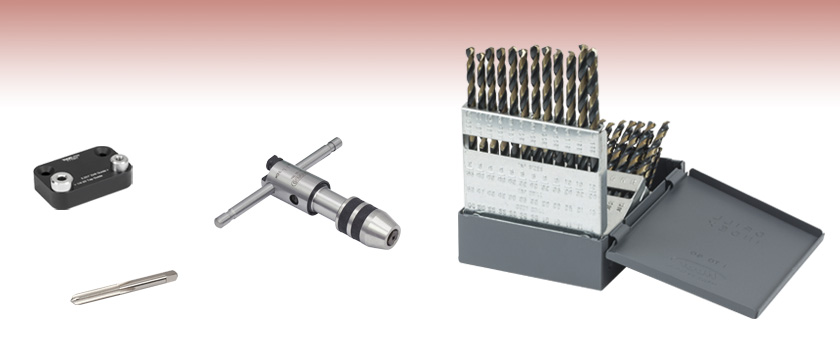

Taps and Drill Bit Kit

- Individual Imperial & Metric Plug Taps

- 60-Piece Drill Bit Kit

- Tap Guides Help Ensure Tapped Holes are

Perpendicular to Flat Surfaces

TTT001

Tap Guide for Optical Tables and Breadboards

TAP1480

1/4"-80 Tap

TW25

Tap Wrench

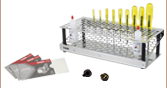

DK3

60-Piece Drill Bit Kit

Please Wait

Click to Enlarge

The TAPSM1 Imperial Tap for Tapping Thorlabs' SM1 Standard Threads

Click to Enlarge

The TAPSM05 Imperial Tap for Tapping Thorlabs' SM05 Standard Threads

Features

- Wide Selection of Plug Taps Including Thorlabs' SM05 (0.535"-40) and SM1 (1.035"-40) Standards

- Drill Kit Includes 60 Drill Bits in an Embossed Steel Case

- Universal Tap Wrench is an Essential Tool for Custom Applications

- Table and Breadboard Tapping Guide for Repairing Damaged Tapped Holes

The items on this webpage can be used to add taps in user-selected locations and repair damaged tapped holes on breadboards and optical tables.

| SM05 Threading: Ø1/2" Lens Tubes, 16 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 0.535"-40.0 UNS-2A | Internal Thread, 0.535"-40.0 UNS-2B | ||

| Max Major Diameter | 0.5340" | Min Major Diameter | 0.5350" |

| Min Major Diameter | 0.5289" | Min Pitch Diameter | 0.5188" |

| Max Pitch Diameter | 0.5178" | Max Pitch Diameter | 0.5230" |

| Min Pitch Diameter | 0.5146" | Min Minor Diameter (and 83.3% of Thread) | 0.508" |

| Max Minor Diameter | 0.5069" | Max Minor Diameter (and 64.9% of Thread) | 0.514" |

| RMS Threading: Objective, Scan, and Tube Lenses | |||

|---|---|---|---|

| External Thread, 0.800"-36.0 UNS-2A | Internal Thread, 0.800"-36.0 UNS-2B | ||

| Max Major Diameter | 0.7989" | Min Major Diameter | 0.8000" |

| Min Major Diameter | 0.7934" | Min Pitch Diameter | 0.7820" |

| Max Pitch Diameter | 0.7809" | Max Pitch Diameter | 0.7866" |

| Min Pitch Diameter | 0.7774" | Min Minor Diameter (and 83.3% of Thread) | 0.770" |

| Max Minor Diameter | 0.7688" | Max Minor Diameter (and 64.9% of Thread) | 0.777" |

| C-Mount Threading: Machine Vision Lenses, CCD/CMOS Cameras | |||

|---|---|---|---|

| External Thread, 1.000"-32.0 UN-2A | Internal Thread, 1.000"-32.0 UN-2B | ||

| Max Major Diameter | 0.9989" | Min Major Diameter | 1.0000" |

| Min Major Diameter | 0.9929" | Min Pitch Diameter | 0.9797" |

| Max Pitch Diameter | 0.9786" | Max Pitch Diameter | 0.9846" |

| Min Pitch Diameter | 0.9748" | Min Minor Diameter (and 83.3% of Thread) | 0.966" |

| Max Minor Diameter | 0.9651" | Max Minor Diameter (and 64.9% of Thread) | 0.974" |

