Zinc Selenide Plano-Concave Lenses, AR Coated: 2 - 13 µm

- AR Coating Optimized for the 2 - 13 µm Range

- Ideal for CO2 Laser Applications Due to Low Absorption Coefficient

- Use to Diverge Collimated Incident Light

LC7142-E4

Ø1'' Lens,

f = -200 mm

LC7759-E4

Ø1'' Lens,

f = -25.4 mm

Please Wait

| Common Specifications | |

|---|---|

| Substrate Material | Zinc Selenidea |

| AR Coating Range | 2.0 - 13.0 μm |

| Reflectanceb (Per Surface) | Ravg < 3.5% Rabs < 6% |

| Transmissionb | Tavg > 92% Tabs > 85% |

| Diameter Tolerance | +0.0/-0.1 mm |

| Thickness Tolerance | ±0.1 mm |

| Focal Length Tolerance | ±1% |

| Surface Quality | 60-40 Scratch-Dig |

| Surface Powerc (Plano Side) | λ/2 |

| Spherical Surface Powerc,d (Concave Side) | 3λ/2 |

| Surface Irregularityc (Peak to Valley) | λ/2 |

| Centration | <3 arcmin |

| Clear Aperture | >Ø20.3 mm |

| Design Wavelength | 10.6 μm |

| Click on the red Document icon next to the item numbers below to access the Zemax file download. Our entire Zemax Catalog is also available. |

Features

- ZnSe Substrate

- Broadband AR Coating for the 2 - 13 μm Range

- Focal Lengths from -25.4 mm to -200 mm Available

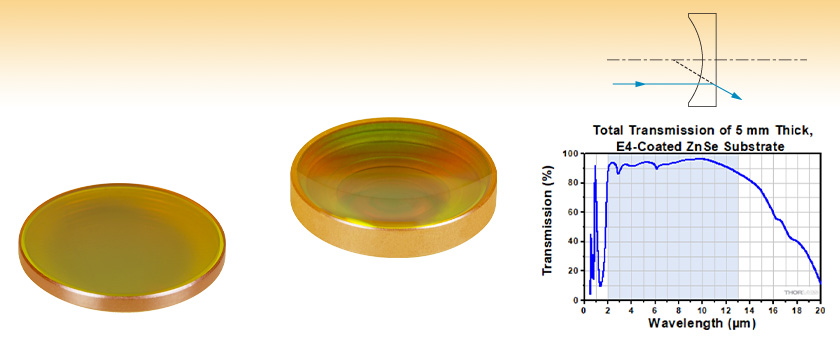

Thorlabs' Ø1" Zinc Selenide (ZnSe) Plano-Concave Lenses are available with a broadband AR coating optimized for the 2 µm to 13 μm spectral range deposited on both surfaces. This coating greatly reduces the high surface reflectance of the substrate, yielding an average transmission >92% across the AR coating range. See the Graphs tab for detailed information.

Like all plano-concave lenses, these lenses have negative focal lengths and can be used to diverge collimated beams; in this case, the curved surface should face the source in order to minimize spherical aberration. In addition, they can be employed to offset the effects of spherical aberration caused by other lenses in an optical system. ZnSe lenses are particularly well suited for use with high-power CO2 lasers.

This substrate scratches easily and should be handled with care. When handling optics, always wear gloves. This is especially true when working with zinc selenide, as it is a hazardous material. For your safety, please follow all proper precautions. For the MSDS for ZnSe in English, click here, and for the MSDS in Japanese, click here. Thorlabs will accept all ZnSe windows back for proper disposal. Please contact Tech Support to make arrangements for this service.

| Selection Guide |

|---|

| Zinc Selenide Lenses |

| Other MIR Lenses |

| Other Spherical Singlets |

Click to Enlarge

Click for Raw Data

This graph shows the measured transmission of an AR-coated zinc selenide window (Item # WG71050-E4) at normal incidence. The shaded region denotes the AR coating range, over which Tavg > 92%. Performance outside of the specified range is not guaranteed and varies from lot to lot.

