Laser Safety Fabric

- Withstands High Laser Energy According to EN 12254: 2010(E) Certification

- 1.0 m, 3.05 m, or 10.0 m Lengths of Laser Rated Fabric

- Can Be Cut to Custom Sizes

- Flame Retardant

This fabric may be cut into custom sizes to meet specific experimental needs.

LPCM1

1.6 m x 1.0 m

LPCM10

1.6 m x 10.0 m

Please Wait

| Laser Safety Fabric Certifications | |

|---|---|

| Wavelength | Certificationa |

| D AB10 I AB5 R AB4 M AB4 |

|

| D AB7 | |

| R AB6 I AB8 M AB8 |

|

| D AB5 | |

| D AB4 I AB5 R AB2 |

|

Click to Enlarge

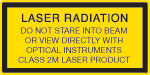

A laser safety label is attached to the rolls of fabric with 1.0 m and 3.05 m lengths.

Features

- Certified to EN 12254: 2010(E)*

- 1.6 m Wide Fabric in 1.0 m, 3.05 m, and 10.0 m Lengths

- 1.65 mm Thick

- Can Be Easily Cut into Custom Sizes

- Flame Retardant

- Custom Lengths Available by Contacting Tech Support

Thorlabs' laser safety fabric is designed to withstand high laser energy up to EN 12254: 2010(E) certification with the flexibility to be cut into custom sizes to suit experimental needs. The laser rated material is made of a rubber compound fabric, which is the same material used to make our laser safety curtain panels. The certification levels in the table to the right are expanded in the Certifications tab above. The customizable nature of this fabric makes it ideal for creating window covers and building custom enclosures for experiments and optical systems. Please ensure that the cutting tool you are using is sharp in order to reduce frayed edges. A red laser safety label, as seen in the image to the right, is attached to each sheet of 1.0 m long and 3.05 m long fabric.

Some material may need to be trimmed off either end of the LPCM10 prior to use. However, a minimum of 10.0 m of usable material is included. Please note that the LPCM10 is shipped in a crate weighing over 60 kg (132 lbs) and requires a forklift for transport. The roll itself is approximately 30 kg (66 lbs); a team lift is recommended.

*DISCLAIMER

This laser safety fabric has been tested by a third party using EN specifications; see the Certifications tab above for details. Due to manufacturing variances, mechanical wear, and laser damage, Thorlabs assumes no responsibility for laser material failure. Please consult your local laser safety specialist before purchasing to ensure that the fabric is suitable for your application. To minimize risk, inspect the material before each use and ensure that it is in excellent condition.

DISCLAIMER

This laser safety fabric has been tested by third parties using a variety of state regulations and EN specifications. Due to manufacturing variances, mechanical wear, and laser damage, Thorlabs assumes no responsibility for laser material failure. Please consult your local laser safety specialist before purchasing to ensure that the fabric is suitable for your application. To minimize risk, inspect the material before each use and ensure that it is in excellent condition.

| EN Certificationa | ||||

|---|---|---|---|---|

| Certification Requirements | Test Parameters | Damage Threshold | Maximum Spectral Transmittance Ratio |

Certification Levela |

| EN 12254: 2010 (E), 180 - 315 nm Range | 266 nm, 3 ns Pulses (FWHM), 50 kHz | 1 x 107 W/m2 | 1 x 10-10 | D AB10 |

| EN 12254: 2010 (E), 180 - 315 nm Range | 266 nm, 240 ms Pulses (FWHM), 10 Hz | 3 x 106 J/m2 | 1 x 10-5 | I AB5 |

| EN 12254: 2010 (E), 180 - 315 nm Range | 266 nm, 5 ns Pulses (FWHM), 10 Hz | 3 x 105 J/m2 | 1 x 10-4 | R AB4 |

| EN 12254: 2010 (E), 180 - 315 nm Range | 266 nm, 800 ps Pulses (FWHM), 20 Hz | 3 x 1014 J/m2 | 1 x 10-4 | M AB4 |

