Amplified Piezoelectric Actuators, 220 µm to 2500 µm Travel

- Discrete Piezo Stacks in Flexure Housings

- Free Stroke Displacement Options from 220 µm to 2500 µm

- Up to 100 N Forces

- Flexure Housing Amplifies Piezo Displacement

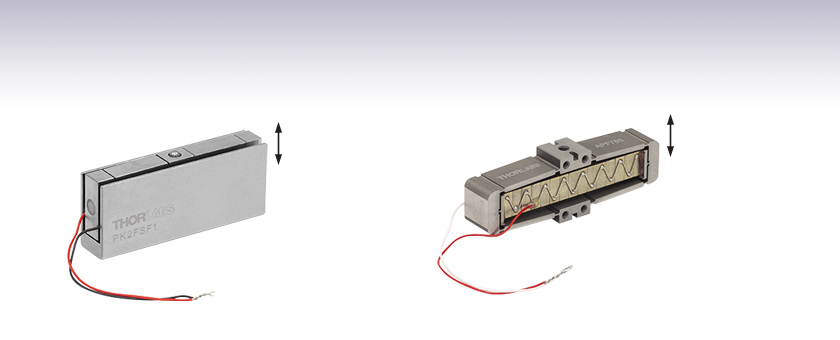

PK2FSF1

Amplified Piezoelectric Actuator with 220 µm Displacement

APF705

Amplified Piezoelectric Actuator with 560 µm Displacement

Direction of Translation

Direction of Translation

Please Wait

| Piezo Actuator Comparisona | ||

|---|---|---|

| Item # | PK2F Series | APF Series |

| Drive Voltage Range (Max) | 0 to 75 V | -30 to 150 V |

| Max Displacement | 220 µm or 420 µm | 390 µm, 560 µm, 1500 µm, or 2500 µm |

| Mounting Options | M2.5 Taps and Top Ball Contact |

Tapped Holes on Top, Bottom, Front, and Back |

Click to Enlarge

PK2F Series Piezo Flexure Mount Without U-Shaped Protective Cover

Features

- Discrete Piezo Stacks in Flexure Housings

- Pre-Attached Wires for Ease of Integration

- For Use in Open-Loop Experimental Setups

- Ideal for Use in OEM Applications

Thorlabs' Amplified Piezoelectric Actuators each consist of a discrete piezoelectric stack mounted inside a flexure housing. The flexure mount acts as a lever arm that amplifies the free stroke displacement of the stand-alone discrete stack. While the displacement achieved by this assembly is significantly larger than that of the piezo stack, the fast response times and low drive voltage ranges of the discrete stack are maintained. Because this displacement is created by a piezo stack within a flexure mount, these actuators do not suffer from backlash.

PK2F Series

The PK2F Series Amplified Piezos accept a drive voltage from 0 to 75 V and include a U-shaped, protective metal cover, as well as a ball contact for mounting a load on top. These piezo actuators come with pre-attached wires; the electrode attached to the red wire should be positively biased, and the electrode attached to the black wire should be grounded. The U-shaped metal cover protects the piezo stack and wire connections. The tungsten-carbide spherical contact on the top of the actuator housing allows for precise mounting of the load along the translation axis and prevents undesired stress along the other axes. Additionally, it has two M2.5 taps to provide easy and secure mounting options. Each stack is covered on four sides by an insulating ceramic layer that acts as a barrier to moisture. The ceramic layer offers better protection against moisture than an epoxy coating.

APF Series

The APF Series can be driven by voltages from -30 to 150 V and are installed in an open frame with several tapped holes for mounting components, making them ideal for OEM integration. The piezo actuators come with pre-attached wires. Under typical usage conditions, the electrode attached to the black wire (APF503) or white wire (APF705 and APF710) should be grounded, while a bi-polar power supply is used to apply a voltage from -30 V to +150 V to the red wire. Alternatively, the full range of motion can be achieved by holding the black or white wire at +30 V and varying the voltage on the red lead between 0 and +180 V if a bipolar power supply is not available. The flexure housing has one tapped mounting hole on the top and on the bottom, as well as four tapped mounting holes on the front and on the back. These mounting options provide flexibility when integrating the actuators into a setup, but care must be taken to align the load properly with the actuator's translation axis to avoid introducing angular resonance modes.

Note: When building the setup, keep the wire leads of each piezo bundled together to avoid static discharge, which can damage the piezo elements.

