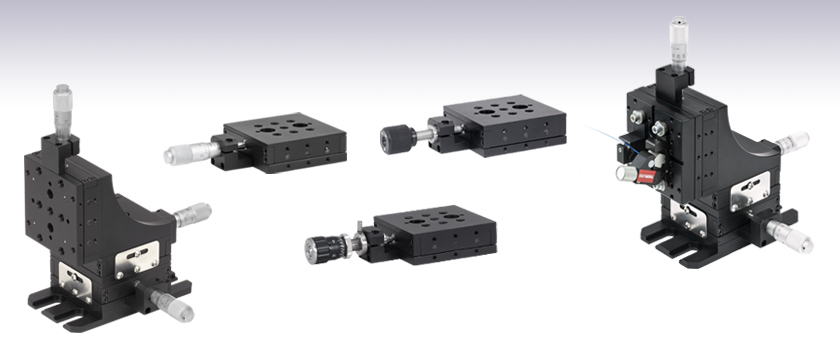

1/2" (12.7 mm) Travel Translation Stages

- 2.4" x 2.4" Stage with 1/4"-20 (M6) Mounting Holes

- Modular Design for Building 1-, 2-, or 3-Axis Stages

- Models with Adjuster Screws, Micrometers, or Differential Adjusters

MT3

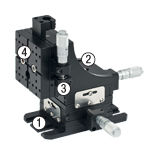

XYZ Stage with Standard Micrometers

MT1

Standard Micrometer

Application Idea

MT3 Stage Shown with an MT406 Top Plate, HFF001 Fiber Clamp, and HFS001 Strain Relief for Fiber Coupling Applications

MT1B

1/4"-170 Adjuster Screw

MT1A

Differential Adjuster

Please Wait

| Common Specifications | |

|---|---|

| Travel | 1/2" (12.7 mm) |

| Configuration | Left or Right Handed |

| XY Stacked Orthogonality | <5 mrad |

| Angular Deviation | <250 µrad |

| Bearing Type | Ball on Hardened V-Grooves |

| Ball Bearing-Mechanism Manual Translation Stages |

|---|

| 1/4" (6 mm) Travel |

| 1/2" (12.7 mm) Travel |

| 1/2" (13 mm) Travel, Miniature |

| 1" (25 mm) Travel |

| 2" (50 mm) Travel |

Click to Enlarge

The adjuster on the MT1(/M), MT1B(/M), or MT1A(/M) stage

can be replaced with any Ø3/8" (Ø9.5 mm) barrel actuator,

such as this ZFS13B motor actuator.

Features

- Modular Design Allows Stages to be Easily Configured in XY and XYZ Orientations

- Manual or Motorized Actuator-Equipped Models Available

- Compatible with All Ø3/8" (Ø9.5 mm) Actuators

- 1/4"-20 (M6) and 8-32 (M4) Mounting Holes

- Side-Located Screw for Locking in Place

Thorlabs' MT Translation Stages have a 1/2" (12.7 mm) translation range and feature hardened steel linear bearings for precise motion and long life. Once the desired position is reached, the stage may be locked using the side-located 1/16" (1.5 mm) hex locking screw. MT1(/M), MT1B(/M), or MT1A(/M) stages can be combined to form 2- and 3-axis platforms; see the XYZ Assembly tab for more information.

These translation stages are available preconfigured with a 1/4"-170 adjuster [Item # MT1B(/M)], a standard micrometer [Item # MT1(/M)], or a DM10 differential adjuster [Item # MT1A(/M)]. The actuator on an MT translation stage can be removed by loosening the screw on the barrel clamp. For more information about removing the actuator and attaching it to one side of the stage, please refer to the Actuator Removal tab.

Each stage comes with two precision dowel pins that allow for multiple stages to be stacked in a right- or left-handed XY configuration with an excellent orthogonality of <5 mrad. The right-handed XYZ configuration is available fully assembled [see Item # MT3 (MT3/M) or MT3A (MT3A/M) below].

Note: Thorlabs' MT translation stages can be purchased without a micrometer by contacting Tech Support. This allows the user to choose from any of our manual and motorized actuators with Ø3/8" (Ø9.5 mm) barrel sizes. We also offer barrel adapters for select screw adjusters, making them compatible with the stages below.