| EN 12254: 2010 (E), 315 - 1050 nm Range | 532 nm (CW) | 1 x 107 W/m2 | 1 x 10-7 | D AB7 |

| EN 12254: 2010 (E), 315 - 1400 nm Range | 1064 nm / 532 nm, 10 ns Pulses (Square), 5 Hz | 5 x 103 J/m2 | 1 x 10-6 | R AB6 |

| EN 12254: 2010 (E), 315 - 1400 nm Range | 1064 nm, 300 µs Pulses (Square), 20 Hz | 5 x 105 J/m2 | 1 x 10-8 | I AB8 |

| EN 12254: 2010 (E), 315 - 1400 nm Range | 1064 nm / 532 nm, 500 ps / 400 ps Pulses (Square), 20 Hz | 1.5 x 104 J/m2 | 1 x 10-8 | M AB8 |

| EN 12254: 2010 (E), 1050 - 1400 nm Range | 1070 nm (CW) | 2.5 x 106 W/m2 | 1 x 10-5 | D AB5 |

| EN 12254: 2010 (E), 1400 - 10 600 nm Range | 10.6 µm (CW) | 1 x 107 W/m2 | 1 x 10-4 | D AB4 |

| EN 12254: 2010 (E), 1400 - 10 600 nm Range | 10.6 µm, 100 ms Pulses (Square), 10 Hz | 1 x 107 J/m2 | 1 x 10-5 | I AB5 |

| EN 12254: 2010 (E), 1400 - 10 600 nm Range | 10.6 µm, 100 ns Pulses (Square), 1 Hz | 1 x 104 J/m2 | 1 x 10-2 | R AB2 |

| Other EN Certificationsa | |||

|---|---|---|---|

| Certification Type | Test Wavelength | Pulsewidth (FWHM) | Comments |

| Mechanical Strength | N/A | N/A | UV-Exposed Protected Fabric. All samples meet requirement. |

| Resistance to Ignition | N/A | N/A | Flame does not reach the test mark with the burner in position, and self-extinguishes after removal of the burner. Material does not continue to glow for more than one second after removal of the burner. |

| Spectral Transmittance | 200 nm - 50 000 nm | N/A | Samples do not exhibit transmission windows from 200 nm to 50 000 nm. |

| Stability to Temperature | Various | Various | No degradation was observed in any AB level for any sample. |

| Stability to UV Radiation | All | 10 ns - 20 ns | Samples do not exhibit any cracking, peeling, or degradation. For laser wavelengths, samples do not exceed maximum spectral transmission for scale number. Samples maintained optical density using both laser and spectrophotometer. |

| Additional Certifications | |

|---|---|

| Certification Requirements | Comments |

| Boston Fire Department Classification Fire Test: BFD IX-1 |

After flame does exceed two seconds; flame propogation and after flame does not extend beyond six inches from the bottom edge. Propagating afterglow does not exceed forty seconds; non-propogating afterglow in the charred area does not exceed eighty seconds. |

| California Administrative Code Title 19: Public Safety, Section 1237 |

The char length did not exceed 6.0 inches, and the average afterflame time did not exceed 4.0 seconds in length or width directions. |

| NFPA No. 701 Standard Methods of Fire Test for Flame Propogation of Textiles and Films, 2019 Edition, (Test 1)a | The average percent weight loss does not exceed 40% and the average residual flame does not exceed 2.0 seconds. |

| NYC Cal. No. 294-40-SR | No flashing occured at any time, and the average continuation of flaming did not exceed three seconds. The average continuation of glow at the edge of the charred area did not exceed twenty seconds after the cessation of flaming. |

Laser Safety and Classification

Safe practices and proper usage of safety equipment should be taken into consideration when operating lasers. The eye is susceptible to injury, even from very low levels of laser light. Thorlabs offers a range of laser safety accessories that can be used to reduce the risk of accidents or injuries. Laser emission in the visible and near infrared spectral ranges has the greatest potential for retinal injury, as the cornea and lens are transparent to those wavelengths, and the lens can focus the laser energy onto the retina.