These actuators can be driven with the MDT69xB and KPC101 open-loop controllers, and the MPZ601 or BPC30x closed-loop controllers. These controllers are capable of providing drive voltages from 0 to 150 V and thus will not achieve the full range of the APF series piezo actuators. Please also note that these actuators do not contain a strain gauge and will therefore not provide positional feedback information when closed-loop controllers are used. If closed-loop feedback is required, consider the Piezoelectric Actuators with Attached Strain Gauges. Please see the Operation tab for additional guidance on integrating these piezoelectric devices into applications, special operational considerations, and data that will allow their lifetimes to be estimated when their operational conditions are known.

Thorlabs also offers Co-Fired Piezoelectric Stacks with maximum displacements from 4.6 µm to 20.0 µm, including one with a built-in strain gauge that can be used to provide feedback. Unlike discrete piezo stacks that are composed of PZT chips that have been bonded together, co-fired piezoelectric stacks are composed of PZT chips that have been sintered together to form a single monolithic structure. Our piezoelectric tutorial contains more information about the design and function of piezoelectric stacks.

Click to Enlarge

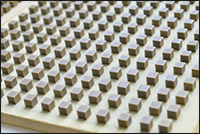

Dicing the PZT Block into Individual Elements

Click to Enlarge

Chips After Binder Burnout and Sintering

Thorlabs' In-House Piezoelectric Manufacturing

Our piezoelectric chips are fabricated in our production facility in China, giving us full control over each step of the manufacturing process. This allows us to economically produce high-quality products, including custom and OEM devices. A glimpse into the fabrication of our piezoelectric chips follows. For more information about our manufacturing process and capabilities, please see our Piezoelectric Capabilities page.

- Build Blocks from Flexible Sheets of Lead Zirconate Titanate (PZT) or BiScO3-PbTiO3 (BSPT) Powder

- Screen Print Electrodes on Each Individual Sheet

- Layer the Printed Sheets One Top of Another

- Consolidate the Layered Sheets in an Isostatic Press

- Dice the Block into Individual Elements

- Purge Solvent and Binder Material Residues by Heat Treating the Elements

- Sinter the Elements to Fuse the Piezoelectric Pressed Powder and Grow PZT or BSPT Crystals

- Lap the Elements to Achieve Tight Dimensional Tolerances: ±5 µm for Each Element

- Screen Print the Outer Electrodes on the Elements

- Align the Individual PZT or BSPT Crystals Along the Same Axis by Poling the Elements

Displacement vs. Voltage Curves

The displacement vs. voltage hysteresis curves for the amplified piezos are available here. The hysteresis is a result of some variability in the orientations of the ferroelectric domain polarizations within the PZT crystal. During fabrication, the polarizations of the large majority of crystal domains are aligned along the same direction by applying a strong electric field, which is considerably stronger than the one applied during device operation, across the PZT crystal. It is the contribution of other, extrinsic, ferroelectric domains that are the source of the hysteresis, and the magnitudes of their contributions depend on factors that include the mechanical pre-loading of the actuator, the temperature of the device, the control frequency, the dimensions of the device, and the history of the voltage signal driving the device.

To view the plots, click More [+] in the appropriate row below.

| PK2F Series Hysteresis |

|---|

Click to Enlarge The displacement response of the PK2FSF1 amplified PZT actuator to applied voltage is plotted above. To view an excel file that contains these data values, please click here.  Click to Enlarge The displacement response of the PK2FVF1 amplified PZT actuator to applied voltage is plotted above. To view an excel file that contains these data values, please click here. |

| APF503, AP705, APF710 Hysteresis |

|---|

|

In these tests, the voltage was first increased from 0 V to 150 V, then decreased to -30 V, and finally returned to 0 V. The initial and final positions are offset slightly due to hysteresis.

