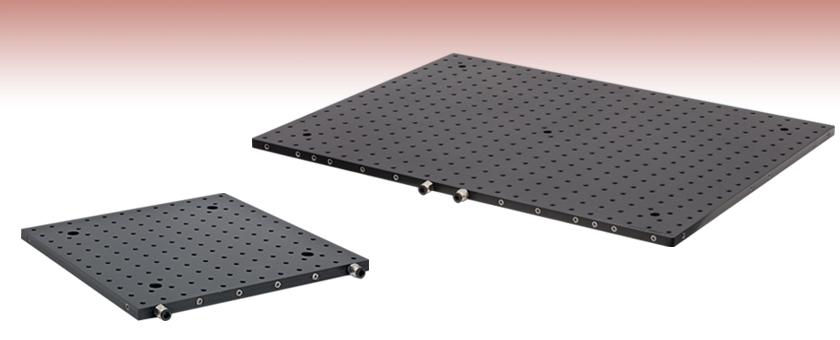

Water-Cooled Breadboards

- Cool or Heat Work Surface via Internal Water Channels (0 to 60 °C)

- Matte Black-Anodized Finish Reduces Reflections

- Through-Tapped Mounting Holes

MBC12

12" x 12"

Water-Cooled

Breadboard

MBC1824

18" x 24"

Water-Cooled

Breadboard

Please Wait

| Specification | Imperial Boards | Metric Boards |

|---|---|---|

| Breadboard Specifications | ||

| Material | Aluminum Plate | |

| Finish | Matte Black Anodized | |

| Thickness | 0.5" | 12.7 mm |

| Flatness | ±0.006" over 1 ft2 | ±0.15 mm over 0.3 m2 |

| Hole Size and Spacing | 1/4"-20 Tapped Holes on 1" Centers |

M6 Tapped Holes on 25 mm Centers |

| Distance from Edge to First Hole |

0.50" on All Sides | 12.5 mm on All Sides |

| Number of Counterbored Holesa |

Four 1/4" Located at Corners - Inset 2" |

Four M6 Located at Corners - Inset 50 mm |

| Water Channel Specifications | ||

| Pressure Rating | 80 psi | |

| Operating Temperature Range | 0 °C to 60 °C | |

| Push-Fit Pipe Fitting Inner Diameter |

1/4" | 6 mm |

Click for Details

Click for DetailsCutaway of the MBC1824 Breadboard Showing Water Channels, Fittings, and Plugs

Features

- Standard Metric and Imperial Hole Patterns

- Black-Anodized Surface with Low Reflectance

- Working Pressure: Rated up to 80 psi

- Operating Temperature Range: 0 to 60 °C

- Offset Mounting Counterbores Allow a Full, Uninterrupted, Threaded Hole Matrix

- Larger Breadboards Have a Fifth Centrally-Located Counterbore

- Imperial: At Least 18" Wide

- Metric: At Least 450 mm Wide

Thorlabs' Water-Cooled Breadboards are versions of our anodized aluminum breadboards that have been plumbed to accept a water or coolant supply. They feature a standard 1" (25 mm) hole pattern and are ideal for applications involving sensors, detectors, lasers, LEDs, or other apparatuses that may require temperature stabilization. These boards can be used in applications requiring cooling or heating.

Each breadboard has two fittings that accept tubing with 1/4" (6 mm) outer diameter. These fittings allow for easy connection to a water or coolant supply such as our LK220 liquid chiller. 16' (5 m) of polyurethane connection tubing is included with each breadboard and can be trimmed to suit the particular application. To do so, simply cut the tubing to the required length, trim the tubing edges flush, insert the tubing into the push-to-fit connectors, and connect the other end to your water supply/chiller unit. We offer separate polyurethane hoses with 11/64" inner diameter (ID) and 1/4" outer diameter (OD), or with 1/4" ID and 3/8" OD. Coupling inserts and bodies for both sizes are available for connecting between these hoses, including coupling between the two sizes.

