Ø1/2" Translating Post Holders

- Translating Post Holders Provide Non-Rotating Height Adjustment

- Two-Line Contact with Mounting Post for Stability

- Swivel Base Adapter Available for Easy Alignment

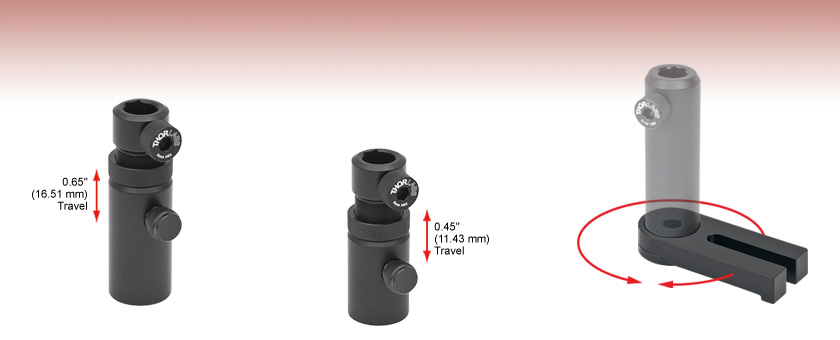

PH3T

PH2T

UPHA

360° Continuous

Rotation

Please Wait

Features

- Translating Post Holders Provide 0.025" (0.635 mm) Translation per Actuator Ring Rotation

- Swivel Base Adapter Available for Securing Post Holders to an Optical Table or Breadboard

- Custom Options Available; Contact Tech Support for Details

Thorlabs' specialty post holders provide mounting solutions for unique applications that could benefit from post holders that offer fine adjustment. Our Translating Post Holders provide height adjustment with ranges of either 0.45" (11.43 mm) or 0.65" (16.51 mm). For each revolution of the actuator ring, the post translates 0.025" (0.635 mm).

These Ø1/2" post holders feature an extra wide square relief cut machined vertically along the length of the part, as shown in the drawing to the right. This channel provides a highly-stable two-line contact between the post and post holder. Other post holder designs that do not have a relief cut provide less holding power, which leads to a downward drift in the post's position with time.

A swivel base adapter, which provides access to multiple mounting holes, allows the translating post holders to be mounted to an optical table or breadboard with easy alignment. We also offer replacement spring-loaded, hex locking thumbscrews to secure the post in the holder.

Insights into Design

Scroll down to read about a feature included in our optical post holders to enhance stability.

- Post Holders: Rectangular Channel in the Inner Bore

Click here for more insights into lab practices and equipment.

Post Holders: Rectangular Channel in the Inner Bore

Click to Enlarge

Figure 2: Top view. The three contact locations between the post and post holder, highlighted in red, prevent the post from translating or rotating around the X or Y axes. Friction resists the post's translation and rotation around the Z axis.

Click to Enlarge

Figure 1: A channel with sharp edges is machined into the inner bore of Thorlabs' post holders.

Figure 3: A broach, such as the one illustrated above, has a row of teeth, the next taller than the previous. With the teeth in contact with the material, a machine pulls the broach across the surface. Each tooth removes a small amount of material, and the depth of the channel created by the broach equals the overall difference in tooth height.

All of Thorlabs' post holders include a channel, with straight parallel edges, running the length of the inner bore (Figure 1). Tightening the setscrew pushes the post against the two edges of the channel (Figure 2). Since the edges of the channel are separated by a wide distance, approximately half the inner diameter of the post holder, the seating of the post against the channel's edges is stable and repeatable.

Contact with the two edges of the channel eliminates four of the post's six degrees of freedom, since the edges block the post from translating along or rotating around either the Y or Z axis. In addition, the friction between the side of the post and the edges of the channel resists the post's movement along and around the X axis, which are the post's two remaining degrees of freedom.

Without the channel in the inner bore, there would be a single line of contact between the post and post holder. The position of the post would not be stable, since the post would be free to rotate around the Z axis and shift along the Y axis.

Even if this instability resulted in submicron-scale unwanted shifts in each component's position in an optical setup, the cumulative effect could have a significant negative impact on system performance. In addition, more frequent realignment of the system could be required.

