2" (50 mm) Travel Translation Stages

- 2" (50 mm) Travel, Dual Resolution Coarse/Fine Drive System

- Supports 70 lbs Horizontal Load and 40 lbs Vertical Load

- Large Mounting Surface with Numerous Mounting Features

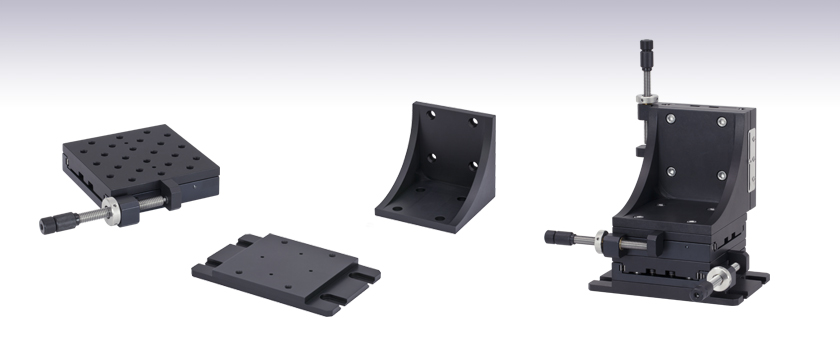

LT1

LT101

LT102

LT3

Please Wait

Mounting the LT1 Single Axis Translation Stage to an LT101 Base Plate

| Ball Bearing-Mechanism Manual Translation Stages |

|---|

| 1/4" (6 mm) Travel |

| 1/2" (13 mm) Travel |

| 1/2" (13 mm) Travel, Miniature |

| 1" (25 mm) Travel |

| 2" (50 mm) Travel |

Features

- 2" (50 mm) Travel, Dual Resolution Coarse and Fine Drive System

- Adjustment

- Coarse: 0.055" per Revolution

- Fine: 0.010" per Revolution

- Load Capacity

- Horizontal: 70 lbs (31 kg)

- Vertical: 40 lbs (18 kg)

- Large Mounting Surface with Numerous Mounting Features

- Modular Design Allows Quick Assembly of 2- or 3-Axis Stage

The LT1 and LT3 Translation Stages provide 2" (50 mm) travel on each axis and feature a 3.75" x 3.75" (95 mm x 95 mm) mounting surface with a generous supply of 1/4"-20 (M6) tapped mounting holes. These stages are intended for general purpose laboratory applications that benefit from a high degree of adaptability. A dual action coarse and fine actuator design provides easy, rapid motion via a coarse pitch lead screw (18 TPI) and high resolution via a fine lead screw (100 TPI) that is placed in series with the coarse adjuster. Travel can be locked using a locking plate that is located on the side opposite to these actuators.

The LT1(/M) stages are easily assembled into XY, XZ, YZ, or XYZ configurations using our SH25S025 1/4" long (SH6MS06 6 mm long) cap screws. We recommend these cap screws due the shorter thread depth required to assemble multi-axis stages. Precision alignment holes that allow the individual stages to be assembled into multi-axis systems as well as dowel pins are provided to ensure that the axes are perpendicular. The procedure for mounting the LT1 stage to an LT101 base plate is shown in the video to the right.

Alternatively, our 2" (50 mm) crossed-roller bearing stages feature low angular deviation, high load capacity, a graduated micrometer, and integrated dovetails for quick multi-axis construction.

| Item # | LT1, LT3 |

|---|---|

| Travela | 2.0" (50 mm) |

| Max Load Vertical | 40 lbs (18 kg) |

| Max Load Horizontal | 70 lbs (31 kg) |

| Orthogonality | <2 mrad |

| Angular Deviation | <2 mrad |

| Coarse Thread Pitch | 18 TPI |

| Fine Adjustment Range | 0.5" |

| Fine Adjustment Thread Pitch | 100 TPI |

Click to Enlarge

LT1 Packaging

Smart Pack

- Reduce Weight of Packaging

- Increase Usage of Recyclable Materials

- Improve Packing Integrity

- Decrease Shipping Costs

Thorlabs' Smart Pack Initiative is aimed at minimizing waste while providing adequate protection for our products. By eliminating any unnecessary packaging, implementing design changes, and utilizing eco-friendly materials, this initiative seeks to reduce the environmental impact of our product packaging.

