Z-Axis Translation Stages and Accessories for 30 mm Cage Systems

- 1/2" (13 mm) or 12 mm Manual Travel Along Optic Axis

- Version with 160 µm Piezo-Driven Fine Adjustment

- Modular Design with Interchangeable Optic Mounts

CT104

Ø1/2" Rotation Mount

CT101

Ø1" (Ø25 mm) Optic Mount

CT102

Ø1/2" XY

Translation Mount

CT103

Blank Plate for

Custom Machining

CT1A

1/2" Travel, Micrometer Drive

CT1P

12 mm Travel with M6 x 0.25 Screw,

160 µm Closed-Loop Piezo Travel

Please Wait

Click to Enlarge

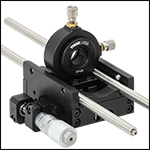

Gold Mirror Mounted in CT101 Optic Mount Secured to CT1P Translation Stage

Features

- Translation of Components Along 30 mm Cage System Optical Axis

- CT1P(/M) Stage Offers 12 mm Manual Travel and 160 µm Closed-Loop Piezo Travel (Min)

- CT1A(/M) Stage Includes 1/2" (13 mm) Travel Micrometer and CT101 Optic Mount

- Interchangeable Optic Mounts Sold Separately

Thorlabs' Z-Axis Translation Stages can be fixed to two cage rods in a 30 mm cage system while allowing the translation along the optical axis of a component secured to the moving world of the stage. The CT1P(/M) translation stage with integrated piezo actuator features 12 mm of manual travel as well as at least 160 µm of piezo travel with 0.5 µm resolution in closed-loop operation. The CT1A(/M) manual translation stage includes a CT101 optic mount and features a 1/2" (13 mm) travel micrometer with 0.001" (10 μm) graduations. These stages are fully compatible with all the optic mounts sold on this page.

We offer optic mounts that are specifically designed for both the CT1A(/M) and the CT1P(/M) stages, as well as our 1/4" Translation Stages. These mounts include a fixed optic mount, an XY translation mount, a rotation mount, and a blank plate for custom machining. See below for details.

| Manual Stage with Integrated Piezo Actuator | ||

|---|---|---|

| Item # | CT1P | CT1P/M |

| Travel Range | Coarse: 12.0 mm (250 µm per Revolution) Fine (Piezo): 160 µm (Closed Loop)a |

|

| Moving World Load Capacity (Max) | 40 g | |

| Coarse Adjustment Screw | M6 x 0.25 mm | |

| Piezo Fine Resolution (Closed Loop) | 0.5 µm | |

| Theoretical Open Loop Resolutionb | 8.0 nm | |

| Piezo Drive Voltagec | -10 V to 140 V, 6 mA Max | |

| Power Consumption | 5 V, 500 mA Max (270 mA Typical) | |

| EXT IN | MMCX Connector 0 to 10 VDC, 1.6 Hz Low Pass Filter |

|

| MONITOR Out | MMCX Connector 0 to 10 V (Max Load 20 kOhm) | |

| I/O (Trigger) | MMCX Connector 0 to 5 V (TTL) | |

| Drive Output Update Rate | 10 Hz | |

| Control Loop | Dual PID | |

| Thermal Stability | 144 nm/°C (Typical) | |

| Bearing Type | Crossed-Roller Bearings | |

| Moving World Mounting | Six 4-40 Mounting Holes, 4 mm Keyway |

Six M3 Mounting Holes, 4 mm Keyway |

| Fixed World Mounting | Two 8-32 Mounting Holes | Two M4 Mounting Holes |

| Operating Temperature | 10 to 40 °C (50 to 104 °F) | |

| Stage Outer Dimensions (L x W x H) | 3.35" x 2.36" x 1.69" (85.0 mm x 60.0 mm x 43.0 mm) |

|

| Cable Length | 1 m (3.3') | |

| Weight (Including Cable) | 305 g (10.75 oz) | |

| Compatible Accessories | CT101, CT102, CT104, CT103 | |

| Manual Stage | ||

|---|---|---|

| Item # | CT1A | CT1A/M |

| Travel Range | 1/2" | 13 mm |

| Micrometer Drive | 0.001" per Graduation | 10 µm per Graduation |

| Bearing Type | Linear Ball Bearings | |

| Moving World Mounting | Six 4-40 Mounting Holes, 4 mm Keyway |

|

| Included Accessory | CT101 | |

| Other Compatible Accessories | CT102, CT104, CT103 | |

| Stage Outer Dimensions (L x W x H)a | 2.35" x 2.54" x 1.25" (59.7 mm x 64.5 mm x 31.6 mm) |

|

| Weight | 250 g (8.82 oz) | |

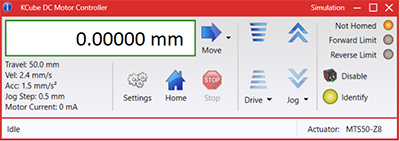

Software

Kinesis Version 1.14.50

The Kinesis Software Package, which includes a GUI for control of Thorlabs' Kinesis system controllers.

