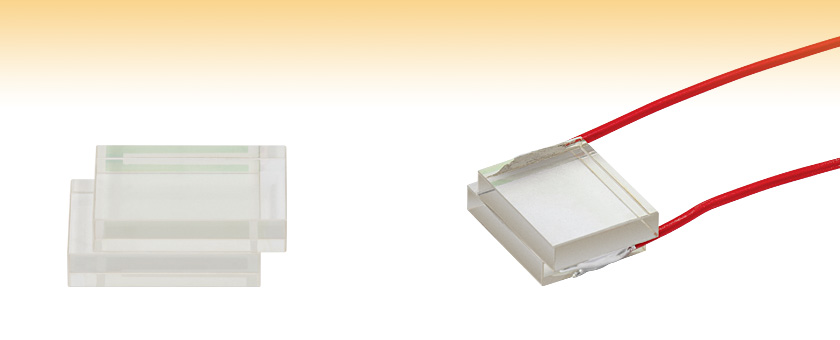

Empty Liquid Crystal Cells

- Seven Different Cell Gaps

- Two Liquid Crystal Inject Holes

- AR Coating (350 - 700 nm) on Both Sides

LCC1312-A

LCC1318-A

Filled Cell with Wires Attached

Please Wait

Features

- Models with Seven Different Cell Gaps Available

- Anti-Reflective Coating (350 - 700 nm) on Both Sides

- High Resistance Indium Tin Oxide (ITO) Conductive Layer (350 - 450 Ω/sq Resistance)

- All Models Except 20 µm Cell Feature an Anti-Parallel PI Alignment Layer

- Custom Cells Available Upon Request to Tech Support

Thorlabs’ empty liquid crystal cells are designed for testing liquid crystal compounds and materials. These cells are coated with an Indium Tin Oxide (ITO) conductive layer and a Polyimide (PI) alignment layer (20 µm version has no PI layer). Seven cells are available with various sized spacers to provide cell gaps from 3 µm to 20 µm, and all are designed for simple filling in the lab (See the Filling and ITO tab).

Our empty cells are optimized for high transmission in the visible range, using UV Fused Silica glass, a broadband anti-reflective coating, and thin film, high resistance ITO. If your application requires liquid crystal cells for other wavelength ranges, please contact us for such a custom cell.

Empty cells with cell gaps from 3 to 10 µm are rubbed and assembled for anti-parallel alignment of the liquid crystal. The LCC1324-A has a 20 µm gap and no polyimide alignment layer. This cell is designed for use with materials that do not require an alignment layer, such as Polymer Dispersed Liquid Crystal (PDLC) materials. Thorlabs can also provide cells with different alignment methods such as 90° twist, parallel alignment, or with custom PI material.

Thorlabs also offers the LCC25 and KLC101 liquid crystal controllers which provide active DC offset compensation while applying an AC voltage (0 to 25 Vrms).

| Item # | LCC1310-A | LCC1312-A | LCC1314-A | LCC1316-A | LCC1318-A | LCC1322-A | LCC1324-A |

|---|---|---|---|---|---|---|---|

| Cell Gap | 3 ± 0.3 µm | 4 ± 0.4 µm | 5 ± 0.5 µm | 6 ± 0.6 µm | 8 ± 0.8 µm | 10 ± 1 µm | 20 ± 2 µm |

| Cell Gap Uniformity | 5% over the Entire Clear Aperture | ||||||

| ITO Resistance (See Below) | 350 - 450 Ω/sq | ||||||

| AR Coating | Ravg <0.5%, 350 nm – 700 nm | ||||||

| External Dimensions | 17 ± 0.1 mm x 12 ± 0.1 mm x 6 ± 0.2 mm | ||||||

| Clear Aperture | 10 mm x 10 mm | ||||||

| Surface Quality | 40 -20 Scratch Dig | ||||||

| Surface Flatness | λ/10 @ 633 nm | ||||||

| PI Alignment | Anti-Parallel | N/A | |||||

| Glass Material | UV Grade Fused Silica | ||||||

Sheet Resistance

The resistance of a thin film is usually described using the sheet resistance (Rs) instead of the resistivity (ρ). Sheet resistance is defined as the ratio between the resistivity (ρ) and the film thickness (t), with units of ohms per square (Ω/sq). It is a more convenient parameter for users because the film thickness has been taken into account and only two dimensions (the length L and the width W) are needed to calculate the resistance of the thin film, which is R = Rs*L/W. Since a square has L = W, the resistance of a square of the thin film is constant and equal to the sheet resistance, regardless of the size of the square. Our liquid crystal cells are 12 mm x 15 mm, so the actual resistance is 15/12 times the sheet resistance.