The updated LT1(/M) packaging primarily consists of recycled paper and cardboard and weighs 56.05% less than the original packaging. This weight change results in a 71.88 kg reduction in travel-based CO2 emissions per year, based on typical product sales.

As we move through our product line, we will indicate re-engineered, eco-friendly packaging with our Smart Pack logo, which can be seen above.

| Posted Comments: | |

Jueun Kwon

(posted 2023-07-17 13:37:07.063) Can I get LT1/M in a XY configuration? Thanks. jdelia

(posted 2023-07-18 04:51:17.0) Thank you for contacting Thorlabs. You can combine 2x LT1(/M) stages in an XY configuration using the included dowel pins and some short cap screws. I have reached out to you directly to discuss your application further. florent.burdin

(posted 2019-03-12 11:40:26.097) I received today the LT3/M. I am a bit disappointed because there is no graduated scale to measure the translation distance. It was obvious to me that this kind of accurate translation stage would have it but I was wrong.

Could you propose compatible micrometer drives ?

Thanks,

Florent llamb

(posted 2019-03-12 04:13:17.0) Hello Florent, thank you for your feedback. I have brought this to our marketing and engineering teams' attention for improvement. The LT- series stages feature a 5/16"-18 threaded main adjuster screw, which threads directly into a bushing on the stage. These are not designed for replacement with standard micrometers, but instead to have a dual resolution adjustment. Our XR50- series stages would provide the same travel range and a micrometer-driven solution. I have reached out to you directly to discuss your application further. user

(posted 2018-11-07 12:57:27.99) Hello, I am interested in your product LT1/M that has to be mounted over the base plate LT101/M. It has only 1 axis of translation (say x). Can I use two LT1/M products orthogonal to each other on the same plane so that, it becomes translational in 2 directions? or Can I get a separate product with 2 axis of translation (say xy)? YLohia

(posted 2018-11-07 08:59:51.0) Hello, thank you for contacting Thorlabs. The LT1/M can be configured to an XY plane. You simply have to purchase two LT1/Ms and use the dowel pins provided along with four of our SH25S025 cap screws to mate the x-stage to the y-stage. sergei.sochava

(posted 2018-10-25 11:35:07.92) Hello,

I am a long time customer and an admire of Thorlabs.

This time I am disappointed to find out that LT1 can not be attached with standard 1/4-20 cap screws. Moreover, low profile 1/4-20 screws sold by Thorlabs are a bit too long to attach one stage to another (work fine attaching to a table or to LT101 adapter plate). Thorlabs should provide compatible screws or at least warn customers clearly in the product description.

Best regards,

Sergei mmcclure

(posted 2018-10-26 09:47:48.0) Hello, Sergei. Thank you very much for contacting us. You are correct that standard-length cap screws, such as those included in our HW-KIT2 hardware kit, are not sufficient for assembling multi-axis stages with the LT1 due to their longer lengths. Thus, we recommend using our SH25S025 cap screws, which are 1/4" (6.4 mm) long. We will add this information to the web presentation. ludoangot

(posted 2018-10-18 20:02:09.563) Does the stage comprise a vernier scale or any form of ruler to be able to know the traveled distance? The CAD drawing doesn't show the relevant side of the stage, and the only relevant photo, that of the LT3 isn't clear (it seems there's no scale). If your stage doesn't comprise a vernier you should definitely add one or propose one as an option. llamb

(posted 2018-10-19 11:29:03.0) Thank you for your feedback. I have added this idea to our internal product forum for future discussion. Alternatively, our XR50- series stages also offer a 2" travel range, are able to be assembled as a 3-axis stage, and feature a micrometer with a graduated scale, with 10 um increments to better track your position. If you would prefer the design of the LT3, we may be able to offer a custom solution to fit your needs. I will reach out to you directly by email. cflamme

(posted 2014-04-02 10:01:14.447) does the LT! have a locking freature? jlow

(posted 2014-04-02 02:14:08.0) Response from Jeremy at Thorlabs: The LT1 does have a locking plate on the side opposite the lead screws. aaronleow

(posted 2013-07-23 09:41:46.687) Hi,

Just wondering if you still have not integrated a 2" travel Metric with Micrometer Dial in your existing lineup? If so, what is the customised pricing for one? Thanks.

