature a side-located hole for using a balldriver or the SPW501 Spanner Wrench to provide extra leverage when tightening or loosening components.

Thorlabs offers a line of adapters and accessories that increase the usability of these posts, including electrical isolation adapters and anti-rotation adapters. Also available are Ø12 mm pedestal posts with a bottom-located 4-40 (M3) or a 1/4"-20 (M6) tapped hole and a top-located 4-40 (M3) or 8-32 (M4) removable setscrew. Please see our complete line of Ø1/2" Post Assemblies for other compatible accessories.

Click to Enlarge

Unanodized Aluminum Post Holder

Click to Enlarge

Type-II Anodized Aluminum Post Holder

The anodizing of aluminum is a widely utilized conversion coating technique applied to a wide range of materials and employed in various decorative and engineering applications. In the simplest of terms, anodizing is an electrochemical process that modifies the parent material’s surface hardness, reflectivity, lubricity, adhesion, light suppression, and electrical /thermal insulating properties. While the anodizing process can be performed on a variety of electrically conductive materials, it is predominantly used to plate aluminum, thereby improving the component’s surface properties.

Within the anodizing process, there are three alternative processes that, while similar, produce slightly different end properties: Type-I (Chromic Acid Anodize), Type-II (Sulfuric Acid Anodize), and Type-III (Hard Anodize). An explanation of each process is provided below. The main purpose of these three processes is to control the oxidation reaction that occurs naturally when raw aluminum is exposed to oxygen in the atmosphere.

The anodizing process starts by mounting the substrate/parts to be anodized onto a conductive rack/jig (usually constructed from titanium or aluminum); these racks are then immersed into an electrolyte solution, which has a composition that is similar to battery acid. A DC power supply is then added to the entire cell/anodizing system; this promotes electrolysis of water within the electrolyte via electron transfer and separation of water molecules, which in turn promotes oxygen evolution at the anode (hence the term anodizing).

This reaction forms a tightly packed hexagonal structured layer on the exposed surfaces of the aluminum components. Once hydrated/sealed (in most cases), the resulting item has improved corrosion resistance and is electrically insulated. The density, thickness, and sometimes color of the resultant anodic film can be precisely controlled through the use of various electrolyte solutions, concentrations, temperatures, and current densities. After this initial conversion coating has taken place, various different chemical species (i.e., PTFE, metallic species, or colored pigments) can be adsorbed / deposited into the oxidized film, which can further enhance the Anodic film’s performance or aesthetics.

Click for Details

Type-III Anodized Aluminum Post

Type-I Anodization

Type-I (Chromic Acid Anodizing) Oxidation is generally utilized for aerospace applications (soon to be replaced by Tartaric Anodizing) or general bonding applications. The standard film thickness is between 0.5 µm to 18 µm, making it too thin for external use. This type of plating provides a moderate improvement in corrosion resistance and electrical insulation as well as excellent adhesive bonding properties due to the film structure.

Type-II Anodization

Type-II (Sulfuric Acid Anodizing) Oxidation is widely used for architectural and decorative purposes due to its film structure and performance capabilities. Typical film thicknesses can range between 5 µm and 25 µm. The increased film thickness and differences in film structure compared to Type-I provide an increase in the film’s abrasion resistance and electrical insulation. Films such as Type I and Type II can be machined post anodizing; however, due to the increase in hardness introduced by the anodic film tool, the lifetime of the cutting tool will be diminished.

Type-III Anodization

Type-III (Hard Anodizing/Hard-Coat) Oxidation is the thickest, densest, and most robust type of anodizing available and is predominantly used exclusively for engineering purposes. It has a typical thickness between 25 µm to 150 µm and is often referred to as ‘Hard Anodizing’ or ‘Hard Coat Anodizing’. The increased thickness and film density produced by this type of anodizing make an extremely hard and very rugged coating with a greatly reduced wear-and-tear characteristic. This Anodic process exhibits all of the benefits offered by Type-II, but provides a lower co-efficient of friction, better corrosion resistance, and maximum surface hardness. However, due to the increased thickness and hardness of this type of anodizing, components anodized in this way cannot be easily machined post processing without specialist tooling.

