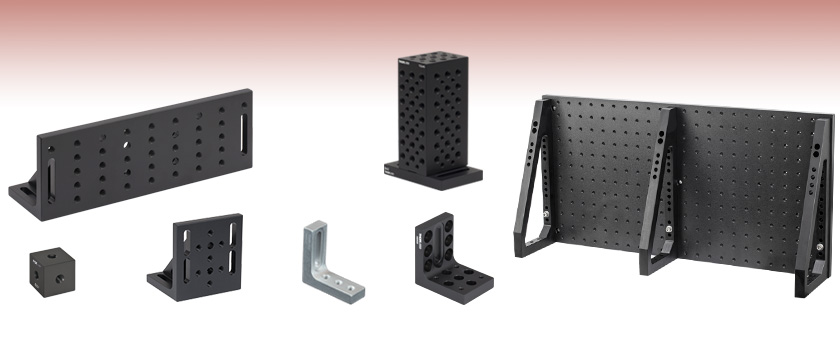

Right-Angle Mounting Adapters

- Stably Mount Small or Large Optomechanics at 90°

- Slotted, Counterbored, and Tapped Holes Enable

Virtually Any Configuration

AP90L

Large Right-

Angle Plate

RM1F

1/4"-20 Tapped

Construction Cube

AB90CV

Vacuum-Compatible

Right-Angle Bracket with 1/4" (M6)

Counterbored Slot and 1/4"-20 Taps

AB90E

Right-Angle Bracket with 1/4" (M6)

Counterbored Slot and 8-32 Taps

TS240

Tombstone Mounting Block

Application Idea

VB01 Brackets Hold Large

Breadboards at 90º

AP90

Right-Angle Plate

Please Wait

| Quick Links | |

|---|---|

| General-Purpose Right-Angle Brackets |

Right-Angle Plates |

| Right-Angle Brackets for Rails |

Construction Cubes |

| Vertical Brackets | Large Right-Angle Brackets |

| Mounting Block | Low-Profile Screws |

Thorlabs' Right-Angle Mounting Adapters assist in creating sturdy three-dimensional optomechanical assemblies and are suited for setups of virtually any size. They can be used directly with mounted optomechanics or as supports for larger structures. The parts shown below are either machined from a single block of aluminum or constructed from extruded lengths of aluminum for exceptional precision and rigidity. We also offer vacuum-compatible versions of our general-purpose Right-Angle Brackets for 1/4"-20 (M6) Cap Screws.

Thorlabs also manufactures an Adjustable Mounting Plate and Right-Angle Clear Aperture Brackets for other applications requiring vertical mounting, as well as 30°, 45°, and 60° angled mounting plates. For mounting two posts at a right angle we offer Ø1/2" Post Angle Mounting Clamps and Ø1" Post 90° Mounting Clamps.

Click to Enlarge

Updated TS240 Packaging

Smart Pack Goals

- Reduce Weight of Packaging

- Increase Usage of Recyclable Materials

- Improve Packing Integrity

- Decrease Shipping Costs

Thorlabs' Smart Pack Initiative is aimed at minimizing waste while providing adequate protection for our products. By eliminating any unnecessary packaging, implementing design changes, and utilizing eco-friendly materials, this initiative seeks to reduce the environmental impact of our product packaging.

The updated TS240 and TS240/M packaging consists of recycled cardboard and weighs 6.7% and 14.7% less, respectively, than the original packaging. This weight change results in a respective 0.86 kg and 1.85 kg reduction in travel-based CO2 emissions per year, based on typical product sales. The other products on this page have transitioned, or are in the process of transitioning to recycled paper packaging.

As we move through our product line, we will indicate re-engineered, eco-friendly packaging with our Smart Pack logo, which can be seen above.

| Posted Comments: | |

jeff secor

(posted 2024-10-28 22:11:37.377) make metric to imperial adapter plates for hole spacing conversion.

like a right angle bracket with 25 / 50 mm slot spacing on one side, and 1 inch slot spacing on the other arm. I want to mount a metric breadboard vertical on an imperial table.

Also should make bread boards with interleaved metric / imperial and color code the holes with paint

thanks cdolbashian

(posted 2024-10-30 04:19:59.0) Thank you for reaching out to us with this feedback! For the smaller slotted right angle brackets, the slots are designed such that they could be used with imperial or metric spacing. For the larger brackets, as you mentioned, I think there is definitely some design space where a hybrid imperial-metric

right angle bracket design could be advantageous. Regarding the imperial/metric breadboards, typically it is good practice to use all imperial, or all metric parts, to avoid stripping threaded holes and getting screws stuck or broken-off in threaded holes. I have reached out to you directly to discuss your suggestions. Joseph Tokarski

(posted 2024-10-01 16:27:48.737) I would like to get a copy of the Specification Sheet for the AB90B/M, if one exists, for my records and BOM.