| SM1 Threading: Ø1" Lens Tubes, 30 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 1.035"-40.0 UNS-2A | Internal Thread, 1.035"-40.0 UNS-2B | ||

| Max Major Diameter | 1.0339" | Min Major Diameter | 1.0350" |

| Min Major Diameter | 1.0288" | Min Pitch Diameter | 1.0188" |

| Max Pitch Diameter | 1.0177" | Max Pitch Diameter | 1.0234" |

| Min Pitch Diameter | 1.0142" | Min Minor Diameter (and 83.3% of Thread) | 1.008" |

| Max Minor Diameter | 1.0068" | Max Minor Diameter (and 64.9% of Thread) | 1.014" |

| SM30 Threading: Ø30 mm Lens Tubes | |||

|---|---|---|---|

| External Thread, M30.5 x 0.5 – 6H/6g | Internal Thread, M30.5 x 0.5 – 6H/6g | ||

| Max Major Diameter | 30.480 mm | Min Major Diameter | 30.500 mm |

| Min Major Diameter | 30.371 mm | Min Pitch Diameter | 30.175 mm |

| Max Pitch Diameter | 30.155 mm | Max Pitch Diameter | 30.302 mm |

| Min Pitch Diameter | 30.059 mm | Min Minor Diameter (and 83.3% of Thread) | 29.959 mm |

| Max Minor Diameter | 29.938 mm | Max Minor Diameter (and 64.9% of Thread) | 30.094 mm |

| SM1.5 Threading: Ø1.5" Lens Tubes | |||

|---|---|---|---|

| External Thread, 1.535"-40 UNS-2A | Internal Thread, 1.535"-40 UNS-2B | ||

| Max Major Diameter | 1.5339" | Min Major Diameter | 1.535" |

| Min Major Diameter | 1.5288" | Min Pitch Diameter | 1.5188" |

| Max Pitch Diameter | 1.5177" | Max Pitch Diameter | 1.5236" |

| Min Pitch Diameter | 1.5140" | Min Minor Diameter (and 83.3% of Thread) | 1.508" |

| Max Minor Diameter | 1.5068" | Max Minor Diameter (and 64.9% of Thread) | 1.514" |

| SM2 Threading: Ø2" Lens Tubes, 60 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 2.035"-40.0 UNS-2A | Internal Thread, 2.035"-40.0 UNS-2B | ||

| Max Major Diameter | 2.0338" | Min Major Diameter | 2.0350" |

| Min Major Diameter | 2.0287" | Min Pitch Diameter | 2.0188" |

| Max Pitch Diameter | 2.0176" | Max Pitch Diameter | 2.0239" |

| Min Pitch Diameter | 2.0137" | Min Minor Diameter (and 83.3% of Thread) | 2.008" |

| Max Minor Diameter | 2.0067" | Max Minor Diameter (and 64.9% of Thread) | 2.014" |

| SM3 Threading: Ø3" Lens Tubes | |||

|---|---|---|---|

| External Thread, 3.035"-40.0 UNS-2A | Internal Thread, 3.035"-40.0 UNS-2B | ||

| Max Major Diameter | 3.0337" | Min Major Diameter | 3.0350" |

| Min Major Diameter | 3.0286" | Min Pitch Diameter | 3.0188" |

| Max Pitch Diameter | 3.0175" | Max Pitch Diameter | 3.0242" |

| Min Pitch Diameter | 3.0133" | Min Minor Diameter (and 83.3% of Thread) | 3.008" |

| Max Minor Diameter | 3.0066" | Max Minor Diameter (and 64.9% of Thread) | 3.014" |

| SM4 Threading: Ø4" Lens Tubes | |||

|---|---|---|---|

| External Thread, 4.035"-40 UNS-2A | Internal Thread, 4.035"-40.0 UNS-2B | ||

| Max Major Diameter | 4.0337" | Min Major Diameter | 4.0350" |

| Min Major Diameter | 4.0286" | Min Pitch Diameter | 4.0188" |

| Max Pitch Diameter | 4.0175" | Max Pitch Diameter | 4.0245" |

| Min Pitch Diameter | 4.0131" | Min Minor Diameter (and 83.3% of Thread) | 4.008" |

| Max Minor Diameter | 4.0066" | Max Minor Diameter (and 64.9% of Thread) | 4.014" |

| Posted Comments: | |

user

(posted 2024-05-13 21:30:09.42) What is the distance from the bottom of the sm05 tap to the first full thread? cdolbashian

(posted 2024-05-24 09:55:56.0) As the taper on the threads are approximately 5-6 threads deep and the thread pitch is ~.635mm. As such the first full thread starts at around 3-4mm. I have contacted you directly to discuss your application and your need for a perhaps-more-specific value. Kyle Douglass

(posted 2024-03-28 08:32:33.53) Hello!