Most Thorlabs components feature a Type-II matte-black anodized finish to promote light-absorption and provide improved wear resistance, while maintaining the ability to be machined with common tooling. In certain Thorlabs designs, Type-III or “Hard Coat Anodizing” has been chosen to offer maximum surface-hardness and wear resistance due to the requirements presented by the product’s intended application, such as our TRA series non-magnetic, low-reflectivity aluminum posts.

| Posted Comments: | |

Clayton Moss

(posted 2024-05-15 11:36:38.283) TR3E (at least units I received) has an incorrect engraving. The engravings are marked from 0.40 up to 2.80 near the top, the problem being that the 0.40" engraving is located at 0.90" high on the post. Thus you get 48 engravings that are supposed to be 0.05" apart put into a space that would only correctly hold 38 engravings, so the entire scale is approx. 0.8x the correct size/spacing.

TR2E is marked properly. Rober Collison

(posted 2020-11-30 19:21:18.303) Can you tell me how to order a 1/2" post with 1/4"-20 threaded holes at both ends? In other words, I want a 1/2" post, 8" long, but I want it to be symmetrical. I don't care if it has bored through diameter hole...though I suppose it would be nice. Best, Rob YLohia

(posted 2020-12-01 10:27:28.0) Thank you for contacting Thorlabs. Custom items can be requested by emailing techsupport@thorlabs.com. Alternately, you could use a 8-32 to 1/4"-20 screw thread adapter from this page: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_ID=1745 user

(posted 2020-08-06 16:03:09.927) Victor, from the technical support, was extremely helpful in the live chat, and promptly provided the information I needed about optomechanics solutions, such as translational stages, optical posts, mounting brackets and screws. Thanks for your help! YLohia

(posted 2020-09-24 03:50:58.0) Thank you very much for your feedback! We are happy to hear that our Applications Engineers were able to help you with your technical questions. Daniel Wolberg

(posted 2019-11-05 07:58:33.09) Hi,

RoHS file does not download, please send file by e-mail,

Thanks, YLohia

(posted 2019-11-05 10:43:47.0) Hello, thank you for contacting Thorlabs. We are sorry to hear about the issues caused by the broken RoHS link. We will reach out to you via email with the proper certification. laura.fegely

(posted 2018-11-28 17:24:47.423) Have you thought about offering a 1/2" post with 1/4-20 holes on both ends? I have a block which would normally be fixed to an optical table, so it has 1/4-20 holes w/ counterbore, but since I need to lift it up off the surface of the table on posts, I need to use washers to adapt it to 8-32, which isn't as precise and needs to be carefully sized. It would be nice to have a post with 1/4-20 holes on both ends for these sort of situations. YLohia

(posted 2018-11-29 02:27:10.0) Hello, thank you for your feedback. We have actually discussed this internally before, but unfortunately, we cannot offer such 1/2" posts due to low demand. There are a few alternative options of achieving the same results. One can use 1" posts, which we do offer with 1/4"-20 taps on both ends. You could also use the RA360 parallel clamp to stack two posts next to each other (with one being inverted and exposing the "bottom" 1/4-20 tap in the upwards position). Alternately, we also sell a variety of screw thread adapters here such as the AS25E8E: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=1745. If we see a high demand for such 1/2" posts in the future, we can certainly consider adding them to our stock inventory. user

(posted 2018-06-20 15:00:25.41) Concerning the TRT2 translating optical post, will the top part (with the M4 set screw) rotate during height adjustment? It says "non rotating tip" but I think this only means after you have locked it with the ring? YLohia

(posted 2018-06-22 09:15:35.0) The top does not rotate during height adjustment. ta

(posted 2017-05-29 09:40:15.28) I would like to know the heat resistance of the three types of anodisation listed below. How high a temperature can the three classes reach without any degradation of the surface?

Type-I Anodization

Type-I (Chromic Acid Anodizing) Oxidation is generally utilized for aerospace applications (soon to be replaced by Tartaric Anodizing) or general bonding applications. The standard film thickness is between 0.5 µm to 18 µm, making it too thin for external use. This type of plating provides a moderate improvement in corrosion resistance and electrical insulation as well as excellent adhesive bonding properties due to the film structure.

Type-II Anodization

Type-II (Sulfuric Acid Anodizing) Oxidation is widely used for architectural and decorative purposes due to its film structure and performance capabilities. Typical film thicknesses can range between 5 µm and 25 µm. The increased film thickness and differences in film structure compared to Type-I provide an increase in the film’s abrasion resistance and electrical insulation. Films such as Type I and Type II can be machined post anodizing; however, due to the increase in hardness introduced by the anodic film tool, the lifetime of the cutting tool will be diminished.