Thank you. jdelia

(posted 2024-10-01 03:12:36.0) Thank you for contacting Thorlabs. We unfortunately do not have a spec sheet for this item. All the specifications and support documentation such as CAD drawings can be found on the product family page: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=223&pn=AB90B/M Jeff Secor

(posted 2024-01-04 09:51:03.81) Need vertical supports 300-500 mm tall. Your products do not have good structure when mounted on vertical rails jpolaris

(posted 2024-01-04 06:19:59.0) Thank you for contacting Thorlabs. I have reached out to you directly to get clarification on the issue with structure of TS240 that you have found, as well as to work out a potential solution with you. z lucky

(posted 2023-01-31 18:37:15.27) Why don't you just give simple dimension on the product

like height and width. without having to go to all the other precedures. jdelia

(posted 2023-02-01 10:22:42.0) Thank you for contacting Thorlabs. The length, width, and height of the AP90 bracket can be found readily available under the "Overview" section of our product family page. David Moy

(posted 2021-06-23 11:17:22.987) We would like a version of this bracket where the 3 holes in the bottom (shortest) leg of the bracket are replaced with a single slot. YLohia

(posted 2021-06-28 11:18:44.0) Hello, custom products can be requested by clicking on the "Request Quote" button above or by contacting your local Thorlabs Tech Support group. We will discuss the possibility of offering this directly. Mark Vervest

(posted 2020-07-29 15:39:26.213) There is an inconsistency.

The title/label of this item says "M6 Tapped Holes" but the technical PDF drawing says "M6X1.0-6H THRU". llamb

(posted 2020-07-31 02:42:51.0) Thank you for your feedback on the AB90A/M. The holes are indeed tapped with an M6 x 1.0 thread, as opposed to smooth Ø6 mm holes, and they pass THRU the entire material's thickness, as opposed to being blind holes of a finite depth. We will consider clarifying these call-outs. gergely.ercsey

(posted 2016-07-07 13:08:34.17) Dear Madam/Sir!

The holes should be in exact distance from the bottom. For example the first hole's axis distance from the bottom should be in 20mm.

Best Regards,

Gergely Ercsey tcohen

(posted 2012-06-15 18:57:00.0) Response from Tim at Thorlabs: Thank you for sharing this idea with us! We would like to send you some complementary pieces for your feedback. We will also update this page to indicate that they were customer inspired. patrick.berry

(posted 2012-06-15 15:15:36.0) I see you now have added the brackets I designed to the catalog! I will definitely be buying many of these! tcohen

(posted 2012-04-26 18:00:00.0) Update from Tim at Thorlabs to the customer who couldn’t consistently fit the washer onto the XE25A90: Your suggestion led to an updated design that solved this problem. Thank you for your feedback! bdada

(posted 2012-03-13 11:49:00.0) Response from Buki at Thorlabs to lujun0260:

Thank you for your feedback. It sounds like you want pricing for our products but we already include that information on our website. I have contacted you to learn more about what you require. lujun0260

(posted 2012-03-10 06:21:00.0) please price list tcohen

(posted 2012-02-28 09:22:00.0) Response from Tim at Thorlabs: Thank you for your valuable feedback on the XE25A90. We do not have your email to contact you, but if you would like help or to further discuss the problem, please contact us at techsupport@thorlabs.com. user

(posted 2012-02-25 11:51:39.0) Can't consistantly fit washer on XE25A90 - XE25-Series Right Angle Bracket. Thorlabs

(posted 2010-11-03 13:29:20.0) Response from Javier at Thorlabs to Patrick. Thank you for your feedback. I will contact you directly to get details about your application. We can discuss the possibility of custom making this part and/or potentially adding it to our catalog. patrick.berry

(posted 2010-11-03 09:27:57.0) It would be nice if you had some 90 degree brackets available which were the size of the AB90 but had 1/4-20 threaded holes on one or both sides. It would also be nice to have one that was half as wide, possibly with one counterbored 1/4-20 and one threaded on each side. klee

(posted 2009-09-14 17:15:44.0) A response from Ken at Thorlabs to sabba_yoni: We do not have any angle bracket that is smaller than the AB90. However, we can custom make one if you can send us a sketch or drawing. sabba_yoni

