Motorized Precision Rotation Stage with DC Servo Motor

- Continuous 360° Motorized Rotation

- Rotational Velocity: 25 Degree/Second

- Tapped Platform for Mounting Prisms or Other Optics

PRMTZ8

Motorized Continuous

Rotation Stage

Application Idea

PRMTZ8 with PM3 Clamping Arm

and Pellin Broca Prism

OVERVIEW

| Key Specificationsa | |

|---|---|

| Platform Size | Ø66.2 mm (2.61") |

| Platform Mounting Holes | Eight 6-32 (M4) Sixteen 8-32 (M4) Five 1/4"-20 (M6) |

| Bidirectional Repeatability | ±0.1° |

| Backlash | ±0.3° |

| Max Rotation Velocity | 25 deg/s |

| Horizontal On-Axis Load Capacityb | 15 N (1.5 kg, 3.4 lbs) |

| Repeatable Incremental Motion (Min) | 0.04° |

| Percentage Accuracy | 0.1% |

| Home Location Accuracy | ±0.2° |

| Range | 360° Continuous |

Features

- 25 deg/sec Rotation Velocity

- Mounting Holes for Prism Clamps (Sold Below) or Other Optomechanics

- 1° Graduations on Main Dial

- Compact Design is Only 25 mm Tall

- Home Limit Switch For Precise 0° Locating within ±0.2°

- Recommended Driver: KDC101 DC Servo Controller

The PRMTZ8 is a compact, DC servo motorized 360° rotation stage with a tapped platform. The user can measure the angular displacement of the platform by using the Vernier scale (5 arcmin resolution) in conjunction with the graduation marks that are marked on the rotating platform in 1° increments. This rotation stage is also equipped with a home limit switch to facilitate automated rotation to the precise 0° position, allowing absolute angular positioning thereafter. The limit switch is designed to allow continuous rotation of the stage over multiple 360° cycles.

The KDC101 DC Servo Controller, sold separately below, is the ideal companion for achieving smooth, continuous motion that can be automated via the software interface. The stage, controller, and KPS101* or KPS201 power supply are available for purchase together as a bundle (Item #s KPRMTE and KPRMTE/M respectively).

The PRMTZ8 is supplied with 430 mm (16.93") of cable. An 2.5 m (8 ft) extension cable (PAA632) is available separately.

*This previous-generation item is not available for individual purchase. If a replacement is needed, the KPS201 Power Supply can be used.

SPECS

| Motor Specifications | |

|---|---|

| Motor Type | DC Servo |

| Nominal Voltage | 6 V |

| No Load Speed | 6560 rpm |

| No Load Current | 7.43 mA |

| Nominal Speed | 1050 rpm |

| Nominal Torque (Maximum Continuous Torque) | 1.26 mN•m |

| Nominal Current (Maximum Continuous Current) | 0.156 A |

| Stall Torque | 1.54 mN•m |

| Starting Current | 0.184 A |

| Maximum Efficiency | 65% |

| Terminal Resistance | 32.7 Ω |

| Terminal Inductance | 0.607 mH |

| Torque Constant | 8.38 mN•m/A |

| Speed Constant | 1140 rpm/V |

| Speed / Torque Gradient | 4450 rpm/mN•m |

| Mechanical Time Constant | 13.9 ms |

| Rotor Inertia | 0.298 g•cm2 |

| Stage Specifications | |

|---|---|

| Translation and Motion Parameters | |

| Travel Range | 360° Continuous |

| Bidirectional Repeatabilitya | ±0.1° |

| Backlashb | ±0.3° |

| Max Rotation Velocity | 25 deg/s |

| Calculated Resolution | 2 arcsec (0.0005°) |

| Horizontal On-Axis Load Capacityc | 15 N (1.5 kg, 3.4 lbs) |

| Min Repeatable Incremental Motiond | 0.04° |

| Percentage Accuracy | 0.1% |

| Home Location Accuracy | ±0.2° |

| Wobble | 200 µrad |

| Physical | |

| Platform Size | Ø66.2 mm (2.61") |

| Platform Mounting Holes | Eight 6-32 (M4) Sixteen 8-32 (M4) Five 1/4"-20 (M6) |

