Passivated Stainless Steel Breadboards

- Through-Tapped 1/4"-20 (M6) Mounting Holes

- Custom Sizes Available

- Out-of-the-Box Vacuum Compatible Down to 10-6 Torr

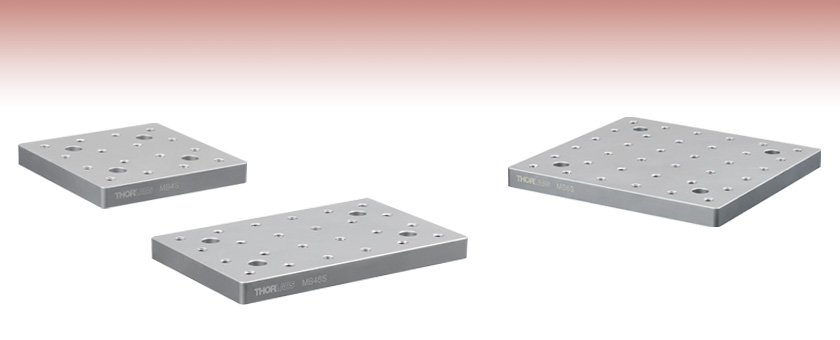

MB4S

4" x 4"

1/4"-20 Taps

MB46S

4" x 6"

1/4"-20 Taps

MB6S

6" x 6"

1/4"-20 Taps

Please Wait

| Specification | Imperial Boards | Metric Boards |

|---|---|---|

| Material | 416 Stainless Steel | |

| Flatness | ±0.006" over 1 ft2 | ±0.15 mm over 0.09 m2 |

| Breadboard Thickness | 1/2" | 12.7 mm |

| Hole Size and Spacing | 1/4"-20 Tapped Holes on 1" Centers |

M6 Tapped Holes on 25 mm Centers |

| Distance from Edge to First Hole |

1/2" on All Sides | 12.5 mm on All Sides |

| Number of Counterbored Holes | Four 1/4" Located at Corners Inset 1" | Four M6 Located at Corners Inset 25 mm |

Click to Enlarge

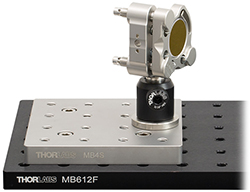

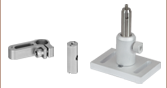

Stainless Steel Breadboard Mounted to Aluminum Breadboard for Magnetic Components

Click to Enlarge

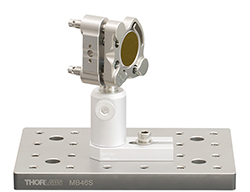

Stainless Steel Breadboard with Vacuum Compatible Components

Features

- Passivated Stainless Steel Breadboards

- Vacuum-Compatible Down to 10-6 Torr Out of the Box

- May be Attached to our Aluminum Breadboards to Add Magnetic Capabilities

- Standard Imperial (1/4"-20) and Metric (M6) Breadboard Hole Patterns

- Offset Counterbored Mounting Holes Allow a Full, Uninterrupted, Threaded Hole Matrix

Thorlabs' passivated stainless steel, 1/2" (12.7 mm) thick breadboards provide a stiff, magnetic, and vacuum-compatible surface for mounting small subsystems. Breadboards are through tapped in a standard 1" (imperial) or 25 mm (metric) hole pattern offset 1/2" or 12.5 mm, respectively, from the edges of the board. Four standard 1/4" (M6) mounting holes are counterbored to create an uninterrupted surface for your application.

The 1/4"-20 (M6) tapped holes are threaded completely through these breadboards, allowing components to be mounted on either side. The four standard mounting holes are located at each corner of the breadboard, inset 1" from each edge on imperial breadboards (25 mm on metric). Ø1.5" mounting posts can increase the height of these breadboards by securing them to the surface of an optical table (or another breadboard). The counterbored mounting holes allow for these breadboards to be attached to any of our non-magnetic aluminum breadboards, providing a means to use magnetic bases or other magnetic accessories. The mounting holes may be used to attached the breadboards to optical tables, other breadboards, mounting posts, brackets, or a variety of other surfaces or mounts.