The modular design of the MT translation stages allows the assembly of a 2- or 3-axis stage within minutes. Each stage comes with two precision dowel pins that allow multiple stages to be arranged in a right- or left-handed XY configuration with excellent orthogonality. Follow the steps below to build a 3-axis XYZ translator (MT3 or MT3/M) from individual components.

Step One

Screw MT401(/M) Base to MT1(/M) Translation Stage using two 1/4"-20 (M6) cap screws.

Step Two

Attach second, orthogonal MT1 Translation Stage, as shown above, using two 1/4"-20 (M6) cap screws.

Step Three

Screw MT402 Angle Bracket to MT1 Translation Stage, as shown above, using two 1/4"-20 (M6) cap screws.

Step Four

Screw third MT1(/M) Translation Stage to back of MT402 Angle Bracket, using two 1/4"-20 (M6) cap screws.

MT Translation Stage Actuator Removal

Each of our MT translation stages features a removable actuator. This feature allows the actuator to be mounted to the side of the stage opposite of the locking plate using an MT405 side-mounted actuator adapter and a 3/32" hex drive. Please note that the side of the stage with the locking plate is not designed to mount an actuator using the MT405 adapter. Although an MT1 stage is shown, removal of the actuator is similar for MT1B(/M) and MT1A(/M) stages.

The MT1 features a removable micrometer mounted to the front of the stage. Using the MT405 adapter and a 3/32" hex drive, the micrometer can be mounted in two additional orientations for a total of three orientations. We do not recommend mounting the actuator in orientations other than the three shown below. Do not remove the locking plate and attempt to mount an actuator on that side of the stage.

Note: Since our MT translation stages can be used with a range of different actuators, please ensure that there is sufficient clearance to side mount other actuators using the MT405 adapter. The MT stage's actuator can be side mounted using the MT405. For questions about compatibility with other actuators, please contact Tech Support.

Orientation 1

Click to Enlarge

Orientation 1: Micrometer Mounted to Front of MT1 Stage

Orientation 2

Click to Enlarge

Orientation 2: Right-Handed Configuration with Micrometer Mounted to Side of Stage Opposite of Locking Plate

Orientation 3

Click to Enlarge

Orientation 3: Left-Handed Configuration with Micrometer Mounted to Side of Stage Opposite of Locking Plate

Video Insight Clip: Replacing the Actuator on a Thorlabs MT Linear Translation Stage

This Video Insight clip demonstrates how to replace the included manual actuator on a Thorlabs MT translation stage by a motorized actuator for remote operation. When making such a replacement, be sure to verify compatibility between the travel range and mounting barrel size of the motorized actuator and the MT translation stage. For more details on installing a motorized actuator, you can find the full Insight here.

If you would like more information about tips, tricks, and other methods we often use in the lab, we recommend our other Video Insights. In addition, our webinars provide practical and theoretical introductions to our different products.

Click to Enlarge

MT1 Packaging

| Item # | % Weight Reduction | CO2-Equivalent Reductiona |

|---|---|---|

| MT1 | 35.44% | 57.95 kg |

| MT1/M | 35.44% | 55.72 kg |

Smart Pack

- Reduce Weight of Packaging Materials

- Increase Usage of Recyclable Packing Materials

- Improve Packing Integrity

- Decrease Shipping Costs

Thorlabs' Smart Pack Initiative is aimed at waste minimization while still maintaining adequate protection for our products. By eliminating any unnecessary packaging, implementing packaging design changes, and utilizing eco-friendly packaging materials for our customers when possible, this initiative seeks to improve the environmental impact of our product packaging. Products listed above are now shipped in re-engineered packaging that minimizes the weight and the use of non-recyclable materials.b As we move through our product line, we will indicate re-engineered packages with our Smart Pack logo.

| Posted Comments: | |

Ryan Desaulniers

(posted 2024-02-12 10:37:38.087) Just wanted to let you know it looks like your part's PDF drawing doesn't look like it matches up with the STEP file or the actual part.

Dimension 1.50in between dowel pin holes appears to be 1.60in on the part I received and your step file.

Just figured I'd let you guys know.