| Dimensions | 137.4 mm x 73.3 mm x 25 mm (5.41" x 2.88" x 0.98") |

| Weight | 0.38 kg (0.84 lbs) |

| Cable Length | 430 mm (16.93") |

PIN DIAGRAM

Motor Connector Pin Out

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | Ground/Return | 9 | Ident Resistora |

| 2 | Reserved For Future Use | 10 | Vcc/Ident Resistor |

| 3 | Limit Switch | 11 | Encoder Channel B |

| 4 | Reserved For Future Use | 12 | Reserved For Future Use |

| 5 | Motor (+) | 13 | Encoder Channel A |

| 6 | Reserved For Future Use | 14 | Ident EEPROM |

| 7 | Motor (-) | 15 | Ident EEPROM |

| 8 | Reserved For Future Use | - | - |

D-Type Male

KINESIS SOFTWARE

Software

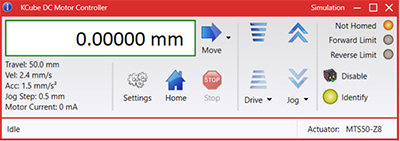

Kinesis Version 1.14.50

The Kinesis Software Package, which includes a GUI for control of Thorlabs' Kinesis system controllers.

Also Available:

- Communications Protocol

Kinesis GUI Screen

Thorlabs offers the Kinesis® software package to drive our wide range of motion controllers. The software can be used to control devices in the Kinesis family, which covers a wide variety of motion controllers ranging from small, low-powered, single-channel drivers (such as the K-Cubes™) to high-power, multi-channel benchtop units and modular 19" rack nanopositioning systems (the MMR60x Rack System).

The Kinesis Software features .NET controls which can be used by 3rd party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications. Low-level DLL libraries are included for applications not expected to use the .NET framework and APIs are included with each install. A Central Sequence Manager supports integration and synchronization of all Thorlabs motion control hardware.

By providing this common software platform, Thorlabs has ensured that users can mix and match any of our motion control devices in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from single-axis to multi-axis systems and control all from a single, PC-based unified software interface.

The software package allows two methods of usage: graphical user interface (GUI) utilities for direct interaction with and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

VERNIER SCALES

Reading a Vernier Scale on a Linear Main Scale

Vernier scales are typically used to add precision to standard, evenly divided scales (such as the scales on Thorlabs' rotation, goniometric, or translation mounts). A vernier scale has found common use in many precision measurement instruments, the most common being calipers and micrometers. The vernier scale uses two scales side-by-side: the main scale and the vernier scale. The direct vernier scale has a slightly smaller spacing between its tick marks owing to the vernier scale having N ticks for every N - 1 ticks on the main scale. Hence, the lines on the main scale will not line up with all the lines on the vernier scale. Only one line from the vernier scale will match well with one line of the main scale, and that is the trick to reading a vernier scale.

Figures 1 through 3 show a linear vernier scale system for three different situations. In each case, the scale on the left is the main scale, while the small scale on the right is the vernier scale. When reading a vernier scale, the main scale is used for the gross number, and the vernier scale gives the precision value. In this manner, a standard ruler or micrometer can become a precision instrument.

The 0 on the vernier scale is the "pointer" (marked by a red arrow in Figures 1 - 5) and will indicate the main scale reading. In Figure 1 we see the pointer is lined up directly with the 75.6 line. Notice that the only other vernier scale tick mark that lines up well with the main scale is 10. Since the pointer lines up with the main scale’s 75.6, the reading from Figure 1 is 75.60 (in whatever units the instrument measures).