Also Available:

- Communications Protocol

Kinesis GUI Screen

Thorlabs offers the Kinesis® software package to drive our wide range of motion controllers. The software can be used to control devices in the Kinesis family, which covers a wide variety of motion controllers ranging from small, low-powered, single-channel drivers (such as the K-Cubes™) to high-power, multi-channel benchtop units and modular 19" rack nanopositioning systems (the MMR60x Rack System).

The Kinesis Software features .NET controls which can be used by 3rd party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications. Low-level DLL libraries are included for applications not expected to use the .NET framework and APIs are included with each install. A Central Sequence Manager supports integration and synchronization of all Thorlabs motion control hardware.

By providing this common software platform, Thorlabs has ensured that users can mix and match any of our motion control devices in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from single-axis to multi-axis systems and control all from a single, PC-based unified software interface.

The software package allows two methods of usage: graphical user interface (GUI) utilities for direct interaction with and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

Legacy Software

Select products are still capable of running the legacy APT™ software package. Information on software compatibility can be found in the product documentation (![]() ), and additional details about the APT software can be found here.

), and additional details about the APT software can be found here.

| Posted Comments: | |

Andreas Baum

(posted 2024-07-24 06:38:49.613) Dear Thorlabs,

I am currently fiddling with integrating a CT1A/M in a setup which has 60 mm cage systems and 30mm ones nested. The main hurdle is the side mounted actuator (I put in a Z925B motor which was available), which collides with the 60mm cage. Maybe a version of the CT1A(/M) with an end-mounted actuator port, like it is on the CT1P, would be a good addition to the product line.

Best

Andreas jdelia

(posted 2024-07-25 01:15:42.0) Thank you for contacting Thorlabs. While you would not be able to simply drop this product into a pre-existing 60 mm cage system, you can include in such a system by either only having three of the four cage rods utilized where this part is mounted, or using an adapter such as our LCP6X and not having the cage rods go all the way through the holes on the 60 mm cage plate corners, essentially having two separate 60 mm cage systems on either side of the CT1A(/M). I have reached out to you directly to discuss this further. Aaron Mueninghoff

(posted 2024-03-09 09:08:34.96) The locking screws included with this are too short. They have to be screwed almost completely out of the threading to actually lock the cage rods. If they were just 1.5 times longer, it would be much better. jdelia

(posted 2024-03-11 02:04:31.0) Thank you for reaching out. We will look into the possibility of incorporating this suggestion in the future with regards to our part CT1A. user

(posted 2020-09-16 13:19:20.33) I suggest adding an option for imperial or metric micrometer (as the included micrometer) YLohia

(posted 2020-09-16 03:48:25.0) Thank you for your feedback. We will consider adding this to our stock catalog. Please note that the CT1 can be ordered with a metric micrometer as a special item by emailing techsupport@thorlabs.com. Alternately, you may purchase the 148-801ST (metric micrometer) separately and install it in your CT1. Ken Li

(posted 2020-08-21 22:03:39.79) Please provide tolerance on the bottom key which is shown as nominal width of 4.0mm. What's the max/min of that width?

-Ken Li

510-410-4283 YLohia

(posted 2020-08-24 10:27:57.0) Hello Ken, thank you for contacting Thorlabs. The tolerance on the bottom key for the CT102 is 0.157" +0.000"/-0.001". Eric Mueller

(posted 2020-05-28 12:54:57.197) No metric version of the CT1 available (incl. a metric micrometer)?

Cheers,

Eric llamb

(posted 2020-05-28 05:14:27.0) Hi Eric, thank you for your feedback. The imperial micrometer included with the CT1 may be switched out with a metric micrometer (Item # 148-801ST) as needed. We can also provide a custom CT1 with a metric micrometer already included. I have reached out to you directly to discuss this option. akastengren

(posted 2018-08-29 10:46:00.683) Is there a way to put a stepper motor actuator on this product? YLohia

(posted 2018-08-29 11:48:38.0) Hello, thank you for contacting Thorlabs. Yes, it is possible to install a stepper motor actuator (such as the ZST213B) in the CT1 since it has a 3/8" mounting barrel. acable

(posted 2007-12-31 08:28:00.0) The description in the price box for the CT1 reads: 1/2" Cage Translation Stage. Please consider: 1/2" Travel 30mm Cage translator with CT101. |

