Aluminum Protective Screens

- Flat and Curved Profiles for Tailored Shielding

- Joiners Available for Flat Profile Barriers

- Bead Blasted to Ensure Consistently High Diffusion

- Versions with Laser-Engraved Target Grid Available

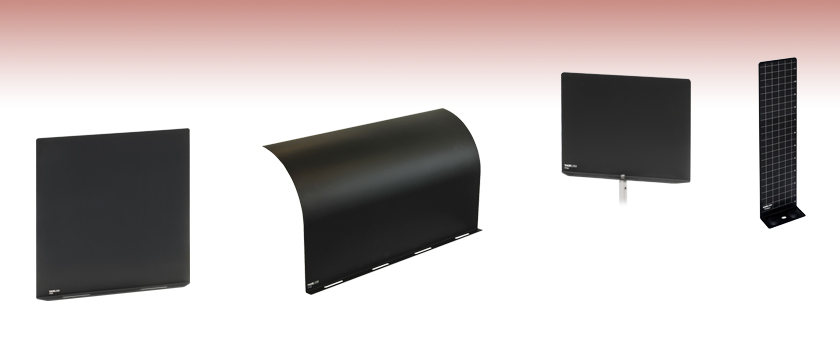

TPS4

Centered Through Hole for

8-32 (M4) Post Mounting

TPS9

24" x 12"

TPS5

12" x 12"

TPSM2(/M)

11.81" x 2.95"

Magnetic Target Grid with

Engravings Every 1/2" (10 mm)

Please Wait

Thorlabs' Aluminum Protective Screens prevent stray or unwanted light from entering or exiting an experimental setup. The aluminum is treated prior to anodization to create a homogeneously diffusive surface that is superior to textured surfaces, which scatter light unevenly. These screens are available with flat and curved surfaces. The curved screens are particularly useful for shielding laser beams that might be reflected upwards. For applications that require laser alignment and beam blocking, we offer flat screens that feature an imperial or metric laser-engraved target grid on one side and powerful magnets in the base for flexibility when positioning the screen on magnetic surfaces.

These screens are not intended to serve as permanent beam dumps. For such applications, Thorlabs offers a comprehensive family of beam traps and beam blocks.

The laser optical density and barrier threshold of the material and coating used to manufacture the products featured here were tested at various wavelengths in accordance with EN 12254 and ANSI Z136.7. The results are tabulated below:

EN 12254

| Test Wavelength | Spot Diameter | Exposure Duration | Laser Optical Density |

|---|---|---|---|

| 532 nm | 910 µm | 100 Seconds | D,AB7 |

| 1070 nm | 910 µm | 100 Seconds | D,AB7 |

| 10.6 µm | 956 µm | 100 Seconds | D,AB5 |

ANSI Z136.7

| Test Wavelength | Spot Diameter | Exposure Duration | Test Irradiance | Laser Barrier Threshold |

|---|---|---|---|---|

| 532 nm | 532 µm | 100 Seconds | 2546 W/cm2 | No Penetration |

| 1070 nm | 910 µm | 100 Seconds | 150 KW/cm2 | No Penetration |

| 10.6 µm | 956 µm | 100 Seconds | 27.4 W/cm2 | No Penetration |

| Posted Comments: | |

Benoit RAPHALEN

(posted 2024-08-26 10:11:40.97) Hello,

Does those products (TPSx) are certified as

Food certificate or food contact ?

