Vytran® Fiber Window Stripper for Polyimide-Coated Fiber

- Strip Optical Fiber with Polyimide Coating

- Accepts Fibers with Coating Diameters 100 µm - 250 µm, 400 µm, or 500 µm

- Create Window Strip Regions 1 mm to 50 mm Long

FWS100

Fiber Window Stripper

VHW250

Insert Set for

Ø100 to Ø250 µm Fiber

VHW500

Insert Set for Ø500 µm Fiber

FWSBLADE

Replacement Blade for the FWS100; Sold in Packs of 100

Please Wait

Click to Enlarge

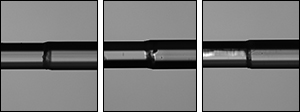

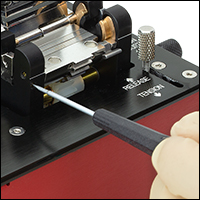

Click to EnlargeBlade Mechanism Positioned Above the Fiber (Left);

Stripped Fiber (Right)

Click to Enlarge

Click to EnlargeStripped polyimide coating on Ø120 µm cladding and Ø150 µm coating fibers. A clean, beveled edge, as shown in the images above, is desireable for minimizing recoating defects after splicing.

Features

- Accepts Fibers with Coating Diameters of 100 µm - 250 µm, 400 µm, or 500 µm

- Accepts Fiber with Cladding Diameters from 80 µm to 400 µm

- Mechanical Stripper with Manual Rotation

- Strip a 1 mm - 50 mm Long Window of Polyimide-Coated Fiber

- Fiber Holder Insert Sets:

- VHW250: Accepts Ø100 µm - Ø250 µm Fiber

- VHW400: Accepts Ø400 µm Fiber

- VHW500: Accepts Ø500 µm Fiber

- Replacement Blades Available in Packs of 100

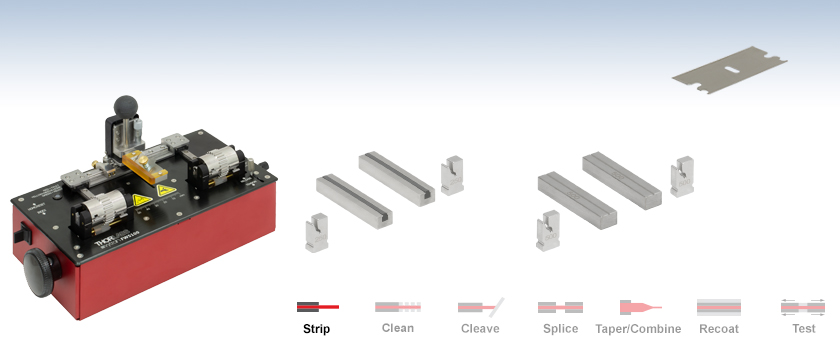

Thorlabs' Vytran® FWS100 Fiber Window Stripper is designed for stripping polyimide-coated optical fiber. Polyimide coatings have high temperature and chemical resistance, and are therefore difficult to remove without leaving a residue or damaging the fiber. Unlike the typical chemical stripping method, which uses hot sulfuric acid, this window stripper provides a clean and safe solution for stripping polyimide-coated fiber by using a mechanical blade (replacements sold below) and repeated stripping passes to gently remove the coating. Rotation barrels on either end of the stripper are used to hold an optical fiber under tension. The FWS100 stripper can strip a 1 mm to 50 mm long window region, and accepts fiber with cladding diameters from 80 µm to 400 µm and coating diameters of 100 µm to 250 µm, 400 µm, or 500 µm. After stripping, we recommend using an ultrasonic cleaner that is compatible with window stripped fiber to clean.

Each rotation barrel requires a bottom insert, top insert, rear guide, and front guide to properly hold a fiber in place during the stripping process. The inserts grip the fiber in place, while the guides assist with loading fiber and keeping the fiber close to the center of rotation. The FWS100 window stripper includes two top inserts and two rear guides that are pre-installed. These are compatible with all fiber sizes and should not be removed by the user. In addition, users will need to purchase and install one fiber holder insert set (sold separately below), containing two bottom inserts and two front guides. We offer three insert sets for Ø100 µm to Ø250 µm, Ø400 µm, or Ø500 µm coated fiber.

| FWS100 Window Stripper Specifications | |

|---|---|

| Accepted Fiber Material | Silica |

| Accepted Coating Material | Polyimide |

| Accepted Cladding Diameters | 80 µm - 400 µm |

| Accepted Coating Diameters | 100 µm - 250 µm, 400 µm, 500 µma |

| Strip Length | 1 mm - 50 mm |

| Strip Method | Multiple Pass with Manual Rotation |

| Strip Blade | Single-Edge Precision Blade with Power Assist Advance |

| Blade Lifetime | 100 - 200 Strips per Blade |

| Fiber Rotation | Manual Rotation with 20 Detent Positions at 18° Apart |

| Electrical Power | 12 VDC Input; 100 - 240 VAC AC Adapter Included |

| Dimensions (L x W x H) |

10.78" x 5.06" x 6.19" (273.7 mm x 128.5 mm x 157.3 mm) |

| Weight | 2.2 kg |

| Operating Conditions | 0 °C to 40 °C 0% - 85% RH (Non-Condensing) |

| Storage Conditions | -40 °C to 80 °C 0% - 95% RH (Non-Condensing) |

Product DemonstrationsThorlabs has demonstration facilities for the Vytran® fiber glass processing systems offered on this page within our Morganville, New Jersey and Exeter, Devonshire offices. We invite you to schedule a visit to see these products in operation and to discuss the various options with a fiber processing specialist. Please schedule a demonstration at one of our locations below by contacting technical support. We welcome the opportunity for personal interaction during your visit! Thorlabs Vytran Europe