Click to Enlarge The displacement response of the APF503 amplified piezo actuator to applied voltage is plotted above. To view an excel file that contains these data values, please click here.  Click to Enlarge The displacement response of the APF705 amplified piezo actuator to applied voltage is plotted above. To view an excel file that contains these data values, please click here.  Click to Enlarge The displacement response of the APF710 amplified piezo actuator to applied voltage is plotted above. To view an excel file that contains these data values, please click here. |

| APFH720 Hysteresis |

|---|

|

The displacement response of the APFH720 amplified piezo actuator to applied voltage is plotted above. The left graph shows a voltage cycle from 0 to 150 V, while the right graph shows a voltage cycle over the full -30 to 150 V range. To view an excel file that contains these data values, please click here. |

Resonant Frequency vs. Load Curves

A parameter of significance to many applications is the rate at which the piezoelectric actuator changes its length. This dimensional rate of change depends on a number of factors, including the bandwidth of the piezoelectric actuator (its resonant frequency), the absolute maximum bandwidth of the driver (its slew rate), the maximum current the piezoelectric device can produce, the capacitance of the piezoelectric stack, and the amplitude of the driving signal. The length of the voltage-induced extension is a function of the amplitude of the applied voltage driving the actuator and the length of the piezoelectric stack. The higher the capacitance, the slower the dimensional change of the actuator.

Quick changes in the applied voltage result in fast dimensional changes to the piezoelectric stack. Assuming the driving voltage signal resembles a step function, the minimum time, Tmin, required for the length of the actuator to transition between its initial value and that corresponding to the final applied voltage is approximately 1/3 the period of resonant frequency. If there is no load applied to the piezoelectric stack, its resonance frequency is ƒo and its minimum response time is:

After reaching this nominal extension, there will follow a damped oscillation in the length of the actuator around this position. Controls can be implemented to mitigate this oscillation, but doing so may slow the response of the actuator.

Applying a load to the actuator will reduce the resonant frequency of the piezoelectric stack. Given the unloaded resonant frequency of the actuator, the mass of the stack, m, and the mass of the load, M, the loaded resonant frequency (ƒo') may be estimated using the following equation:

.

.The unloaded resonant frequencies of the amplified piezos can be seen by clicking More [+] in the rows below.

| PK2F Series Resonant Frequency vs. Load |

|---|

Click to Enlarge The resonant frequency of the PK2FSF1 amplified PZT actuator as a function of the applied load is plotted above. To view an excel file that contains these data values, please click here.  Click to Enlarge The resonant frequency of the PK2FVF1 amplified PZT actuator as a function of the applied load is plotted above. To view an excel file that contains these data values, please click here. |

| APF503, APF705, APF710 Resonant Frequency vs. Load |

|---|

Click to Enlarge Linear resonance occurs when the mounted load is symmetric with respect to the top mounting hole, or "on axis.". Angular resonance occurs when a load is mounted asymmetrically with respect to the top mounting hole, or "off axis." Due to the geometry of the flexure housing, the actuators are prone to resonance in the yaw of the mounting surface as a result of off-axis mounting. To minimize angular resonance modes, keep the load's center of mass as close to the top mounting hole as possible.  Click to Enlarge The resonant frequency of the APF503 amplified PZT actuator as a function of the applied load is plotted above. To view an excel file that contains these data values, please click here.  Click to Enlarge The resonant frequency of the APF705 amplified PZT actuator as a function of the applied load is plotted above. To view an excel file that contains these data values, please click here.  Click to Enlarge The resonant frequency of the APF710 amplified PZT actuator as a function of the applied load is plotted above. To view an excel file that contains these data values, please click here. |

| APFH720 Resonant Frequency vs. Load |

|---|

Click to Enlarge Linear resonance occurs when the mounted load is symmetric with respect to the top mounting hole, or "on axis.". Angular resonance occurs when a load is mounted asymmetrically with respect to the top mounting hole, or "off axis." Due to the geometry of the flexure housing, the actuator is prone to resonance in the yaw of the mounting surface as a result of off-axis mounting. To minimize angular resonance modes, keep the load's center of mass as close to the top mounting hole as possible.  Click to Enlarge The resonant frequency of the APFH720 amplified PZT actuator as a function of the applied load is plotted above. To view an excel file that contains these data values, please click here. |

Click to Enlarge

The image above shows the PK2F series flexure mount without the U-shaped protective cover.

Operation Notes

Power Connections

PK2F Series: The electrodes connected to the red wire should be connected to the positive voltage terminal and the electrode connected to the black wire should be grounded. The voltage applied across the wires should be between 0 V and +75 V; applying a negative bias may cause mechanical failure.

APF Series: Typically, the electrode attached to the black wire (APF503 and APFH720) or white wire (APF705 and APF710) should be grounded, while a bi-polar power supply is used to apply a voltage from -30 V to +150 V to the red wire. Alternatively, the full range of motion can be achieved by holding the black or white wire at +30 V and varying the voltage on the red lead between 0 and +180 V if a bi-polar power supply is not available.