Depending on the environmental temperature and humidity levels and the temperature of the board, condensation can form on the breadboard surface. Please see the table below and to the right for guidelines on how this can be avoided.

| Operating Temperature and Condensationa | |||

|---|---|---|---|

| Relative Air Humidity (RH%) |

Temperature Differenceb (ΔT ºC) |

Relative Air Humidity (RH%) |

Temperature Differenceb (ΔT ºC) |

| 95% | 1 ºC | 55% | 9 - 12 ºC |

| 90% | 2 ºC | 50% | 10 - 13 ºC |

| 85% | 2 - 3 ºC | 45% | 12 - 14 ºC |

| 80% | 3 - 4 ºC | 40% | 13 - 17 ºC |

| 75% | 4 - 5 ºC | 35% | 16 - 19 ºC |

| 70% | 5 - 6 ºC | 30% | 18 - 21 ºC |

| 65% | 6 - 8 ºC | 25% | 21 - 23 ºC |

| 60% | 7 - 9 ºC | 20% | 24 - 27 ºC |

Each breadboard features four or five mounting holes, offset from the array of 1/4"-20 (M6) threaded holes, which are counterbored to create an uninterrupted surface for any intended application. The four standard mounting holes are located at each corner of the breadboard, inset 2" (50 mm) from each edge. The larger breadboards (imperial boards 18" or wider and metric boards 450 mm or wider) have a fifth counterbored mounting hole at their center. Utilizing the center mounting hole increases the number of mounting options available, reduces stress at the corner mounting holes, and increases rigidity when heavy loads are placed on the boards. The mounting holes may be used to attach the breadboards to optical tables, other breadboards, mounting posts, brackets, or a variety of other surfaces or mounts.

Other Breadboard Options

Thorlabs offers a variety of other breadboards, including damped honeycomb optical breadboards for applications sensitive to vibrations, solid aluminum breadboards with 1" (25 mm) or 1/2" (12.7 mm) hole spacings, and high-density optical breadboards compatible with our mini-series optomechanics. Please see the BB Selection Guide tab for our full range of breadboards.

For other cooled breadboard options, including temperature-controlled mini-series breadboards with internal thermoelectric cooling, see the Cooled BB Selection Guide tab.

Optical Breadboard Enclosures are available to protect sensitive equipment from dust, stray light, acoustic noise, and thermal variations. Enclosures are offered completely sealed or with sliding door access.

| Item # | Dimensions (L x W x H) |

Unpackaged | Packaged Shipping | ||

|---|---|---|---|---|---|

| Mass (kg) |

Weight (lbs) |

Mass (kg)a |

Weight (lbs)a |

||

| Imperial | |||||

| MBC12 | 12" x 12" x 0.5" | 2.70 | 5.95 | 4.00 | 8.82 |

| MBC1218 | 12" x 18" x 0.5" | 4.3 | 9.48 | 4.99 | 11.00 |

| MBC2412 | 12" x 24" x 0.5" | 5.7 | 12.57 | 7.00 | 15.43 |

| MBC1824 | 18" x 24" x 0.5" | 8.6 | 18.96 | 9.98 | 22.00 |

| Item # | Dimensions (L x W x H) |

Unpackaged | Packaged Shipping | ||

|---|---|---|---|---|---|

| Mass (kg) |

Weight (lbs) |

Mass (kg)a |

Weight (lbs)a |

||

| Metric | |||||

| MBC3030/M | 300 mm x 300 mm x 12.7 mm | 2.70 | 5.95 | 4.00 | 8.82 |

| MBC3045/M | 300 mm x 450 mm x 12.7 mm | 4.3 | 9.48 | 4.99 | 11.00 |

| MBC6030/M | 300 mm x 600 mm x 12.7 mm | 5.7 | 12.57 | 7.00 | 15.43 |

| MBC4560/M | 450 mm x 600 mm x 12.7 mm | 8.6 | 18.96 | 9.98 | 22.00 |

| Cooled Breadboard Selection Guide | |||

|---|---|---|---|

| Water-Cooled Breadboards | Liquid-Cooled Cold Plates | Temperature-Controlled Mini-Series Breadboard | |

| Representative Photos (Click to Enlarge) |  |

|

|

| Tapped Holes | 1/4"-20 (Imperial) M6 (Metric) |

1/4"-20, 8-32, 6-32, and 4-40 (Imperial) M6, M4, and 4-40 (Metric) |

1/4"-20 and 8-32 (Imperial) M6 and M4 (Metric) |

| Available Sizes (L x W x H) |

12" x 12" x 1/2" to 18" x 24" x 1/2" (Imperial) 300 x 300 x 12.7 mm to 450 x 600 x 12.7 mm (Metric) |