(posted 2009-09-14 15:46:52.0) i need a small "angle bracket" , like 1.5*1 inch

did you have something like that? |

| Product Image (Click to Enlarge) |

|

|

|

|

|

| Item # | AB90 | AB90H | AB90A(/M) | AB90B(/M) | AB90C(/M) |

| Counterbored Mounting Slots | Two 1/4" (M6) Slots | N/A | One 1/4" (M6) Slot | ||

| Counterbored Mounting Holes | N/A | Two 1/4" (M6) Holes | N/A | ||

| Tapped Holes | None | Six 1/4"-20 (M6) Holes per Side |

Two 1/4"-20 (M6) Holes per Side |

Three 1/4"-20 (M6) Holes on One Side |

|

| Dimensions (L x W x H) [Click for Mechanical Drawing] |

2.00" x 1.50" x 2.00" (50.8 x 38.1 x 50.8 mm) |

2.00" x 0.75" x 1.58" (50.8 x 19.1 x 40.0 mm) |

2.00" x 1.50" x 2.00" (50.8 x 38.1 x 50.8 mm) |

2.00" x 0.75" x 2.00" (50.8 x 19.1 x 50.8 mm) |

2.00" x 0.75" x 2.00" (50.8 x 19.1 x 50.8 mm) |

These vacuum-compatible versions of the AB90, AB90H, AB90A(/M), and AB90C(/M) brackets above are chemically cleaned and prepared for vacuum applications before packaging. They are compatible directly out of the packaging with vacuum environments down to 10-6 Torr. With additional cleaning and processing, they can be used at even lower pressures, only limited by the outgassing rate of the aluminum. The material properties of the aluminum and the cleaning methods completed by the end user should be used to determine the appropriateness of these products and materials in a specific vacuum system.

Thorlabs also offers a variety of other vacuum-compatible optomechanical components and breadboards that can be combined to build experimental setups for use within a vacuum chamber.

| Product Image (Click to Enlarge) |

|

|

|

|

| Item # | AB90V | AB90HV | AB90AV(/M) | AB90CV(/M) |

| Counterbored Mounting Slots | Two 1/4" (M6) Slots | One 1/4" (M6) Slot | ||

| Counterbored Mounting Holes | N/A | |||

| Tapped Holes | None | Six 1/4"-20 (M6) Holes per Side |

Three 1/4"-20 (M6) Holes on One Side |

|

| Dimensions (L x W x H) [Click for Mechanical Drawing] |

2.00" x 1.50" x 2.00" (50.8 x 38.1 x 50.8 mm) |

2.00" x 0.75" x 1.58" (50.8 x 19.1 x 40.0 mm) |

2.00" x 1.50" x 2.00" (50.8 x 38.1 x 50.8 mm) |

2.00" x 0.75" x 2.00" (50.8 x 19.1 x 50.8 mm) |

| Vacuum Compatibility | >10-6 Torra | |||

| Material | 6061-T6 Aluminum | |||

| Packaging | Double Vacuum Bagged | |||

| Product Image (Click to Enlarge) |

|

|

|

|

| Item # | AB90D | AB90E(/M) | AB90F(/M) | AB90G |

| Counterbored Mounting Slots | One #8 (M4) Slot One 1/4" (M6) Slot |

One 1/4" (M6) Slot | N/A | One #8 (M4) Slot One 1/4" (M6) Slot |

| Counterbored Mounting Holes | Six #8 (M4) Holes Six 1/4" (M6) Holes |

Five #8 (M4) Holes Six 1/4" (M6) Holes |

One #8 (M4) Hole One 1/4" (M6) Hole |

N/A |

| Tapped Holes | N/A | Four 8-32 (M4) Holes | Two 8-32 (M4) Holes Two 1/4"-20 (M6) Holes |

N/A |

| Dimensions (L x W x H) [Click for Mechanical Drawing] |

2.00" x 1.50" x 2.00" (50.8 x 38.1 x 50.8 mm) |

2.00" x 1.50" x 2.00" (50.8 x 38.1 x 50.8 mm) |

2.00" x 0.75" x 2.00" (50.8 x 19.1 x 50.8 mm) |

2.00" x 0.75" x 2.00" (50.8 x 19.1 x 50.8 mm) |

- One-Piece Aluminum Construction for Excellent Rigidity

- Angled Rear Support Structure Reinforces Mounted Optomechanics

- Parallel and Perpendicular to Within 0.002" (0.05 mm)

- Physical Dimensions:

- AP90(/M): 2.88" x 2.50" x 3.00" (73.2 mm x 63.5 mm x 76.2 mm)

- AP90L(/M): 8.80" x 2.50" x 3.00" (223.5 mm x 63.5 mm x 76.2 mm)

The AP90(/M) Right-Angle Plate is an ideal solution for building sturdy three-dimensional optomechanical assemblies that require vertical positioning. This plate provides four 1/4"-20 (M6) clearance slots, seven 1/4"-20 (M6) tapped holes, and two 1/4"-20 (M6) counterbores oriented at 90° from the optical table surface. Its base contains two 1.30" (34 mm) long, 1/4"-20 (M6) clearance slots and two 1/4"-20 (M6) counterbores for mounting to an optical table.