Regards,

Aaron cdaly

(posted 2013-07-24 13:36:00.0) Response from Chris at Thorlabs: Thank you for using our feedback tool. We do not currently offer this as a stock component, but can provide a custom stage with the 2" 151-411ST micrometer as a custom. For custom requests please contact tech support@thorlabs.com. I will email you directly to get started on a quote. tcohen

(posted 2012-11-22 11:53:00.0) Response from Tim at Thorlabs to Silvio: The maximum runout of the LNR50 is +/-10um over its full 50mm of travel and this is tested on every one produced. Your conversion to 200urad appears correct. We will clean up our web presentation to make the performance differences more readable. jlow

(posted 2012-11-14 05:47:59.707) Response from Jeremy at Thorlabs: The 2 "steel cylinders" are the alignment pins. These are used when you need to assemble more than one LT1 into an XYZ configuration. jason.mershon

(posted 2012-11-13 15:49:29.453) product looks great.

Along with said product, I received a small envelope with a collar intended to collapse the brass collet on the stage.

Also inside said envelope are 2 small steel cylinders, diameter 1/8" X 1/4" long. What are they for? silvio.koller

(posted 2012-11-07 10:34:19.41) Dear Sir or Madame

Dispite the feedbacks I still don't understand what the quality difference of the LNR and LT1 stage is.

The runoff of the LNR gives an angular deviation of alpha<10*10^-6/(50*10^-3)=200urad over the full range.

The angle given in the reply of the feedback gives a run off of 4*10^-6*50*10^-3m =200nm which would be amazing and much less than the specs given.

Also if I use ratio of the angles for the LT1 and LNR given in the comment I get a run off for the LT1 that is 150/4*10 um =375 um, which is realy bad.

Could you explain how you convert the run off and the angular deviation?

Kind regards,

Silvio Koller tcohen

(posted 2012-05-03 12:20:00.0) Response from Tim at Thorlabs: Thank you for your feedback. An additional LT102 (and possibly an additional tap/adapter depending on your mounting requirements) may serve your purpose. I will contact you to discuss the placement of the load and some of the options that may be suitable for your setup. igkiou

(posted 2012-04-30 14:04:19.0) Hi, I am interested in an XYZ configuration, for a load of max. 5kg. The load needs to be mounted in such a way such that the mounting axis (the screws used for the mounting) are perpendicular to the surface of the optical table. I am considering using the LT3 with an additional right angle bracket attached on the Z-stage (the load would be mounted on the free side of the bracket). Would you recommend the LT3 for this load and mounting setup? Also, what bracket and possibly adapter plate would you suggest I use for this? (The load is mounted through a 1/4-20 mount and requires about 3x3 inches space). Thank you in advance for your assistance! jjurado

(posted 2011-08-12 11:39:00.0) Response from Javier at Thorlabs to last poster: Thank you very much for your feedback! We will revisit the design of the LT1 2" translation stage to determine the best way to fit a threaded or a barrel mounted micrometer. Please contact us at techsupport@thorlabs.com if you would like to follow up with us. user

(posted 2011-08-12 09:19:05.0) Disappointed to receive this item and learn that this stage does not allow replacement of the lead screw with a micrometer and that the screw mount and seat are not reconfigurable. It looks like it will be easy to machine out the screw mount to fit a threaded mic. Adam

(posted 2010-05-25 10:36:36.0) A response from Adam at Thorlabs to tshiflett: We can offer a LT1 with a micrometer as a custom made product. I will contact you directly to see if you are interested in this option. tshiflett

(posted 2010-05-25 10:12:35.0) Hello, my company bought the LT1 a few months back. It works good but they can me to make a change. They want to be able to tell the distance that it is moving. Is there any vernier scales or something that you can recommend to do this.