2" x 2" x 0.87" or 4" x 6" x 0.87" (Imperial) 50.8 x 50.8 x 22 mm or 101.6 x 152.4 x 22 mm (Metric) |

4" x 5" x 2.46" (Imperial) 101.6 x 127.0 x 62.5 mm (Metric) |

| Cooling | External Water or CDTX Coolant | External Water or CDTX Coolant | Internal Thermoelectric Cooler with Temperature Settable from 5 °C to 45 °C |

| Operating Temperature Range | 0 °C to 60 °C | -15 °C to 60 °C | 0 °C to 45 °C |

| Temperature Readout | None | TH10K Thermistor Readout Via 2.5 mm Stereo Jack | Automatic Temperature Control with TH10K Thermistor Readout to Software GUI Via USB |

| Mounting Options | 1/4" or 6 mm Counterbored Through Holes | Threaded Mounting Holes for Posts on Bottom and Sides, and Side Slots for Clamping to Table | Threaded Mounting Holes for Posts on Bottom and Sides, and Rubber Feet on Bottom |

| Breadboards |  Nexus, Optimized Damping |

Intrinsically Damped |

Aluminum Honeycomb |

Stainless Steel |

Solid Aluminum |

|---|---|---|---|---|---|

| Construction | |||||

| Breadboard Thickness | 60 mm (2.4") 110 mm (4.3") |

58 mm (2.28") | 25 mm (0.98") 55 mm (2.2") |

12.7 mm (0.5") | 7.0 mm (0.28") 9.5 mm (0.375") 12.7 mm (0.5") 19.05 mm (0.75") |

| Working Surface | 4003 Grade Stainless Steel or 304L Grade Nonmagnetic Steel Top Plate |

4003 Grade Stainless Steel Top Plate | Aluminum | 416 Grade Stainless Steel | Solid Aluminum Anodized or Unanodized |

| Top Skin | 5 mm (0.20") | 5 mm (0.20") | 6 mm (0.24") | N/A | N/A |

| Bottom Skin | 5 mm (0.20") | 3 mm (0.12") | 3 mm (0.12") | N/A | N/A |

| Core Design | High-Density Plated Steel Honeycomb, 0.26 mm Thick | High-Density Plated Aluminum Honeycomb | N/A | N/A | |

| Side Panels | Rigid Steel Box Section | Unplasticized Polyvinyl Chloride (uPVC) | Black Laminated Aluminum Sides |

N/A | N/A |

| Ferromagnetism | Magnetic or Non-Magnetic Options | Magnetic | Non-Magnetic | Magnetic | Non-Magnetic |

| Sealed Holes | Sealed (25 mm Depth) or Non-Sealed Options | Non-Sealed | N/A | N/A | |

| Thread Options | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6), 4-40 (M3), or 8-32 (M3) and 1/4"-20 (M6) Tapped Holes |

|

| Spacing | 1" (25 mm) Centers | 1" (25 mm) Centers | 1" (25 mm) Centers | 1" (25 mm) Centers or 0.5" (12.7 mm) Centers |

|

| Distance from Edge to First Holes |

0.5" (12.5 mm) on all Sides | 0.5" (12.5 mm) or 1.0" (25 mm) on all Sides |

0.5" (12.5 mm) on all Sides | 0.5" (12.5 mm) on all Sides | |

| Performancea | |||||

| Damping |  |

|

|

N/A | N/A |

| Stiffness |  60 mm (2.4") Thick |

58 mm (2.28") Thick |

25 mm (0.98") Thick |

12.7 mm (0.5") Thick |

7.0 mm (0.28") Thick |

110 mm (4.3") Thick |

55 mm (2.2") Thick |

19.05 mm (0.75") Thick |

|||

Optical Breadboard Selection Guides

The selection guides below list every size offered for our honeycomb, solid aluminum, and acrylic breadboards. Simply locate the specific width and length needed and then select the type of breadboard. Expand each table by clicking the More [+] button within the header.