Click to Enlarge

Click for Raw Data

This plot gives the measured reflectance (per surface) at an 8° angle of incidence (AOI) of our -E4 AR-coated zinc selenide substrates. The average reflectance is <3.5% per surface within the shaded wavelength range of 2.0 - 13.0 µm.

| Recommended Mounting Options for Thorlabs Lenses | ||

|---|---|---|

| Item # | Mounts for Ø2 mm to Ø10 mm Optics | |

| Imperial | Metric | |

| (Various) | Fixed Lens Mounts and Mini-Series Fixed Lens Mounts for Small Optics, Ø5 mm to Ø10 mm | |

| (Various) | Small Optic Adapters for Use with Standard Fixed Lens Mounts, Ø2 mm to Ø10 mm | |

| Item # | Mounts for Ø1/2" (Ø12.7 mm) Optics | |

| Imperial | Metric | |

| LMR05 | LMR05/M | Fixed Lens Mount for Ø1/2" Optics |

| MLH05 | MLH05/M | Mini-Series Fixed Lens Mount for Ø1/2" Optics |

| LM05XY | LM05XY/M | Translating Lens Mount for Ø1/2" Optics |

| SCP05 | 16 mm Cage System, XY Translation Mount for Ø1/2" Optics | |

| (Various) | Ø1/2" Lens Tubes, Optional SM05RRC Retaining Ring for High-Curvature Lenses (See Below) |

|

| Item # | Mounts for Ø1" (Ø25.4 mm) Optics | |

| Imperial | Metric | |

| LMR1 | LMR1/M | Fixed Lens Mount for Ø1" Optics |

| LM1XY | LM1XY/M | Translating Lens Mount for Ø1" Optics |

| ST1XY-S | ST1XY-S/M | Translating Lens Mount with Micrometer Drives (Other Drives Available) |

| CXY1A | 30 mm Cage System, XY Translation Mount for Ø1" Optics | |

| (Various) | Ø1" Lens Tubes, Optional SM1RRC Retaining Ring for High-Curvature Lenses (See Below) |

|

| Item # | Mount for Ø1.5" Optics | |

| Imperial | Metric | |

| LMR1.5 | LMR1.5/M | Fixed Lens Mount for Ø1.5" Optics |

| (Various) | Ø1.5" Lens Tubes, Optional SM1.5RR Retaining Ring for Ø1.5" Lens Tubes and Mounts |

|

| Item # | Mounts for Ø2" (Ø50.8 mm) Optics | |

| Imperial | Metric | |

| LMR2 | LMR2/M | Fixed Lens Mount for Ø2" Optics |

| LM2XY | LM2XY/M | Translating Lens Mount for Ø2" Optics |

| CXY2 | 60 mm Cage System, XY Translation Mount for Ø2" Optics |

|

| (Various) | Ø2" Lens Tubes, Optional SM2RRC Retaining Ring for High-Curvature Lenses (See Below) |

|

| Item # | Adjustable Optic Mounts | |

| Imperial | Metric | |

| LH1 | LH1/M | Adjustable Mount for Ø0.28" (Ø7.1 mm) to Ø1.80" (Ø45.7 mm) Optics |

| LH2 | LH2/M | Adjustable Mount for Ø0.77" (Ø19.6 mm) to Ø2.28" (Ø57.9 mm) Optics |

| VG100 | VG100/M | Adjustable Clamp for Ø0.5" (Ø13 mm) to Ø3.5" (Ø89 mm) Optics |

| SCL03 | SCL03/M | Self-Centering Mount for Ø0.15" (Ø3.8 mm) to Ø1.77" (Ø45.0 mm) Optics |

| SCL04 | SCL04/M | Self-Centering Mount for Ø0.15" (Ø3.8 mm) to Ø3.00" (Ø76.2 mm) Optics |

| LH160C | LH160C/M | Adjustable Mount for 60 mm Cage Systems, Ø0.50" (Ø13 mm) to Ø2.00" (Ø50.8 mm) Optics |

| SCL60CA | SCL60C/M | Self-Centering Mount for 60 mm Cage Systems, Ø0.15" (Ø3.8 mm) to Ø1.77" (Ø45.0 mm) Optics |

Mounting High-Curvature Optics

Thorlabs' retaining rings are used to secure unmounted optics within lens tubes or optic mounts. These rings are secured in position using a compatible spanner wrench. For flat or low-curvature optics, standard retaining rings manufactured from anodized aluminum are available from Ø5 mm to Ø4". For high-curvature optics, extra-thick retaining rings are available in Ø1/2", Ø1", and Ø2" sizes.

Extra-thick retaining rings offer several features that aid in mounting high-curvature optics such as aspheric lenses, short-focal-length plano-convex lenses, and condenser lenses. As shown in the animation to the right, the guide flange of the spanner wrench will collide with the surface of high-curvature lenses when using a standard retaining ring, potentially scratching the optic. This contact also creates a gap between the spanner wrench and retaining ring, preventing the ring from tightening correctly. Extra-thick retaining rings provide the necessary clearance for the spanner wrench to secure the lens without coming into contact with the optic surface.

| Posted Comments: | |

| No Comments Posted |

Products Home

Products Home

ZnSe, -E4 Coated

ZnSe, -E4 Coated