Caution: After driving, the piezo is fully charged. Directly connecting the positive and negative electrodes has the risk of electricity discharging, spark, and even failure. We recommend using a resistor (>1 kΩ) between the electrodes to release the charge.

Interfacing the Amplified Piezoelectric Actuator with a Load

PK2F Series: Loads should be mounted to the spherical contact point. Mounting a load to any other side of the device may lead to mechanical failure.

APF Series: Loads should be mounted to the taps on the top or sides of the actuator housing. Be careful to align the load properly with the actuator's translation axis to avoid introducing angular resonance modes.

Soldering Wire Leads to the Electrodes

If wire leads must be reattached to the electrodes, a soldering temperature no higher than 370 °C (700 °F) should be used, and heat should be applied to each electrode for a maximum of 2 seconds. Solder the lead to the middle of the electrode and keep the spot over which heat is applied as small as possible.

Operating Under High-Frequency Dynamic Conditions

It may be necessary to implement an external temperature-control system to cool the device when it is operated at high frequencies. High-frequency operation causes the internal temperature of the piezoelectric device to rise. The temperature of the device should not be allowed to exceed its specified maximum operating temperature.

Estimating Device Lifetime for DC Drive Voltage Conditions

The lifetime of a piezoelectric device is a function of the operating temperature, applied voltage, and relative humidity conditions. Lifetimes are reduced as a consequence of humidity-driven electrolytic reactions, which occur at the electrodes of the piezoelectric devices when a DC voltage is applied. These reactions both generate hydrogen and result in metal dendrites growing from the cathode towards the anode. The hydrogen liberated by the electrolytic reaction chemically reacts with and degrades the piezoelectric material. Dendrites that grow to electrically connect the cathode and anode result in increasing levels of leakage current. Failed piezoelectric devices are defined as those that exhibit leakage current levels above an established threshold.

A ceramic moisture-barrier layer that insulates Thorlabs' piezoelectric devices on four sides is effective in minimizing the effects of humidity on device lifetime. As there is interest in estimating the lifetime of piezoelectric devices, Thorlabs conducted environmental testing on our ceramic-insulated, low-voltage, piezoelectric actuators. The resulting data were used to create a simple model that estimates the mean time to failure (MTTF), in hours, when the operating conditions of humidity, temperature, and applied voltage are known. The estimated MTTF is calculated by multiplying together three factors that correspond, respectively, to the operational temperature, relative humidity, and fractional voltage of the device. The fractional voltage is calculated by dividing the operational voltage by the maximum specified drive voltage for the device. The factors for each parameter can be read from the following plots, or they may be calculated by downloading the plotted data values and interpolating as appropriate.

In the following plots, the solid-line segment of each curve represents the range of conditions over which Thorlabs performed testing. These are the conditions observed to be of most relevance to our customers. The dotted-line extensions to the solid-line segments represent extrapolated data and represent a wider range of conditions that may be encountered while operating the devices.

Calculation of MTTF to Estimate Lifetimes: MTTF = fV * fT * fH

Given the relative humidity conditions, device temperature, and DC operational voltage, the device lifetime can be estimated. It is the product of voltage, temperature, and humidity factors, which can be determined using relationships plotted at right, lower-right, and below.

As an example, when a device of type PK2FSF1 is operated with a voltage of 60 V, at a temperature of 30 °C, and in an environment with 75% relative humidity:

- From the graph below, the voltage factor is 427 (the maximum rated voltage, Vmax, of the PK2FSF1 is 75 V, giving V/Vmax = 60 V / 75 V = 0.80).

- From the graph at right, the temperature factor is 83

- From the graph at lower-right, the humidity factor is 2.8

Then MTTF = 472 * 83 * 2.8 = 99234.8 hours, which is greater than 11 years.

The data shown in these graphs was taken using the PK2FSF1 piezo actuator. The other actuators on this page exhibit similar performance.

Click to Enlarge

For an Excel file containing these fH vs. relative humidity data, please click here.