Todd Adam

(posted 2010-03-31 17:12:39.0) A response from Adam at Thorlabs to James: We can modify the hole on the LT1 to hold a 151-412ST micrometer. The lead time for this modification will be ~4 weeks. I will email you directly to see if you are interested in a quotation. james.lloyd-hughes

(posted 2010-03-31 10:33:24.0) I was wondering if one or all of the actuators of the stages in the LT3 can be changed for a micrometer? jens

(posted 2010-02-11 14:02:35.0) A reply from Jens at Thorlabs: The runout of maximum 10um over the travel range for the LNR stage corresponds to a value of about 4urad, giving a considerably tighter specification then for the LT1 stage. I will work with our motion control team on spec table which will allow easier comparison. user

(posted 2010-02-11 02:06:59.0) I was trying to compare this stage with the Steel LNR stage with regard to travel straightness but I cant because the LNR straightness is shown as a runout and this one is shown as micro radians. I assume the LNR is better but maybe not and I dont want to pay more if I dont need to. Could you make the specs comparible. It just seems such an obvious thing to do unless you dont want to allow customers to compare. klee

(posted 2009-12-15 10:44:02.0) A response from Ken at Thorlabs to benjamin_teokc: The standard LT1 is a right-handed version. We could possibly do a left-handed version but the price will be much higher since we have to make special top and bottom plates from scratch. If you are interested in a formal quotation, please send your contact information to techsupport@thorlabs.com and we will prepare a quotation for you. benjamin_teokc

(posted 2009-12-14 20:58:57.0) I was wondering if there is a left hand as well as right hand version for product No. LT1? |

Manual Linear Translation Stages

Thorlabs' manual translation stages are offered in a range of maximum travel distances, from less than 1/4" (6 mm) to 2" (50 mm) and longer for our long travel, large area platforms. Many of these stages can be ordered in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our Multi-Axis Stages, which offer finer adjustment than our standard manual translation stages. In addition to linear translation stages, we offer rotation stages, pitch and yaw platforms, and goniometers. We also offer motorized translation stages that are powered by DC Servo motors, stepper motors, or direct drive technology.

Crossed-Roller Bearing Stages

These linear translation stages feature crossed-roller bearing travel mechanisms for precision motion, high load capacity, and low angular deviation. The LNR Series stages feature all-steel body construction, while the LX, XRN, and XR Series stage bodies are constructed of cast tool and jig aluminum. We also offer several vertical crossed-roller bearing stages (see below).

| Crossed-Roller Bearing Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | LNR Series 25 mm Stages | LX Series 25 mm Stages |

XRN Series 25 mm Stages | XR Series 25 mm Stages | XR Series 50 mm Stages | LNR Series 50.8 mm Stages |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 50 mm (1.97") | 50.8 mm (2") |

| Drive Type | Multiple | Micrometer | Micrometer | Micrometer | Micrometer | Multiple |

| Platform Size | 2.34" x 2.36" (59.4 mm x 60.0 mm) |

2.56" x 2.56" (65.0 mm x 65.0 mm) |

2.00" x 3.35" (50.7 mm x 85.0 mm) |

2.98" x 4.33" (75.7 mm x 110.0 mm) |

2.98" x 5.51" (75.7 mm x 140.0 mm) |

3.94" x 3.94" (100.0 mm x 100.0 mm) |

| Possible Axis Configurations |

X, XZ, XY, XYZ | X, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, XY, XYZ |

| Additional Details | ||||||

Ball Bearing Stages

These translation stages feature hardened steel linear bearings for precise motion and long life. They are available with a variety of actuators and in single-axis or preassembled multi-axis configurations.