That is essentially all there is to reading a vernier scale. It's a very straightforward way of increasing the precision of a measurement instrument. To expound, let’s look at Figure 2. Here we see that the pointer is no longer aligned with a line on the main scale, but instead it is slightly above 75.6 and below 75.7; thus, the gross measurement is 75.6. The first vernier line that coincides with a main scale line is the 5, shown with a blue arrow. The vernier scale gives the final digit of precision; since the 5 is aligned to the main scale, the precision measurement for Figure 2 is 75.65.

Since this vernier scale is 10% smaller than the main scale, moving the vernier scale by 1/10 of the main scale will align the next vernier marking. This asks the obvious question: what if the measurement is within the 1/10 precision of the vernier scale? Figure 3 shows just this. Again, the pointer line is in between 75.6 and 75.7, yielding the gross measurement of 75.6. If we look closely, we see that the vernier scale 7 (marked with a blue arrow) is very closely aligned to the main scale, giving a precision measurement of 75.67. However, the vernier scale 7 is very slightly above the main scale mark, and we can see that the vernier scale 8 (directly above 7) is slightly below its corresponding main scale mark. Hence, the scale on Figure 3 could be read as 75.673 ± 0.002. A reading error of about 0.002 would be appropriate for

this instrument.

Click to Enlarge

Figure 1: An example of how to read a vernier scale. The red arrow indicates what is known as the pointer. Since the tick mark labeled 10 on the vernier scale aligns with one of the tick marks on the main scale, this vernier scale is reading 75.60 (in whatever units the instrument measures).

Click to Enlarge

Figure 2: The red arrow indicates the pointer and the blue arrow indicates the vernier line that matches the main scale. This scale reads 75.65.

Click to Enlarge

Figure 3: The red arrow indicates the pointer, and the blue arrow indicates the vernier line that matches the main scale. This scale reads 75.67 but can be accurately read as

75.673 ± 0.002.

Reading a Vernier Scale on a Rotating Main Scale

The vernier scale may also be used on rotating scales where the main scale and vernier scale do not share units. Figures 4 and 5 show a vernier scale system for two different situations where the main scale is given in degrees and the vernier scale has ticks every 5 arcmin (60 arcmin = 1°). In each case, the scale on the top is the main scale, while the small scale on the bottom is the vernier scale.

In Figure 4 we see the pointer is lined up directly with the 341° line. Notice that the only other vernier scale tick marks that line up well with the main scale are ±60 arcmin. Since the pointer lines up with the main scale at 341°, the reading from Figure 4 is 341.00°.

There are two ways to determine the reading if the zero on the vernier scale line is between two lines of the main scale. For the first method, take the line on the left side of the pointer on the vernier scale and subtract that value (in arcmin) from the value on the main scale that is to the right on the main scale. As an example, in Figure 5 the vernier pointer is between 342° and 343°; using the left blue arrow of the vernier scale results in

As we've seen here, vernier scales add precision to a standard scale measurement. While it takes a bit of getting used to, with a little practice, reading these scales is fairly straightforward. Vernier scales, whether they are direct or retrograde*, are read in the same fashion.

*A retrograde vernier scale has a larger spacing between its tick marks with N ticks for every N + 1 ticks on the main scale.

Click to Enlarge

Figure 4: An example of a vernier scale where the main scale and the vernier scale are in different units (degrees and arcmins, respectively). The red arrow indicates the pointer. This scale reads 341.00°.

Click to Enlarge

Figure 5: The red arrow indicates the pointer and the blue arrows give the precision value from the vernier scale.

This scale reads 342.75°.

ROTATION MOUNTS AND STAGES

Rotation Mount and Stage Selection Guide

Thorlabs offers a wide variety of manual and motorized rotation mounts and stages. Rotation mounts are designed with an inner bore to mount a Ø1/2", Ø1", or Ø2" optic, while rotation stages are designed with mounting taps to attach a variety of components or systems. Motorized options are powered by a DC Servo motor, 2 phase stepper motor, piezo inertia motor, or an Elliptec™ resonant piezo motor. Each offers 360° of continuous rotation.

