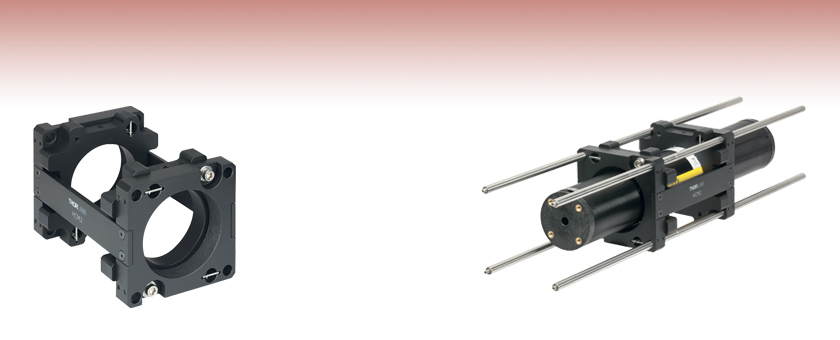

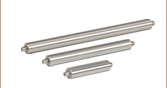

HeNe to 60 mm Cage System Adapter Plate

- Mount Ø1.74" or Ø1.77" HeNe Lasers in 60 mm Cage Systems

- SM2 (2.035"-40) Lens Tube and Ø1/2" or Ø1" Post Compatible

- ±1.0 mm of X and Y Translation for Alignment

HCM2

Application Idea

Please Wait

Features

- 60 mm Cage and SM2 (2.035"-40) Lens Tube System Compatible

- Ø1/2" and Ø1" Post Mountable

- Double-Bore Mounting Design

- Compatible with All Lengths of Ø1.74" to Ø1.77" (Ø44.2 mm to Ø45.0 mm) HeNe Laser Sources

- ±1.0 mm (0.04") of Manual X and Y Translation

- 4.5" (114.3 mm) Overall Length

The HCM2 Adapter Plate is designed to enable integration of a cylindrical HeNe laser with a diameter between 1.74" and 1.77" (44.2 mm and 45.0 mm) into a 60 mm cage system or SM2 (2.035"-40) lens tube system. This adapter allows ±1.0 mm (0.04") of coarse X & Y manual translation for positioning of the laser source. The slip-plate design provides smooth, easy adjustments and and the position can be locked using four 5/32" (4 mm) hex screws. A pair of double-bored mounting plates ensures a true 3-point contact for stable mounting of the HeNe laser using two nylon-tipped 5/64" (2 mm) hex setscrews. Two 8-32 (M4) taps allow the HCM2 to be mounted on our standard Ø1/2" posts or Ø1" posts with 8-32 (M4) taps.

Cage System Overview

The Cage Assembly System provides a convenient way to construct large optomechanical systems with an established line of precision-machined building blocks designed for high flexibility and accurate alignment.

16 mm, 30 mm, and 60 mm Cage System Standards

Thorlabs offers three standards defined by the center-to-center spacing of the cage assembly rods (see image below). The 16 mm cage, 30 mm cage, and 60 mm cage standards are designed to accommodate Ø1/2", Ø1", and Ø2" optics, respectively. Specialized cage plates that allow smaller optics to be directly inserted into our larger cage systems are also available.

Standard Threads

The flexibility of our Cage Assembly System stems from well-defined mounting and thread standards designed to directly interface with a wide range of specialized products. The three most prevalent thread standards are our SM05 Series (0.535"-40 thread), SM1 Series (1.035"-40 thread), and SM2 Series (2.035"-40 thread), all of which were defined to house the industry's most common optic sizes. Essential building blocks, such as our popular lens tubes, directly interface to these standards.

An example of the standard cage plate measurements determining cage system compatibility.

| Standard Cage System Measurements | |||

|---|---|---|---|

| Cage System | 16 mm | 30 mm | 60 mm |

| Thread Series | SM05 | SM1 | SM2 |

| Rod to Rod Spacing | 16 mm (0.63") | 30 mm (1.18") | 60 mm (2.36") |

| Total Length | 25 mm (0.98") | 41 mm (1.60") | 71.1 mm (2.80") |

| Cage Components | ||

|---|---|---|

| Cage Rods | 16 mm | These rods are used to connect cage plates, optic mounts, and other components in the cage system. The SR Series Cage Rods are compatible with our 16 mm cage systems, while the 30 mm and 60 mm cage systems use ER Series Cage Rods. |

| 30 mm | ||

| 60 mm | ||

| Cage Plates | 16 mm | These serve as the basic building blocks for a cage system. They may have SM-threaded central bores, smooth bores sized for industry standard optics or to accommodate the outer profile of our SM Series Lens Tubes, or specialized bores for other components such as our FiberPorts. |

| 30 mm | ||

| 60 mm | ||

| Optic Mounts | 16 mm | Thorlabs offers fixed, kinematic, rotation, and translation mounts specifically designed for our Cage Systems. |

| 30 mm | ||

| 60 mm | ||

| Cage Cubes | 16 mm | These cubes are useful for housing larger optical components, such as prisms or mirrors, or optics that need to sit at an angle to the beam path, such as beamsplitters. Our cage cubes are available empty or with pre-mounted optics. |

| 30 mm | ||

| 60 mm | ||

| Replacement Setscrews | Replacement setscrews are offered for our 16 mm (SS4B013, SS4B025, and SS4B038) and 30 mm (SS4MS5 and SS4MS4) cage systems products. | |

| Post and Breadboard Mounts and Adapters | Mounting options for cage systems can be found on our Cage System Construction pages. Cage Systems can be mounted either parallel or perpendicular to the table surface. | |

| Size Adapters | Cage System Size Adapters can be used to integrate components from different cage system and threading standards. | |

| Specialized Components | Thorlabs also produces specialized cage components, such as Filter Wheels, a HeNe Laser Mount, and a FiberPort Cage Plate Adapter, allowing a wide range of our products to be integrated into cage-mounted optical systems. Explore our Cage Systems Visual Navigation Guide to see the full range of Thorlabs' cage components. | |

Insights into HeNe Lasers

Scroll down to read about:

- HeNe Lasers: Handling and Mounting Guidelines

Click here for more insights into lab practices and equipment.