Click to Enlarge

Transmission of Unpolarized Light in a Liquid Crystal Cell Filled with a Typical Nematic LC Material

Recommended Filling Procedures

Filling Using the Capillary Effect

- In a clean environment, remove the cell from the packaging. Place a drop of liquid crystal material on one of the filling ports and wait for the LC material to completely fill the cell. Note: Depending on the LC material and cell gap, this can take anywhere from 10 minutes to several hours.

- After the cell is completely full, seal the two holes with UV glue (such as the NOA68) and cure the glue. Note: If you are using nematic LC material you will need to bake the filled cell for two hours at a temperature above the clearing temperature (i.e., the temperature at which the liquid crystal becomes isotropic) to get a homogenous alignment of the LC material.

Filling Using a Vacuum Chamber

- In a clean environment, remove the cell from the package. Using UV glue (such as the NOA68), seal one hole and cure the UV glue.

- Insert the cell into a vacuum chamber, place the liquid crystal material in a container under the cell (but not touching the cell), and hold the cell with a device that can later be lowered.

- Evacuate the vacuum chamber to a level of 10 Pa, and heat the chamber to a temperature above the LC clearing point.

- After the chamber has reached the required vacuum level and temperature, lower the cell so that the filling hole touches the LC.

- Release the pressure in the chamber and the LC will fill the cell.

- Slowly reduce the temperature back to room temperature.

- Remove the cell from the chamber, seal the second hole with UV glue, and cure the glue.

Electrical Connections

After completing the filling using either method, use a low temperature indium alloy solder or conductive epoxy to connect wires to the two ITO strips.

| Posted Comments: | |

Abir Ahmed

(posted 2022-10-22 12:37:26.693) LCC25 Liquid Crystal Controller outputs a square wave only? Can I get triangular output?

I want to sweep -10V to +10V. cdolbashian

(posted 2022-10-31 01:14:42.0) Thank you for contacting Thorlabs. The output waveform of LCC25 only supports square wave. Derek G

(posted 2022-06-19 22:11:15.357) Can you make LC cells with any other thickness glass? I am hoping to image the liquid crystal inside of the cell and thick glass will make it hard to get good image quality and magnification without discussions a lot of money on new objectives. Any recommendations in case you cannot make a cell with thinner glass? Any advice on imaging through thick glass with relatively inexpensive objectives? Thanks cdolbashian

(posted 2022-06-24 03:57:34.0) Thank you for contacting Thorlabs. The LC cells with thinner glass would be a customized version, not a catalog product. Please feel free to contact us with your requirements at techsales@thorlabs.com to discuss this further. Linda Hirst

(posted 2022-02-09 20:00:10.953) I want to know how many cells we get for the price - its cant be just one?? cdolbashian

(posted 2022-02-14 01:32:32.0) Thank you for contacting Thorlabs. The catalog price is the unit price of one cell. Michael Rubal

(posted 2021-01-18 17:00:16.537) I was curious about the Empty Liquid Crystal Cells (ELCC). Most of my prior work has invovled the anlaysis of thermotropic liquid crystals and lyotropic liquid cystals by polarized optical micrscopy. I would like to explore using your ELCC, but had a few basic questions:

1) Can you use the ELCC on a standard microscope stage with polarizers?

2) What is the simplest controller you need for this? I was primarly interested in DC voltage changes. I assume I could sinply add a power source with controlled voltage (ie battery).

3) Can these cells be reusable?