These breadboards may also be used within a vacuum environment down to 10-6 Torr. After passivation, breadboards are double bagged in a clean environment to eliminate contamination when transported into a cleanroom. Gloves should be used when handling breadboards to prevent surface contamination from skin oils. For use in a sensitive vacuum system, a thorough pre-baking in a bake-out oven should be performed to remove all moisture and surface volatiles. Additional cleaning may be needed depending on the system requirements. For additional information on preparing these breadboards for vacuum applications, please contact Tech Support.

Custom sizes are available; contact Tech Support for more information. We also offer a broad selection of solid aluminum breadboards and steel and aluminum honeycomb breadboards. For vacuum chamber applications, unanodized solid aluminum breadboards are also available in a variety of sizes. For a quick comparison of our different breadboard options, please see the BB Selection Guide tab.

| Item # | Dimensions (L x W x H)a |

Unpackaged Weight |

Packaged Shipping Weightb |

|---|---|---|---|

| Imperial | |||

| MB4S | 4" x 4" x 1/2" | 2.45 lbs | 2.73 lbs |

| MB46S | 4" x 6" x 1/2" | 3.51 lbs | 3.81 lbs |

| MB6S | 6" x 6" x 1/2" | 5.16 lbs | 5.45 lbs |

| Metric | |||

| MB10S/M | 100 mm x 100 mm x 12.7 mm | 1.11 kg | 1.24 kg |

| MB1015S/M | 100 mm x 150 mm x 12.7 mm | 1.59 kg | 1.73 kg |

| MB15S/M | 150 mm x 150 mm x 12.7 mm | 2.34 kg | 2.46 kg |

| Posted Comments: | |

Ludo Angot

(posted 2019-09-11 15:25:22.53) Hello, this is a nice addition to your product line and I've ordered one of these. However, for the use case of adding magnetic functionality to an aluminum breadboard, may I suggest you offer a thinner version of these breadboards? You could for example use the same 5 mm thickness as your Nexus series steel skin. The newly designed steel breadboard could be blank with just 4 mounting holes to attach to an existing breadboard or have a set of clearance holes with the same spacing as metric or imperial breadboards. This design would be more economical for your customers and serves the useful purpose of having a magnetic flat surface. llamb

(posted 2019-09-11 11:35:06.0) Thank you for your feedback! I have added this idea to our internal product forum for further review. |

| Breadboards |  Nexus, Optimized Damping |

Intrinsically Damped |

Aluminum Honeycomb |

Stainless Steel |

Solid Aluminum |

|---|---|---|---|---|---|

| Construction | |||||

| Breadboard Thickness | 60 mm (2.4") 110 mm (4.3") |

58 mm (2.28") | 25 mm (0.98") 55 mm (2.2") |

12.7 mm (0.5") | 7.0 mm (0.28") 9.5 mm (0.375") 12.7 mm (0.5") 19.05 mm (0.75") |

| Working Surface | 4003 Grade Stainless Steel or 304L Grade Nonmagnetic Steel Top Plate |

4003 Grade Stainless Steel Top Plate | Aluminum | 416 Grade Stainless Steel | Solid Aluminum Anodized or Unanodized |

| Top Skin | 5 mm (0.20") | 5 mm (0.20") | 6 mm (0.24") | N/A | N/A |

| Bottom Skin | 5 mm (0.20") | 3 mm (0.12") | 3 mm (0.12") | N/A | N/A |

| Core Design | High-Density Plated Steel Honeycomb, 0.26 mm Thick | High-Density Plated Aluminum Honeycomb | N/A | N/A | |

| Side Panels | Rigid Steel Box Section | Unplasticized Polyvinyl Chloride (uPVC) | Black Laminated Aluminum Sides |