-Ryan Desaulniers jdelia

(posted 2024-02-15 04:21:21.0) Thank you for contacting Thorlabs. The 1.50" called out in our CAD drawing only refers to the two pairs of dowel pin holes on the sides of the base of MT1. For the two dowel pin holes located on the mounting surface of the MT1, the distance is not called out in our CAD drawing, but it is in fact 1.60". Nazim Bharmal

(posted 2022-05-12 14:00:27.753) Is the maximum horizontal load incorrect? 90lbs seems unrealistic. jdelia

(posted 2022-05-26 10:55:56.0) Thank you for contacting Thorlabs and for pointing this out. The 90 lbs load spec is a typo and we will look into getting that fixed. The listed load capacity should actually be around 50 lbs. user

(posted 2022-03-22 09:07:39.36) Hello,

We use this stage at out company on a gluing setup, to hold the part to be glued in position. However, we noticed what appears to be the glue shrinkage affecting the position of the part while curing. At the moment, we are looking for something similar with a locking mechanism so that the part does not move during the curing process. Could you direct me to such a solution.

Thank you and best regards. jdelia

(posted 2022-03-23 09:13:33.0) Thank you for contacting Thorlabs. Fortunately, the MT1/M stage does in fact feature a side-located set screw to lock the platform in place. I have also reached out to you individually to discuss your application. youngsun jo

(posted 2021-10-20 19:42:49.713) Nice to meet you. I have a question about the spec content.

I'm not sure what you mean by horizontal and vertical loads. Is the micrometer's axis the reference? YLohia

(posted 2021-12-23 10:44:39.0) Thank you for contacting Thorlabs. The horizontal load capacity refers to the maximum load the stage can bare when the base of the stage is parallel to the optical table. Similarly, the vertical load capacity is the maximum load the stage can bare when the base of the stage is perpendicular to the optical table. user

(posted 2021-04-12 05:44:50.67) Hello, can you give information about the tolerances used, especially for the height of the MT1-M Stage and the Base Plate (MT401-M)? Thank you YLohia

(posted 2021-04-14 10:12:36.0) A true tolerance value would depend on the location of the moving world along the travel range, and require an extensive GD&T calculation. Based on the top and bottom plates’ height tolerances alone (and not taking into account the pre-loaded ball bearings that lie between the plates), a loose estimate is on the order of ±0.015” for the overall height tolerance. The MT401/M has a height tolerance of 0.400" ± 0.005" akuznetsov

(posted 2019-01-02 17:01:10.087) MT401 is missing min. breadboard mount screw distance call out in the PDF, please add min and maximum screw distance callout for securing to breadboard. llamb

(posted 2019-01-03 10:49:46.0) Thank you for pointing this out. The minimum breadboard mounting screw distance you're looking for is 2.94" for the MT401. Our team will update the PDF drawings. user

(posted 2018-07-19 11:04:50.51) Is the stage as shown in the pictures and CAD files in a central or extremal position with respect to specified 13 mm travel? I.e. is there room for it to travel 6.5 mm in both directions or can it only/predominantly in one, from the position in which it is shown (i.e. top holes on travelling sled aligned with counterbores of bottom part, so that M6 screw can be inserted for screwing onto breadboard, if I see correctly). llamb

(posted 2018-07-19 08:43:56.0) Thank you for contacting Thorlabs. The stages shown here are in their nominal, centered position. This means that from the position shown in the CAD file and drawings they can translate in either direction at ±6.5 mm. The clearance bores on the base of the stages can be accessed from this nominal position. kswitkowski

(posted 2018-03-22 06:55:55.117) Hi,

I am using MT3A/M since 2 years, and I noticed quite high slack's on all axes. Do you have any advice, how can I minimize it. I have already tightened all screws and It did not improve. llamb

(posted 2018-04-03 04:41:20.0) Hello, thank you for contacting Thorlabs. Quantifying the slack and load would be the first step for minimizing these effects. The bearing mechanism cannot easily be adjusted remotely, so we typically suggest these to be returned for on-site evaluation if performing poorly. I will reach out to you directly to troubleshoot further. tomerg

(posted 2015-12-02 11:24:07.25) Hi there.

