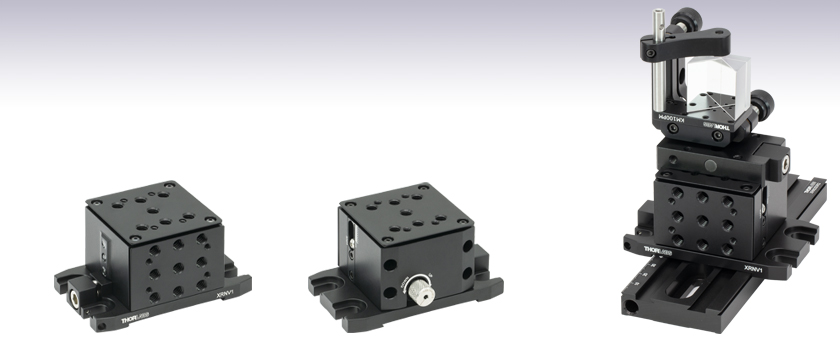

Compact Quick-Connect Vertical Stage, 9 mm Travel, Crossed Roller Bearings

- 9 mm Vertical Travel Stage

- Integrated 2" Dovetails for Multi-Axis Construction

- Crossed-Roller Bearings for High Load Capacity and Low Angular Deviation

Front

Back

XRNV1

Vertical Translation Stage

Application Idea

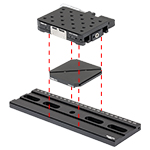

XRNV1 Stage Mounted on 2" Dovetail Rail for Coarse Linear Positioning

with HRS1015-P01 Retroreflector

Mounted via XRN25-RC2 Adapter

Please Wait

| Specifications | |

|---|---|

| Bearing Type | Crossed-Roller Bearings |

| Drive Mechanism | Worm-Gear-Driven Lift Screw |

| Travel Range | 9.0 mm (0.35") |

| Working Height Range | 44.0 mm to 53.0 mm (1.73" to 2.08") |

| Adjustment per Knob Revolution | 0.25 mm (0.01") |

| Maximum Drive Resolution | 10 µm (0.0004") |

| Horizontal Load Capacitya | 22.2 N (5.0 lbs) |

| Inverted Load Capacitya | 6.67 N (1.50 lbs) |

| Angular Deviation | <250 µrad |

| Straightness | <10 µm |

| Backlash | <5 µm |

| Spring Preload at 0 mm Travelb | 7.55 N (1.70 lbs) |

| Spring Preload at 13 mm Travelb | 21.73 N (4.89 lbs) |

| Dimensions (Including Base Plate) | 85.0 mm x 51.0 mm x 44.0 mmc (3.35" x 2.36" x 1.73"c) |

| Weight | 0.31 kg (0.68 lbs) |

| Material | Black-Anodized Aluminum |

Click for Details

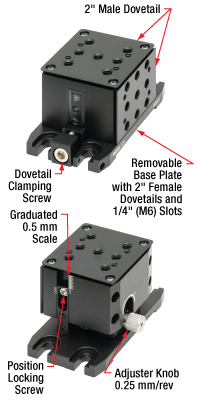

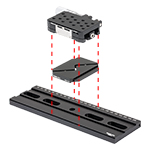

Key Features of the XRNV1(/M) Vertical Translation Stage. The top image shows the stage at its lowest position; the bottom image shows the stage fully raised.

Features

- 9 mm of Vertical Travel

- 2" Dovetails on Top and Bottom for Use with XRN Series Stages and 2" Dovetail Rail Systems

- 2" Male Dovetail on Front Plate for Use with Quick-Connect Rail Platforms

- 1/4"-20 (M6) and 6-32 (M4) Tapped Holes on Top Plate and Front

- Graduated Millimeter Scale Indicates Stage Height

- Compact Footprint: 85.0 mm x 51.0 mm (With Removable Base Plate)

- Quickly Connect Stages and Accessories Using 2" Dovetails

- See the Quick-Connect Stages Tab for Complete Line of Components

The XRNV1(/M) Vertical Translation Stage provides 9.0 mm of height adjustment for a working height range of 44.0 mm to 53.0 mm. The adjustment knob provides 0.25 mm of height adjustment per revolution and is located on the back of the stage near the base in order to keep the user's hand away from the beam path. The stage position can be locked by the side-located locking screw with a 5/64" (2 mm) hex key or balldriver. Crossed-roller steel bearings support precision motion and high load capacities, while the body is machined from cast tool and jig aluminum for high stability and minimal internal stress.