Thanks in advance,

Kind Regards tschofield

(posted 2024-09-05 05:33:21.0) Thank you for your question. Unfortunately, the TPSx series of Aluminium Protective Screens are not rated or certified to be used in culinary settings. I will reach out to you directly to discuss your application further Erik Hinkelmann

(posted 2023-03-10 13:21:11.5) I am interested in more test data for tests in accordance with EN 12254. I am interested in the range 1500-1600 nm. Could you provide this? Thank you. JReeder

(posted 2023-03-13 07:48:29.0) Thank you for your enquiry. I have reached out to you directly to discuss this further. Moritz von Sivers

(posted 2022-06-15 14:59:57.12) It would be nice to have a version with engraved lines every millimeter for better alignment DJayasuriya

(posted 2022-06-16 06:25:15.0) Thank you for your feedback, we have passed this on to our engineering group. David Winter

(posted 2022-01-05 09:59:59.033) great idea but let down by poor fixing of magnets, one came off after a few minutes use cwright

(posted 2022-01-06 03:19:54.0) Response from Charles at Thorlabs: Thank you for your feedback, I'm sorry to hear you have been inconvenienced. I would expect an insufficient application of glue was used in production. We will reach out to you for your order details so we can offer a replacement screen. colin.hebert

(posted 2016-09-21 14:43:25.147) Would it be possible to get a copy of the full ANSI Z136.7 test results that are listed under the Test Data tab for these products?

Thank you! jlow

(posted 2016-09-23 04:49:08.0) Response from Jeremy at Thorlabs: We will contact you directly to provide this. user

(posted 2016-08-02 10:36:21.353) Please consider adding 6" and 18" (15, 45 cm) long versions of the aluminum protective screens, so that combinations can be used for any breadboard size you carry. For example, no combination of screens you have currently will cover an MB4560/M. bwood

(posted 2016-08-03 06:52:27.0) Response from Ben at Thorlabs: Thank you for your interest in our product range. We can offer custom sizes in these screens if needed, please contact your local technical support office for information on this. However, I will pass this suggestion onto our engineers, to see if they could make these sizes part of our standard product range. demuth2

(posted 2015-03-05 12:28:13.46) In the IR regime, anodized aluminum acts as a very good reflector... It would be a VERY useful graph to show reflectance (or absorptance) as a function of wavelength at 0deg and 45deg. Is this possible? Can you send me the data/upload it to your website?

Do you have any other beam blockers that have low reflectance at 1um?

-James rcapehorn

(posted 2015-03-10 05:30:45.0) Response from Rob at Thorlabs: Thank you for your interest in our product range. You are correct that anodized aluminium does usually have a relatively high reflectance in the IR region, unfortunately however we do not have any data for this particular product. I will contact you directly to further discuss your options. max.schiller

(posted 2013-05-03 09:20:45.997) Hi. Is it possible to order bigger plates (at least 1mx1m)? Delivery - Germany. cdaly

(posted 2013-05-08 14:18:00.0) Response from Chris at Thorlabs: We have done custom sizes in the past, but the largest to date is 24"x14". I will look into this for you and contact you directly to discuss the possibilities. user

(posted 2013-03-21 23:02:52.457) I am appalled at the cost of the TPS5. I can buy a 1' x 1' sheet of pre-cut 6061 aluminum from McMaster for less than $19, and anodize it in the university shop. I could make one of these myself for half the cost of what you are charging. It does not seem that your manufacturing is very cost sensitive. jlow

(posted 2013-03-29 08:17:00.0) Response from Jeremy at Thorlabs: When we (Thorlabs) set out to build a cost effective laser screen, we had a couple of goals plus a few constraints that needed to be met that may make our screens more expensive than what you can produce in your university machine shop. Because our customers rely on us to repeatedly provide the same product every time they buy it, we had to start with much higher tolerances on the initial sheet of aluminum than the part you referenced from McMaster Carr. Also, a standard sheet of aluminum often has tooling marks from the press or draw procedure. As a result, we prepare the surface of the plates by bead blasting the final surface in a way that provides a consistent and diffuse reflection of light incident on the screen. The corners are rounded for safety and mounting slots are machined. The product is then given a high quality anodized finished and priced so that it is hopefully a good value for our customers. Thorlabs is constantly looking for improvements in our manufacturing efficiencies that will allow us to maintain or even reduced the price on our products. Based on your feedback, I have requested that this product line be evaluated to see if Thorlabs can reduce the cost. jlow