1. The 1/2" and 2" manual translation stages have locking screws while that of the 1" does not have, right? what is the reason and can the 1" stage (pt1a/m for example) be configured with a locking screw?

2. If I want to order the mt1/m with differential adjuster (dm10), do I recieve the stage with the standard micrometer and the adjuster separately, or can I get the stage with no micrometer at a lower cost?

Thanks, Tomer. besembeson

(posted 2015-12-02 04:18:32.0) Response from Bweh at Thorlabs USA: It depends on the design and the choice of micrometer/actuators. The PT1A/M has a locking screw for the coarse adjustment. We can provide the MT1/M with the differential adjuster, DM10 already mounted as a special item. We can also provide the stage without the adjuster if you prefer that. I will followup with you regarding quoting these, and a special PT1A/M as required by your application. tesar

(posted 2013-08-27 12:15:19.03) Is the MT1/M translation stage available without a micrometer? jlow

(posted 2013-08-27 08:59:00.0) Response from Jeremy at Thorlabs: The translation stage is available without a micrometer. We will contact you directly for a quote. jlow

(posted 2013-01-04 08:36:00.0) Response from Jeremy at Thorlabs: Both the flatness and straightness for the stage should be =0.001". mayeul.duranddegevigney

(posted 2013-01-03 09:26:25.33) Hello,

Do you have information on the flatness and straightness of this stage?

Kind Regards user

(posted 2011-03-15 15:02:31.0) height of mt1 not shown in drawing Thorlabs

(posted 2010-10-12 18:48:57.0) Response from Javier at Thorlabs to piaa06: We can certainly offer the ball bearings separately. I will contact you directly to discuss the details. piaa06

(posted 2010-10-12 15:29:05.0) Hello,

Can I buy the ball bearings inside the MT1 stage separately?

I recently lost some of them. klee

(posted 2009-12-09 12:44:14.0) A response from Ken at Thorlabs to mheinric: Can you tell me what software you used to open them? I could open them in SolidWorks with no problem. mheinric

(posted 2009-12-09 09:31:25.0) Your AutoCAD dxf drawings for the MT1 & MT1/M are corrupt. jens

(posted 2009-06-15 15:45:18.0) A reply from Jens at Thorlabs: the MT stages offer a modular design which means that you can combine individual stages with manual actuator and DC motor, the part number for the manual version is MT1 for the motorized version MT1-Z8. In order to connect them you would need the base plate MT401 and the bracket MT402. We can set up a single part number for this and assemble it here for you. Since in that case the items will not just be shipped from stock it might add one or two days to the lead time, using that standard part numbers the items can ship same day. bilal

(posted 2009-06-15 12:29:50.0) Hello,

I need the MT3/M but I need the Z axis movement to be motorized. will you ba able to supply such positioner (complete)? how long will it take? how much will it cost me?

thanks

Best regards

Bilal Saudi

Pythagoras-Solar Ltd. Tyler

(posted 2008-12-09 10:33:06.0) A response from Tyler at Thorlabs to cohensr: The solid model drawing of the mt1/m stage was sent to you. Thank you for considering one of our translation stages. cohensr

(posted 2008-11-29 17:06:56.0) Dear Sir.

Pls send me solid model of mt1/m stage.

the model in your site build from surfaces and is not solid.

Thank You

Shlomo Tyler

(posted 2008-10-27 14:17:26.0) A response from Tyler at Thorlabs to ken.harte: The drawings for each translation stage are available on the "Drawings and Documents" tab located above. I will check to make sure that the files are properly linked. I will also email the file directly to you. Thank you for your interest in our products and if we can assist you in any other way, please ask. ken.harte

(posted 2008-10-23 13:43:48.0) I cant get a DXF drawing of this stage, which I need to integrate it into an optical system. |

Manual Linear Translation Stages

Thorlabs' manual translation stages are offered in a range of maximum travel distances, from less than 1/4" (6 mm) to 2" (50 mm) and longer for our long travel, large area platforms. Many of these stages can be ordered in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our Multi-Axis Stages, which offer finer adjustment than our standard manual translation stages. In addition to linear translation stages, we offer rotation stages, pitch and yaw platforms, and goniometers. We also offer motorized translation stages that are powered by DC Servo motors, stepper motors, or direct drive technology.