The stage includes seven 1/4"-20 (M6 x 1.0) mounting holes on the top plate and an additional nine 1/4"-20 (M6 x 1.0) mounting holes on the front vertical face. There are also four 6-32 (M4 x 0.7) tapped holes on the top and four 6-32 (M4 x 0.7) holes on the side for use with the PM3(/M) and PM4(/M) clamping arms (sold separately below). The base plate has four mounting slots for use with 1/4" (M6) cap screws. The base can be removed, exposing a Ø1/2" mounting boss on the bottom of the unit, which can be used to mount the stage on a BA2E(/M) base plate or an XRN-RB(/M) rotation adapter.

The top and bottom of the stage feature 2" dovetails for compatibility with our XRN series of quick-connect linear and rotation stages; By connecting multiple stages via these dovetails, the user can easily construct multi-axis configurations. Additional functionality is provided by our line of 2" dovetail rail components, including rails, rail carriers, a rotation adapter, and adapters for mounting on 3" dovetail components. For more information about our quick-connect construction components, see the Quick-Connect Stages tab.

Caution: Do not attempt to adjust the stage height while the locking screw is engaged. Doing so has the potential to damage the stage or cause it to perform outside of specification.

| Posted Comments: | |

| No Comments Posted |

Manual Linear Translation Stages

Thorlabs' manual translation stages are offered in a range of maximum travel distances, from less than 1/4" (6 mm) to 2" (50 mm) and longer for our long travel, large area platforms. Many of these stages can be ordered in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our Multi-Axis Stages, which offer finer adjustment than our standard manual translation stages. In addition to linear translation stages, we offer rotation stages, pitch and yaw platforms, and goniometers. We also offer motorized translation stages that are powered by DC Servo motors, stepper motors, or direct drive technology.

Crossed-Roller Bearing Stages

These linear translation stages feature crossed-roller bearing travel mechanisms for precision motion, high load capacity, and low angular deviation. The LNR Series stages feature all-steel body construction, while the LX, XRN, and XR Series stage bodies are constructed of cast tool and jig aluminum. We also offer several vertical crossed-roller bearing stages (see below).

| Crossed-Roller Bearing Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | LNR Series 25 mm Stages | LX Series 25 mm Stages |

XRN Series 25 mm Stages | XR Series 25 mm Stages | XR Series 50 mm Stages | LNR Series 50.8 mm Stages |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 50 mm (1.97") | 50.8 mm (2") |

| Drive Type | Multiple | Micrometer | Micrometer | Micrometer | Micrometer | Multiple |

| Platform Size | 2.34" x 2.36" (59.4 mm x 60.0 mm) |

2.56" x 2.56" (65.0 mm x 65.0 mm) |

2.00" x 3.35" (50.7 mm x 85.0 mm) |

2.98" x 4.33" (75.7 mm x 110.0 mm) |

2.98" x 5.51" (75.7 mm x 140.0 mm) |

3.94" x 3.94" (100.0 mm x 100.0 mm) |

| Possible Axis Configurations |

X, XZ, XY, XYZ | X, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, XY, XYZ |

| Additional Details | ||||||

Ball Bearing Stages

These translation stages feature hardened steel linear bearings for precise motion and long life. They are available with a variety of actuators and in single-axis or preassembled multi-axis configurations.