Manual Rotation Mounts

| Rotation Mounts for Ø1/2" Optics | |||||||

|---|---|---|---|---|---|---|---|

| Item # | MRM05(/M) | RSP05(/M) | CRM05 | PRM05(/M)a | SRM05 | KS05RS | CT104 |

| Click Photo to Enlarge |

|

|

|

|

|

|

|

| Features | Mini Series | Standard | External SM1 (1.035"-40) Threads |

Micrometer | 16 mm Cage-Compatible | ±4° Kinematic Tip/Tilt Adjustment Plus Rotation | Compatible with 30 mm Cage Translation Stages and 1/4" Translation Stagesb |

| Additional Details | |||||||

| Rotation Mounts for Ø1" Optics | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # | RSP1(/M) | LRM1 | RSP1D(/M) | DLM1(/M) | CLR1(/M) | RSP1X15(/M) | RSP1X225(/M) | PRM1(/M)a |

| Click Photo to Enlarge |

|

|

|

|

|

|

|

|

| Features | Standard | External SM1 (1.035"-40) Threads |

Adjustable Zero | Two Independently Rotating Carriages | Rotates Optic Within Fixed Lens Tube System |

Continuous 360° Rotation or 15° Increments |

Continuous 360° Rotation or 22.5° Increments |

Micrometer |

| Additional Details | ||||||||

| Rotation Mounts for Ø1" Optics | ||||||

|---|---|---|---|---|---|---|

| Item # | LM1-A & LM1-B(/M) |

CRM1T(/M) | CRM1LT(/M) | CRM1PT(/M) | KS1RS | K6XS |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Features | Optic Carriage Rotates Within Mounting Ring | 30 mm Cage-Compatiblea | 30 mm Cage-Compatible for Thick Opticsa |

30 mm Cage-Compatible with Micrometera |

±4° Kinematic Tip/Tilt Adjustment Plus Rotation | Six-Axis Kinematic Mounta |

| Additional Details | ||||||

| Rotation Mounts for Ø2" Optics | |||||||

|---|---|---|---|---|---|---|---|

| Item # | RSP2(/M) | RSP2D(/M) | PRM2(/M) | LM2-A & LM2-B(/M) |

LCRM2A(/M) | KS2RS | K6X2 |

| Click Photo to Enlarge |  |

|

|

|

|

|

|

| Features | Standard | Adjustable Zero |

Micrometer | Optic Carriage Rotates Within Mounting Ring | 60 mm Cage-Compatible | ±4° Kinematic Tip/Tilt Adjustment Plus Rotation | Six-Axis Kinematic Mount |

| Additional Details | |||||||

| Rotation Drive Mechanism and Adjustment Range | Manual, 360° Continuous | Coarse: Manual, 360° Continuous; Fine: ±7° Micrometer |

Manual, 360° Continuous | ||||

| Optic Mounting | Internally SM2-Threaded Carriage | Internal SM2 Threads in LM2-A |

Internally SM2-Threaded Carriage | ||||

| Maximum Accepted Optic Thickness | 0.51" (13 mm) | 0.54" (13.7 mm) | 0.48" (12.2 mm) | 0.46" (11.7 mm) | 0.52" (13.2 mm) | 0.47" (12 mm) | 0.53" (13.4 mm) |

| Post Mounting | 8-32 (M4) Tap | 8-32 (M4) Tap in LM2-B | 8-32 (M4) Tap | Four Counterbores for 8-32 (M4) Cap Screws | Six Counterbores for 8-32 (M4) Cap Screws | ||

| Cage System Compatibility | N/A | Four 4-40 (M3) Taps on Rotation Dial with 60 mm Spacing |