N/A | N/A |

| Ferromagnetism | Magnetic or Non-Magnetic Options | Magnetic | Non-Magnetic | Magnetic | Non-Magnetic |

| Sealed Holes | Sealed (25 mm Depth) or Non-Sealed Options | Non-Sealed | N/A | N/A | |

| Thread Options | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6), 4-40 (M3), or 8-32 (M3) and 1/4"-20 (M6) Tapped Holes |

|

| Spacing | 1" (25 mm) Centers | 1" (25 mm) Centers | 1" (25 mm) Centers | 1" (25 mm) Centers or 0.5" (12.7 mm) Centers |

|

| Distance from Edge to First Holes |

0.5" (12.5 mm) on all Sides | 0.5" (12.5 mm) or 1.0" (25 mm) on all Sides |

0.5" (12.5 mm) on all Sides | 0.5" (12.5 mm) on all Sides | |

| Performancea | |||||

| Damping |  |

|

|

N/A | N/A |

| Stiffness |  60 mm (2.4") Thick |

58 mm (2.28") Thick |

25 mm (0.98") Thick |

12.7 mm (0.5") Thick |

7.0 mm (0.28") Thick |

110 mm (4.3") Thick |

55 mm (2.2") Thick |

19.05 mm (0.75") Thick |

|||

Optical Breadboard Selection Guides

The selection guides below list every size offered for our honeycomb, solid aluminum, and acrylic breadboards. Simply locate the specific width and length needed and then select the type of breadboard. Expand each table by clicking the More [+] button within the header.

Thorlabs also offers several unique breadboard solutions. For applications requiring temperature control, we offer anodized aluminum water cooled breadboards in several sizes, in addition to a temperature-controlled mini-series breadboard for small-scale operations. Our anodized aluminum large-area translation stages and rotating breadboards offer hand-operated positioning control, while our manual and motorized translating mounting platforms are ideal for use in microscopy applications.

| Imperial Optical Breadboard Size Options | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Honeycomb | Stainless Steel | Solid Aluminuma | ||||||

| Nexus (60 mm Thick)b |

Nexus (110 mm Thick)b |

Intrinsically Damped (58 mm Thick) |

Aluminum (25 mm Thick) |

Aluminum (55 mm Thick) |

Standard | Double Density | High Density | |||

| Metric Optical Breadboard Size Options | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Honeycomb | Stainless Steel | Solid Aluminuma | ||||||