| Ball Bearing Stages | |||||

|---|---|---|---|---|---|

| Product Family | MS Series 1/4" Stages | T12 Series 1/2" Stages | MT Series 1/2" Stages | PT Series 1" Stages | LT Series 2" Stages |

| Click Photo to Enlarge |  |

|

|

|

|

| Travel | 1/4" (6.4 mm) | 1/2" (12.7 mm) | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50 mm) |

| Drive Type | Multiple | Thumbscrew | Multiple | Multiple | Differential Micrometer |

| Platform Size | 1.17" x 1.17" (29.7 mm x 29.7 mm) |

0.76" x 0.81" (19.3 mm x 20.6 mm) |

2.40" x 2.41" (61.0 mm x 61.2 mm) |

3.00" x 4.00" (76.2 mm x 101.6 mm) |

3.75" x 3.75" (95.3 mm x 95.3 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | |||||

Dovetail Stages

These compact stages incorporate dovetails and a leadscrew for the translation mechanism. They are suitable in general purpose motion control applications.

| Dovetail Stages | |||

|---|---|---|---|

| Product Family | DT Series 1/2" Stages | DTS Series 1" Stages (Vacuum-Compatible Version Available) |

DTS Series 2" Stage |

| Click Photo to Enlarge |  |

|

|

| Travel | 1/2" (12.7 mm) | 1" (25 mm) | 2" (50 mm) |

| Drive Type | Thumbscrew | Thumbscrew | Thumbscrew |

| Platform Size | 1.00" x 1.00" (25.4 mm x 25.4 mm) | 2.68" x 2.95" (68.0 mm 75.0 mm) | 2.68" x 3.74" (68.0 mm x 95.0 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZa | X, XY, XYZ |

| Additional Details | |||

Flexure Stages

Thorlabs' Nanoflex™ translation stages feature frictionless flexure mechanisms for improved positioning and resolution when compared to similar stages made using bearings. The translation of the stage is accomplished by the elastic deformation (flexing) of a linkage attached to the mounting platform. Most models also include piezo actuators for small position adjustments.

| Flexure Stages | ||||

|---|---|---|---|---|

| Product Family | Nanoflex™ 1.5 mm Stage | Nanoflex™ 5 mm Stages | ||

| Click Photo to Enlarge |  |

|

|

|

| Travel | 1.5 mm (0.06") + 25 µm Piezo | 5 mm (0.20") | 5 mm (0.20") + 20 µm Piezo | |

| Drive Type | Thumbscrew and Piezo Actuator | Differential Micrometer | Differential Micrometer and Open-Loop Piezo Actuator |

Differential Micrometer and Closed-Loop Piezo Actuator |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) | 2.95" x 2.95" (75.0 mm x 75.0 mm) | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | ||||

Vertical Stages

We offer vertical translation stages with crossed-roller bearings for precise motion as well as long travel vertical stages for heavy-duty applications.

| Vertical Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | XRN Series 9 mm Vertical Stage | XR Series 14 mm Vertical Stage | MVS Series 1/2" Vertical Stage | MVS Series 1" Vertical Stage | VAP Series 4" Vertical Stage | VAP Series 10" Vertical Stage |

| Click Photo to Enlarge |  |

|

|

|

|

|

| Travel | 9.0 mm (0.35") | 14.0 mm (0.55") | 1/2" (13.0 mm) | 1" (25.0 mm) | 4" (101.6 mm) | 10" (254 mm) |

| Drive Type | Worm-Gear Driven Lift Screw | Micrometer | Adjuster Knob and Coarse Manual Positioning | |||

| Platform Size | 2.00" x 2.00" (50.7 mm x 50.7 mm) |

2.98" x 2.98" (75.7 mm x 75.7 mm) |

2.36" x 2.36" (60.0 mm x 60.0 mm) | 3.00" x 6.00" (76.2 mm 152.4 mm) | ||

| Additional Details | ||||||

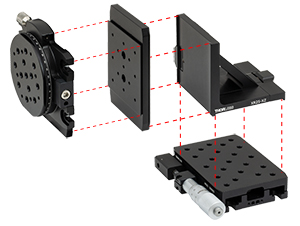

Build Multi-Axis Configurations

Click for Details

Z-axis assembly kits allow stages to be mounted in vertical orientations.