N/A | Four Bores for Ø6 mm Cage Rods with 60 mm Spacing |

N/A | N/A | |

Manual Rotation Stages

| Manual Rotation Stages | ||||||

|---|---|---|---|---|---|---|

| Item # | RP005(/M) | PR005(/M) | MSRP01(/M) | RP01(/M) | RP03(/M) | QRP02(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Features | Standard | Two Hard Stops | ||||

| Additional Details | ||||||

| Manual Rotation Stages | ||||||

|---|---|---|---|---|---|---|

| Item # | XRNR1(/M) | XRR1(/M) | PR01(/M) | CR1(/M) | XYR1(/M) | OCT-XYR1(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Features | Fine Rotation Adjuster and 2" Wide Dovetail Quick Connect |

Fine Rotation Adjuster and 3" Wide Dovetail Quick Connect |

Fine Rotation Adjuster and SM1-Threaded Central Aperture |

Fine Pitch Worm Gear | Rotation and 1/2" Linear XY Translation | |

| Additional Details | ||||||

Motorized Rotation Mounts and Stages

| Motorized Rotation Mounts and Stages with Central Clear Apertures | |||||

|---|---|---|---|---|---|

| Item # | DDR25(/M) | PDR1C(/M) | PDR1(/M) | PDR1V(/M) | PDXR1(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

| Features | Compatible with SM05 Lens Tubes, 16 mm Cage System, & 30 mm Cage System |

Compatible with 16 mm Cage System |

Compatible with SM05 Lens Tubes & 30 mm Cage System |

Vacuum-Compatible; Also Compatible with SM05 Lens Tubes & 30 mm Cage System |

Compatible with SM05 Lens Tubes & 30 mm Cage System |

| Additional Details | |||||

| Motorized Rotation Mounts and Stages with Central Clear Apertures | |||||

|---|---|---|---|---|---|

| Item # | K10CR1(/M) | PRM1Z8(/M)a | DDR100(/M) | ELL14 | HDR50(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

| Features | Compatible with SM1 Lens Tubes & 30 mm Cage System | Compatible with SM1 Lens Tubes, 16 mm Cage System, 30 mm Cage System |

Compatible with SM1 Lens Tubes, Open Frame Design for OEM Applications |

Compatible with SM2 Lens Tubes |

|

| Additional Details | |||||

| Motorized Rotation Mounts and Stages with Tapped Platforms | ||

|---|---|---|

| Item # | PRMTZ8(/M)a | ELL18(/M)b |

| Click Photo to Enlarge |

|

|

| Features | Tapped Mounting Platform for Mounting Prisms or Other Optics | Tapped Mounting Platform, Open Frame Design for OEM Applications |

| Additional Details | ||

Motorized Rotation Stage

Click to Enlarge

PRMTZ8/M Platform Taps

Click to Enlarge

PRMTZ8 Platform Taps

The rotating platform features five 1/4"-20 (M6) tapped holes and sixteen 8-32 (M4) holes for general optomechanics, as well as eight 6-32 (M4) holes for compatibility with our PM3 and PM4 prism clamping arms (available below).

The PRMTZ8 is supplied with 16" (0.4 m) of cable. An 8 ft (2.5 m) extension cable (PAA632) is available separately.

Part Number | Description | Price | Availability |

|---|---|---|---|

PRMTZ8/M | Motorized Precision Rotation Stage with Ø65 mm Platform (Metric) | $1,037.68 | Lead Time |

PRMTZ8 | Motorized Precision Rotation Stage with Ø2.56" Platform (Imperial) | $1,037.68 | In Stock |

Motorized Rotation Stage and Controller

The KPRMTE(/M) bundle includes a PRMTZ8(/M) Motorized Rotation Stage with a KDC101 K-Cube™ DC Servo Motor Controller. This controller provides smooth, continuous motion that can be automated via the software interface. Each bundle ships complete with a KPS101* power supply and a location-specific adapter.

The KPRMTE(/M) is supplied with 16" (0.4 m) of cable. An 8 ft (2.5 m) extension cable (PAA632) is available separately.

