N-BK7 Bi-Convex Lenses, Uncoated

- Positive Focal Length for Use at Finite Conjugates

- Uncoated Wavelength Range: 350 - 2000 nm

- Zemax Files Available

LB1157

(Ø6 mm)

LB1494

(Ø9 mm)

LB1092

(Ø1/2")

LB1761

(Ø1")

LB1723

(Ø2")

Please Wait

| N-BK7 Bi-Convex Spherical Singlets | |

|---|---|

| Lens Shape | Convex/Convex |

| Material | N-BK7 (Grade A)a |

| Wavelength Rangeb | 350 nm - 2.0 μm (Uncoated) |

| Design Wavelength | 587.6 nm |

| Index of Refraction | 1.517 (@ 587.6 nm) |

| Surface Quality | 40-20 Scratch-Dig |

| Surface Irregularityc | λ/4 |

| Spherical Surface Powerc | 3λ/2 |

| Abbe Number | Vd = 64.17 |

| Centration | ≤3 arcmin |

| Clear Aperture | >90% of Diameter |

| Diameter Tolerance | +0.0 mm / -0.1 mm |

| Focal Length Tolerance | ±1% |

| Click on the red Document icon next to the item numbers below to access the Zemax file download. Our entire Zemax Catalog is also available. |

Features

- Material: N-BK7

- Wavelength Range: 350 - 2000 nm (Uncoated)

- Available Sizes: Ø6.0 mm, Ø9.0 mm, Ø1/2", Ø1", and Ø2"

- Focal Lengths Available from 10.0 mm to 1.0 m

- Well Suited for Many Finite Imaging Applications

- Offers Excellent Transmittance Throughout the Visible and Near Infrared

Thorlabs' uncoated N-BK7 Bi-Convex Lenses are popular for many finite imaging applications. This type of lens is best suited for use in situations where the object and image are on opposite sides of the lens and the ratio of the image and object distances (conjugate ratio) is between 0.2 and 5. These lenses are designed to have a focal length of f= (R1*R2)/((n-1)*(R2-R1)).

N-BK7 is probably the most common optical glass used for high-quality optical components. It is typically chosen whenever the additional benefits of UV fused silica (i.e., good transmission further into the UV and a lower coefficient of thermal expansion) are not necessary.

Although this page features our uncoated bi-convex lenses, these lenses are also available with one of four antireflection coatings (-A, -AB, -B, or -C) deposited on both sides to reduce the amount of light reflected from each surface. Links to each of these pages can be found in the table to the right. Please see the Graphs tab for coating details.

Lens kits are available. Please click here for information.

| Bi-Convex Lens Selection Guide | |

|---|---|

| N-BK7 | |

| Mounted N-BK7 | |

| UV Fused Silica | |

| CaF2 | |

| ZnSe | -E3 (7 - 12 µm) |

Custom coatings are also available. Please contact Tech Sales for a quote.

Below is the transmission curve for N-BK7, a RoHS-compliant form of BK7. Total Transmission is shown for a 10 mm thick, uncoated sample and includes surface reflections. Each N-BK7 bi-convex lenses can be ordered uncoated (available below) or with one of the following broadband AR coatings: 350 - 700 nm (designated with -A), 400 - 1100 nm (designated as -AB), 650 - 1050 nm (designated as -B), or 1050 - 1700 nm (designated as -C).

Our high-performance multilayer AR coatings have an average reflectance of less than 0.5% (per surface) across the specified wavelength ranges and provide good performance for angles of incidence (AOI) between 0° and 30° (0.5 NA). For optics intended to be used at large incident angles, consider using a custom coating optimized at a 45° angle of incidence; this custom coating is effective from 25° to 52°. The plot shown below indicates the performance of the standard coatings in this family as a function of wavelength. Broadband coatings have a typical absorption of 0.25%, which is not shown in the reflectivity plots.

Click to Enlarge

Click Here for Raw Data

Click to Enlarge

Click to EnlargeA Thorlabs technician measuring the irregularity of one of our singlets using a Zygo GPI-XP/D Interferometer.

Introduction

Thorlabs has a series of quality control procedures in order to ensure our singlets meet our standards and specifications. This starts with in-process inspections of the lens’ imaging capabilities and ends with a final inspection of surface quality and dimensions. Specifications for particular products can be found in their linked documentation by clicking the ![]() symbol. This tab will take you through the general process used to check for quality.

symbol. This tab will take you through the general process used to check for quality.

Singlet Quality Practices

In-process inspection begins once the singlet has been shaped to specifications. Focal length, surface irregularity, and surface power are checked, following sampling plan Level VI given in MIL-PRF-13830B (see below). These three specifications are imperative for proper imaging. Surface irregularity of parts is kept to below either a quarter wavelength or a half wavelength at 633 nm, depending on the material of the singlet. Below is a graph of over 200 batches of singlets with irregularity data of both their front and back sides.