Crossed-Roller Bearing Stages

These linear translation stages feature crossed-roller bearing travel mechanisms for precision motion, high load capacity, and low angular deviation. The LNR Series stages feature all-steel body construction, while the LX, XRN, and XR Series stage bodies are constructed of cast tool and jig aluminum. We also offer several vertical crossed-roller bearing stages (see below).

| Crossed-Roller Bearing Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | LNR Series 25 mm Stages | LX Series 25 mm Stages |

XRN Series 25 mm Stages | XR Series 25 mm Stages | XR Series 50 mm Stages | LNR Series 50.8 mm Stages |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 50 mm (1.97") | 50.8 mm (2") |

| Drive Type | Multiple | Micrometer | Micrometer | Micrometer | Micrometer | Multiple |

| Platform Size | 2.34" x 2.36" (59.4 mm x 60.0 mm) |

2.56" x 2.56" (65.0 mm x 65.0 mm) |

2.00" x 3.35" (50.7 mm x 85.0 mm) |

2.98" x 4.33" (75.7 mm x 110.0 mm) |

2.98" x 5.51" (75.7 mm x 140.0 mm) |

3.94" x 3.94" (100.0 mm x 100.0 mm) |

| Possible Axis Configurations |

X, XZ, XY, XYZ | X, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, XY, XYZ |

| Additional Details | ||||||

Ball Bearing Stages

These translation stages feature hardened steel linear bearings for precise motion and long life. They are available with a variety of actuators and in single-axis or preassembled multi-axis configurations.

| Ball Bearing Stages | |||||

|---|---|---|---|---|---|

| Product Family | MS Series 1/4" Stages | T12 Series 1/2" Stages | MT Series 1/2" Stages | PT Series 1" Stages | LT Series 2" Stages |

| Click Photo to Enlarge |  |

|

|

|

|

| Travel | 1/4" (6.4 mm) | 1/2" (12.7 mm) | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50 mm) |

| Drive Type | Multiple | Thumbscrew | Multiple | Multiple | Differential Micrometer |

| Platform Size | 1.17" x 1.17" (29.7 mm x 29.7 mm) |

0.76" x 0.81" (19.3 mm x 20.6 mm) |

2.40" x 2.41" (61.0 mm x 61.2 mm) |

3.00" x 4.00" (76.2 mm x 101.6 mm) |

3.75" x 3.75" (95.3 mm x 95.3 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | |||||

Dovetail Stages

These compact stages incorporate dovetails and a leadscrew for the translation mechanism. They are suitable in general purpose motion control applications.

| Dovetail Stages | |||

|---|---|---|---|

| Product Family | DT Series 1/2" Stages | DTS Series 1" Stages (Vacuum-Compatible Version Available) |

DTS Series 2" Stage |

| Click Photo to Enlarge |  |

|

|

| Travel | 1/2" (12.7 mm) | 1" (25 mm) | 2" (50 mm) |

| Drive Type | Thumbscrew | Thumbscrew | Thumbscrew |

| Platform Size | 1.00" x 1.00" (25.4 mm x 25.4 mm) | 2.68" x 2.95" (68.0 mm 75.0 mm) | 2.68" x 3.74" (68.0 mm x 95.0 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZa | X, XY, XYZ |

| Additional Details | |||

Flexure Stages

Thorlabs' Nanoflex™ translation stages feature frictionless flexure mechanisms for improved positioning and resolution when compared to similar stages made using bearings. The translation of the stage is accomplished by the elastic deformation (flexing) of a linkage attached to the mounting platform. Most models also include piezo actuators for small position adjustments.

| Flexure Stages | ||||

|---|---|---|---|---|

| Product Family | Nanoflex™ 1.5 mm Stage | Nanoflex™ 5 mm Stages | ||

| Click Photo to Enlarge |  |

|

|

|

| Travel | 1.5 mm (0.06") + 25 µm Piezo | 5 mm (0.20") | 5 mm (0.20") + 20 µm Piezo | |

| Drive Type | Thumbscrew and Piezo Actuator | Differential Micrometer | Differential Micrometer and Open-Loop Piezo Actuator |