(posted 2013-01-17 14:00:00.0) Response from Jeremy at Thorlabs: The grid on the laser safety screen is laser engraved. The price for the product is based on the cost of manufacturing and we are committed to providing the best value to our customers. Samuel.H.Burgen

(posted 2013-01-16 12:43:11.3) Is the grid on the Laser Safety Screen laser marked or screen printed. If screen printed, will the ink burn and/or outgas if it experiences 350 J/cm2 (1064 nm, 20 ns, 20 Hz, Ø1.14 mm) energy flux. Also, don't you think this is a little expensive for what it is. Could you consider lowering the price to about half. For $28 I could take my girlfriend out for a nice dinner and get dessert. Your prices are not as good as they use to be any more. |

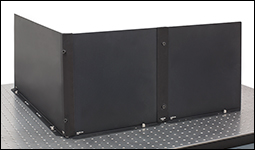

- Bead-Blasted Anodized Aluminum Barriers

- Five Sizes Available (W x H):

- 8" x 6" (203 mm x 152 mm)

- 12" x 6" (305 mm x 152 mm)

- 12" x 12" (305 mm x 305 mm)

- 24" x 6" (610 mm x 152 mm)

- 24" x 12" (610 mm x 305 mm)

Thorlabs' Aluminum Protective Screens prevent stray or unwanted light from entering or exiting an experimental setup. The aluminum is bead blasted prior to anodization to create a homogeneously diffusive surface. With walls just 0.08" (2 mm) thick and bases that are 0.79" (20 mm) wide, these compact, lightweight screens are easily integrated into a laser setup.

The base of each screen contains several slotted mounting holes for 1/4"-20 (M6) cap screws that are each 2" (50.8 mm) long, providing flexible mounting options. The TPS4 additionally contains a centered through hole designed for 8-32 or M4 cap screws, allowing the TPS4 to be mounted to a post. Joiner plates (sold separately below) allow the straight laser safety screens to be joined together to form a continuous barrier.

| Item # | TPS4 | TPS13 | TPS5 | TPS14 | TPS6 |

|---|---|---|---|---|---|

| Size (W x H) | 8" x 6" (203 mm x 152 mm) |

12" x 6" (305 mm x 152 mm) |

12" x 12" (305 mm x 305 mm) |

24" x 6" (610 mm x 152 mm) |

24" x 12" (610 mm x 305 mm) |

| Mounting Holesa | 2 Slotted + 1 Through | 2 Slotted | 2 Slotted | 4 Slotted | 4 Slotted |

| Weight | 0.23 kg (0.51 lbs) | 0.27 kg (0.59 lbs) | 0.5 kg (1.10 lbs) | 0.55 kg (1.21 lbs) | 1 kg (2.20 lbs) |

| Compatible Joiner Plates | TPSJ3 and TPSJ4 | TPSJ3 and TPSJ4 | TPSJ1 and TPSJ2 | TPSJ3 and TPSJ4 | TPSJ1 and TPSJ2 |

| Damage Threshold | >350 J/cm2 (1064 nm, 20 ns, 20 Hz, Ø1.14 mm) | ||||

| Joiner Plate Compatibility | |||

|---|---|---|---|

| Item # | Type | Height | Compatible Screens |

| TPSJ1(/M) | Straight | 12" (305 mm) |

TPS5 and TPS6 |

| TPSJ2(/M) | Corner | ||

| TPSJ3(/M) | Straight | 6" (152 mm) | TPS4, TPS13, and TPS14 |

| TPSJ4(/M) | Corner | ||

- Aluminum Joiner Plates for Straight

Protective Screens - Used to Form a Continuous Barrier

- Straight and Corner Options Available

These Joiner Plates allow our straight laser safety screens to be joined together to form a continuous barrier around an experiment; please refer to the table to the right for compatible screens. Flat and 90° corner plates are available.

The joiner plates consist of a front and back plate that fit in front of and behind the screens to be joined. When properly positioned, the joiner plates are designed to overlap the screens by about 1/4" (6 mm) on each side. The plates are then bolted together using the two black 1/4"-20 (M6) cap head screws supplied to sandwich the screens between the plates.