Type-III Anodization

Type-III (Hard Anodizing/Hard-Coat) Oxidation is the thickest, densest, and most robust type of anodizing available and is predominantly used exclusively for engineering purposes. It has a typical thickness between 25 µm to 150 µm and is often referred to as ‘Hard Anodizing’ or ‘Hard Coat Anodizing’. The increased thickness and film density produced by this type of anodizing make an extremely hard and very rugged coating with a greatly reduced wear-and-tear characteristic. This Anodic process exhibits all of the benefits offered by Type-II, but provides a lower co-efficient of friction, better corrosion resistance, and maximum surface hardness. However, due to the increased thickness and hardness of this type of anodizing, c nbayconich

(posted 2017-06-15 05:00:53.0) Thank you for contacting Thorlabs. Thorlabs currently only uses Type 2 and Type 3 anodization for our products.

Type 2 anodization will crack around 100 ºC.

For Type 3 anodization the inert nature of the Hardcoat shows no effect after short exposure to temperatures as high as 2000°C and permits operating temperatures of 500°C. (It is recommended that parts subject to open flame have greater thicknesses.)

A Techsupport representative will contact you directly. conway.langham

(posted 2016-02-05 17:30:09.9) would it be possible to create a shorter version of the TRT2/M (38mm or even 25mm). Thank you besembeson

(posted 2016-02-10 08:50:18.0) Response from Bweh at Thorlabs USA: Thanks for your request. We can look into this as a special item for now. We will contact you. daniel.weber

(posted 2014-04-05 14:35:41.703) Dear Sir or Madam,

do you offer adapter from 8-32 to 1/4"-20 studs for the optical posts. So one could use at the top part of the posts for both thread sizes?

Best regards

Daniel Weber ChristianTMWeber

(posted 2013-06-10 14:08:30.8) Hello, what is the magnetic permeability of the steel used for the posts?

Regards cdaly

(posted 2013-06-11 14:59:00.0) Response from Chris at Thorlabs: Thank you for using our web feedback. Unfortunately, we have not measured the magnetic permeability, but the stainless steel used is 303 grade. cdaly

(posted 2012-11-30 16:23:33.093) Response from Chris at Thorlabs: Thank you for using our feedback feature. We are unable to provide 2010 SolidWorks files directly as the version we use for design (2012) restricts us from creating backwards compatible files, but we do have Step files available for download as well. These files can be opened in SolidWorks 2010 and then saved as an .sldprt file, which will give you the format you require. xiaoqiang026403

(posted 2012-11-29 02:12:56.95) I use SolidWorks 2010,but some of your products' Drawing and Documents (SolidWorks) are opened by SolidWorks 2012. Could you send the SolidWorks Documents in version 2010? tcohen

(posted 2012-05-22 12:32:00.0) Response from Tim at Thorlabs: Our standard 1/2" Diameter Stainless Steel Optical Posts are machined to a diameter of .499" +.000" -.002". ygan1129

(posted 2012-05-21 15:14:28.0) What are the tolerances on the diameter of the posts? tcohen

(posted 2012-02-27 11:03:00.0) Response from Tim at Thorlabs: Thank you for your feedback. There are different mounting methods and so your part list will depend on your preferred setup. I have contacted you directly to discuss your options. ahmadvand

(posted 2012-02-27 02:32:19.0) Dear Thorlabs;

I want to buy below parts for my university. Unfortunatly, I can not choose relevant optomechanic parts, due to the different options.

It would be very appreciated if you give me a complete optomechanic list(post, post holder, lens mount, mirror mount, polarizor mount, laser mount) for constructing a setup with the below parts.