The data used to generate these temperature, voltage, and humidity factor plots resulted from the analysis of measurements obtained from testing devices under six different operational conditions. Different dedicated sets of ten devices were tested under each condition, with each condition representing a different combination of operational voltage, device temperature, and relative humidity. After devices exhibit leakage current levels above a threshold of 100 nA, they are registered as having failed. The individual contributions of temperature, humidity, and voltage to the lifetime are determined by assuming:

- MTTF = fV(V) * fT(T) * fH(H)

- A power law dependence for the voltage: fV(V) = A1Vb1

- An exponential relationship for the relative humidity: fH(T) = A2ecH

- An Arrhenius relationship for the temperature: fT(H) = A3eb2/T

where A1, A2, A3, b1, b2, and c are constants determined through analysis of the measurement data, V is the DC operational voltage, T is the device temperature, and H is the relative humidity. Because the MTTF has a different mathematical relationship with each factor, the dependence of the MTTF on each factor alone may be determined. These are the data plotted above. The regions of the above curves marked by the blue shading are derived from experimental data. The dotted regions of the curves are extrapolated.

Lifetime testing of these devices continues, and additional data will be published here as they become available.

| Posted Comments: | |

jdelia

(posted 2024-10-17 01:28:32.0) Thank you for contacting Thorlabs. These actuators can be driven with the MDT69xB or KPC101 open-loop controllers, and the MPZ601 or BPC30x closed-loop controllers. A member from your local technical support team will contact you directly to help you select a controller and provide a quote. These actuators do not include sensing for closed-loop control (even if a closed-loop controller is used). We can customize amplified actuators with strain gauges, if you are interested, please let our colleague who contacted you know. Taeguk Um

(posted 2023-02-19 05:34:16.937) Hi, I'm taeguk Um in KAIST, KOREA.

I want to know more about APFH720.

In my research, I want reciprocating linear motion with 3 mm stroke and several kHz (about 3kHz). Can I achieve the performance I want with the APFH720?

For reference, there was a thesis that experimented with 5 kHz using this product. Is it okay to use it like this?

Sincerely,

Taeguk Um cdolbashian

(posted 2023-04-03 10:41:39.0) These piezo actuators are supposed to operate with no higher than 1/3 of the resonant frequency. (Piezo is prone to overheating and failure at high frequencies.) Given the parameters of APFH720 (151Hz resonant frequency @5g on-axis load; 2.5mm free stroke), 5kHz driving is possible but the voltage/stroke needs to be limited to a low level. We will get in touch with you directly to discuss this further GIANLUCA GAGLIARDI

(posted 2022-05-24 10:57:54.5) We purchased a PK2FSF1 actuator. We drove it always with your Thorlabs piezo driver. Suddenly, the actuator stopped working as expected and despite voltage applied no movement manifests. Apparently, the piezo inside was not working but we tried without external voltage amplifier, using a function generator only, and the piezo played sound clearly.

Do you have any suggestion or test to maek?

In case the device is dead, I wonder if we have still a chance to repair it mounting a new piezo element inside.

Gianluca cdolbashian

(posted 2022-05-27 12:43:11.0) Thank you for contacting Thorlabs. It's worth checking the capacitance and resistance of the piezo element, the piezo element may be damaged if the capacitance is less than 85% of the specified value (9.0 uF), or if its resistance is in the hundreds or thousands of ohms. It is also worth checking if the driver still works well. In case the device is damaged, please feel free to contact the local Tech Support team (in your case Europe@thorlabs.com) to send the unit back for further inspection/repair. jaakko.palosaari

(posted 2016-08-25 07:00:17.043) Can the piezoelectric actuator PKFVF1 be driven with a square wave signal(Vpp:0 to +75) ? johng

(posted 2015-09-11 13:13:22.29) This is a very good product. Would you have a chart of the freq. response verses load?

Thank you,

JOhn besembeson

(posted 2015-10-05 10:59:19.0) Response from Bweh at Thorlabs USA: We don't have such a graph at this time. I will follow-up regarding estimating the resonant frequency and piezo bandwidth for your particular case. |

- Amplified Piezo in Flexure Housing with U-Shaped Protective Cover

- Tungsten-Carbide Spherical Contact on Top for Mounting a Load

- M2.5-Threaded Holes on Bottom

- Positive Voltage Pushes Load Outward

- Amplified Piezo in Open-Frame Flexure Housing

- Threaded Mounting Holes on Top, Bottom, Front, and Back

- Positive Voltage Pulls Load Inward (APF503, APF705, APF710) or Pushes Load Outward (APFH720)

Products Home

Products Home

Zoom

Zoom

Amplified Piezo Actuators

Amplified Piezo Actuators