Differential Micrometer and Closed-Loop Piezo Actuator |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) | 2.95" x 2.95" (75.0 mm x 75.0 mm) | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | ||||

Vertical Stages

We offer vertical translation stages with crossed-roller bearings for precise motion as well as long travel vertical stages for heavy-duty applications.

| Vertical Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | XRN Series 9 mm Vertical Stage | XR Series 14 mm Vertical Stage | MVS Series 1/2" Vertical Stage | MVS Series 1" Vertical Stage | VAP Series 4" Vertical Stage | VAP Series 10" Vertical Stage |

| Click Photo to Enlarge |  |

|

|

|

|

|

| Travel | 9.0 mm (0.35") | 14.0 mm (0.55") | 1/2" (13.0 mm) | 1" (25.0 mm) | 4" (101.6 mm) | 10" (254 mm) |

| Drive Type | Worm-Gear Driven Lift Screw | Micrometer | Adjuster Knob and Coarse Manual Positioning | |||

| Platform Size | 2.00" x 2.00" (50.7 mm x 50.7 mm) |

2.98" x 2.98" (75.7 mm x 75.7 mm) |

2.36" x 2.36" (60.0 mm x 60.0 mm) | 3.00" x 6.00" (76.2 mm 152.4 mm) | ||

| Additional Details | ||||||

| Item # | MT1B | MT1B/M |

|---|---|---|

| Actuator | 1/4"-170 TPI Adjustera | |

| Resolution | 0.006" (149.4 µm) Translation per Revolution | |

| Travel | 0.50" (12.7 mm) | |

| Taps | Top: 1/4"-20 (Qty. 7) Bottom: 1/4"-20 (Qty. 7) and 8-32 (Qty. 4) |

Top: M6 (Qty. 7) Bottom: M6 (Qty. 7) and M4 (Qty. 4) |

| Barrel Size | Ø3/8" (Ø9.5 mm) | |

| Vertical Load Capacity (Max) | 4.4 lbs (2 kg) | |

| Horizontal Load Capacity (Max) | 7 lbs (3.2 kg) | |

The MT1B(/M) translation stage is configured with a 1/4"-170 TPI adjuster, which has a 0.50" (12.7 mm) travel range. The adjuster can either be actuated by hand or by the 5/64" (2.0 mm) hex located on the end. Each stage contains seven 1/4"-20 (M6) tapped holes that are 0.25" (6.2 mm) deep. Two oversized 1/4" (M6) counterbores allow the stage to be directly attached to a mounting adapter (sold below) or a metric or imperial breadboard with user-supplied cap screws.

The bottom face of the MT1B(/M) has four 8-32 (M4) tapped holes for mounting which are exposed when multiple stages are used to form a 2- or 3-axis stage. See the XYZ Assembly tab for more information.

The MT405 Side-Mounted Actuator Adapter (sold below) can be used to mount the adjuster only on the side without the locking plate. The side of the stage with the locking plate is not designed to mount an adjuster. See the Actuator Removal tab, above, for details about side-mounting the adjuster on an MT1B(/M) stage.

| Item # | MT1 | MT1/M |

|---|---|---|

| Actuator | 148-811ST Micrometer | 148-801ST Micrometer |

| Resolution | 0.025" Translation per Revolution |

0.5 mm Translation per Revolution |

| Travel | 0.50" | 12.7 mm |

| Engraving | 0.001" (25.4 µm) per Division |

10 µm (0.0004") per Division |

| Taps | Top: 1/4"-20 (Qty. 7) Bottom: 1/4"-20 (Qty. 7) and 8-32 (Qty. 4) |

Top: M6 (Qty. 7) Bottom: M6 (Qty. 7) and M4 (Qty. 4) |

| Barrel Size | Ø3/8" (Ø9.5 mm) | |

| Vertical Load Capacity (Max) | 4.4 lbs (2 kg) | |

| Horizontal Load Capacity (Max) | 50 lbs (23 kg) | |

The MT1(/M) translation stage is configured with the 148-811ST micrometer drive, which has a 1/2" range and 0.001" per division. The MT1/M is configured with the 148-801ST micrometer drive, which has a 12.7 mm range and 10 µm per division. Each stage contains seven 1/4"-20 (M6) tapped holes that are 0.25" (6.2 mm) deep. Two oversized 1/4" (M6) counterbores allow the stage to be directly attached to a mounting adapter (sold below) or a metric or imperial breadboard with user-supplied cap screws.