Best Regards

Hossein Ahmadvand

Parts:

- HNL050L-EC - HeNe Laser, 632.8 nm, 5 mW, Polarized, 220 VAC

- GTH10M-A - Mounted Glan Thompson Calcite Polarizer, 10 mm x 10 mm Clear Aperture, 350 - 700 nm AR Coating

- LPVISB050-MP - Ø12.5 mm SM05-Mounted Linear Polarizer, VIS B (500 - 720 nm)

- DET36A/M - Si Detector, 350-1100 nm, 14 ns Rise Time, 13 mm2, Metric

- DET10A/M - Si Detector, 200-1100 nm, 1 ns Rise Time, 0.8 mm2, Metric

- CM1-PBS252 - Cube-Mounted Polarizing Beamsplitter, 620 - 1000 nm

- MC2000 - Optical Chopper System with MC1F10 10-slot (36°) Chopper Blade

- MC1F100 - 100 Slot Blade for Optical Chopper, 250 Hz - 10kHz

- PF05-03-P01 - Ø1/2" (Ø12.7 mm) Protected Silver Mirror, 0.24" (6.0 mm) Thick

- BB05-E02 - Ø1/2" Broadband Dielectric Mirror, 400-750 nm

- LB4915 - f = 50.0 mm, Ø1/2" UV Fused Silica Bi-Convex Lens, Uncoated bdada

(posted 2012-02-02 18:54:00.0) Response from Buki at Thorlabs:

Thank you for using our feedback forum. We understand that it may not always be convenient to adjust the height of the post within the post holder. We have passed on your suggestion to our design team and we will consider it as we continue to expand our selection of posts.

Please contact TechSupport@thorlaabs.com if you have any questions. user

(posted 2012-02-02 15:37:56.0) I would like to see 2.5" tall posts offered. The gap from 2" to 3" can be critical and hard to fill without a post size in between. klee

(posted 2009-12-03 10:46:47.0) A response from Ken at Thorlabs to eoconnor: The tolerance on the length of the post is ±0.005". eoconnor

(posted 2009-12-02 21:22:32.0) Can you please give me the tolerance on the length of the post?

Thank you! Laurie

(posted 2009-01-12 18:46:24.0) Response from Laurie at Thorlabs to wenzao_li: All of the documentation for the product line can be found by clicking on the "Drawings & Documents" Tab on this page. If you experience problems with any of the files, please let us know. wenzao_li

(posted 2009-01-12 18:08:13.0) The drawings are missing on this web page

http://www.thorlabs.com/NewGroupPage9.cfm?ObjectGroup_ID=1266 Tyler

(posted 2008-04-09 14:29:12.0) Response from Tyler at Thorlabs: Thank you for the product feedback on the 2.5 mm hole on the post that is used for tightening. I will forward this comment to our product engineers so that they can consider this when designing any future post or post holder products. user

(posted 2008-04-09 12:31:33.0) The 5/64" (2.5mm) hole is always getting caught in the post holder. This can be somewhat irritating. However, I do like the ability to tighten something down without damaging the outside shank. technicalmarketing

(posted 2008-02-08 11:00:42.0) If you are looking for a 12.5 mm diameter post with M4 taps on both ends, you have two options: (1)You can purchase one of our TR series posts and an AS4M6M adapter, which will allow you to switch from the internal M6 threading on the one side of the post to internal M4 threads. (2) Contact our technical support staff (techsupport@thorlabs.com) and request a quote for a custom TR post with M4 taps on both ends. hholst-pedersen

(posted 2008-02-08 10:14:39.0) Hi!

I need more Ø 12,5mm posts with #8-32 (m4) tapped holes in both top and base.

Where can I find that?

I only find Ø1/2" posts with #8-32 tapped hole in top and #4-40 in base!

Best regards, Hege Holst-Pedersen |

- One 8-32 Tapped Hole on Top and One 1/4"-20 Tapped Hole at Base

- Removable Double-Ended 8-32 Setscrew

- Available Individually in Lengths Ranging from 0.75" to 12"

- Packs of 5 Also Available for 0.75" to 6" Lengths

These virtually non-magnetic 303 stainless steel (SS) posts are precision ground to Ø1/2". One end has a 1/4"-20 tapped hole, while the other end has a removable SS8E50D double-ended 8-32 setscrew [5/64" (2 mm) hex]. A side-located Ø1/8" (Ø3.2 mm) hole is bored straight through the post; using a balldriver or the SPW501 Spanner wrench on the hole provides extra leverage when tightening mounted components. To reduce packaging waste, we offer our most popular sizes in packs of five.

For shorter posts without a side-located bore, see our Ø1/2" (Ø12.7 mm) optical posts with hex tops sold below.