Thorlabs also offers several unique breadboard solutions. For applications requiring temperature control, we offer anodized aluminum water cooled breadboards in several sizes, in addition to a temperature-controlled mini-series breadboard for small-scale operations. Our anodized aluminum large-area translation stages and rotating breadboards offer hand-operated positioning control, while our manual and motorized translating mounting platforms are ideal for use in microscopy applications.

| Imperial Optical Breadboard Size Options | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Honeycomb | Stainless Steel | Solid Aluminuma | ||||||

| Nexus (60 mm Thick)b |

Nexus (110 mm Thick)b |

Intrinsically Damped (58 mm Thick) |

Aluminum (25 mm Thick) |

Aluminum (55 mm Thick) |

Standard | Double Density | High Density | |||

| Metric Optical Breadboard Size Options | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Honeycomb | Stainless Steel | Solid Aluminuma | ||||||

| Nexus (60 mm Thick)b |

Nexus (110 mm Thick)b |

Intrinsically Damped (58 mm Thick) |

Aluminum (25 mm Thick) |

Aluminum (55 mm Thick) |

Standard | Double Density | High Density | |||

| 50 mm | 75 mm | - | - | - | - | - | - | - | - | MSB5075/M |

| 75 mm | 100 mm | - | - | - | - | - | - | - | - | MSB7510/M |

| 75 mm | 150 mm | - | - | - | - | - | - | - | - | MSB7515/M |

| 100 mm | 100 mm | - | - | - | - | - | MB10S/M | - | - | - |

| 100 mm | 150 mm | - | - | - | - | - | MB1015S/M | MB1015/M MB1015U/M |

M45B1015/Mc | MSB1015/M |

| 100 mm | 300 mm | - | - | - | - | - | - | MB1030/M | - | - |

| 100 mm | 600 mm | - | - | - | - | - | - | - | MB1060/M | - |

| 100 mm | 900 mm | - | - | - | - | - | - | - | MB1090/M | - |

| Ø149 mm | - | - | - | - | - | - | - | MBR150U/M | - | |

| Ø150 mm | - | - | - | - | - | - | - | MBR150/M | - | |

| 150 mm | 150 mm | - | - | - | - | - | MB15S/M | MB1515/M MB1515U/M |

M45B1515/Mc | MSB15/M |

| 150 mm | 300 mm | - | - | - | - | - | - | MB1530F/M | MB1530/M M45B1530/Mc |

- |

| 150 mm | 450 mm | - | - | - | - | - | - | MB1545/M | - | - |

| 150 mm | 600 mm | - | - | - | - | - | - | MB1560/M | - | - |

| 150 mm | 900 mm | - | - | - | - | - | - | MB1590/M | - | - |

| 150 mm | 1200 mm | - | - | - | - | - | - | MB15120/M | - | - |

| 180 mm | 230 mm | - | - | - | - | - | - | - | - | MSB1823/M MSBU1823/M |

| 200 mm | 200 mm | - | - | - | - | - | - | MB2020/M MB2020U/M |

- | - |

| 200 mm | 250 mm | - | - | - | - | - | - | MB2025/M | - | - |

| 200 mm | 600 mm | - | - | - | - | - | - | - | MB2060/M | - |

| 200 mm | 900 mm | - | - | - | - | - | - | - | MB2090/M | - |

| 250 mm | 300 mm | - | - | - | - | - | - | MB2530/M MB2530U/M |

- | - |

| Ø300 mm | - | - | - | - | - | - | - | MBR300/M MBR300U/M |

- | |

| 300 mm | 300 mm | B3030Ad B3030Ld |

- | - | PBG3030Ae | - | - | MB3030/M MB3030U/M |

MB3030D/M | MS12B/M MSB30/M |

| 300 mm | 450 mm | B3045Ad B3045Ld |

- | B3045AX | PBG3045Ae | - | - | MB3045/M MB3045A/Mf MB3045U/M |

- | MSB3045/M |

| 300 mm | 600 mm | B3060Ad B3060L |

- | B3060AXd | PBG3060A | PBG52502d | - | MB3060/M MB3060U/M |

- | - |

| 300 mm | 900 mm | B3090Ad B3090Ld |

- | - | PBG3090Ae | PBG52503d | - | MB3090/M | - | - |

| 300 mm | 1200 mm | - | - | - | - | - | - | MB30120/M | - | - |

