Large-Area Translation Stages

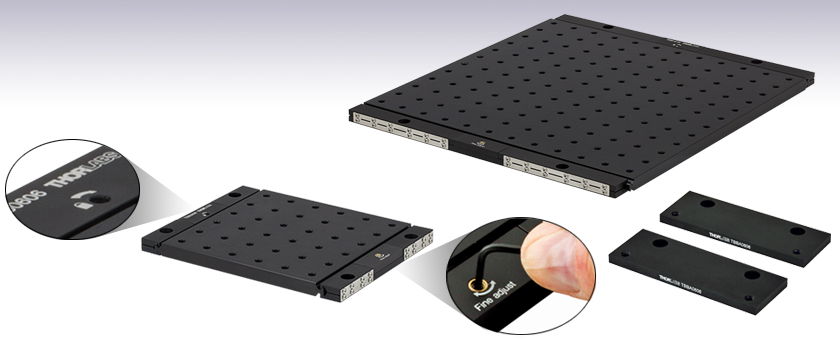

- Hand Operated Translation with Position Lock

- Fine Adjustment Using Hex Key Socket

- 0.5" (12.7 mm) Deck Height

- Adapter Plates for 2-Axis Configurations

Motion Locking

Screw

Fine Adjustment

Using Hex Key

TBB0606

TBBA0606

Adapter Plates

TBB1212

Please Wait

| Item # | TBB0606 (TBB1515/M) |

TBB1212 (TBB3030/M) |

|---|---|---|

| Travel Range | 2.4" (60 mm) | 4.8" (120 mm) |

| Working Height | 0.5 " (12.7 mm) | |

| Rack and Pinion Adjustment Ratio |

31.4 mm per rev of Hex Screw | |

| Max Load Capacity | 44 lb (20 kg) | |

| Rack and Pinion Load Capacity |

22 lb (10 kg) | |

| Run Out Over Full Travel Range |

<50 μm | |

| Pitch Deviation | ±0.015° | ±0.025° |

| Yaw Deviation | ±0.005° | ±0.01° |

| Outer Dimensions (W x D) |

6" x 7.66" (150.0 mm x 191.7 mm) |

12" x 13.66" (300.0 mm x 341.4 mm) |

| Moving Platform Dimensions (W x D) |

6.0” x 5.95” (150.0 mm x 147.6 mm) |

12.0” x 11.92” (300.0 mm x 297.5 mm) |

| Weight | 1.7 lb (780 g) | 6.7 lb (3.06 kg) |

| Construction | Solid Aluminum | |

| Finish | Black Anodized | |

Features

- Hand Operated Translation

- Fine Adjustment via Rack and Pinion Using 2 mm Hex Key Socket

- Two Imperial and Two Metric Sizes Available (See Table to the Right)

- 0.5" (12.7 mm) Deck Height Matches Standard Breadboards

- Position Locking via 2 mm Setscrew

- Black Anodized Aluminum Construction

These Large-Area Translation Stages are available in two imperial and two metric sizes: 6" x 7.66" (TBB0606), 12" x 13.66" (TBB1212), 150 mm x 191.7 mm (TBB1515/M), and 300 mm x 341.4 mm (TBB3030/M). They have been designed for use in applications requiring adjustable positioning of a complete experiment. The TBB0606 (TBB1515/M) provides 2.4" (60 mm) of travel, whereas the TBB1212 (TBB3030/M) provides 4.8" (120 mm) of travel.

Coarse positioning is achieved simply by pushing the moving platform. Fine positioning over the full range of travel is achieved by adjustment of the rack and pinion using a 2 mm hex key. Motion can be locked by tightening the locking screw with a 2 mm hex key.

The working height of all the stages is 0.5" (12.7 mm), which is the same as our standard MB series breadboards. They are through-drilled with 1/4"-20 (M6) threaded holes in the standard 1" (25 mm) offset hole pattern. Two stages can be fixed together in a 2-axis XY configuration by using the appropriate TBBA series adapter plates described below. The height of the 2-axis assembly is 32.75 mm (1.29"). The finish on the stages and adapter plates is a black, low reflective anodized coating.

| Posted Comments: | |

Nitesh Singh

(posted 2023-06-27 03:58:28.947) Please have an option of at least 75x75 aperture. As some experiments it has required us to have such stages at some elevation with see through window. do'neill

(posted 2023-06-28 04:07:17.0) Response from Daniel at Thorlabs. Thank you for you feedback and you suggestion, we will look into this. In the meantime I will reach out to you to discuss your application and see if I can help. John M

(posted 2020-11-24 16:46:12.73) Is the travel for the TBB1212 4.8" in both directions or 2.4" in either direction? cwright

(posted 2020-11-25 09:41:46.0) Response from Charles at Thorlabs: Hello John, the travel range of the TBB1212 is a total of 4.8", with 2.4" of travel in either direction from the centre. Sunmin Ryu

(posted 2020-03-06 03:02:39.32) Is this correct? 31 mm per revolution is not fine adjustment.