- One M4 Tapped Hole at Top and One M6 Tapped Hole at Base

- Removable Double-Ended M4 Setscrew

- Available Individually in Lengths Ranging from 20 to 300 mm

- Packs of 5 Also Available for 20 to 150 mm Lengths

These virtually non-magnetic 303 stainless steel (SS) posts are precision ground to Ø12.7 mm. One end has an M6 tapped hole, while the other end has a removable SS4M12D double-ended M4 setscrew [2 mm (5/64") hex]. To easily distinguish these metric posts from their imperial counterparts featured above, the metric posts have a ring-shaped groove in the tapered section of the post. A side-located Ø3.2 mm (Ø1/8") hole is bored straight through the post; using a balldriver or the SPW501 Spanner wrench on the hole provides extra leverage when tightening mounted components. To reduce packaging waste, we offer our most popular sizes in packs of five.

For shorter posts without a side-located bore, see our Ø1/2" (Ø12.7 mm) optical posts with hex tops sold below.

- One M4 Tapped Hole at Top and One M6 Tapped Hole at Base

- Removable Double-Ended M4 Setscrew

- Ø12 mm Outer Diameter for Compatibility with Japanese Standard Post Holders and Optomechanics

- Available Individually in Lengths Ranging from 20 to 300 mm

- Packs of 5 Also Available for 20 to 100 mm Lengths

These virtually non-magnetic 303 stainless steel (SS) posts are precision ground to Ø12 mm. One end has an M6 tapped hole, while the other end has a removable SS4M12D double-ended M4 setscrew [2 mm (5/64") hex]. To easily distinguish these as metric posts, there is a ring-shaped groove in the tapered section of the post. A side-located Ø3.2 mm (Ø1/8") hole is bored straight through the post; using a balldriver or the SPW501 Spanner wrench on the hole provides extra leverage when tightening mounted components. To reduce packaging waste, we offer our most popular sizes in packs of five.

These Ø12 mm posts are directly compatible with our standard Ø1/2" Post Holders and most of their compatible products. For components that require a post diameter of 1/2" (12.7 mm), such as our BA2E flexure post mount, we recommend using our AD12BA barrel adapter to bridge the 0.03" (0.7 mm) gap.

| Vacuum Compatibility Specifications | |

|---|---|

| Vacuum Compatibility as Packageda |

>10-6 Torr |

| Materials | 304L Stainless Steel (Post) 316 Stainless Steel (Setscrew) |

| Preparation and Packaging |

Chemically Cleaned and Double Vacuum Bagged |

- Constructed of 304L (Post) and 316 (Setscrew) Stainless Steel for Vacuum Applications

- One 8-32 (M4) Tapped Hole on Top and One 1/4"-20 (M6) Tapped Hole at Base

- Removable 8-32 (M4) Setscrew

- Available in Lengths Ranging from 0.75" to 3" (20 mm to 75 mm for Metric Posts)

These virtually non-magnetic, vacuum-compatible 304L stainless steel posts are precision ground to Ø1/2" (Ø12.7 mm). One end has a 1/4"-20 (M6) tapped hole, while the other end has a removable 8-32 (M4) threaded setscrew [5/64" (2 mm) hex]. A side-located Ø1/8" (Ø3.2 mm) hole is bored straight through the post; using a balldriver or the SPW501 Spanner wrench on the hole provides extra leverage when tightening mounted components. The 8-32 (M4) threaded hole is also vented into the side-located Ø1/8" (Ø3.2 mm) hole. We recommend using a vented cap screw in the 1/4"-20 (M6) tapped hole.

Vacuum Compatibility

Our vacuum-compatible posts are chemically cleaned and prepared for vacuum applications before packaging. They are compatible directly out of the packaging with vacuum environments down to

Our vacuum-compatible posts are packaged in double airtight bags for cleanroom and vacuum chamber applications. We also offer additional vacuum-compatible Ø1/2" post system components.

Click to Enlarge

These posts are designed to be mounted using our POLARIS-CA5(/M) Non-Bridging Clamping Arm.

- Compatible with Mounts with Threaded Mounting Holes

- Counterbore Hole for #8 (M4) Mounting Screw

- Two Ø2 mm Alignment Pin Holes for Precision Mounting (Dowel Pins Not Included)

- Vacuum Compatible to 10-9 Torr at 25 °C with Proper Bake Out*

- 303 Stainless Steel Heat-Treated to Remove Internal Stresses for Increased System Stability

These Ø1/2" (Ø12.7 mm) posts feature a #8 (M4) counterbore hole for compatibility with mounts with threaded mounting holes, such as our KM05(/M) mirror mount. The top of the posts have two Ø2 mm alignment pin holes, which are located on either side of the counterbore hole. Dowel pins are not included. These posts are designed to mount to an optical surface using our POLARIS-CA5(/M) Polaris non-bridging clamping arms for Ø1/2" posts or other comparable optomechanical components.