Would you also happen to sell dies for creating SM1 external threads? I've only been able to find taps on your website.

Many thanks. jdelia

(posted 2024-03-28 01:08:31.0) Thank you for contacting Thorlabs. We unfortunately do not currently offer dies as part of our catalog. I have reached out to you directly to discuss alternative vendors. chua ss

(posted 2023-10-26 15:51:12.683) Dear Sir/Madam,

Kindly quote us the current price and the shipping charges as below ;

1. MACHINE TAP (THOR) PO 0.535" X 40

Q’ty : 5pcs

Your prompt reply on the above mentioned is highly appreciated.

Thanks and Regards.

S.S. Chua (Ms)

Purchase Coordinator

Creative Precision Engineering Sdn. Bhd. [CO. NO :199101017821 (228132-T)]

32, Lorong IKS Juru 3, IKS Juru,

14100 Simpang Ampat,

Penang, Malaysia.

Tel : 604-5071330, Ext : 120

H/P : +012-5681921

Email : pur02@creative-pe.com jdelia

(posted 2023-10-26 02:45:19.0) Thank you for contacting Thorlabs. You may request a quote for the TAPSM05 by reaching out to your local sales team at sales@thorlabs.com or 973-300-3000, or by adding the item to your shopping cart directly on the website. Maxwell Lightstone

(posted 2023-02-01 17:02:56.033) Can you sell a 25.75 mm drill bit to go with the SM1 tap? There isn't a good way to drill those holes right now, and we don't always want to use a lathe or a mill.

Best regards,

Maxwell Lightstone, MASc

Mechanical Engineer jdelia

(posted 2023-02-03 03:04:51.0) Thank you for your feedback. We unfortunately do not offer a drill bit for SM1 taps as we typically suggest milling out a pilot bore. I have contacted you directly to discuss your application and the possibility of offering this in the future. Ahn Chang-Joon

(posted 2023-01-14 23:41:30.687) I found the tool Tapsm1 for SM1 Internal Thread here.

However, no tools can be found for the SM1 External Thread.

Can I purchase a tool for this?

If possible, please reply to mertul@kit-fa.com jdelia

(posted 2023-01-17 04:30:58.0) Thank you for contacting Thorlabs. I have reached out to you directly to discuss your application as well as methods that will allow you to cut external SM1 threads. Enrico Renna

(posted 2022-08-03 14:31:43.523) Hello, would it be possible to buy a tap for SM18 thread ? We still have some issue to produce something that would function with the SM18RR. I couldn't find it on the webpage. Thank you very much! jdelia

(posted 2022-08-03 03:02:30.0) Thank you for contacting Thorlabs. We will reach out to you directly regarding the possibility of quoting this out to you as a custom part. Evgeny Rozemblit

(posted 2021-12-20 06:15:41.993) Hello,

Need your help, do you know where I can find the GO-NOT GO gauge for 0.800"x36 thread? jgreschler

(posted 2021-12-23 10:46:46.0) Thank you for reaching out to Thorlabs. I have reached out to you directly to discuss this further. user

(posted 2021-08-11 11:36:02.887) It would be helpful if both bottoming and plug taps were offered for the SM05 and SM1 threads. The plug tap with the tapered threading doesn't work well on shallow depth holes. cdolbashian

(posted 2021-08-27 11:10:48.0) Thank you for your suggestion! As we are hungry for feedback, we will look into the potential availability of this product as a stock option in the future. user

(posted 2021-04-12 03:34:23.157) Hi, does Thorlabs sell M38 x 0.5 taps to accommodate the thread of the TTL-200 tube lens?

