Illuminated Laser Safety Signs

- Lightbox Provides Uniform Illumination of Laser Safety Signs

- Safety Signs with Notice, Caution, Warning, or Danger Signal Words

LSS10

LED Lightbox

LSS10D

Danger Sign

LSS10W4

Class 4 Warning Sign

Please Wait

Click to Enlarge

LSS10 Lightbox Illuminating LSS10C Caution Sign

Features

- Lightbox with LED Light Guide Panel

- Laser Interlock Features Integrated into Lightbox

- Signs for ANSI-Certified Signal Words: Notice, Caution, Warning, or Danger

- Signs Designed to Meet IEC and ANSI Laser Safety Standards

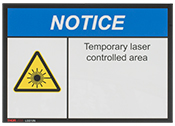

Thorlabs offers an LED light guide laser safety lightbox and signal word laser safety signs. Laser safety signs are required for laser-controlled areas and indicate to personnel when and where a laser system is in use. Offered in Notice, Caution, Warning, or Danger signal words and constructed from high-impact polystyrene (HIPS), Thorlabs' laser safety signs allow the user to indicate wavelength and optical density (OD) specifications of the laser emission. These signs, which are designed to meet IEC and ANSI laser safety standards, are appropriate for standalone use, or they can be uniformly illuminated using the LSS10 lightbox for increased visibility. The LSS10 lightbox can be mounted to virtually any wall in either left- or right-handed orientations. The front of the lightbox can be opened via a hinged panel, allowing laser safety signs to be easily inserted. The lightbox accepts 10” x 14” (25.6 cm x 35.8 cm) signs.

Laser Safety and Classification

Safe practices and proper usage of safety equipment should be taken into consideration when operating lasers. The eye is susceptible to injury, even from very low levels of laser light. Thorlabs offers a range of laser safety accessories that can be used to reduce the risk of accidents or injuries. Laser emission in the visible and near infrared spectral ranges has the greatest potential for retinal injury, as the cornea and lens are transparent to those wavelengths, and the lens can focus the laser energy onto the retina.

Safe Practices and Light Safety Accessories

- Laser safety eyewear must be worn whenever working with Class 3 or 4 lasers.

- Regardless of laser class, Thorlabs recommends the use of laser safety eyewear whenever working with laser beams with non-negligible powers, since metallic tools such as screwdrivers can accidentally redirect a beam.

- Laser goggles designed for specific wavelengths should be clearly available near laser setups to protect the wearer from unintentional laser reflections.

- Goggles are marked with the wavelength range over which protection is afforded and the minimum optical density within that range.

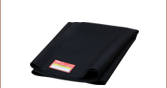

- Laser Safety Curtains and Laser Safety Fabric shield other parts of the lab from high energy lasers.

- Blackout Materials can prevent direct or reflected light from leaving the experimental setup area.

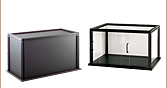

- Thorlabs' Enclosure Systems can be used to contain optical setups to isolate or minimize laser hazards.

- A fiber-pigtailed laser should always be turned off before connecting it to or disconnecting it from another fiber, especially when the laser is at power levels above 10 mW.

- All beams should be terminated at the edge of the table, and laboratory doors should be closed whenever a laser is in use.

- Do not place laser beams at eye level.

- Carry out experiments on an optical table such that all laser beams travel horizontally.

- Remove unnecessary reflective items such as reflective jewelry (e.g., rings, watches, etc.) while working near the beam path.

- Be aware that lenses and other optical devices may reflect a portion of the incident beam from the front or rear surface.

- Operate a laser at the minimum power necessary for any operation.

- If possible, reduce the output power of a laser during alignment procedures.

- Use beam shutters and filters to reduce the beam power.

- Post appropriate warning signs or labels near laser setups or rooms.

- Use a laser sign with a lightbox if operating Class 3R or 4 lasers (i.e., lasers requiring the use of a safety interlock).

- Do not use Laser Viewing Cards in place of a proper Beam Trap.