The bottom face of the MT1(/M) has four 8-32 (M4) tapped holes for mounting which are exposed when multiple stages are used to form a 2- or 3-axis stage. See the XYZ Assembly tab for more information.

The MT405 Side-Mounted Actuator Adapter (sold below) can be used to mount the micrometer only on the side without the locking plate. The side of the stage with the locking plate is not designed to mount a micrometer. See the Actuator Removal tab, above, for details about side-mounting the micrometer on an MT1(/M) stage.

| Item # | MT1A | MT1A/M |

|---|---|---|

| Actuator | DM10 Differential Adjuster | |

| Coarse Resolution | 0.5 mm (0.02") Translation per Revolution | |

| Coarse Range | 0.50" (12.7 mm) | |

| Fine Resolution | 25 µm (0.001") Translation per Revolution | |

| Fine Range | 250 µm (0.01") | |

| Travel | 0.50" (12.7 mm) | |

| Engraving | 0.5 µm per Division | |

| Taps | Top: 1/4"-20 (Qty. 7) Bottom: 1/4"-20 (Qty. 7) and 8-32 (Qty. 4) |

Top: M6 (Qty. 7) Bottom: M6 (Qty. 7) and M4 (Qty. 4) |

| Barrel Size | Ø3/8" (Ø9.5 mm) | |

| Vertical Load Capacity (Max) | 4.4 lbs (2 kg) | |

| Horizontal Load Capacity (Max) | 50 lbs (23 kg) | |

For applications that require increased resolution, the MT1A(/M) translation stage is configured with the DM10 differential adjuster. The differential adjustment knob provides 25 µm of translation per revolution over a 250 µm range and is engraved with graduations every 0.5 µm. The coarse adjustment, which can be locked using a thumbscrew on the mounting collar, provides 0.02" (0.50 mm) of translation per revolution over a range of 0.50" (12.7 mm). Each stage contains seven 1/4"-20 (M6) tapped mounting holes that are 0.25" (6.2 mm) deep.

Two oversized 1/4" (M6) counterbores allow the stage to be directly attached to a mounting adapter (sold below) or a metric or imperial breadboard with user-supplied cap screws.

The bottom face of the MT1A(/M) has four 8-32 (M4) tapped holes for mounting which are exposed when multiple stages are used to form a 2- or 3-axis stage. See the XYZ Assembly tab for more information.

The MT405 Side-Mounted Actuator Adapter (sold below) is designed to mount the adjuster only on the side without the plate. The side of the stage with the locking plate is not designed to mount an adjuster. See the Actuator Removal tab, above, for details about side-mounting the adjuster on an MT1A(/M) stage.

| Item # | MT3 | MT3/M |

|---|---|---|

| Actuators | 148-811ST Micrometer | 148-801ST Micrometer |

| Resolution | 0.025" Translation per Revolution |

0.5 mm Translation per Revolution |

| Travel | 0.50" | 12.7 mm |

| Engraving | 0.001" (25.4 µm) per Division |

10 µm (0.0004") per Division |

| Taps | Top: 1/4"-20 (Qty. 7) Bottoma: 1/4"-20 (Qty. 7) and 8-32 (Qty. 4) |

Top: M6 (Qty. 7) Bottoma: M6 (Qty. 7) and M4 (Qty. 4) |

| Barrel Size | Ø3/8" (Ø9.5 mm) | |

- Preconfigured, 3-Axis, Right-Handed XYZ Translators

- Fully Assembled Stages Include Both the MT401(/M) and MT402 Adapter Plates

The MT3(/M) translation stage is fitted with standard 1/2" (12.7 mm) micrometer drive. The quick-change modular design utilizes precision-aligned dowel pins to ensure orthogonality between stages and allows the user to reconfigure stages quickly as applications change.

Four 1/4" (M6) counterbored slots on the included adapter allow the stage to be directly attached to a breadboard with user-supplied cap screws. Each stage contains seven 1/4"-20 (M6) and four 8-32 (M4) tapped mounting holes that are 0.22" (5.6 mm) deep.