I need to use that lens directly in a custom mount that is too small for the SM2 thread of the TTL200-A or the adapter. YLohia

(posted 2021-04-12 04:42:49.0) Hello, custom taps can be requested by clicking on the "Request Quote" button above or by contacting your local Thorlabs Tech Support team (in your case, techsupport.se@thorlabs.com). We will discuss the possibility of offering this directly. Frank Seifert

(posted 2019-11-05 12:56:04.46) Hi, it is great that Thorlabs offers a lot of the special taps (metric & imperial) to allow the customer to do their own adapters. However I'm missing the M15.5 x 0.5 tap for the

SM15RR. Is it possible to purchase a M15.5 x 0.5 tap? Thanks! llamb

(posted 2019-11-06 09:49:47.0) Thank you for your feedback! Custom taps can be requested by clicking the red "Request Quote" button above or emailing techsupport@thorlabs.com. I have reached out to you directly in this case to discuss this possibility. Chris Betters

(posted 2019-04-08 04:44:40.833) Can you provide a tap for SMA threads (1/4-32)?

Thanks Chris YLohia

(posted 2019-04-09 03:13:43.0) Hello Chris, thank you for contacting Thorlabs. Custom taps can be requested by clicking the red "Request Quote" button above or emailing techsupport@thorlabs.com. We will reach out to discuss your requirements. ghovorka

(posted 2019-01-16 09:57:30.87) It would be very useful to have a tap for M10.5x0.5 threads. It is a great size for mounting 10mm OD optics with the SM10RR retaining ring, but can't be used as easily for custom mounts without a tap available. llamb

(posted 2019-01-17 12:02:50.0) Thank you for your feedback. I have added this idea into our internal product forum for further discussion. We can currently offer the M10.5 x 0.5 plug tap as a special item. I have reached out to you by email directly to discuss this special quote. kitchinsf

(posted 2018-10-24 16:12:02.7) It would be helpful to offer a tap guide for ensuring perpendicular taps to the work surface. Since the SM05, SM1, and SM2 are not very common outside of Thor, a tap guide that includes these (at least the SM05 and SM1, SM2 is a bit too large) it would be very helpful. The table tap guide is very useful but is limited in its functionality. llamb

(posted 2018-11-05 10:48:40.0) Thank you for your feedback. Tap guides like the TTT001(/M) typically need a flat reference plane like an optical table to fix to first. Most optomechanical parts with SM- threads are rounded or cylindrical, making it difficult to create a standardized tapping guide that fits to all components. We do not recommend hand-tapping these larger threads, but instead recommend using a type of drill press with a clutch for reversing the tap out of the threads. wenzel.jakob

(posted 2017-12-02 22:26:07.137) I'm also interested in a tap for SM2 threads. Could you please provide me with a quote? Thank you. tfrisch

(posted 2017-12-05 01:54:35.0) Hello, thank you for contacting Thorlabs. We will reach out to you with a quote for an SM2 tap. pierrick.cheiney

(posted 2017-06-21 13:57:27.263) Hello,

I cannot find a tap for the SM2 threads. Would it be possible to get one?

Thanks, tfrisch

(posted 2017-06-27 11:19:36.0) Hello, thank you for contacting Thorlabs. We will reach out to you with a quote. user

(posted 2017-03-15 08:46:56.48) What tapping depth can each tap achieve?! This is key info that needs to be added to this webpage. Also of interest are: overall length, shank diameter. tcampbell

(posted 2017-03-23 01:55:10.0) Response from Tim at Thorlabs: thank you for your feedback. We have added the thread depth and overall length of each tap to the webpage. ludoangot

(posted 2016-09-26 11:22:33.873) Hello, it would be very useful and convenient if you could offer precision quality individual drill in the sizes required for the taps you sell. jlow

(posted 2016-09-29 10:55:03.0) Response from Jeremy at Thorlabs: Thank you for your feedback, we will look into offering these. johannes.hohlbein

(posted 2016-06-27 09:37:37.37) I would also be interested in a tap to match the SM2 lens tube system. acaballero

(posted 2016-05-10 10:03:46.95) I could really use a tap to match the SM2 lens tube system. besembeson

(posted 2016-05-10 04:59:37.0) Response from Bweh at Thorlabs USA: We can provide this to you. I will follow-up via email. cbrideau

(posted 2016-01-04 19:09:52.09) An 8/32 imperial tap would be very useful to complement the M4 metric tap. besembeson

(posted 2016-01-05 08:26:53.0) Response from Bweh at Thorlabs USA: We typically stock and provide mostly specialty taps that aren’t easily found as a convenience to those looking to integrate our components in their systems. As #8-32 is a very common thread, its tap can be easily found at local convenient stores or many other places online so we don't stock this. ghall

(posted 2015-11-24 11:50:45.943) What style of taps are those? For through holes or bottoming?