Click to Enlarge

CT1P Mounted to Optical Table Using CT1PA Adapter Plate

Click to Enlarge

CT1P Adjusters and Connectors

- Integrated Piezo Actuator and Driver

- 160 µm Closed Loop Piezo Travel Range

- 0.5 µm Resolution (Closed Loop)

- M6 x 0.25 Screw for Coarse Adjustment

- 12 mm Travel

- 250 µm Adjustment per Revolution

- Precision Crossed-Roller Bearings

- Control Piezo with Knob, Kinesis® GUI, or External Voltage

- Adapter Plate for Secure Mounting (Sold Separately)

- Accessories Available for Mounting Optics (Sold Separately)

Click to Enlarge

Adapter Plate for Mounting CT1P(/M) Stage

The CT1P(/M) 12 mm Manual Travel Translation Stage with Integrated Piezo Actuator is designed to be used in 30 mm cage systems that require translating a component along the optical axis of the cage system. This stage incorporates precision crossed-roller bearings to ensure smooth, high-resolution motion. The stage can be roughly positioned using the "COARSE ADJUST" knob, which provides 250 µm of travel per revolution and can be locked using the included 1.5 mm hex key. The piezo actuator integrated in this stage must have power supplied using the included micro USB to USB A cable. The USB cable should be connected to a PC directly or via a powered USB hub. Turning the "FINE ADJUST" knob provides an adjustment of 0.5 µm resolution through 160 µm of travel in closed-loop operation. The piezo can be toggled between open- and closed-loop modes via the "OPEN/CLOSE" button on the front. Holding this button homes the piezo, putting it in the middle of its travel range. The coarse and fine adjustment knobs can be operated using a 2 mm (5/64") balldriver (not included); they should not be operated simultaneously.

The piezo actuator can also be controlled remotely using the Kinesis® software or by applying an external voltage to the EXT IN port (MMCX, 0 to 10 VDC). The default parameters of the CT1P(/M) stage can be altered using the Kinesis software, and settings such as jog step, PID parameters, and Trigger I/O can be persisted to the hardware as well. The two bidirectional I/O ports (MMCX) are disabled on default, but can be enabled using Kinesis and allow the user to use them either as input or output. Input mode uses TTL logic, while output mode provides a push-pull drive of 5 V, with a maximum current limit of 8 mA. There is also a MONITOR output port (MMCX, 0 to 10 V) which provides a digital representation of the piezo voltage. To download the software, see the Kinesis Software tab.

The moving world of the stage features six 4-40 (M3) holes and a center 4 mm keyway, allowing the accessories sold below to be easily mounted to the CT1P(/M) and exchanged depending on the application. Two 30 mm cage rods can be attached to the fixed world of the stage by positioning them in the slots on each side. The rods can then be secured by tightening the four included cone-ended M4 setscrews using a 2 mm (5/64") hex key or balldriver. If the stage is only mounted to the cage system, the cage rods should be supported near the stage using cage system mounts.

The CT1P(/M) stage features two 8-32 (M4) holes on the bottom which can be used to mount the stage in a variety of configurations. The CT1PA adapter plate, sold separately, offers a quick, low-profile solution to securing the stage, as shown in the image above to the right. Alternatively, the stage can be mounted using our Ø1/2" optical post assemblies or Ø1" optical post assemblies, although care should be taken to accomodate the non-standard hole spacing of 3.11" (79.0 mm). This can be achieved using pedestal posts with clamping forks, pedestal post holders with clamping forks, or a variety of post holder bases.

For more information on purchasing a custom stage with an imperial adjustment screw, contact Tech Support.

Click to Enlarge

CXY1A XY Translator Coupled to a CT1A Z-Axis Translation Mount Using an SM1S15 Lens Tube

- Includes 1/2" (13 mm) Travel Micrometer with 0.001" (10 µm) per Graduation

- Comes with CT101 Ø1" Optic Mount for Optics up to 0.27" (6.9 mm) Thick

- Precision Linear Ball Bearings

- Lockable Design

The CT1A(/M) Manual Translation Stage is designed to be used in 30 mm cage systems that require translation along the optical axis of the cage. This translation stage includes a CT101 Ø1" optic mount, which is also available separately below. Precision linear ball bearings are used to ensure smooth, high-resolution motion. The CT1A(/M) features a graduated micrometer that provides 1/2" (13 mm) of linear translation with 0.001" (10 µm) graduations. A 5/64" (2 mm) hex on the micrometer allows for actuation in space-constrained environments. The smallest incremental movement of the carriage is approximately 1 µm.