| Ball Bearing Stages | |||||

|---|---|---|---|---|---|

| Product Family | MS Series 1/4" Stages | T12 Series 1/2" Stages | MT Series 1/2" Stages | PT Series 1" Stages | LT Series 2" Stages |

| Click Photo to Enlarge |  |

|

|

|

|

| Travel | 1/4" (6.4 mm) | 1/2" (12.7 mm) | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50 mm) |

| Drive Type | Multiple | Thumbscrew | Multiple | Multiple | Differential Micrometer |

| Platform Size | 1.17" x 1.17" (29.7 mm x 29.7 mm) |

0.76" x 0.81" (19.3 mm x 20.6 mm) |

2.40" x 2.41" (61.0 mm x 61.2 mm) |

3.00" x 4.00" (76.2 mm x 101.6 mm) |

3.75" x 3.75" (95.3 mm x 95.3 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | |||||

Dovetail Stages

These compact stages incorporate dovetails and a leadscrew for the translation mechanism. They are suitable in general purpose motion control applications.

| Dovetail Stages | |||

|---|---|---|---|

| Product Family | DT Series 1/2" Stages | DTS Series 1" Stages (Vacuum-Compatible Version Available) |

DTS Series 2" Stage |

| Click Photo to Enlarge |  |

|

|

| Travel | 1/2" (12.7 mm) | 1" (25 mm) | 2" (50 mm) |

| Drive Type | Thumbscrew | Thumbscrew | Thumbscrew |

| Platform Size | 1.00" x 1.00" (25.4 mm x 25.4 mm) | 2.68" x 2.95" (68.0 mm 75.0 mm) | 2.68" x 3.74" (68.0 mm x 95.0 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZa | X, XY, XYZ |

| Additional Details | |||

Flexure Stages

Thorlabs' Nanoflex™ translation stages feature frictionless flexure mechanisms for improved positioning and resolution when compared to similar stages made using bearings. The translation of the stage is accomplished by the elastic deformation (flexing) of a linkage attached to the mounting platform. Most models also include piezo actuators for small position adjustments.

| Flexure Stages | ||||

|---|---|---|---|---|

| Product Family | Nanoflex™ 1.5 mm Stage | Nanoflex™ 5 mm Stages | ||

| Click Photo to Enlarge |  |

|

|

|

| Travel | 1.5 mm (0.06") + 25 µm Piezo | 5 mm (0.20") | 5 mm (0.20") + 20 µm Piezo | |

| Drive Type | Thumbscrew and Piezo Actuator | Differential Micrometer | Differential Micrometer and Open-Loop Piezo Actuator |

Differential Micrometer and Closed-Loop Piezo Actuator |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) | 2.95" x 2.95" (75.0 mm x 75.0 mm) | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | ||||

Vertical Stages

We offer vertical translation stages with crossed-roller bearings for precise motion as well as long travel vertical stages for heavy-duty applications.

| Vertical Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | XRN Series 9 mm Vertical Stage | XR Series 14 mm Vertical Stage | MVS Series 1/2" Vertical Stage | MVS Series 1" Vertical Stage | VAP Series 4" Vertical Stage | VAP Series 10" Vertical Stage |

| Click Photo to Enlarge |  |

|

|

|

|

|

| Travel | 9.0 mm (0.35") | 14.0 mm (0.55") | 1/2" (13.0 mm) | 1" (25.0 mm) | 4" (101.6 mm) | 10" (254 mm) |

| Drive Type | Worm-Gear Driven Lift Screw | Micrometer | Adjuster Knob and Coarse Manual Positioning | |||

| Platform Size | 2.00" x 2.00" (50.7 mm x 50.7 mm) |

2.98" x 2.98" (75.7 mm x 75.7 mm) |

2.36" x 2.36" (60.0 mm x 60.0 mm) | 3.00" x 6.00" (76.2 mm 152.4 mm) | ||

| Additional Details | ||||||

Products Home

Products Home

Ball Bearing Mechanism, Dual Resolution Adjuster

Ball Bearing Mechanism, Dual Resolution Adjuster