What class are they in terms of the tolerance/allowance?

Specifically looking at the M11x0.5 tap. besembeson

(posted 2015-12-02 12:12:21.0) Response from Bweh at Thorlabs USA: This is a 4 flute, straight flute hand tap with a 6H class fit. cbrideau

(posted 2014-01-13 14:58:47.927) What would you recommend for drilling out a broken-off cap screw? The stainless steel of the screw is quite hard, so I'm not sure what would have a decent chance of actually boring through it... jlow

(posted 2014-01-14 02:59:05.0) Response from Jeremy at Thorlabs: You can use a sharp carbide drill bit for this. You can use a sharp punch and a hammer to create a pilot first. The screw is susceptible to hardening, so once you begin the drill process, you should not stop until you are through the screw. Also, there should be a steady stream of some sort of cutting fluid on the drill bit so it does not get too hot. Your university machine shop or a local machine shop should have this cutting fluid readily available. user

(posted 2013-11-07 15:40:06.927) Why not sell the die too? jlow

(posted 2013-11-11 10:54:51.0) Response from Jeremy at Thorlabs: We do not stock the dies but we can provide it. Since you did not leave your contact info, can you contact us at techsupport@thorlabs.com to request a quote for the die you are looking? Thanks. user

(posted 2013-07-15 16:12:23.917) Worst drill bit set ever!. Tried to drill through copper 1/4" copper and was not able to because the drills are just dull. I would not sell these at all. cdaly

(posted 2013-07-18 10:15:00.0) Response from Chris at Thorlabs: Thank you for your feedback. It may be a matter of drill speed and feed. Please contact as at techsupport@thorlabs.com to discuss the conditions further. nejbauer

(posted 2013-03-19 07:25:05.243) Hi,

Do you have taps for imperial thread 8-32, which is very popular in your products?

Best regards,

Michal Nejbauer tcohen

(posted 2013-03-21 15:51:00.0) Response from Tim at Thorlabs to Michal: Thank you for contacting us! We look to stock specialty taps that aren’t easily found as a convenience to those looking to integrate our components in their devices. #8-32 is a ubiquitous tap and you will most probably have luck finding it at your local hardware store. jlow

(posted 2012-07-31 15:26:00.0) A response from Jeremy at Thorlabs: We will get in contact with you directly regarding a quote for this. sfnagle

(posted 2012-07-31 13:52:09.0) I was wondering if you sell the die that goes with this tap size. I need to make external SM1 threads for a custom part in my set-up. Thanks. gregory.futia

(posted 2010-12-15 16:44:34.0) Where do you get a .508" through drill to use with the SM05 tap, 83373? |

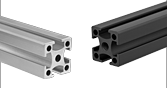

Click to Enlarge

Diagram of a Standard Tap

- Specialized Plug Taps

- Covers SM05, SM1, and Most Other Threads Used by Thorlabs

- Material: High-Speed Steel

These specialty taps aid in the integration of our optomechanical components into your custom-built devices. Our imperial taps selection includes many of the thread standards used by Thorlabs, including our SM05 (0.535"-40) and SM1 (1.035"-40) standards. Please see below for our metric taps.

Tapping Recommendations

To tap a hole, first machine a pilot bore, using the table below to find the recommended pilot bore diameter. The bore can be made using a drill bit or an end mill. For fine pitch threads, the pilot bore should be tightly toleranced because of the shallow thread depth; a reamer is also recommended in this case.

Next, secure the tap into a tap wrench, drill press, or lathe to create the threads. Lubricant or tapping fluid should be used to create the hole. If resistance is felt while tapping, carefully rotate the tap backwards to remove it, as broken taps are exceptionally difficult to remove.