Our AP90L(/M) Large Right-Angle Plate is a heavy-duty mount, capable of holding breadboards at 90° relative to an optical table's surface. This plate provides a generous array of 31 1/4"-20 (M6) tapped holes and six 1/4"-20 (M6) counterbores oriented at 90° from the optical table surface. Its base contains three 1/4"-20 (M6) clearance slots and six 1/4"-20 (M6) counterbored holes for mounting to an optical table.

For an alternative 90° mounting option, the top plate on our AP180 Adjustable Angle Plate can be positioned to provide mounting configurations similar to the AP90. Thorlabs also offers 45° and 30°/60° mounting plates.

Click for Details

MSAP90 Mechanical Drawing

- One-Piece Aluminum Construction for Excellent Rigidity

- Angled Rear Support Structure Reinforces Mounted Optomechanics

- Parallel and Perpendicular to Within 0.002" (0.05 mm)

Our MSAP90(/M) Mini-Series Right-Angle Plate, based upon our popular AP90 Right-Angle Plate design, is an ideal solution for constructing rigid three-dimensional assemblies with our Mini-Series components. This bracket provides four 4-40 (M3) clearance slots, seven 4-40 (M3) tapped holes, and two 4-40 (M3) counterbores oriented at 90° from an optical table surface. Its base contains two 1.0" (25.4 mm) long, 4-40 (M3) clearance slots and two 4-40 (M3) counterbores for mounting to a Mini-Series Breadboard.

Click to Enlarge

50 mm Rail Bolted to Optical Table

Click to Enlarge

Reinforced 25 mm Rail Corner

Click to Enlarge

25 mm Rail Enclosure Bolted to Optical Table

- Brace Rail Corners or Mount Rails Vertically

- One-Piece Aluminum Construction for Excellent Rigidity

- For Use With 1/4"-20 (M6) Cap Screws

- Versions for 25 mm, 50 mm, and 75 mm Rails

These right-angle brackets can be used to fasten optical construction rails to each other or to an optical table. Each bracket can be secured to an optical rail by screwing it to T-nuts (not included) inserted into the rail channels. Either the XE50A90 or the XE75A90 bracket may be used with our 50 mm x 75 mm rails, depending on which side of the rail(s) the bracket is attached to.

The XE25A90 bracket is ideal for fastening our optical enclosures to an optical table or breadboard.

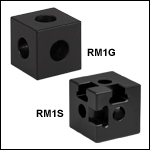

Click to Enlarge

RM1S Slotted Cube Securing a Hardboard Enclosure Wall

Click to Enlarge

Low-Profile Channel Screws in RM1G

- RM1G: Counterbored on Three Sides

- RM1S: Counterbored on Three Sides and Slotted to Accommodate Enclosure Walls

- One-Piece Aluminum Construction for Excellent Rigidity

- Parallel and Perpendicular to Within 0.002" (0.05 mm)

These Construction Cubes contain three 1/4" (M6) counterbores on adjacent faces. They can be connected to up to three optomechanical components by tightening our Low-Profile Channel Screws (sold below) through the counterbores, as shown in the images to the right. In addition, the RM1S cube has slotted corners to accept posterboard and hardboard walls for the construction of light-tight optical enclosures. Since both these cubes are machined from a single block of aluminum, they are ideal for constructions that need to be as sturdy as possible.

If compatibility with more than three optomechanical components is needed, or if components are to be placed on opposing faces, please consider the RM1F Construction Cube below.

Click to Enlarge

RM1F Being Used to Mount Two Ø1" Pillar Posts at a Right Angle for an Optomechanical Assembly

| Item # | Size | Taps |

|---|---|---|

| MSCB3 | 1/2" | 8-32 |

| RM1FA | 1" | 8-32 |

| RM1F | 1" | 1/4"-20 |

| MSCB3/M | 12.7 mm | M4 x 0.7 |

| RM1FA/M | 25.0 mm | M4 x 0.7 |

| RM1F/M | 25.0 mm | M6 x 1.0 |

- Attach up to Six Optomechanics at Right Angles

- One-Piece Aluminum Construction for Excellent Rigidity

- Parallel and Perpendicular to Within 0.002" (0.05 mm)

These construction cubes have one centered tapped hole on each of their sides. Machined from a single block of aluminum, they are ideal for constructions that need a high degree of sturdiness. By using setscrews, up to six optomechanics can be attached to each cube.