At this point, some uncoated singlets will proceed to final inspection, while others will receive an antireflective (AR) coating. The application of optical coatings has its own in-process inspections. To ensure the AR coating is applied properly, we verify both reflectance and transmission performance by scanning witness pieces using spectrophotometry; the material of these 2 mm thick witness samples matches the other parts in the run. For reflectance verification, we use at least one witness sample for each coating run. Transmitting optics receive two AR coatings, one on each surface, so for the verification of transmission, we use one witness sample that is also coated on both of its sides. Large runs use multiple witness samples to ensure the uniformity across the deposition chamber. By testing coating performance during every run, variance over time is kept low. To see how coatings vary, see the table below.

Final inspection of both uncoated and AR-coated singlets includes a batch check of diameter and thickness and a 100% visual check to ensure that the surface quality, chamfer, and clear aperture meet our published specifications. While surface quality is cosmetic to a degree, scratches, digs, and other inclusions in the surface of a part can increase the chances of damage to the singlet when used with high-power sources. These inspections are done in a clean, dark room under lighting that meets the requirements of MIL-PRF-13830B. Inspection under a single light source in a dark room allows for inconsistencies in the glass to be located without being obscured by glare or reflections.

MIL-PRF-13830B: Performance Specifications for Optical Components

MIL-PRF-13830B is a document created by the U.S. Army Armament Research, Development and Engineering Center's Defense Quality and Standardization Office for the specifications covering how finished optical components should be manufactured, assembled, and inspected. While primarily for use in letting the military dictate how products they use can be incorporated into their equipment, these standards have been adopted by many optics manufacturers. To download a copy of the full document,

| -A Coating 350 nm to 700 nm |

-B Coating 650 nm to 1050 nm |

-C Coating 1050 nm to 1700 nm |

Singlet Irregularity |

||

| Coating Variance: Transmission |

Click to Enlarge |

Click to Enlarge |

Click to Enlarge |

Click to Enlarge |

|

| Coating Variance: Reflectance |

Click to Enlarge |

Click to Enlarge |

Click to Enlarge |

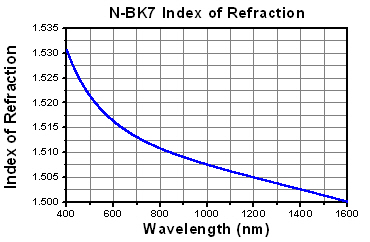

Click on the image to download the raw data. In the thick lens equation, use the index of refraction for N-BK7 at the wavelength of interest to approximate the wavelength-dependent focal length of any of the plano-convex lenses.

The focal length of a thick spherical lens can be calculated using the thick lens equation below. In this expression, nl is the index of refraction of the lens, R1 and R2 are the radii of curvature for surfaces 1 and 2, respectively, and d is the center thickness of the lens.

![]()

For bi-convex lenses, where the front and back radii of curvature are equal in magnitude and opposite in sign, R1 = -R2 = R, we have

![]()

The focal length of the lens calculated using the simplified thick lens equation directly above is the distance between the second (back) principle plane (H") and the position at which a collimated beam incident on the curved surface of the bi-convex is focused. The same analysis can be performed using a point source and the first (front) principle plane (H'). The principle plane positions of a thick lens can be calculated with the following equations:

![]() and

and ![]()

Again, for the same bi-convex lens, R1 = -R2 = R, we can solve for H' and H' :

![]()

| Recommended Mounting Options for Thorlabs Lenses | ||

|---|---|---|

| Item # | Mounts for Ø2 mm to Ø10 mm Optics | |

| Imperial | Metric | |

| (Various) | Fixed Lens Mounts and Mini-Series Fixed Lens Mounts for Small Optics, Ø5 mm to Ø10 mm | |

| (Various) | Small Optic Adapters for Use with Standard Fixed Lens Mounts, Ø2 mm to Ø10 mm | |

| Item # | Mounts for Ø1/2" (Ø12.7 mm) Optics | |

| Imperial | Metric | |

| LMR05 | LMR05/M | Fixed Lens Mount for Ø1/2" Optics |

| MLH05 | MLH05/M | Mini-Series Fixed Lens Mount for Ø1/2" Optics |

| LM05XY | LM05XY/M | Translating Lens Mount for Ø1/2" Optics |

| SCP05 | 16 mm Cage System, XY Translation Mount for Ø1/2" Optics | |

| (Various) | Ø1/2" Lens Tubes, Optional SM05RRC Retaining Ring for High-Curvature Lenses (See Below) |

|

| Item # | Mounts for Ø1" (Ø25.4 mm) Optics | |

| Imperial | Metric | |

| LMR1 | LMR1/M | Fixed Lens Mount for Ø1" Optics |

| LM1XY | LM1XY/M | Translating Lens Mount for Ø1" Optics |

| ST1XY-S | ST1XY-S/M | Translating Lens Mount with Micrometer Drives (Other Drives Available) |