If using these specialty taps for production, precision ring and plug gauges should be used to verify hole diameters. For additional details on threading and taps, please consult the Machinery's Handbook, available in many machine shops and bookstores.

| Item # | Thread Type | Thread Depth (T) |

Overall Length (L) |

Shank Size (S) |

Pilot Bore | Example Uses | ||

|---|---|---|---|---|---|---|---|---|

| Diameter | Tolerancea | Imperial Drill Sizeb | ||||||

| TAP080 | 0-80 | 0.31" | 1.63" | 0.141" | 0.049" | +0.003"/-0.002" | - | Holes for Locking Setscrews |

| TAP256 | 2-56 | 0.44" | 1.75" | 0.141" | 0.070" | ±0.004" | #50 (0.0700") |

Mounting Holes on Miniature Translation Stages |

| TAP440 | 4-40 | 0.56" | 1.88" | 0.141" | 0.089" | ±0.005" | #43 (0.0890") |

Holes for Cage Rod Locking Setscrews |

| TAP680 | 6-80 | 0.69" | 2.00" | 0.141" | 0.126" | ±0.002" | 1/8" (0.1250") |

Holes for 6-80 Adjustment Screws |

| TAP832 | 8-32 | 0.75" | 2.13" | 0.168" | 0.135" | +0.004"/-0.005" | #29 (0.1360") |

Mounting Holes for 8-32 Screws |

| TAP316100 | 3/16"-100 | 0.88" | 2.38" | 0.194" | 0.177" | +0.002"/-0.001" | #16 (0.1770") |

Holes for 3/16"-100 Adjustment Screws |

| TAP1420 | 1/4"-20 | 1.00" | 2.50" | 0.255" | 0.202" | +0.005"/-0.006" | #7 (0.2010") |

Mounting Holes for 1/4"-20 Screws |

| TAP1480 | 1/4"-80 | 1.00" | 2.50" | 0.255" | 0.238" | ±0.002" | B (0.2380") |

Holes for 1/4"-80 Adjustment Screws |

| TAP14100 | 1/4"-100 | 1.00" | 2.50" | 0.255" | 0.240" | +0.002"/-0.001" | - | Holes for 1/4"-100 Adjustment Screws |

| TAP51632 | 5/16"-32 | 1.13" | 2.72" | 0.318" | 0.282" | +0.004"/-0.003" | 9/32" (0.2812") |

Mounting Holes for 3/16"-100 Locking Bushings with 5/16"-32 External Threads |

| TAP3824 | 3/8"-24 | 1.25" | 2.94" | 0.381" | 0.335" | ±0.005" | Q (0.3340") |

Mounting Hole for HAFC Fiber Bulkhead Adapter, 3/8" Standard Tapped Holes |

| TAP3840 | 3/8"-40 | 1.25" | 2.94" | 0.381" | 0.348" | ±0.003" | S (0.3480") |

Mounting Holes for 1/4"-80 Locking Bushings with 3/8"-40 External Threads |

| TAP38100 | 3/8"-100 | 1.25" | 2.94" | 0.381" | 0.365" | +0.002"/-0.001" | - | Holes for 3/8"-100 Fine Adjustment Screws |

| TAPSM05 | 0.535"-40 (SM05 Standard) |

1.66" | 3.59" | 0.429" | 0.511" | ±0.003" | - | Internal Threads on Ø1/2" Lens Tubes |

| TAPRMS | 0.800"-36 (RMS Standard) |

2.00" | 4.47" | 0.652" | 0.773" | +0.004"/-0.003" | - | Mounts for RMS-Threaded Objectives |

| TAPCM | 1.00"-32 (C-Mount Standard) |

2.50" | 5.13" | 0.800" | 0.970" | ±0.004" | - | Internal Threads on C-Mount Extension Tubes, Mounts for Machine Vision Camera Lenses |

| TAPSM1 | 1.035"-40 (SM1 Standard) |

1.50" | 4.00" | 0.896" | 1.011" | ±0.003" | - | Internal Threads on Ø1" Lens Tubes |

Click to Enlarge

Diagram of a Standard Tap

- Specialized Plug Taps

- Covers Many Threads Used by Thorlabs

- Material: High-Speed Steel

These specialty taps aid in the integration of our optomechanical components into your custom-built devices. Our metric taps selection includes many of the thread standards used by Thorlabs. Please see above for our imperial taps, as well as taps for our SM05 (0.535"-40) and SM1 (1.035"-40) standards.

Tapping Recommendations

To tap a hole, first machine a pilot bore, using the table below to find the recommended pilot bore diameter. The bore can be made using a drill bit or an end mill. For fine pitch threads, the pilot bore should be tightly toleranced because of the shallow thread depth; a reamer is also recommended in this case.

Next, secure the tap into a tap wrench, drill press, or lathe to create the threads. Lubricant or tapping fluid should be used to create the hole. If resistance is felt while tapping, carefully rotate the tap backwards to remove it, as broken taps are exceptionally difficult to remove.