Safe Practices and Light Safety Accessories

- Laser safety eyewear must be worn whenever working with Class 3 or 4 lasers.

- Regardless of laser class, Thorlabs recommends the use of laser safety eyewear whenever working with laser beams with non-negligible powers, since metallic tools such as screwdrivers can accidentally redirect a beam.

- Laser goggles designed for specific wavelengths should be clearly available near laser setups to protect the wearer from unintentional laser reflections.

- Goggles are marked with the wavelength range over which protection is afforded and the minimum optical density within that range.

- Laser Safety Curtains and Laser Safety Fabric shield other parts of the lab from high energy lasers.

- Blackout Materials can prevent direct or reflected light from leaving the experimental setup area.

- Thorlabs' Enclosure Systems can be used to contain optical setups to isolate or minimize laser hazards.

- A fiber-pigtailed laser should always be turned off before connecting it to or disconnecting it from another fiber, especially when the laser is at power levels above 10 mW.

- All beams should be terminated at the edge of the table, and laboratory doors should be closed whenever a laser is in use.

- Do not place laser beams at eye level.

- Carry out experiments on an optical table such that all laser beams travel horizontally.

- Remove unnecessary reflective items such as reflective jewelry (e.g., rings, watches, etc.) while working near the beam path.

- Be aware that lenses and other optical devices may reflect a portion of the incident beam from the front or rear surface.

- Operate a laser at the minimum power necessary for any operation.

- If possible, reduce the output power of a laser during alignment procedures.

- Use beam shutters and filters to reduce the beam power.

- Post appropriate warning signs or labels near laser setups or rooms.

- Use a laser sign with a lightbox if operating Class 3R or 4 lasers (i.e., lasers requiring the use of a safety interlock).

- Do not use Laser Viewing Cards in place of a proper Beam Trap.

Laser Classification

Lasers are categorized into different classes according to their ability to cause eye and other damage. The International Electrotechnical Commission (IEC) is a global organization that prepares and publishes international standards for all electrical, electronic, and related technologies. The IEC document 60825-1 outlines the safety of laser products. A description of each class of laser is given below:

| Class | Description | Warning Label |

|---|---|---|

| 1 | This class of laser is safe under all conditions of normal use, including use with optical instruments for intrabeam viewing. Lasers in this class do not emit radiation at levels that may cause injury during normal operation, and therefore the maximum permissible exposure (MPE) cannot be exceeded. Class 1 lasers can also include enclosed, high-power lasers where exposure to the radiation is not possible without opening or shutting down the laser. |  |

| 1M | Class 1M lasers are safe except when used in conjunction with optical components such as telescopes and microscopes. Lasers belonging to this class emit large-diameter or divergent beams, and the MPE cannot normally be exceeded unless focusing or imaging optics are used to narrow the beam. However, if the beam is refocused, the hazard may be increased and the class may be changed accordingly. |  |

| 2 | Class 2 lasers, which are limited to 1 mW of visible continuous-wave radiation, are safe because the blink reflex will limit the exposure in the eye to 0.25 seconds. This category only applies to visible radiation (400 - 700 nm). |  |

| 2M | Because of the blink reflex, this class of laser is classified as safe as long as the beam is not viewed through optical instruments. This laser class also applies to larger-diameter or diverging laser beams. |  |

| 3R | Class 3R lasers produce visible and invisible light that is hazardous under direct and specular-reflection viewing conditions. Eye injuries may occur if you directly view the beam, especially when using optical instruments. Lasers in this class are considered safe as long as they are handled with restricted beam viewing. The MPE can be exceeded with this class of laser; however, this presents a low risk level to injury. Visible, continuous-wave lasers in this class are limited to 5 mW of output power. |  |