Thank you for your time,

Mike Rubal YLohia

(posted 2021-01-22 11:53:49.0) Thank you for contacting Thorlabs. 1) You can certainly use the ELCC with polarizers, but we may or may not have a mounting solution for that based on your microscope's requirements. 2) We recommend using a controller that can supply an AC signal similar to that of our LCC25. We suggest using a square waveform drive for stable operation. Output Voltage Adjustment Range: ± 25 VAC (f = 2kHz, 2kHz is the default frequency of LCC25, other frequencies may be applied if a custom driver is used.) Max Output Current: 15 mA. Please note that there should not be any DC offset as this can build up charge and damage the liquid crystal device. 3) Theoretically the cell can be re-used, however, it's not easy to remove all the LC material, so re-use is not recommended. Paul Cain

(posted 2020-03-11 10:43:50.257) What sort of applications are the Empty Liquid Crystal cells used for?

thank you,

Paul YLohia

(posted 2020-03-12 08:25:04.0) Hello Paul, thank you for contacting Thorlabs. The Empty Liquid Crystal Cells are designed for testing liquid crystal compounds and materials. A typical application is to make liquid crystal devices such as variable retarders : https://www.thorlabs.com/navigation.cfm?guide_id=2258. Nils Maasjost

(posted 2019-04-10 03:43:28.04) Good morning,

I've purchased LC-Cells and now trying to connect the cabels with the cell, but the suggested method of using EG58 led to a mess. Additionally I can't see out of the specs sheet, where I should connect the cabels. Could you give me any recommidations in this regard?

Best regards

Nils Maasjost nbayconich

(posted 2019-04-12 03:06:27.0) Thank you for contacting Thorlabs. There is about a 2mm width layer of exposed ITO coating to apply the wire leads to. Please see the example drawing in the link below, the best way to connect your wire leads is to place them as close to the edge of the substrate as possible to avoid contact with the PI layer.

https://www.thorlabs.us/images/TabImages/Liquid_Crystal_Cell_D1-780.gif Maoqi.Lin

(posted 2019-01-22 14:02:09.307) Hi, I am very interested in purchasing these liquid crystal cells. Are they reusable?

Also, in terms of the liquid crystal controller, since it is a little over budget for me, can I simply use any other AC power suppliers which manages the voltage, current and frequency? Many thanks nbayconich

(posted 2019-01-24 11:22:03.0) Thank you for contacting Thorlabs. Theoretically the cell can be re-used, however, it's not easy to remove all the liquid crystal material,and we have no suggested method to remove it, so re-use is not recommended.

For third party controllers, we recommend using a controller that can supply an AC current similar to our LCC25 controllers specifications. We suggest you use a square wave form driving signal for stable operation.

Output Voltage Adjustment Range: ± 25 VAC (f = 2000 ± 5 Hz)

Max Output Current: 15 mA

Please note that there should not be any DC offset as this can build up charge and damage the liquid crystal device, as stated in LCC25’s description:

“The DC offset compensation automatically zeroes the DC bias across the LC device in order to counteract the buildup of charges, and avoid damage to the LC device.” 381529773

(posted 2018-11-16 21:49:19.003) Dear thorlabs,

I want konw the material of the spacers in the cell,does it a thin film and distributes all over the cell?And if it scatter or absorb light? nbayconich

(posted 2018-11-20 08:29:01.0) Thank you for contacting Thorlabs. The spacers we use in our LCC products are little balls blended with specific glue which are on the substrates’ edges, which will not interfere with the cell surface as to cause scattering or absorption within the clear aperture. zhangyongbin2015

(posted 2018-09-29 11:06:24.943) Dear, we want to know the maximum permitted thickness of the liquid layer with the preferential orientation if customizing a cell. Can you suggest the maximum thickness of the liquid crystal to me? Thank you very much. YLohia

(posted 2018-10-22 02:37:51.0) The largest thickness of LC cell we can offer is 50um. Would you be able to explain what you mean by “ensure the preferential orientation”? Please reach out to us at techsupport.cn@thorlabs.com. zhangyongbin2015

(posted 2018-09-29 10:48:29.8) Dear, we want to investigate the nonlinear phenomenon of the nematic liquid crystals. In order to have a macroscopic order, the liquid crystals is needed to be integrated into a cell. We want to know the maximum permitted thickness (important) of the liquid layer? Or if you have any method to achieve a test of a thick liquid sample and ensure the preferential orientation? Thank you. mariachiara.ubaldi

(posted 2018-05-09 15:23:31.75) Dear Thorlabs

I have three of your cells and would like to use one of them for characterization purposes by splitting the glasses+ITO+polymmide apart.