HeNe Lasers: Handling and Mounting Guidelines

Click to Enlarge

Figure 1: The external housing of HeNe lasers is mechanically coupled to the components of the lasing cavity. Stress applied to the external housing can misalign and potentially fracture lasing cavity components, which can negatively impact the quality and power of the output laser beam (red arrow) or lead to laser failure

| 1. | High Reflector Optics | 7. | Anode |

| 2. | Gas Reservoir | 8. | Glass Laser Bore |

| 3. | Outer Housing | 9. | |

| 4. | Glass | 10. | Potting Compound |

| 5. | Glass-Metal Seal | 11. | Cathode |

| 6. | Output Coupling Optics |

HeNe lasers should be handled and mounted with care to protect them from damage.

Never apply a bending force to the laser housing. Stress applied to the laser's external housing can misalign or damage components in the laser cavity. This can:

- Affect the output beam quality.

- Result in reduced output power.

- Affect the beam pointing.

- Cause multimode effects.

Factory packaging protects the HeNe lasers from shocks and vibrations during shipping, but end users directly handle the bare laser housing. Due to this, HeNe lasers are in greater danger of experiencing dangerous stress during handling by the end user.

A result is that the primary cause of damage to HeNe lasers is rough handling after receipt of the laser. In extreme cases, shock and vibrations can shatter or fracture glass components internal to the laser.

To maintain the optimum performance of your HeNe laser, do not drop it, never use force when inserting it into fixture, and use care when installing it into mounts, securing it using cage components or ring accessories that grip the housing, transporting it, and storing it.

HeNe lasers will provide optimum performance over a long lifetime when they are handled gently.

Date of Last Edit: Dec. 4, 2019

| Posted Comments: | |

Nazim Bharmal

(posted 2023-05-16 13:58:42.287) What limitations are there to mounting the laser vertically? Our interest is to have a 45 degree mirror to point the beam and by changing laser-mirror distance, to adjust the final beam height. ksosnowski

(posted 2023-05-16 01:01:21.0) Hello Nazim, thanks for reaching out to Thorlabs. Our HCM2 mount was not designed with vertical orientation in mind and this is not recommended. In this direction, as there are few small points of contact at the mount's double bores, the total contact area giving holding friction is small, so the weight of the laser may overcome this resulting in a slip scenario. Attempts to tighten the locking screws too much can deform the laser housing, which can deform the HeNe cavity, effecting the optical performance of the system in terms of stability and power. So tightening would not be effective to overcome this effect. For this reason I would recommend using a pair of mirrors as a periscope in order to keep the HeNe itself horizontal. Ben Carey

(posted 2022-08-03 15:38:09.307) Do you have a method of mounting smaller diameter HeNe's to a cage system? I have a 1.245" diameter HeNe and it looks like this won't work. jdelia

(posted 2022-08-04 02:45:48.0) Thank you for contacting Thorlabs. While we do not have a direct replacement for this adapter for smaller diameter HeNe's, I have contacted you directly regarding alternative solutions. dentwistle

(posted 2019-03-12 07:35:35.157) Is this compatible with the 60mm mounting base (LCPB1) so it can be bolted down to an optical table/breadboard without the use of posts? llamb

(posted 2019-03-14 01:35:54.0) Thank you for your feedback. Yes, the HCM2 can indeed fit onto the LCPB1. They can be connected using a #8-32 cap screw, or an M4 cap screw in the case of the HCM2/M and the LCPB1/M. wenzel.jakob

(posted 2017-12-13 22:18:01.53) One comment: the metric version (HCM2/M) has a 101.6mm (4 inch) separation between the four M4 mounting holes, which means that it can't be mounted to a metric breadboard without extra elements (e.g. base plates). It would probably make sense to design this part with a 100mm separation in a future revision. nbayconich

(posted 2017-12-21 04:44:05.0) Thank you for your feedback. We have reviewed the design and we will be shifting the mounting holes so they will be 100mm in the future for the HCM2/M. bdada

(posted 2011-10-03 15:53:00.0) Response from Buki at Thorlabs:

The HCM2 XY adjustable HeNe mount is designed for 1.75" diameter HeNe lasers. Our 5mW HeNe lasers has a 1.74" diameter, so they will fit. Below is a link to our selection of HeNe lasers, including the 5mW version.

http://www.thorlabs.us/NewGroupPage9.cfm?ObjectGroup_ID=1516

This mount is not designed for thermal stability. Please contact TechSupport@thorlabs.com if you hae additional questions or wish to discuss your application. user

(posted 2011-09-18 19:19:44.0) Is there a limit to how big the HeNe is? Would some or all of the 5 mW or greater HeNes fit? Is this thermally stable? |

Products Home

Products Home

HeNe 60 mm Cage System Mount

HeNe 60 mm Cage System Mount