A Ø6 mm alignment bore is located 20 mm from the base and can be used in combination with our cage rods for the alignment of multiple mounts along a common optical axis or for fine angle tuning. Note that the alignment bore does not go completely through the PLS-HC1 and PLS-HC246/M posts. Instead, these posts contain two bores on opposite sides, within ±0.3°, that are 0.08" (2.0 mm) deep. Given their shorter length, a through bore would interfere with the counterbore and prevent components from being securely attached to the post.

Popular post lengths are available from stock; custom lengths can be requested by contacting Tech Support. Since the counterbore posts require Polaris clamping arms for Ø1/2" posts or other optomechanical components for mounting to an optical surface, the minimum length for custom posts should not be less than the height of the mounting component, which is 0.45" (11.4 mm) for these Polaris clamping arms.

*These posts are assembled in a clean environment, chemically cleaned using the Carpenter AAA passivation method to remove sulfur, iron, and contaminants from the surface, and double vacuum bagged. Prior to placing any components in a sensitive vacuum system, a thorough pre-baking in a bake-out oven should be performed to remove all moisture and surface volatiles. Contact Tech Support for details.

Click to Enlarge

Directly attach a Polaris mount via a top-located 8-32 (M4) mounting hole without the need for a thread adapter. Dowel pins (not included) provide precision mounting.

OEM Solutions and Volume Orders

Thorlabs manufactures custom and high-volume Polaris products for use in custom and OEM systems. For pricing information on high-volume orders of our standard posts, please contact OEM Sales.

- Designed to Mount Polaris Mounts Up to Ø2"

- One Top-Located 8-32 (M4 x 0.7) Mounting Hole

- One Bottom-Located 1/4"-20 (M6 x 1.0) Mounting Hole

- Two Ø2 mm Alignment Pin Holes Around Each Mounting Hole for Precision Mounting (Dowel Pins Not Included)

- Vacuum Compatible to 10-9 Torr at 25 °C with Proper Bake Out

- 303 Stainless Steel Heat-Treated to Remove Internal Stresses for Increased System Stability

These Ø1/2" (Ø12.7 mm) posts feature one top-located 8-32 (M4 x 0.7) mounting hole and one bottom-located 1/4"-20 (M6 x 1.0) mounting hole. They are designed to mount Polaris mirror mounts up to Ø2"; see the table below for the resulting optic axis heights when used with each mount size. Each end of the post has two Ø2 mm alignment pin holes, which are located on either side of the mounting hole. Dowel pins are not included.

A Ø6 mm alignment bore is located 20 mm from the base and can be used in combination with our cage rods for the alignment of multiple mounts along a common optical axis or for fine angle tuning. Note that the alignment bore does not go completely through the PLS-H1 and PLS-H246/M posts. Instead, these posts contain two bores on opposite sides, within ±0.3°, that are 0.15" (3.8 mm) deep. Given their shorter length, a through bore would interfere with the mounting threads and prevent components from being securely attached to the post. In the custom post configurator below, any post with a length of 1.49" (37.6 mm for metric posts) or less will have a similar alignment bore configuration.

| Polaris® Mount and Post Interoperabilitya | |||||||

|---|---|---|---|---|---|---|---|

| Item # | Post Length (L) |

Resulting Optical Axis Height (Optic Center) | |||||

| Ø1/2" Mountsb |

POLARIS-K05P2 Ø1/2" Mount |

Kinematic |

Ø1.5 mm Mount & Ø2" Fixed Mount |

Ø2" Kinematic Mounts |

|||

| 1.00" | 1.50" | 1.62" | 1.75" | 2.00" | 2.25" | 2.40" | |

| 1.50" | 2.00" | 2.12" | 2.25" | 2.50" | 2.75" | 2.90" | |

| PLS-H2 | 2.00" | 2.50" | 2.62" | 2.75" | 3.00" | 3.25" | 3.40" |

| 24.6 mm | 37.3 mm | 40.3 mm | 43.7 mm | 50.0 mm | 56.4 mm | 60.2 mm | |

| 37.3 mm | 50.0 mm | 53.0 mm | 56.4 mm | 62.7 mm | 69.1 mm | 72.9 mm | |

| PLS-H496/M | 49.6 mm | 62.3 mm | 65.3 mm | 68.7 mm | 75.0 mm | 81.4 mm | 85.2 mm |