If using these specialty taps for production, precision ring and plug gauges should be used to verify hole diameters. For additional details on threading and taps, please consult the Machinery's Handbook, available in many machine shops and bookstores.

| Item # | Thread Type | Thread Depth (T) |

Overall Length (L) |

Shank Size (S) |

Pilot Bore | Example Uses | |||

|---|---|---|---|---|---|---|---|---|---|

| Diameter | Tolerancea | Metric Drill Sizeb | Imperial Drill Sizeb | ||||||

| TAPM202 | M2 x 0.2 | 11.35 mm | 44.7 mm | 2.72 mm | 1.805 mm | +0.013 mm/-0.026 mm | 1.80 mm (0.0709") |

- | Holes for M2 x 0.2 Adjustment Screws |

| TAPM2502 | M2.5 x 0.2 | 12.7 mm | 46.0 mm | 3.58 mm | 2.313 mm | ±0.030 mm | 2.3 mm (0.0905") |

- | Holes for M2.5 x 0.2 Adjustment Screws |

| TAPM302 | M3 x 0.2 | 16.0 mm | 49.3 mm | 3.58 mm | 2.813 mm | ±0.030 mm | 2.8 mm (0.1102") |

#34 (0.1110") |

Holes for M3 x 0.2 Adjustment Screws |

| TAPM3025 | M3 x 0.25 | 16.0 mm | 49.3 mm | 3.58 mm | 2.766 mm | ±0.037 mm | 2.75 mm (0.1083") |

7/64" (0.1093") |

Holes for M3 x 0.25 Adjustment Screws |

| TAPM4025 | M4 x 0.25 | 19.1 mm | 54.1 mm | 4.27 mm | 3.77 mm | ±0.037 mm | 3.75 mm (0.1476") |

#26 (0.1470") |

Holes for M4 x 0.25 Fine Adjustment Screws |

| TAPM407 | M4 x 0.7 (M4 Standard) |

19.1 mm | 54.0 mm | 4.27 mm | 3.332 mm | ±0.090 mm | 3.3 mm (0.1299") |

#30 (0.1285") |

Mounting Holes for M4 Screws |

| TAPM4505 | M4.5 x 0.5 | 22.4 mm | 60.5 mm | 4.93 mm | 4.029 mm | ±0.070 mm | 4.0 mm (0.1575") |

#21 (0.1590") |

Mounting Hole for M3 x 0.25 Adjuster Nutc |

| TAPM6025 | M6 x 0.25 | 25.4 mm | 63.5 mm | 6.48 mm | 5.575 mm | ±0.0165 mm | 5.6 mm (0.2205") |

#2 (0.2210") |

Holes for M6 x 0.25 Adjustment Screws |

| TAPM605 | M6 x 0.5 | 25.4 mm | 63.5 mm | 6.48 mm | 5.526 mm | ±0.068 mm | 5.5 mm (0.2165") |

7/23" (0.2187") |

Mounting Bores for Aspheric Lens Housingsd |

| TAPM610 | M6 x 1.0 (M6 Standard) |

25.4 mm | 63.5 mm | 6.48 mm | 5.035 mm | ±0.118 mm | 5.1 mm (0.2008") |

#8 (0.1990") |

Mounting Holes for M6 Screws |

| TAPM7505 | M7.5 x 0.5 | 28.7 mm | 69.0 mm | 8.08 mm | 7.026 mm | +0.068 mm/-0.067 mm | - | - | Mounting Bores for Ø7 mm Optic Mounts |

| TAPM805 | M8 x 0.5 | 28.7 mm | 69.1 mm | 8.08 mm | 7.526 mm | ±0.068 mm | 7.5 mm (0.2953") |

M (0.2950") |

Mounting Bores for Aspheric Lens Housingsd |

| TAPM905 | M9 x 0.5 | 31.8 mm | 74.7 mm | 9.68 mm | 8.526 mm | ±0.068 mm | 8.5 mm (0.3346") |

Q (0.3340") |

Mounting Bores for Aspheric Lens Housingsd |

| TAPM1005 | M10 x 0.5 | 31.8 mm | 74.7 mm | 9.68 mm | 9.526 mm | ±0.068 mm | 9.5 mm (0.3740) |