Rack and Pinion Adjustment Ratio: 31.4 mm per rev of Hex Screw AManickavasagam

(posted 2020-03-09 12:26:13.0) Response from Arunthathi at Thorlabs: Thanks for your query. Fine positioning is achieved by adjustment of the rack and pinion using a hex key and this would be 31.4 mm per rev of hex screw. This was termed fine positioning relatively comparing it to coarse adjustment which is done by pushing the moving platform. GARY FRENCH

(posted 2020-03-02 16:20:03.037) DO YOU SELL THE TBB6060 WITH THE 1/4-20 HOLE PATTERN? AManickavasagam

(posted 2020-03-05 03:35:50.0) Response from Arunthathi @ Thorlabs: Thanks for your query. Yes, the TBB0606 and the TBB1212 comes with 1/4-20 and the metric versions (/M) comes with M6 hole pattern. Kai.Viherkanto

(posted 2018-11-07 11:51:58.437) Could you make TBB1212 with a longer travel, up to 300 mm? Or is it possible to connect two on top of each other and still support 20 kg in the extreme position?

Do you have another platform solution for ca 300 mm linear travel?

Best regards

Kai Viherkanto AManickavasagam

(posted 2018-11-09 09:57:45.0) Response from Arunthathi @ Thorlabs: Thanks for your query. Apologies we are unable to offer longer travel TBB* stage. Mounting two TBB1212 on top of each other will allow to support ~ 16.5 kgs (excluding the weight of the mounted stage which is 3.06 kgs) at the extreme positions.

Unfortunately, there is no similar platform alternative for 300 mm travel, the only other option we could offer, if suitable for your application would be to mount a breadboard on a LTS300 stage.

Thanks. thibaut.moulin

(posted 2018-01-16 14:59:10.7) Good product but the the fine adjustment with rack and pinion is not manufacturing with good quality.

Plastic material is not good for the life of the stage.

A aluminium rack and pinion should be better and a accurate fine adjustment too.

Please upgrade this excellent solution. AManickavasagam

(posted 2018-01-19 08:28:04.0) Response from Arunthathi at Thorlabs: Thank you for your feedback. our stages do get tested extensively for high reliability and lifetime. However, I will pass on your comments to our engineers. |

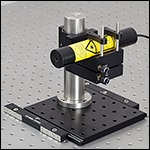

Click to Enlarge

HeNe Laser Mounted on TBB0606 Using Ø1.5" Post and Previous Generation C1503 Kinematic V-Clamp

- Coarse Adjustment by Hand:

- TBB0606: 2.4"

- TBB1212: 4.8"

- TBB1515/M: 60 mm

- TBB3030/M: 120 mm

- Hex Screw Adjustment: 31.4 mm per Revolution

- Array of 1/4"-20 (M6) Tapped Mounting Holes

These large-area translation stages are ideal for adjusting the position of an entire subassembly on the optical table. Two imperial and two metric sizes are available. Imperial stages include an array of 1/4"-20 tapped holes, while metric stages feature M6 tapped holes.

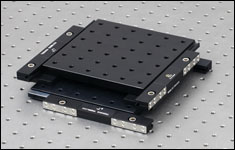

Two large-area translation stages can be combined to form an XY stage using the 2-axis adapter plates sold separately below.

Click to Enlarge

Two TBB0606 Stages Shown in an XY Configuration

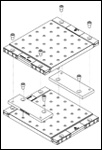

Click to Enlarge

TBBA0606 Installation Details

- Assemble 2-Axis Large-Area Translation Stages

- Two Adapter Plates Included

- Easy Assembly using Eight 1/4"-20 (M6) Cap Screws

These adapter plates allow our large-area translation stages featured here to be mounted in a 2-axis XY configuration. The TBBA0606 (TBBA1515/M) is for use with TBB0606 (TBB1515/M) stages, whereas the TBBA1212 (TBBA3030/M) is for use with TBB1212 (TBB3030/M) stages. Please note that these plates are for use only with stages of the same type. The working height of the resulting 2-axis stage assembly is 32.75 mm (1.29”), with the full travel range in both X and Y directions.

Products Home

Products Home

Zoom

Zoom

Linear: Long Travel Large Area Platforms

Linear: Long Travel Large Area Platforms