*This previous-generation item is not available for individual purchase. If a replacement is needed, the KPS201 Power Supply can be used.

Part Number | Description | Price | Availability |

|---|---|---|---|

KPRMTE/M | Motorized Precision Rotation Stage with Ø65 mm Platform (Metric) Bundled with DC Servo Motor Driver and Power Supply | $1,662.79 | 3 Weeks |

KPRMTE | Motorized Precision Rotation Stage with Ø2.56" Platform (Imperial) Bundled with DC Servo Motor Driver and Power Supply | $1,662.79 | 3 Weeks |

K-Cube™ DC Servo Motor Controller

Click to Enlarge

Click to EnlargeKCH601 USB Controller Hub (Sold Separately) with Installed K-Cube™ Modules

- Front Panel Velocity Wheel and Digital Display for Controlling Motorized Stages or Actuators

- Two Bidirectional Trigger Ports to Read or Control External Equipment

- Interfaces with Computer Using Included USB Cable

- Fully Compatible with Kinesis® Software Package

- Compact Footprint: 60.0 mm x 60.0 mm x 49.2 mm (2.42" x 2.42" x 1.94")

- Power Supply Not Included (See Below)

Thorlabs' KDC101 K-Cube Brushed DC Motor Controller provides local and computerized control of a single motor axis. It features a top-mounted control panel with a velocity wheel that supports four-speed bidirectional control with forward and reverse jogging as well as position presets. A backlit digital display is also included that can have the backlit dimmed or turned off using the top-panel menu options. The front of the unit contains two bidirectional trigger ports that can be used to read a 5 V external logic signal or output a 5 V logic signal to control external equipment. Each port can be independently configured.

The unit is fully compatible with our Kinesis software package. Please see the Kinesis Software tab for more information.

Please note that this controller does not ship with a power supply. Compatible power supplies are listed below. Additional information can be found on the main KDC101 DC Servo Motor Controller page.

Part Number | Description | Price | Availability |

|---|---|---|---|

KDC101 | K-Cube Brushed DC Servo Motor Controller (Power Supply Not Included) | $772.66 | 3 Weeks |

Compatible Power Supplies

Click for Details

Each KPS201 power supply includes one region-specific adapter, which can be selected upon checkout.

Click to Enlarge

The KPS201 Power Supply Unit

- Individual Power Supply

- KPS201: For K-Cubes™ or T-Cubes™ with 3.5 mm Jacks

- USB Controller Hubs Provide Power and Communications

- KCH301: For up to Three K-Cubes or T-Cubes

- KCH601: For up to Six K-Cubes or T-Cubes

The KPS201 power supply outputs +15 VDC at up to 2.66 A and can power a single K-Cube or T-Cube with a 3.5 mm jack. It plugs into a standard wall outlet.

The KCH301 and KCH601 USB Controller Hubs each consist of two parts: the hub, which can support up to three (KCH301) or six (KCH601) K-Cubes or T-Cubes, and a power supply that plugs into a standard wall outlet. The hub draws a maximum current of 10 A; please verify that the cubes being used do not require a total current of more than 10 A. In addition, the hub provides USB connectivity to any docked K-Cube or T-Cube through a single USB connection.

For more information on the USB Controller Hubs, see the full web presentation.

Part Number | Description | Price | Availability |

|---|---|---|---|

KPS201 | 15 V, 2.66 A Power Supply Unit with 3.5 mm Jack Connector for One K- or T-Cube | $40.33 | In Stock |

KCH301 | USB Controller Hub and Power Supply for Three K-Cubes or T-Cubes | $598.63 | 3 Weeks |

KCH601 | USB Controller Hub and Power Supply for Six K-Cubes or T-Cubes | $724.52 | 3 Weeks |