3/8" (0.3750") |

Mounting Bores for Aspheric Lens Housingsd |

| TAPM10505 | M10.5 x 0.5 | 31.8 mm | 74.7 mm | 9.70 mm | 10.026 mm | +0.068 mm/-0.067 mm | - | - | Mounting Bores for Ø10 mm Optic Mounts |

| TAPM1105 | M11 x 0.5 | 36.6 mm | 80.3 mm | 8.20 mm | 10.526 mm | ±0.068 mm | 10.5 mm (0.4133") |

Z (0.4130") |

Mounting Holes for Mounted Aspheric Lens Pair Housingsd |

| TAPM1205 | M12 x 0.5 | 42.1 mm | 85.7 mm | 9.32 mm | 11.526 mm | ±0.068 mm | 11.5 mm (0.4528") |

29/64" (0.4531") |

Mounting Bores for Aspheric Lens Housingsd |

| TAPM1405 | M14 x 0.5 | 42.2 mm | 91.2 mm | 10.90 mm | 13.526 mm | ±0.068 mm | 13.5 mm (0.5315") |

17/23" (0.5312") |

- |

| TAPM20505 | M20.5 x 0.5 | 50.8 mm | 113.5 mm | 16.56 mm | 20.026 mm | +0.068 mm/-0.067 mm | - | - | Mounting Bores for for Ø20 mm Lens Mounts |

| TAPM25075 | M25 x 0.75 (M25 Standard) | 63.5 mm | 130.3 mm | 20.32 mm | 24.284 mm | ±0.096 mm | - | - | Mounts for M25-Threaded Objectives |

- 60 Number-Sized Drill Bits Ranging from #1 Bit to #60 Bit

- Bit Material: High-Speed Steel

- 135° Point Angle

- Sizes Embossed in Steel Case

The DK3 Drill Bit Kit includes 60 drill bits of standard jobber length. The bits are constructed from high-speed steel and have a 135° point angle. This kit holds the bits in a compact, all-steel index case, with the bit sizes, tap sizes, tap drill sizes, and body drill (clearance) sizes embossed in the case.

Click to Enlarge

Ratcheting Selector Knob and Sliding Crossbar

- Universal Ratcheting Tap Wrench with Sliding Crossbar

- Accommodates Taps from #0 to 1/4" or M2 to M6

- Shank Size from 0.141" to 0.255" or 3.6 mm to 6.5 mm

This machinist-quality Hand Tap Wrench is ideally suited for everyday tapping requirements. The rugged stainless steel design provides durability and long life, and the crossbar conveniently slides to provide extra torque when required. Ratcheting in either direction can be selected using the knob at the top of the wrench (see photo to the right). The Hand Tap Wrench can accommodate taps as small as #0 or 2 mm and as large as 1/4" or 6 mm.

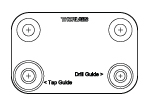

Repairing a Damaged Tapped Hole

Click to Enlarge

Once the TTT001(/M) guide is properly aligned over the hole, use the TW25 Hand Tap Wrench with a 1/4"-20 tap (Item # TAP1420) or an M6 tap (Item # TAPM610) to restore the threads.

Click to Enlarge

To repair a hole with the TTT001(/M) guide, first secure it to the optical table using the included countersunk screws. These screws are designed to center the steel bushing over the damaged hole.

Click for Details

TTT001(/M) Tap Guide Dimensions

- Repair 1/4"-20 or M6 Holes in Optical Tables and Breadboards

- Bushings Help Ensure Tapped Holes are Perpendicular to the Work Surface

- Two 1/4"-20 or M6 Countersunk Mounting Screws Supplied

The TTT001(/M) Tap Guide is designed to assist in the re-drilling and re-tapping of an optical table or breadboard damaged by broken screws or cross threading. Two countersunk mounting screws (also known as flat head socket cap screws) are supplied for bolting the guide to the existing 1/4"-20- or M6-threaded hole matrix. A toughened, tool-grade steel bushing insert acts as a precise guide for drilling the broken screw out of the damaged hole. Another steel bushing guides the tap into the drilled-out hole, restoring the threads and ensuring that the resulting tapped hole is perpendicular to the work surface.

The main cause of tap breakage is unwanted sideways motion when the operator attempts to rotate the tap while simultaneously applying a force not purely parallel to the drill axis. This device discourages this costly error. We advise the use of a sharp, carbide-tipped drill bit to drill out the broken screw. When mounting the tap guide, care should be taken not to overtighten the countersunk mounting screws.

Products Home

Products Home

Zoom

Zoom

Drill Bits/Taps

Drill Bits/Taps