- Mount Large Breadboards at a 90° Angle

- One-Piece Construction for Excellent Rigidity

- Parallel and Perpendicular Within 0.003" (0.07 mm)

- 6", 11.75", or 18" Brackets Available

- Each Bracket Sold Individually

These Vertical Brackets are designed to mount any of our aluminum breadboards vertically on an optical table. The edges contain 1/4" (M6) clearance holes and 1/4"-20 (M6) tapped holes at regular spacings, providing a high degree of mounting flexibility. The VB01A(/M) has three 1/4"-20 (M6) tapped holes along the 45° edge for additional mounting options. 6", 11.75", and 18" tall brackets are available.

Click to Enlarge

Two AP90RL Brackets Connected by an Arched Slot

- Large Mounting Surface with Tapped Holes on Front, Sides, and Top

Two Arched Slots for Rotating Base by up to ±50°- One-Piece Aluminum Construction for Excellent Rigidity

- Parallel and Perpendicular to Within 0.002" (0.05 mm)

- Physical Dimensions: 5.00" x 3.40" x 7.00" (127.0 mm x 86.4 mm x 177.8 mm)

The AP90RL(/M) Large Angle Bracket is a heavy-duty component ideal for mounting breadboards and other bulky optomechanics at right angles to an optical table. The front, sides, and top contain a generous array of 1/4"-20 (M6) tapped holes and clearance holes, and the front additionally provides two parallel 2.40" (61 mm) long clearance slots. The base contains two 1/4"-20 (M6) clearance slots and five clearance holes, as well as two arched 1/4"-20 (M6) slots that provide continuous rotation of ±50° prior to fastening the bracket down.

Click to Enlarge

Click to EnlargeTwo Kinematic Mirror Mounts on a Tombstone Block

- Suitable for Fixing a Large Number of Optomechanics

- Equipped with 1/4"-20 (M6) and 8-32 (M4) Tapped Holes at Regular Spacings

- Mounted on Included, Removable BA2(/M) Base

- Total of 160 Tapped Holes

- Mounting Block Dimensions

- TS240: 2.00" x 1.47" x 4.00" (L x W x H)

- TS240/M: 50.0 mm x 37.3 mm x 100.0 mm (L x W x H)

By offering a total of 160 1/4"-20 (M6) and 8-32 (M4) tapped holes, the TS240(/M) Tombstone Mounting Block provides

The photo to the right shows the TS240 with two KM100 Kinematic Mounts, two ME1-P01 Protected Silver Mirrors, and two BA2 Bases. One BA2(/M) base is included with the tombstone mounting block; mounts and mirrors are sold separately.

| Item # | Threading | Thread Length | Hex | Head Height | Quantity | Material |

|---|---|---|---|---|---|---|

| SH25LP38 | 1/4"-20 | 0.38" (9.7 mm) | 1/8" | 0.13" (3.2 mm) | 100 | Steel, Black Oxide Finish |

| SH25LP63 | 0.63" (15.9 mm) | 50 | ||||

| SH6M8LP | M6 x 1.0 | 8 mm (0.31") | 4 mm | 4 mm (0.16") | 50 | |

| SH6M10LP | 10 mm (0.39") | 100 | ||||

| SH6M16LP | 16 mm (0.63") | 50 |

Click to Enlarge

Low-Profile Screw in RM1G Construction Cube

Click to Enlarge

Standard Cap Screw in RM1G Construction Cube

Our Low-Profile Channel Screws have a reduced cap head height relative to standard screws, permitting them to be used in tight spaces. In particular, they are recommended when neighboring screws are at a right angle and in close proximity, as in our XE25W3 Corner Cube or RM1G and RM1S Construction Cubes.

Shown to the right are a standard cap screw and a low-profile channel screw installed in an RM1G cube. The low-profile screw's shortened cap height prevents neighboring screws from interfering with each other.

The head of each screw also fits into XE rail channels for alternate construction methods, as outlined here.

Products Home

Products Home

Zoom

Zoom Click to Enlarge

Click to Enlarge

Click to Enlarge

Click to Enlarge

90° Mounting Plates and Adapters

90° Mounting Plates and Adapters