The plates are manufactured from the same material, with the same thickness and surface finish, as the protective screens. However, since these are bolted-on joints, it is the user's responsibility to ensure the laser safety-related integrity of the screen-to-joiner plate connections. Please note that these joiner plates cannot be used with the curved protective screens detailed below.

| Item # | TPS8 | TPS7 | TPS9 |

|---|---|---|---|

| Size (W x H) | 8" x 6" (203 mm x 152 mm) |

12" x 12" (305 mm x 305 mm) |

24" x 12" (610 mm x 305 mm) |

| Mounting Holesa | 2 Slotted + 1 Through | 2 Slotted | 4 Slotted |

| Weight | 0.3 kg (0.66 lbs) | 0.7 kg (1.54 lbs) | 1.4 kg (3.08 lbs) |

| Damage Threshold | >350 J/cm2 (1064 nm, 20 ns, 20 Hz, Ø1.14 mm) | ||

- Bead-Blasted Anodized Aluminum Barriers

- Curved Screen Deflects Stray Laser Beams

- Three Sizes Available (W x H):

- 8" x 6" (203 mm x 152 mm)

- 12" x 12" (305 mm x 305 mm)

- 24" x 12" (610 mm x 305 mm)

Relative to the straight protective screens sold above, Thorlabs' Curved Protective Aluminum Screens offer additional blackout and shielding for stray laser beams that might be reflected upwards. The aluminum is bead blasted prior to anodization to create a homogeneously diffusive surface. With walls just 0.08" (2 mm) thick and bases that are 0.79" (20 mm) wide, these compact, lightweight screens are easily integrated into a laser setup.

The base of each screen contains several slotted mounting holes for 1/4"-20 (M6) cap screws that are each 2" (50.8 mm) long, providing flexible mounting options. Additionally, the TPS8 contains a centered through hole designed for an 8-32 or M4 cap screw, allowing the TPS8 to be mounted to a post.

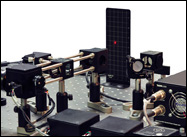

Click to Enlarge

TPSM1 in a Beam Stabilization Setup

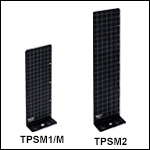

- Aluminum Laser Safety Screen with Laser-Engraved Target Grid

- Available in Two Sizes:

- TPSM1(/M): 7.87" x 2.95" (200.0 mm x 75.0 mm), Footprint: 2.95" x 1.38" (75.0 mm x 35.0 mm)

- TPSM2(/M): 11.81" x 2.95" (300.0 mm x 75.0 mm), Footprint: 2.95" x 1.38" (75.0 mm x 35.0 mm)

- Two Magnets on Underside Provide Holding Force

- Slotted Mounting Hole for Non-Magnetic Surfaces

- Homogeneously Diffusive Anodized Coating

- Damage Threshold: >350 J/cm2 (1064 nm, 20 ns, 20 Hz, Ø1.14 mm)

Our Magnetic Laser Safety Screens are laser engraved on one side with a 1/2" (10 mm for metric versions) target grid for rough laser alignment, while the other side is blank to provide a complete beam blocking option. The base of the screen is fitted with a pair of magnets that hold the screen to magnetic work surfaces and provide flexibility of movement. A through hole is also provided to allow the screen to be tightened down using a cap screw for more permanent placement or for use in non-magnetic applications. The compact size of the screen allows it to fit into small gaps between your accessories, enabling easy integration into a laser setup. This screen is constructed from bead-blasted aluminum to remove any sharp edges, which is then anodized to create a homogeneously diffusive surface.

Please note: Due to the presence of strong magnets, these laser screens should not be used in the vicinity of pacemakers, credit cards, or other devices affected by magnetic fields.

Products Home

Products Home

Zoom

Zoom

Aluminum Screens

Aluminum Screens