The MT Series translation stages can be purchased individually (MT1 Series) or as fully assembled, 3-axis, XYZ translators (MT3 Series). Therefore, the MT3 stage can be disassembled using a 3/16" (5 mm) hex key to customize the positions of the micrometers or to use three MT1 stages separately. See the XYZ Assembly tab for details.

| Item # | MT3A | MT3A/M |

|---|---|---|

| Actuators | DM10 Differential Adjuster | |

| Coarse Resolution | 500 µm (0.02") Translation per Revolution | |

| Coarse Range | 0.50" (12.7 mm) | |

| Fine Resolution | 25 µm (0.001") Translation per Revolution | |

| Fine Range | 250 µm (0.01") | |

| Travel | 0.50" (12.7 mm) | |

| Engraving | 0.5 µm per Division | |

| Taps | Top: 1/4"-20 (Qty. 7) Bottoma: 1/4"-20 (Qty. 7) and 8-32 (Qty. 4) |

Top: M6 (Qty. 7) Bottoma: M6 (Qty. 7) and M4 (Qty. 4) |

| Barrel Size | Ø3/8" (Ø9.5 mm) | |

- Preconfigured, 3-Axis, Right-Handed XYZ Translators

- Fully Assembled Stages Include Both the MT401(/M) and MT402 Adapter Plates

The MT3A(/M) translation stage is offered with three differential micrometers for applications requiring increased resolution. The coarse adjustment, which can be locked using a thumbscrew on the mounting collar, provides 0.5 mm of translation per revolution over a range of 0.50" (12.7 mm). The quick-change modular design utilizes precision-aligned dowel pins to ensure orthogonality between stages and allows the user to reconfigure stages quickly as applications change.

Four 1/4" (M6) counterbored slots on the included adapter allow the stage to be directly attached to a breadboard with user-supplied cap screws. Each stage contains seven 1/4"-20 (M6) and four 8-32 (M4) tapped mounting holes that are 0.22" (5.6 mm) deep.

The MT Series translation stages with differential adjusters can be purchased individually (MT1A Series) or as fully assembled, 3-axis, XYZ translators (MT3A Series). Therefore, the MT3A stage can be disassembled using a 3/16" (5 mm) hex key to customize the positions of the micrometers or to use three MT1A stages separately. See the XYZ Assembly tab for details.

The photo to the right illustrates how each of the accessories below is used with the MT Series Stages.

MT401(/M) Base Plate: The MT401(/M) base plate provides mounting flanges with 1" (25 mm) centers that can be used to fasten the MT series stages to an optical breadboard. This base is ideal for XY or XYZ multi-axis configurations where the standard counterbores in the middle of the stages are obstructed. Two 1/4"-20 cap screws (3/16" hex) or two M6 cap screws (5 mm hex) are included with the MT401 imperial or MT401/M metric base plate, respectively. This base plate is included with the MT3(/M) and MT3A(/M).

MT402 Right-Angle Bracket: The MT402 allows two stages to be mounted perpendicular to each other. This plate is required when assembling stages in an XZ or XYZ configuration. This angle bracket includes four 1/4"-20 screws (3/16" hex) and four M6 screws (5 mm hex) for compatibility with both imperial and metric setups. Balldrivers and hex keys are sold separately here. This angle bracket is included with the MT3(/M) and MT3A(/M).

MT405 Side-Mounted Actuator Kit: The MT405 kit is used to reposition the actuator to the stage’s side when space constraints do not allow for it to protrude from the rear of the stage. Four cap screws are included for mounting. See the Actuator Removal tab above for details about mounting an actuator to the side of an MT stage.

MT406(/M) Adapter Plate for Flexure Stage Accessories: The MT406(/M) fastens directly to the top of the MT series stage with two 1/4"-20 (M6) cap screws. It is compatible with our full range of 3 mm wide alignment key MBT and MAX series flexure stage accessories. This adapter plate is ideal for creating basic fiber coupling solutions.

Products Home

Products Home

Zoom

Zoom

Micrometer Driven, Ball Bearing Mechanism

Micrometer Driven, Ball Bearing Mechanism