Click to Enlarge

7/16" (11 mm) Hex for Extra Leverage During Tightening

Click to Enlarge

TH075 in a Post Holder

- Constructed of 303 Stainless Steel

- Universal 7/16" (11 mm) Hex Top

- One 8-32 (M4) Tapped Hole on Top and One 1/4"-20 (M6) Tapped Hole at Base

- Removable Double-Ended 8-32 (M4) Setscrew

These virtually non-magnetic 303 stainless steel posts are precision ground to Ø1/2" (Ø12.7 mm). One end has a 1/4"-20 (M6) tapped hole, while the other end has a removable SS8E50D 8-32 or SS4M12D M4 threaded setscrew [5/64" (2 mm) hex on both ends]. A common problem with shorter posts is that the thumbscrew of a post holder can get caught in the side-located bore of the post. To prevent this problem, these posts do not have this bore. Instead, the 8-32 (M4) tapped end of the post is a universal 7/16" (11 mm) hex to allow the user to provide extra leverage with a wrench when tightening mounted components. A slim profile wrench (less than 5 mm thick) is recommended for ease of use. To easily distinguish the metric posts from their imperial counterparts, the metric posts have a ring-shaped groove just below the hex.

Click to Enlarge

Click to EnlargeLMR1 Lens Mount on a TR3E Optical Post

Click to Enlarge

Click to EnlargeTR50E/M Graduated

Optical Post

- Engraved Scale for Accurate Post Height Adjustments

- Labeled Increments Every 0.05" (1 mm)

- One 8-32 (M4) Tapped Hole on Top and One 1/4"-20 (M6) Tapped Hole at Base

- Ideal for Use with Lenses in Series

These are identical to our Ø1/2" (Ø12.7 mm) stainless steel (SS) TR posts above, but feature an engraved scale along their side. This scale provides a means to quickly and accurately align optics to your optical axis. A removable SS8E50D 8-32 or SS4M12D M4 threaded setscrew [5/64" (2 mm) hex on both ends] at the top of each post is compatible with many components such as fixed optic mounts, while a 1/4"-20 (M6) tap is on the other end of the post for mounting larger components. A side-located Ø1/8" (Ø3.2 mm) hole is bored straight through the post; using a balldriver or the SPW501 Spanner wrench on the hole provides extra leverage when tightening mounted components.

- Provides 0.25" (6.4 mm) of Travel

- 0.04" (1 mm) Travel per Revolution of Adjustment Collar

- Anti-Backlash Spring Design

- Non-Rotating, Lockable Post Translation

- Removable Double-Ended 8-32 (M4) Setscrew

The TRT2 translating post has been designed to provide quick, stable height adjustment of a mounted component within an optical setup. One end has a 1/4"-20 (M6) tapped hole, while the other end has a removable SS8E50D 8-32 or SS4M12D M4 threaded setscrew [5/64" (2 mm) hex on both ends]. The TRT2 features an adjustment collar that translates the post up to 0.25" (6.4 mm) from its nominal position at 0.04" (1.0 mm) per revolution. When fully compressed, the post is 2.00" (50.8 mm) and a maximum length of 2.25" (57.2 mm). Once the desired height is achieved, the TRT2 can be locked into place with the built-in lock ring. Only the adjustment collar and lock ring rotate on the TRT2 to provide translation; neither the top nor the bottom of the post rotate when translated.

Both the adjustment collar and lock ring have diameters slightly smaller than the post diameter, allowing the entire post to pass through all of our Ø1/2" construction accessories without interference. A side-located Ø1/8" (Ø3.2 mm) hole is bored straight through the post; using a balldriver or the SPW501 Spanner wrench on the hole provides extra leverage when tightening mounted components.