Laser Classification

Lasers are categorized into different classes according to their ability to cause eye and other damage. The International Electrotechnical Commission (IEC) is a global organization that prepares and publishes international standards for all electrical, electronic, and related technologies. The IEC document 60825-1 outlines the safety of laser products. A description of each class of laser is given below:

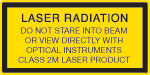

| Class | Description | Warning Label |

|---|---|---|

| 1 | This class of laser is safe under all conditions of normal use, including use with optical instruments for intrabeam viewing. Lasers in this class do not emit radiation at levels that may cause injury during normal operation, and therefore the maximum permissible exposure (MPE) cannot be exceeded. Class 1 lasers can also include enclosed, high-power lasers where exposure to the radiation is not possible without opening or shutting down the laser. |  |

| 1M | Class 1M lasers are safe except when used in conjunction with optical components such as telescopes and microscopes. Lasers belonging to this class emit large-diameter or divergent beams, and the MPE cannot normally be exceeded unless focusing or imaging optics are used to narrow the beam. However, if the beam is refocused, the hazard may be increased and the class may be changed accordingly. |  |

| 2 | Class 2 lasers, which are limited to 1 mW of visible continuous-wave radiation, are safe because the blink reflex will limit the exposure in the eye to 0.25 seconds. This category only applies to visible radiation (400 - 700 nm). |  |

| 2M | Because of the blink reflex, this class of laser is classified as safe as long as the beam is not viewed through optical instruments. This laser class also applies to larger-diameter or diverging laser beams. |  |

| 3R | Class 3R lasers produce visible and invisible light that is hazardous under direct and specular-reflection viewing conditions. Eye injuries may occur if you directly view the beam, especially when using optical instruments. Lasers in this class are considered safe as long as they are handled with restricted beam viewing. The MPE can be exceeded with this class of laser; however, this presents a low risk level to injury. Visible, continuous-wave lasers in this class are limited to 5 mW of output power. |  |

| 3B | Class 3B lasers are hazardous to the eye if exposed directly. Diffuse reflections are usually not harmful, but may be when using higher-power Class 3B lasers. Safe handling of devices in this class includes wearing protective eyewear where direct viewing of the laser beam may occur. Lasers of this class must be equipped with a key switch and a safety interlock; moreover, laser safety signs should be used, such that the laser cannot be used without the safety light turning on. Laser products with power output near the upper range of Class 3B may also cause skin burns. |  |

| 4 | This class of laser may cause damage to the skin, and also to the eye, even from the viewing of diffuse reflections. These hazards may also apply to indirect or non-specular reflections of the beam, even from apparently matte surfaces. Great care must be taken when handling these lasers. They also represent a fire risk, because they may ignite combustible material. Class 4 lasers must be equipped with a key switch and a safety interlock. |  |

| All class 2 lasers (and higher) must display, in addition to the corresponding sign above, this triangular warning sign. |  |

|

| Posted Comments: | |

Babu Kakkattil

(posted 2022-10-27 15:21:21.49) Hi Sir,

We are looking for the Laser warning Light for a simulation laboratory, but out side use. Do you have any model suitable for outdoor use? Please confirm and quote for us for 2nos. cwright

(posted 2022-10-28 05:23:37.0) Response from Charles at Thorlabs: Thank you for your query. Unfortunately we would not be able to supply a model for use outdoors. Patrick Lee

(posted 2021-09-15 12:14:27.313) 1. What is max and min brightness (in Cd/m2) of LSS10 ?

2. Uniformity specification ? ie differences in brightness between center and 8 corners ?

3. LED brightness is controlled by current or PWM - Pulse Width Modulation ? DJayasuriya

(posted 2021-09-16 05:49:27.0) Thank you for your inquiry, the minimum brightness is 8W and max is 15W. Illumination is controlled by turning a knob on the right-hand side of the unit, allowing the brightness to be adjusted to suit the specific location of use. We do not have uniformity specifications, however, this would illuminate the laser safety sign that is inserted to provide a clear indication of the laser in use.