Clamping Arms

Click for Details

Mechanical Drawings

- Provide Clamping Force for Our Platform Mounts

- Threaded Hole on Top and Threaded Stud on Bottom of Post

- 6-32 Threads on PM3 and PM4

- 8-32 Threads on PM5

- M4 x 0.7 Threads on All Metric Versions

- Maximum Optic Heights from 0.97" to 1.65" (24.6 mm to 41.8 mm)

- Extension Posts Available to Increase Max Optic Height

- PM3SP(/M) with PM3(/M): Hold Optics up to 2.21" (56.1 mm) Tall

- PM4SP(/M) with PM4(/M): Hold Optics up to 3.61" (91.7 mm) Tall

Click to Enlarge

Clamping Arm Extension Posts with Metric Indicator Groove

Thorlabs' Clamping Arms provide clamping force to secure optics to our kinematic platform mounts, stages, and V-clamps. The PM3(/M) accommodates optics up to 0.97" tall and features a 0.69" center-to-center distance between the post and the nylon-tipped setscrew that holds the optic. The PM4(/M) accommodates optics up to 1.61" and features a 1.16" center-to-center distance between the post and the nylon-tipped setscrew. The maximum optic height of the PM3(/M) or PM4(/M) Clamping Arms can be extended using our PM3SP(/M) or PM4SP(/M) Extension Posts, respectively. These extension posts are identical to the posts included in each complete clamping arm. Each clamping arm features 6-32 (M4 x 0.7) threads. The PM3 and PM4 can be mounted in 8-32 tapped holes by using the AS6E8E thread adapter, which features internal 6-32 threads and external 8-32 threads. This thread adapter has an outer diameter of 0.24", which is the same as the PM4SP extension post and the post included with the PM4 clamping arm. This allows the clamping arm to be adjusted across the seam between either post and the adapter. The smaller diameters of the included post for the PM3 clamping arm and the PM3SP extension post cause the thread adapter to act as a stop for the clamping arm.

The PM5(/M) clamping arm is made entirely from heat-treated stainless steel, which helps maintain stability in fluctuating temperatures and provides vacuum compatibility. This clamping arm is recommended for use with the POLARIS-K1M4(/M), but it can be used with any platform mount or stage that has one or more 8-32 (M4 x 0.7) tapped holes. The PM5(/M) can hold optics up to 1.65" tall, and the distance from the post center to the contact point that holds the optic is 0.90".

Each clamping arm is attached to its post using a flexure mechanism that locks with a 5/64" (2.0 mm) balldriver or hex key. The setscrew on top of the clamping arm also accepts a 5/64" (2.0 mm) balldriver or hex key in order to clamp down on the optic. The post includes a through hole which can be leveraged for added torque when tightening down the post. Please see the diagram above for additional information.

Part Number | Description | Price | Availability |

|---|---|---|---|

PM3/M | Small Adjustable Clamping Arm, M4 x 0.7 Threaded Post | $21.86 | In Stock |

PM3SP/M | Customer Inspired! Extension Post for PM3/M Clamping Arm, M4 x 0.7 Threaded | $6.06 | In Stock |

PM4/M | Large Adjustable Clamping Arm, M4 x 0.7 Threaded Post | $26.73 | In Stock |

PM4SP/M | Customer Inspired! Extension Post for PM4/M Clamping Arm, M4 x 0.7 Threaded | $6.06 | In Stock |

PM5/M | Stainless Steel Adjustable Clamping Arm, M4 Threaded Post | $66.38 | In Stock |

PM3 | Small Adjustable Clamping Arm, 6-32 Threaded Post | $21.86 | In Stock |

PM3SP | Customer Inspired! Extension Post for PM3 Clamping Arm, 6-32 Threaded | $6.06 | In Stock |

PM4 | Large Adjustable Clamping Arm, 6-32 Threaded Post | $26.73 | In Stock |

PM4SP | Customer Inspired! Extension Post for PM4 Clamping Arm, 6-32 Threaded | $6.06 | In Stock |

PM5 | Stainless Steel Adjustable Clamping Arm, 8-32 Threaded Post | $66.38 | In Stock |