Broaching

The channel's edges must be straight and free of bumps and roughness to hold the post stable. These post holders have straight, sharp edges when examined on a micron scale. If the edges are not completely linear, the post might rock in the holder, and / or it may not be possible to repeatably position the post in the holder.

The smooth, straight edges of the channel are achieved using a machining process called broaching. A broach (Figure 3) resembles a saw whose teeth increase in height along its length.

As the broach is pulled along a surface, each tooth removes a small amount of material. The total depth of the channel cut by the broach equals to the overall difference in tooth height (H2 - H1).

Compared with other approaches for creating channels, broaching is preferred due to its ability to provide straight profiles while being compatible with high-volume production.

Date of Last Edit: Dec. 11, 2019

| Posted Comments: | |

Conner Phillips

(posted 2024-07-11 10:28:04.193) Are the holders designed so that the posts bottom-out inside the translating unit, i.e. is it possible to rotate the post without influencing the set height? jdelia

(posted 2024-07-11 04:23:53.0) Thank you for contacting Thorlabs. The posts do not bottom out inside the translating unit of the post holder. We would suggest utilizing one of our slip-on post collars (https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=2003) to maintain the position. tadej.meznarsic

(posted 2018-08-28 11:14:51.41) This product would be extremely useful to us if it were shorter. We would need minimal height of about 30-50 mm. Is it possible to make it shorter? llamb

(posted 2018-08-29 02:43:05.0) Thank you for contacting Thorlabs. For inquiries about custom products, you may email techsupport@thorlabs.com directly. I will reach out to you by email to discus the possibility of quoting this particular custom product. |

- Two Sizes and Adjustment Ranges Available

- Non-Rotating Height Control: 0.65" (16.5 mm) for PH3T, 0.45" (11.3 mm) for PH2T

- 0.025" (0.635 mm) of Translation per Revolution of Adjustment Ring

Our Translating Post Holders provide lockable, non-rotating height adjustment with convenient one-handed operation. An aluminum thumbscrew with a spring-loaded plunger provides holding force while the wide, square relief cut within the Ø1/2" post bore offers stable two-line contact. A knurled adjustment ring actuates the non-rotating height adjustment, which offers 0.025" (0.635 mm) of translational adjustment per revolution. Once the desired position is achieved, the entire mechanism can be locked using the lower thumbscrew and the locking hex socket on the upper thumbscrew. These thumbscrews should not be tightened beyond the maximum torque of 28 in·lbs (3.2 N·m). The post holders can be used with the Swivel Base Adapter featured below.

- Convert Your Existing Post Holders into UPH-Style Mounts

- 360° Swiveling Base Fastens to Existing PH-Series Post Holders via a 1/4"-20 (M6) Cap Screw

- Magnets in Base Provide Holding Force Prior to Fastening to an Optical Table

- Also Available in Packs of Five

Our 360° swivel base adapter is compatible with the translating post holders (sold above) and minimizes the amount of time it takes to assemble an optical system. In addition, the swivel design is ideal for applications that require a large number of components to be packed into a small area. When our translating posts (featured directly above) are used with the UPHA adapter, the combination is nearly that of our very popular, non-translating UPH Series of Post Holders, which have an attached swivel base; however, unlike with the UPH series post holders, the adapter would prevent the translating post from touching the table. For ease of ordering, these base adapters are also available in packs of five.

| Specification | |

|---|---|

| Maximum Torquea | 28 in·lbs (3.2 N·m) |

Click to Enlarge

Exploded View of the TS25H Thumbscrew

TS25H Drawing

The TS25H has 1/4"-20 threads while the TS6H/M has M6 x 1.0 threads for compatibility with our imperial and metric Ø1/2" post holders, respectively. The recommended maximum torque is 28 in·lbs (3.2 N·m). Please note that we do not recommend using an L wrench to tighten the thumbscrew, as this may break off the screw head.

If a thumbscrew without a spring-loaded tip is preferred, we recommend our vacuum-compatible thumbscrews. Alternatively, the tips can be removed from these thumbscrews by unthreading the setscrew in the front of the thumbscrew with a 1/16" (1.5 mm)

For ease of ordering, these thumbscrews are available individually or in packages of five.

*Delrin® is a registered trademark of DuPont Polymers, Inc.

Products Home

Products Home

Zoom

Zoom

Ø1/2" Translating Post Holders

Ø1/2" Translating Post Holders