The unit is supplied is for external power connections, but the power can be hard-wired to the internal PCB. Please see manual chapter 3 for more information. If you have any questions please feel free to get in touch with your local tech support team. Pedro Encarnacion

(posted 2021-04-19 13:49:37.51) Would like to know if LSS10 is designed to be permanently mounted EXTERNAL to laser lab entrance, and HARD-WIRED to 120VAC power, to be switched from INSIDE the laboratory with a single-pole wall mounted switch? This is how we are seeking to implement. DJayasuriya

(posted 2021-09-03 04:44:17.0) Thank you for your inquiry. The box operates at 100 to 240 VAC, so this is possible. You will be able to find more information in the manual regarding installation. user

(posted 2016-10-28 10:50:02.447) In my experience, laser safety signs need a serious upgrade. Bright LEDs for illumination, and they need to flash or blink, otherwise everybody tunes it out.

So do these flash? Are they modernized with LED illumination? tfrisch

(posted 2016-11-01 01:38:58.0) Hello, thank you for your feedback. These laser safety signs use fluorescent lights, and are not designed to flash. While it is important to have noticeable alerts of high powered lasers, be sure to consult your laser safety officer before making any changes to the way safety equipment operates. zachariaac

(posted 2015-06-17 09:37:46.61) We purchased one of these but disappointment exists because there is no convenient way to control this from a computer or PLC. besembeson

(posted 2015-09-21 11:43:19.0) Response from Bweh at Thorlabs USA: Thanks for the feedback. Unfortunately we don't have such a feature yet on these. |

Click for Details

To insert a laser safety sign, lift the frame on the side with hinges, then insert the appropriate slide.

Click to Enlarge

LSS10 Side Panel Showing Hinges, Brightness Adjuster Wheel, Input for External Interlock, and Rocker Power Switch

- LED Light Guide Panel Provides Uniform Illumination

- Adjustable Brightness

- Easy Sign Insertion

- Internal and External Interlock Features

The LSS10 lightbox illuminates our laser safety signs, which are sold below. Using LED light guide technology, our lightbox offers bright, uniform, efficient illumination (5300 K) with low energy consumption from 8 to 15 W. Rated for 100 to 240 VAC, the LSS10 can be used straight out of the box and features a brightness adjuster wheel and rocker power switch. The LSS10 lightbox can be mounted to virtually any wall in either left- or right-handed orientations. A convenient line cord latch prevents the AC line cord from disengaging from the unit. The LSS10 lightbox is shipped with a region-specific power cord based on the location the order is placed.

This lightbox accepts 10” x 14” signs, such as the ANSI and IEC compliant laser safety signs available below. To insert a sign, simply lift the frame on the side of the lightbox with hinges and insert the appropriate sign (see image to far right).

Interlock-equipped laser systems can be interlocked with the lightbox to prevent laser use when the lightbox is not illuminated. An interlock circuit can be connected to the lightbox interlock either externally or internally. The external interlock connection is achieved via a 2.5 mm phono plug (included). For information on using the safety interlock, please refer to section 4.2 of the manual.

Thorlabs' 10" x 14" laser safety signs are directly compatible with our LSS10 lightbox (sold above) and are also appropriate for standalone use. Signs are available with Notice, Caution, Warning, or Danger signal words, as well as Class 3B Warning, Class 4 Danger, and Class 4 Warning designations, all of which are ANSI Z535 certified. The appropriate choice of sign should be determined in consultation with your laser safety officer or a qualified laser safety authority who is familiar with your setup. These signs are constructed from high-impact polystyrene (HIPS).

Note: These signs are provided without a wavelength or OD specified. Wavelength, OD, and other relevant information can be written on each sign using a marker. You must customize the sign for your specific wavelength and OD as required by ANSI Z136, IEC 60825, and other pertinent laser safety regulations.

Products Home

Products Home

Zoom

Zoom

Laser Safety Signs

Laser Safety Signs