| 350 mm | 1150 mm | - | - | - | - | - | - | MB35115/M | - | - |

| 350 mm | 1425 mm | - | - | - | - | - | - | MB35142/M | - | - |

| 450 mm | 450 mm | B4545Ad B4545Ld |

- | - | PBG4545A | - | - | MB4545/M | - | - |

| 450 mm | 600 mm | B4560Ad B4560Ld |

- | B4560AXd | PBG4560Ae | PBG52522d | - | MB4560/M MB4560A/Mf MB4560U/M |

- | - |

| 450 mm | 750 mm | - | - | - | - | - | - | MB4575/M | - | - |

| 450 mm | 900 mm | - | - | - | - | - | - | MB4590/M | - | - |

| 600 mm | 600 mm | B6060Ad B6060L |

- | B6060AXd | PBG6060Ae | PBG52505d | - | MB6060/M | - | |

| 600 mm | 900 mm | B6090A B6090L B6090ANd B6090Z |

B6090Bd B6090Nd |

B6090AX | PBG6090Ae | PBG52506d | - | MB6090/M | - | - |

| 600 mm | 1200 mm | B60120A B60120L |

B60120Bd B60120Nd |

B60120AX | PBG60120Ae | - | - | MB60120/M | - | - |

| 600 mm | 1500 mm | - | B60150Bd B60150Nd |

- | - | PBG52508d | - | - | - | - |

| 750 mm | 750 mm | B7575A B7575L |

- | - | - | - | - | MB7575/M | - | - |

| 750 mm | 900 mm | B7590A B7590L B7590ANd B7590Z |

B7590Bd B7590Nd |

B7590AX | PBG7590Ae | PBG52510d | - | - | - | - |

| 750 mm | 1200 mm | B75120A B75120L B75120ANd B75120Z |

B75120B B75120Nd |

B75120AX | PBG75120Ae | PBG52511 | - | - | - | - |

| 750 mm | 1500 mm | - | B75150B B75150N |

B75150AX | - | - | - | - | - | - |

| 900 mm | 900 mm | B9090A B9090L |

B9090Bd B9090Nd |

- | - | - | - | - | - | - |

| 900 mm | 1200 mm | B90120A B90120L B90120AN B90120Z |

B90120B B90120N |

B90120AX | PBG90120Ae | PBG52513 | - | - | - | - |

| 900 mm | 1500 mm | - | B90150B B90150N |

B90150AX | - | PBG52514 | - | - | - | - |

| 900 mm | 1800 mm | - | B90180B B90180N |

B90180AX | - | - | - | - | - | - |

| 1200 mm | 1500 mm | - | B120150Bd B120150Nd |

- | - | - | - | - | - | - |

| 1200 mm | 1800 mm | - | B120180B B120180Nd |

- | - | - | - | - | - | - |

| Posted Comments: | |

Joshua Dawes

(posted 2024-05-13 15:33:27.803) Hello!

Does this come in a plain aluminum version for better thermal contact? If not, would you have any issues with my team skimming off .030-.050" of material to remove the finish?

Thank you cstroud

(posted 2024-05-21 11:57:38.0) Thanks for reaching out. We are able to provide un-anodised versions of the water-cooled breadboards. I will contact you directly to discuss this further. Philipp K

(posted 2023-03-08 12:54:44.293) Hi,

is it possbile to change the position of the fittings? E.g. by swapping a plug with a fitting?

Best regards fguzman

(posted 2023-03-08 11:41:41.0) Unfortunately this is not possible, as each breadboard has a specific internal configuration to help obtain an even flow and cooling along its volume. Andrew Chuang

(posted 2022-11-10 15:16:45.283) Can you make smaller water-cooled breadboard? like 4"x6" or similar?

WCP4X6 product line is too thick (22mm) and doesn't have enough mounting hole on the bottom side. ksosnowski

(posted 2022-11-17 12:06:13.0) Thanks for reaching out to Thorlabs. Unfortunately, we cannot provide any custom water cooled breadboards at this time. I have reached out directly for more details about your ideal application so we can consider this for further developments. Mikkel Bregnhøj

(posted 2021-03-23 05:37:51.957) Dear Thorlabs

Would you consider to also manufacture these watercooled breadboards in smaller sizes?