The modular design allows the accessories sold below to be mounted to the movable carriage of the CT1A(/M) translation stage. The included CT101 Ø1" Optic Mount has internal SM1 threading (1.035"-40) for mounting Ø1" optical components up to 0.27" (6.9 mm) thick, or externally SM1-threaded components, such as our SM1 lens tubes. One SM1RR retaining ring, two 4-40 cap screws for securing the mount, a 1/16" and a 5/64" (2 mm) hex key, and two removable dowel pins for alignment are also included with the mount.

Click to Enlarge

Click to EnlargeCT101 Optic Mount with SM1L10 Lens Tube Attached to the CT1A Cage Translation Stage in a 30 mm Cage System

- SM1 (1.035"-40) Threaded Bore Directly Accepts Ø1" Optics up to 0.27" (6.9 mm) Thick

- Compatible with Our Line of SM1 Lens Tubes

- Finger Groove Recess Allows for Ease of Alignment

- Compatible with Our Z-Axis Translation Stages for 30 mm Cage Systems and Our 1/4" Translation Stages

The CT101 provides a means to mount SM1-threaded (1.035"-40) devices as well as Ø1" optics to the CT1A(/M) or CT1P(/M) stages. It is also compatible with our 1/4"-travel translation stages using our MS103 or MS103/M Adapter Plate. One SM1RR retaining ring, two 4-40 and two M3 cap screws, and two removable dowel pins for alignment are included with each unit.

Click to Enlarge

The CT1A Cage Translation Stage Combined with a CT102 Translating Lens Mount to Create an XYZ Configuration

- Provides ±0.04" (±1.0 mm) of Travel in X and Y Directions

- SM05 (0.535"-40) Threaded Bore Directly Accepts Ø1/2" Optics up to 0.39" (9.9 mm) Thick

- Wobble: <100 µrad

- Resolution: 250 µm/rev

- Compatible with Our Z-Axis Translation Stages for 30 mm Cage Systems and Our 1/4" Translation Stages

The CT102 has an internal SM05 (0.535"-40) threading for mounting Ø1/2" optics up to 0.39" (9.9 mm) thick or externally SM05-threaded components. The CT102 allows for ±1 mm of travel in the X and Y direction using M3 x 0.25 fine adjusters. The mount is directly compatible with the CT1A(/M) and CT1P(/M) stages. It is also compatible with our 1/4"-travel translation stages using our MS103 or MS103/M Adapter Plate. One SM05RR retaining ring, which secures a component by sandwiching it between the ring and the back lip on the mount, and two 4-40 and two M3 cap screws for securing the mount are included with each unit.

Click to Enlarge

Click to EnlargeCT104 Rotation Mount Shown with the CT1A Cage Translation Stage in a 30 mm Cage System

- Coarse Rotation: 360° Continuously Adjustable

- Graduations: 2° Increments

- Mount Ø1/2" Optics up to 7.3 mm (0.29") Thick

- Runout: <0.0001" (25 μm) Along Optical Axis

- Max. Clear Aperture: 0.43"

- Lockable Design

- Compatible with Our Z-Axis Translation Stages for 30 mm Cage Systems and Our 1/4" Translation Stages

The CT104 rotation mount provides 360° of continuous rotation for Ø1/2" (Ø12.7 mm) optics and SM05 threaded components. The 2° graduation allows for precise positioning of components, such as linear polarizers and waveplates. A top-mounted nylon-tip setscrew is used to lock the freedom of rotation when the mount has been set in the correct orientation. The mount is directly compatible with the CT1A(/M) and CT1P(/M) stages. It is also compatible with our 1/4"-travel translation stages using our MS103 or MS103/M Adapter Plate. One SM05RR retaining ring, which secures a component by sandwiching it between the ring and the back lip on the mount, and two

Click to Enlarge

Click to EnlargeCT103 Blank Mount Shown on the CT1A Cage Translation Stage

- Ideal for Custom Machining

- Center-Drilled Dimple Allows for User to Precisely Align Along the Cage's Optical Axis

- Finger Groove Recess Allows for Ease of Alignment

- Compatible with Our Z-Axis Translation Stages for 30 mm Cage Systems and Our 1/4" Translation Stages

The CT103 blank device mount has a solid surface to allow the end user to tailor the mount for custom applications. Custom hole sizes and threads can be machined using any size drill bits and taps. A center-drilled dimple is provided to help in aligning with the optical axis during the machining process. The mount is directly compatible with the CT1A(/M) and CT1P(/M) stages. It is also compatible with our 1/4"-travel translation stages using our MS103 or MS103/M. Two

Products Home

Products Home

Zoom

Zoom

Z-Axis Translators with Accessories

Z-Axis Translators with Accessories