Quick-Connect Dovetails

Click to Enlarge

The female dovetails on the bottom of one stage mate with the male dovetails on another.

XR & XRN Dovetail Stages and Accessories

Our XR series manual stages feature quick-connect dovetails that allow for the construction of multi-axis systems without the need for additional hardware. The common dovetail feature with a single locking clamp makes it quick and simple to swap parts in and out while preserving excellent orthogonality.

Our selection of products with a quick-connect dovetail includes:

- Linear Translation Stages:

- Stackable 1-Axis Stages

- Pre-Assembled 2- and 3-Axis Configurations

- Rotational Stages:

- 360° Flat Rotation

- Tip/Tilt Goniometers

- Adapters:

- Z-Axis Assembly Kits

- Parallel and Perpendicular Mounting between 2" and 3" Dovetails

- Rail Accessories:

- Stationary Mounting Platforms

- Rail Component Positioners

- Base Plates and Rails

Most items are available in compact (2" dovetail) and full-size (3" dovetail) varieties. Adapters are available to interface between the two sizes. See the tables below for all available options.

| Linear Translation Stages | |||||

|---|---|---|---|---|---|

| Click Photo to Enlarge |  |

|

|

|

|

| Items | Compact 25 mm Stages | Compact 9 mm Vertical Stage | Full-Size 25 mm Stages | Full-Size 50 mm Stages | 14 mm Vertical Stage |

| Motion | X, Y, Z, XY, XZ, YZ, XYZ | Z (Vertical) | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | Z (Vertical) |

| Quick-Connect Dovetail | 2" Dovetail | 3" Dovetail | |||

| Additional Features | |||||

| Rotation and Goniometric Stages | |||

|---|---|---|---|

| Click Photo to Enlarge |  |

|

|

| Items | Compact Rotation Stage | Compact Goniometric Stages | Full-Size Rotation Stage |

| Motion | 360° Rotation | ±8° Tip/Tilt About Fixed Point Above Stage | 360° Rotation |

| Quick-Connect Dovetail | 2" Dovetail | 3" Dovetail | |

| Additional Features | |||

| Stage Adapters | ||

|---|---|---|

| Z-Axis Assembly Kits |  |

|

| Compact Z-Axis Assembly Kits, 2" Dovetails |

Full-Size Z-Axis Assembly Kits, 3" Dovetails |

|

| Parallel Mounting Adapters |

|

|

| Parallel Mounting Adapter, Male 2" Dovetail to Female 3" Dovetail |

Parallel Mounting Adapter, Male 3" Dovetail to Female 3" Dovetail |

|

| Perpendicular Mounting Adapter |

|

|

| Perpendicular Mounting Adapter Male 2" Dovetail to Female 3" Dovetail | ||

| Dovetail Accessories | ||

|---|---|---|

| Mounting Platforms |  |

|

| 2" Mounting Platforms | 3" Mounting Platforms | |

| Rail Positioners |  |

|

| 2" Rail Positioners | 3" Rail Positioners | |

| Dovetail Bases | |||

|---|---|---|---|

| Base Plates |  |

|

|

| 2" Dovetail Base Plate | 3" Dovetail Base Plate with Rotational Adjustment | ||

| Rails / Extended Bases |

|

|

|

| 2" Dovetail Rails | 3" Dovetail Rails | ||

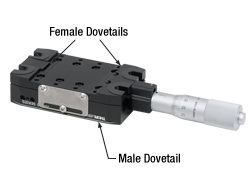

Click to Enlarge

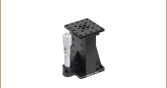

Ø1/2" Mounting Boss

- Mounting Surfaces Feature Sixteen 1/4"-20 (M6 x 1.0) Taps and Eight 6-32 (M4 x 0.7) Taps

- Create Multi-Axis Configurations with Other XRN Series Stages

- Compatible with 2" Dovetail Accessories

This stage provides z-axis translation and is compatible with our line of XRN series quick-connect linear and rotation stages. The 2" dovetails on the top plate and base plate of the stage interface directly with other stages for easy assembly of multi-axis configurations. Additional 2" dovetails on the front face can be used with quick-connect rail platforms.