Click to Enlarge

TR3T and TR3C for Mounting at Arbitrary Angles

- Counterbored and Tapped Posts for Constructing Custom Mounting Configurations

- TR3C (TR75C/M): Five #8 (M4) Counterbores

- TR3T (TR75T/M): Three 8-32 (M4) Tapped Holes

- Removable Double-Ended 8-32 (M4) Threaded Setscrew

These posts are designed for mounting optomechanical components in custom configurations. One end has a 1/4"-20 (M6) tapped hole, while the other end has a removable SS8E50D 8-32 or SS4M12D M4 threaded setscrew [5/64" (2 mm) hex on both ends]. By using a combination of a tapped construction post along with a counterbored construction post, components can be mounted at an arbitrary angle to keep your beam path unobstructed (see image to the right).

The TR3C (TR75C/M) offers five #8 (M4) counterbores and a mounting flat while the TR3T (TR75T/M) offers three 8-32 (M4) tapped holes and a mounting flat. The posts can be combined by using an 8-32 (M4) cap screw. Additionally, a single post may be used to mount an optomechanical component on its side using the mounting flat on each post (see image to the right).

Click to Enlarge

Click to EnlargeClick Here for Raw Data

Our black anodized posts provide low reflectance in the ultraviolet and visible wavelength ranges for which the shaded blue region serves as a guide to the eye; however, the higher reflectance above 700 nm may cause unwanted reflections, especially with intense near-infrared sources.

- Post Constructed using Non-Magnetic Hardcoated Aluminum

- Black Anodized Hard Coating Provides Lower Reflectivity Than Our Stainless Steel Posts

- One 8-32 (M4) Tapped Hole on Top and One 1/4"-20 (M6) Tapped Hole at Base

- Removable Double-Ended 8-32 (M4) 300 Series Stainless Steel Setscrew

- Available in Lengths Ranging from 0.75" to 6" (20 to 150 mm for Metric Posts)

These non-magnetic Ø1/2" posts are made using precision-ground hardcoated aluminum. The anodized hard coat on each post provides an ultra-hardened surface (60 - 70 Rockwell C Scale) for increased wear, abrasion, and corrosion resistance, as well as a black surface for low reflectivity in the ultraviolet and visible wavelength ranges. Therefore, these posts are ideal for applications that are sensitive to magnetic fields or require lower reflection than our stainless steel posts (see the Anodization Classes tab for more information). One end has a 1/4"-20 (M6) tapped hole, while the other end has a removable SS8E50D 8-32 or SS4M12D M4 300 series stainless steel setscrew [5/64" (2 mm) hex on both ends]. A side-located Ø1/8" (Ø3.2 mm) hole is bored straight through the post; using a balldriver or the SPW501 Spanner wrench on the hole provides extra leverage when tightening mounted components.

Click to Enlarge

TR4M Post Spacer Underneath a TR3 Post with a KM100 Mirror Mount.

The 1/4"-20 setscrew is threaded directly into the optical table.

- Available in 1 mm Increments from 1 mm to 10 mm

- 1/4" (M6) Clearance Hole

- Thickness Tolerance of ±0.001"

- Each Pack Includes Five Post Spacers

These stainless steel post spacers, also known as shims, are designed for achieving intermediate heights of our TR series Ø1/2" posts without compromising structural rigidity. They have a diameter of 0.50" (12.7 mm) to fit underneath the Ø1/2" posts sold above. The center clearance hole allows 1/4"-20 (M6) setscrews to pass through to the mating tap of the components on either side of the spacer.

By adding a Ø1/2" post spacer to a TR series post, it is easy to adjust the height of the center of optical components. An optic mounted in our LMR1(/M) or FMP1(/M) mount has its center at a height of 0.87" (22.1 mm) above the top of the post. Placing a TR3M post spacer under the post brings the optical axis height to 0.99" (25.1 mm).

Setscrews are not included with these post spacers. 1/4"-20 and M6 setscrews are available here.

Click to Enlarge

The SPW501 wrench tightens Ø1" posts that have torque slots or holes.

The SPW501 Spanner Wrench is designed to tighten or loosen Ø1" posts that have torque slots, as illustrated in the photo to the right. The SPW501 can also be used with Ø1/2" posts and Ø1" posts that have through holes. The wrench is designed to fit into the slot or through hole and provide leverage for tightening or loosening the post when mounting the post directly to a tapped hole. Please use minimal force when tightening to prevent binding due to overtightening.

Products Home

Products Home

Zoom

Zoom

Ø1/2" Optical Posts

Ø1/2" Optical Posts