| 3B | Class 3B lasers are hazardous to the eye if exposed directly. Diffuse reflections are usually not harmful, but may be when using higher-power Class 3B lasers. Safe handling of devices in this class includes wearing protective eyewear where direct viewing of the laser beam may occur. Lasers of this class must be equipped with a key switch and a safety interlock; moreover, laser safety signs should be used, such that the laser cannot be used without the safety light turning on. Laser products with power output near the upper range of Class 3B may also cause skin burns. |  |

| 4 | This class of laser may cause damage to the skin, and also to the eye, even from the viewing of diffuse reflections. These hazards may also apply to indirect or non-specular reflections of the beam, even from apparently matte surfaces. Great care must be taken when handling these lasers. They also represent a fire risk, because they may ignite combustible material. Class 4 lasers must be equipped with a key switch and a safety interlock. |  |

| All class 2 lasers (and higher) must display, in addition to the corresponding sign above, this triangular warning sign. |  |

|

| Posted Comments: | |

Dylan Black

(posted 2024-04-01 09:40:53.533) I need to black out a window on a door with fabric like this. There are several approaches I could take, but the simplest seems to be attaching velcro strips to the curtain and the door ( https://www.mcmaster.com/products/hook-and-loop/ ) -- will the curtain bond well to rubber or acrylic adhesive that comes with the velcro? spolineni

(posted 2024-04-05 10:55:55.0) Thank you for reaching out to us.The laser safety fabric is non-adhesive, and we advise against using epoxies as they tend to have difficulty adhering. I’ll be reaching out to you directly to provide further assistance with your requirements. user

(posted 2024-03-15 13:45:37.077) To whom it may concern, I see that the fabric meets specified certifications in the 1400 nm to 10.6 µm range. Before a potential purchase, I would like to confirm that the material can withstand CO2 lasers specifically (4kW beam which has a 10.6 µm wavelength) compared to other laser types. cstroud

(posted 2024-03-20 12:03:48.0) Thanks for reaching out. Our laser safety curtains are tested by a third party to EN specifications, which can be seen in the "Certifications" tab. The EN12254 certifications specify a test parameter of 1 x 10^7 W/m^2 at a wavelength of 10.6um. I would recommend that you discuss this with your laser safety officer to confirm whether your laser falls within these specifications. Reno Choi

(posted 2021-12-16 02:02:07.943) I'm looking for a curtain material for my dark room (optical lab with xenon and halogen lamps) and LPCM10 seems appropriate one.

Can you please share spectral reflectivity of LPCM10? Also, thickness and weight (per unit area) of the fabric should be helpful.

I look forward to hearing from you soon. cwright

(posted 2021-12-16 08:26:13.0) Response from Charles at Thorlabs: Thank you for your query. LPCM10 has a thickness of approximately 1.6 mm. The weight of the fabric is approximately 2 kg/m2. Unfortunately we do not have reflectivity data for this fabric.

If you are looking for blackout materials for a dark room then I wonder if you have seen our blackout curtains and materials which may be more suited than the laser safety range: https://www.thorlabs.com/navigation.cfm?guide_id=80. I will reach out to you to discuss this. SooKyung Chun

(posted 2021-01-11 21:29:45.483) To whom it may concern,

I would like to know the reflectance of products at 1.54 um

- products list

1. Laser Safety Fabric

2. BK5(Blackout, Nylon Fabric with Polyurethane Coating)

Regards,

Sookyung Chun DJayasuriya

(posted 2021-01-14 04:30:14.0) Thank you for your inquiry. Unfortunately we do not have any reflection dat. You will be able to find the certificates for safety spec which identifies where the light penetration occurs. Please feel free to contact your local techsupport team if you would have any other questions. |

Products Home

Products Home

Laser Safety Fabric

Laser Safety Fabric