| Nexus (60 mm Thick)b |

Nexus (110 mm Thick)b |

Intrinsically Damped (58 mm Thick) |

Aluminum (25 mm Thick) |

Aluminum (55 mm Thick) |

Standard | Double Density | High Density | |||

| 50 mm | 75 mm | - | - | - | - | - | - | - | - | MSB5075/M |

| 75 mm | 100 mm | - | - | - | - | - | - | - | - | MSB7510/M |

| 75 mm | 150 mm | - | - | - | - | - | - | - | - | MSB7515/M |

| 100 mm | 100 mm | - | - | - | - | - | MB10S/M | - | - | - |

| 100 mm | 150 mm | - | - | - | - | - | MB1015S/M | MB1015/M MB1015U/M |

M45B1015/Mc | MSB1015/M |

| 100 mm | 300 mm | - | - | - | - | - | - | MB1030/M | - | - |

| 100 mm | 600 mm | - | - | - | - | - | - | - | MB1060/M | - |

| 100 mm | 900 mm | - | - | - | - | - | - | - | MB1090/M | - |

| Ø149 mm | - | - | - | - | - | - | - | MBR150U/M | - | |

| Ø150 mm | - | - | - | - | - | - | - | MBR150/M | - | |

| 150 mm | 150 mm | - | - | - | - | - | MB15S/M | MB1515/M MB1515U/M |

M45B1515/Mc | MSB15/M |

| 150 mm | 300 mm | - | - | - | - | - | - | MB1530F/M | MB1530/M M45B1530/Mc |

- |

| 150 mm | 450 mm | - | - | - | - | - | - | MB1545/M | - | - |

| 150 mm | 600 mm | - | - | - | - | - | - | MB1560/M | - | - |

| 150 mm | 900 mm | - | - | - | - | - | - | MB1590/M | - | - |

| 150 mm | 1200 mm | - | - | - | - | - | - | MB15120/M | - | - |

| 180 mm | 230 mm | - | - | - | - | - | - | - | - | MSB1823/M MSBU1823/M |

| 200 mm | 200 mm | - | - | - | - | - | - | MB2020/M MB2020U/M |

- | - |

| 200 mm | 250 mm | - | - | - | - | - | - | MB2025/M | - | - |

| 200 mm | 600 mm | - | - | - | - | - | - | - | MB2060/M | - |

| 200 mm | 900 mm | - | - | - | - | - | - | - | MB2090/M | - |

| 250 mm | 300 mm | - | - | - | - | - | - | MB2530/M MB2530U/M |

- | - |

| Ø300 mm | - | - | - | - | - | - | - | MBR300/M MBR300U/M |

- | |

| 300 mm | 300 mm | B3030Ad B3030Ld |

- | - | PBG3030Ae | - | - | MB3030/M MB3030U/M |

MB3030D/M | MS12B/M MSB30/M |

| 300 mm | 450 mm | B3045Ad B3045Ld |

- | B3045AX | PBG3045Ae | - | - | MB3045/M MB3045A/Mf MB3045U/M |

- | MSB3045/M |

| 300 mm | 600 mm | B3060Ad B3060L |

- | B3060AXd | PBG3060A | PBG52502d | - | MB3060/M MB3060U/M |

- | - |

| 300 mm | 900 mm | B3090Ad B3090Ld |

- | - | PBG3090Ae | PBG52503d | - | MB3090/M | - | - |

| 300 mm | 1200 mm | - | - | - | - | - | - | MB30120/M | - | - |

| 350 mm | 1150 mm | - | - | - | - | - | - | MB35115/M | - | - |

| 350 mm | 1425 mm | - | - | - | - | - | - | MB35142/M | - | - |

| 450 mm | 450 mm | B4545Ad B4545Ld |

- | - | PBG4545A | - | - | MB4545/M | - | - |

| 450 mm | 600 mm | B4560Ad B4560Ld |

- | B4560AXd | PBG4560Ae | PBG52522d | - | MB4560/M MB4560A/Mf MB4560U/M |

- | - |

| 450 mm | 750 mm | - | - | - | - | - | - | MB4575/M | - | - |

| 450 mm | 900 mm | - | - | - | - | - | - | MB4590/M | - | - |

| 600 mm | 600 mm | B6060Ad B6060L |

- | B6060AXd | PBG6060Ae | PBG52505d | - | MB6060/M | - | |

| 600 mm | 900 mm | B6090A B6090L B6090ANd B6090Z |

B6090Bd B6090Nd |

B6090AX | PBG6090Ae | PBG52506d | - | MB6090/M | - | - |

| 600 mm | 1200 mm | B60120A B60120L |

B60120Bd B60120Nd |

B60120AX | PBG60120Ae | - | - | MB60120/M | - | - |

| 600 mm | 1500 mm | - | B60150Bd B60150Nd |

- | - | PBG52508d | - | - | - | - |

| 750 mm | 750 mm | B7575A B7575L |

- | - | - | - | - | MB7575/M | - | - |

| 750 mm | 900 mm | B7590A B7590L B7590ANd B7590Z |

B7590Bd B7590Nd |

B7590AX | PBG7590Ae | PBG52510d | - | - | - | - |

| 750 mm | 1200 mm | B75120A B75120L B75120ANd B75120Z |

B75120B B75120Nd |

B75120AX | PBG75120Ae | PBG52511 | - | - | - | - |

| 750 mm | 1500 mm | - | B75150B B75150N |

B75150AX | - | - | - | - | - | - |

| 900 mm | 900 mm | B9090A B9090L |

B9090Bd B9090Nd |

- | - | - | - | - | - | - |

| 900 mm | 1200 mm | B90120A B90120L B90120AN B90120Z |

B90120B B90120N |

B90120AX | PBG90120Ae | PBG52513 | - | - | - | - |

| 900 mm | 1500 mm | - | B90150B B90150N |

B90150AX | - | PBG52514 | - | - | - | - |

| 900 mm | 1800 mm | - | B90180B B90180N |

B90180AX | - | - | - | - | - | - |

| 1200 mm | 1500 mm | - | B120150Bd B120150Nd |

- | - | - | - | - | - | - |

| 1200 mm | 1800 mm | - | B120180B B120180Nd |

- | - | - | - | - | - | - |

Products Home

Products Home

Solid Stainless Steel Breadboards

Solid Stainless Steel Breadboards