For example, 10x10 or 10x15 cm would be very useful.

Kind regards

//Mikkel Bregnhøj cwright

(posted 2021-03-23 09:09:07.0) Response from Charles at Thorlabs: Hello Mikkel and thank you for your feedback. It is always good for us to hear the needs of our customers directly and we will take this into consideration for future product reviews. jens.kiessling

(posted 2016-04-29 08:44:22.3) Dear Thorlabs team,

which cooling liquid do you recommend for these breadboards? Where can we get it in Germany? Distilled water is getting dark very fast when used in these breadboards, possibly corrosion? msoulby

(posted 2016-04-29 08:44:05.0) Response from Mike at Thorlabs: The water could be becoming coloured due to residue left from the machining process so it may be worth flushing the breadboard before using again. We do not have an special requirements for the water used in the water cooled breadboards as aluminium is typically resistant to corrosion, however non-chlorinated water would be best. makarov

(posted 2014-08-18 17:11:40.337) What's the thread behind the water connectors, and what is the bore diameter of the channels? We are thinking of using it with different connectors. msoulby

(posted 2014-08-22 05:21:01.0) Response from Mike at Thorlabs: The tapped thread size is 1/8 BSPT with a thread depth of 13.0mm bdada

(posted 2011-12-07 12:44:00.0) Response from Buki at Thorlabs:

We are looking into your request for a larger water cooled breadboard and will contact you directly with more information. Please contact TechSupport@thorlabs.com if you have any questions. johannes.kaschke

(posted 2011-12-07 05:48:31.0) Would it be possible to get a custom made 300mm x 600mm version? user

(posted 2010-07-30 12:06:45.0) Wow. That is Cool. Nice work guys. |

| Hoses and Fittings | ||||

|---|---|---|---|---|

| Hose Item # | OD | ID | Compatible Coupling Insert |

Compatible Coupling Body |

| HPU6 | 1/4" | 11/64" | QVF6 | QVM6 |

| HPU9 | 3/8" | 1/4" | QVF9 | QVM9 |

- 5 m Long Polyurethane Hoses Available in Two Sizes:

- 1/4" Outer Diameter and 11/64" Inner Diameter

- 3/8" Outer Diameter and 1/4" Inner Diameter

- Natural White Acetal Coupling Fittings and Inserts with BUNA-N Seals

- Can Withstand 120 psi of Pressure

Thorlabs offers various polyurethane hoses and coupling inserts that allow for easy connection to a water or coolant supply. All items can withstand up to 120 psi of pressure and can be used with water, ethanol-based coolants, or any glycol-based coolant, such as our CDTX Coolant.

The 5 m Long Polyurethane (PU) Hoses have an inner diameter (ID) of 11/64" or 1/4" and outer diameter (OD) of 1/4" or 3/8". These hoses can be used in temperatures from -15 to 60 °C. These hoses are intended to be used alongside our in-line 1/4” OD or 3/8” OD coupling inserts and bodies.

The inserts have male connection ports, while the bodies have female connectors with a self-lock structure for secure connection. Inserts and bodies are intended to be used in pairs, as any coupling insert can mate with any coupling body. The QVF6 coupling body and QVM6 coupling insert can support HPU6 tubing with a 11/64" ID and 1/4" OD, while the QVF9 coupling insert and QVM9 coupling body can support HPU9 tubing with a 1/4" ID and 3/8" OD.

The HPU6 1/4" OD hose is directly compatible with our Water-Cooled Breadboards, while the HPU9 3/8" OD hose can be adapted to be compatible using a QVF6 insert and a QVM9 body, or a QVF9 insert and a QVM6 body.

The hoses, inserts, and bodies can be used for quick connections to a variety of other Thorlabs catalog items, including our LK220 Liquid Chiller, Liquid-Cooled Cold Plates, Spatial Light Modulators, and Liquid-Cooled HHL Laser Mount. The inserts and bodies can be used to convert from 1/4" ID to 11/64" ID hose for any application.

Products Home

Products Home

Zoom

Zoom Water-Cooled Breadboards

Water-Cooled Breadboards