Can you suggest me how to do this?

Best regards

Maria Chiara Ubaldi nbayconich

(posted 2018-05-14 08:18:52.0) Thank you for contacting Thorlabs. The coatings cannot be removed from the finished product but we can possibly provide a customized version without the coating layers you do not require. I will reach out to you directly with more information about our custom capabilities. mariachiara.ubaldi

(posted 2018-02-09 15:45:19.16) Dear Thorlabs

I have one of your cells filled up with liquid crystal and I have to perform ellipsometric measurements. First of all I'd like to know how glass AR coating is made (layers and thickness) in order to insert it in my model.

Besides, have you ever performed full ellipsometric characterization of your cell filled with std liquid crystal? Considering AR and ITO and LC birefringence is a har model to build up.

Best regards

Maria Chiara llamb

(posted 2018-04-03 03:56:31.0) Hello Maria, thank you for contacting Thorlabs. Our AR coating information is proprietary and we do not currently have full-scale testing done on the ellipticity of light through the cells. I will contact you directly to discuss typical cases of ellipticity. mariachiara.ubaldi

(posted 2017-03-20 14:12:15.863) Dear sirs

I encountered issues in filling the cell with a nematic crystal, with low viscosity. I apply a drop onto the filling port, but the gap never fills for capillarity effects, but seems to stay on the top of the port. I cannot use vacuum chamber.

Can you suggest me a solution?

Best regards

Maria Chiara tfrisch

(posted 2017-03-30 02:03:24.0) Hello, thank you for contacting Thorlabs. I will reach out to you directly with my inquiries about your setup and what cell you are using. souravpatranabish

(posted 2016-09-12 15:34:16.847) Can you please let me know that how many empty liquid crystal cells you provide in each unit of the product? Also kindly inform whether the cells have planar (homogeneous) alignment. Thank you. tfrisch

(posted 2016-09-15 01:28:37.0) Hello, thank you for contacting Thorlabs. The cells do have a planar (homogeneous) alignment. Each unit is once empty cell. I have reached out to you directly if you have further questions. milankie

(posted 2016-03-17 13:00:41.68) I am also interested in the damage threshold of the liquid crystals. besembeson

(posted 2016-03-17 02:35:49.0) Response from Bweh at Thorlabs USA: I will contact you about your laser characteristics, as we have not established these values yet. patricio_romero

(posted 2016-02-24 14:08:01.227) The ITO electrodes have a shape? are they a square/rectangle etched electrode? or is deposited all over the glass surface?

Is this glass adequate for Raman measurements? from glass fluorescence point of view?

Is it possible to get other electrodes materials like gold? (~10 nm sputtered gold is still viewable-through under POM) besembeson

(posted 2016-03-08 02:15:26.0) Response from Bweh at Thorlabs USA: The ITO is deposited all over the glass surface. I will contact you regarding your Raman application and the custom cell. mccamyjw

(posted 2015-09-23 14:02:29.763) This is potentially a very interesting experiment for the classroom and my kids. Can you recommend a specific LC material (and perhaps a source)? Or is there a source that sells this as a kit? Finally, is there an easy way to remove the LC after the demo to reuse the unit to try others and/or another class?

Thanks very much

Jim besembeson

(posted 2015-10-01 03:09:40.0) Response from Bweh at Thorlabs USA: We can recommend a liquid crystal named 5CB which has a simple molecule structure and low clearing point. It is commonly used for demonstration and educational purpose. You can check with material vendors like HCCH or Merck regarding acquiring these. Our current device structure makes it impossible to remove LC and re-introduce another. Even if we make a customized cell to do it, it will still be a complicated process to draw the LC out, and the result is difficult to predict. johnnysheng

(posted 2015-01-30 10:46:18.633) What is the laser damage threshold at, e.g., 450nm?

Is the PI layer inorganic? jlow

(posted 2015-01-30 04:37:50.0) Response from Jeremy at Thorlabs: The PI layer is polyimide, which is organic. We do not have a damage threshold specification for this at the moment. I will contact you directly to discuss about this further. |

Products Home

Products Home

Empty Liquid Crystal Cells

Empty Liquid Crystal Cells