| CXY1A | 30 mm Cage System, XY Translation Mount for Ø1" Optics | |

| (Various) | Ø1" Lens Tubes, Optional SM1RRC Retaining Ring for High-Curvature Lenses (See Below) |

|

| Item # | Mount for Ø1.5" Optics | |

| Imperial | Metric | |

| LMR1.5 | LMR1.5/M | Fixed Lens Mount for Ø1.5" Optics |

| (Various) | Ø1.5" Lens Tubes, Optional SM1.5RR Retaining Ring for Ø1.5" Lens Tubes and Mounts |

|

| Item # | Mounts for Ø2" (Ø50.8 mm) Optics | |

| Imperial | Metric | |

| LMR2 | LMR2/M | Fixed Lens Mount for Ø2" Optics |

| LM2XY | LM2XY/M | Translating Lens Mount for Ø2" Optics |

| CXY2 | 60 mm Cage System, XY Translation Mount for Ø2" Optics |

|

| (Various) | Ø2" Lens Tubes, Optional SM2RRC Retaining Ring for High-Curvature Lenses (See Below) |

|

| Item # | Adjustable Optic Mounts | |

| Imperial | Metric | |

| LH1 | LH1/M | Adjustable Mount for Ø0.28" (Ø7.1 mm) to Ø1.80" (Ø45.7 mm) Optics |

| LH2 | LH2/M | Adjustable Mount for Ø0.77" (Ø19.6 mm) to Ø2.28" (Ø57.9 mm) Optics |

| VG100 | VG100/M | Adjustable Clamp for Ø0.5" (Ø13 mm) to Ø3.5" (Ø89 mm) Optics |

| SCL03 | SCL03/M | Self-Centering Mount for Ø0.15" (Ø3.8 mm) to Ø1.77" (Ø45.0 mm) Optics |

| SCL04 | SCL04/M | Self-Centering Mount for Ø0.15" (Ø3.8 mm) to Ø3.00" (Ø76.2 mm) Optics |

| LH160C | LH160C/M | Adjustable Mount for 60 mm Cage Systems, Ø0.50" (Ø13 mm) to Ø2.00" (Ø50.8 mm) Optics |

| SCL60CA | SCL60C/M | Self-Centering Mount for 60 mm Cage Systems, Ø0.15" (Ø3.8 mm) to Ø1.77" (Ø45.0 mm) Optics |

Mounting High-Curvature Optics

Thorlabs' retaining rings are used to secure unmounted optics within lens tubes or optic mounts. These rings are secured in position using a compatible spanner wrench. For flat or low-curvature optics, standard retaining rings manufactured from anodized aluminum are available from Ø5 mm to Ø4". For high-curvature optics, extra-thick retaining rings are available in Ø1/2", Ø1", and Ø2" sizes.

Extra-thick retaining rings offer several features that aid in mounting high-curvature optics such as aspheric lenses, short-focal-length plano-convex lenses, and condenser lenses. As shown in the animation to the right, the guide flange of the spanner wrench will collide with the surface of high-curvature lenses when using a standard retaining ring, potentially scratching the optic. This contact also creates a gap between the spanner wrench and retaining ring, preventing the ring from tightening correctly. Extra-thick retaining rings provide the necessary clearance for the spanner wrench to secure the lens without coming into contact with the optic surface.

| Posted Comments: | |

Tristan Fleming

(posted 2021-01-27 04:53:46.417) Refractive index provided on the Tutorial page seems to contradict the Sellmeier equation included in the Optical Substrates table for NBK7. I calculate a refractive index difference at 832 nm of 1.5072 from the Sellmeier equation, vs. 1.50893 included in the raw data. More importantly for my application the difference from 832 to 904 nm is 1.3e-5 based on the Sellmeier, vs. 1.9e-3 based on the raw data. Which is correct? YLohia

(posted 2021-02-01 10:11:38.0) Hello Tristan, thank you for contacting Thorlabs. We have checked our raw data and made our calculations according to the Sellmeier equation. We put the refractive index at 1.510165009 for 832 nm, which matches up with our data. We will reach out to you directly to compare calculations. panhujie

(posted 2014-04-22 09:34:22.657) I need to know the typical energy density limit for "N-BK7 Bi-Convex Lenses, Uncoated",whose code is LB1761, but I cannot find it out.

And I find that many of your optical products ignore the data(typical energy density limit) or it may be not obvious.

Would you please send me an email and offer me the data since it's very important.

Thanks. jlow

(posted 2014-04-23 03:38:13.0) Response from Jeremy at Thorlabs: The LB1761 is uncoated so it can take a fairly high amount of energy. The surface damage threshold for N-BK7 substrate should be at least 30J/cm^2 (532nm, 10ns). Please note that this is assuming the lens is clean. If there are any contaminants on the surface of the lens, it can be damaged even with low power. |

Products Home

Products Home

N-BK7, Uncoated

N-BK7, Uncoated