The base plate can be removed, exposing a Ø1/2" mounting boss on the bottom of the stage, as shown in the photo to the right. This allows the stage to be mounted on a BA2E(/M) base plate for an even smaller footprint, or on an XRN-RB(/M) rotation adapter for coarse angular positioning.

| Mounting Adapter Compatibility | |||

|---|---|---|---|

| Item # | Orientation | Top Component | Bottom Component |

| XRN-A1 | Perpendicular | XRN25 Series XRNV1 Series XRNR1 Series XRNG1 Series |

XR25 Series XR50 Series XRR1 Series XRV1 Series |

| XRN-A2 | Parallel | ||

- XRN-A1 Adapter Enables Perpendicular Mounting of 2" Dovetail Components onto 3" Dovetail Components

- XRN-A2 Adapter Enables Parallel Mounting of 2" Dovetail Components onto 3" Dovetail Components

- Adapters Add 0.275" (7.0 mm) to the Overall Stacked Height of Components

These adapters enable mounting of quick-connect, crossed-roller bearing stages or accessories with a female 2" dovetail to components with a male 3" dovetail. The two different mounting adapters offer mounting orientations that are at 90° with respect to one another.

To assemble, first loosen the dovetail locking screw on the end of the top stage or accessory. Position the adapter on the bottom stage or rail, then align the top component on the adapter. Lastly, tighten the dovetail locking screw (maximum torque: 15 in•lbs) on the end of the top component until the entire assembly is secure. Please note that the deep-set screws in the sides of the adapter are not user adjustable.

Click for Details

Mechanical Drawings

- Secure Prisms or Cube Optics on Stage Mounting Surface

- 6-32 (M4 x 0.7) Threads on Top and Bottom of Post

- PM3(/M) Small Clamping Arm:

- Up to 0.97" (24.6 mm) Vertical Space Below Clamp

- Clamping Screw is Centered on XRNV1(/M) Mounting Surface

- PM3SP(/M) Extension Post Adds up to 1.24" (31.4 mm) to Arm Height

- PM4(/M) Large Clamping Arm:

- Up to 1.61" (40.9 mm) Vertical Space Below Clamp

- PM4SP(/M) Extension Post Adds up to 2.00" (50.8 mm) to Arm Height

Thorlabs' PM3(/M) and PM4(/M) Clamping Arms use a nylon-tipped setscrew with a 5/64" (2.0 mm) hex to secure prisms or cube optics on the mounting surfaces of the vertical translation stage above. The PM3(/M) provides up to 0.97" (24.6 mm) of vertical space below the clamping arm, while the PM4(/M) provides up to 1.61" (40.9 mm) of vertical space below the clamping arm. The vertical space below the arm can be increased using our PM3SP(/M) or PM4SP(/M) Extension Posts. These extension posts are identical to the posts included in each complete clamping arm.

Note that only the PM3(/M) has a 0.69" (17.5 mm) center-to-center distance between the post and the nylon-tipped setscrew, which places the screw in the center of the mounting surface of the XRNV1(/M). The PM4(/M) has a 1.16" (29.3 mm) center-to-center distance between the post and the nylon-tipped setscrew.

The clamping arm for all items is held to the post using a flexure mechanism that locks with a 5/64" (2.0 mm) balldriver or hex key. The post also offers a through hole for added torque when tightening down the post. Please see the diagram above for additional information.

Products Home

Products Home

Zoom

Zoom

Linear Stage: 9 mm

Linear Stage: 9 mm