|

| Posted Comments: | |

| No Comments Posted |

- Accepts Fiber with Cladding Diameters from 80 µm to 400 µm

- Strip Polyimide Coatings with Diameters 100 µm - 250 µm, 400 µm, or 500 µm

- Mechanical Blade with a Lifetime of 100 - 200 Strips

- Manual Rotation with 20 Detent Positions at 18° Apart

- Includes Top Inserts and Rear Guides

- Includes Tools for Installing Bottom Inserts and Front Guides

- Requires a Fiber Holder Insert Set (Sold Separately Below)

The FWS100 stripper removes polyimide coating from fibers with cladding diameters from 80 µm to 400 µm and coating diameters of 100 µm to 250 µm, 400 µm, or 500 µm. The rotation barrels on either end of the stripper are used to hold an optical fiber under tension. Users can strip 1 mm to 50 mm long window regions by moving the sliding stops to achieve the desired distance; see the image to the lower left.

This stripper is optimized for quick, precise removal of coating with high repeatability and ease of use. A scale that measures 50 mm is provided under the blade for reference; for precise stripping, the fiber should be marked beforehand. The height of the blade can be set by pushing down on the round handle and adjusting the micrometer so the blade makes contact with the coating. Users manually strip the fiber by moving the blade from right to left. The fiber can be rotated in increments of 18° using the rotation knob located on the left side of the unit. For detailed instructions on how to load and strip the fiber, see the manual by clicking the red docs icon (![]() ) below.

) below.

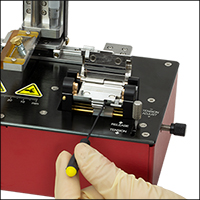

Each rotation barrel requires a bottom insert, top insert, rear guide, and front guide to properly hold a fiber in place during the stripping process. The FWS100 Window Stripper includes two top inserts and two rear guides that are pre-installed in the rotation barrels; see the image to the lower right. These can be used with any fiber size and should not be removed by the user. One fibe holder insert set is required to be purchased separately below. Each set includes two bottom inserts and two front guides. The inserts grip the fiber in place, while the guides keep the fiber close to the center of rotation.

A tool kit and 100 replacement blades are included with the FWS100 stripper. Each unit is shipped with a power supply and location-specific power cord.

Click to Enlarge

Click to EnlargeFeatures of the FWS100 Window Stripper

Click to Enlarge

The FWS100 Window Stripper includes two rear guides and two top inserts. One insert set, which includes two front guides and two bottom inserts, is required to be purchased separately below. The VHW250 insert set is shown here.

Click to Enlarge

Figure 2: Front guides can be secured by tightening the screw with the included screwdriver.

Click to Enlarge

Figure 1: Bottom inserts can be secured by tightening the setscrew on the barrel with the included 0.050" balldriver.

- One is Required to Use the FWS100 Window Stripper

- VHW250: Accepts Ø100 µm - Ø250 µm Fiber

- VHW400: Accepts Ø400 µm Fiber

- VHW500: Accepts Ø500 µm Fiber

- Bottom Inserts Grip Fiber within the Rotation Barrels

- Front Guides Keep Fiber Close to the Center of Rotation

A Fiber Holder Insert Set must be purchased with the FWS100 window stripper to secure the fiber. Each set includes two bottom inserts and two front guides. Each insert is designed to grip the fiber within the rotation barrels. The guides sit beside the barrels and keep the fiber close to the center of rotation.

We offer three fiber holder insert sets that are compatible with specific fiber coating diameters: VHW250 for Ø100 µm to Ø250 µm, VHW400 for Ø400 µm, and VHW500 for Ø500 µm. The VHW250 set has inserts equipped with rubber where the fiber is placed and guides for a range of smaller fibers. The VHW400 and VHW500 sets have inserts with a V-groove designed to hold Ø400 µm or Ø500 µm coated fibers, respectively. Both of these sets include the same front guides, which support Ø400 µm to Ø500 µm coated fiber. Each V-groove insert and each guide is engraved with the largest compatible fiber coating diameter, in microns.

Users will need to install their fiber holder insert set into the FWS100 Window Stripper using its included tool kit. The inserts can be placed into the bottom slots of the rotation barrels and secured by tightening the two setscrews with the 0.050" balldriver, as shown in Figure 1. The guides can be inserted into the front guide holders, where they will help constrain fiber position to the rotational axis. The guides can be secured by tightening the screw with the screwdriver, as shown in Figure 2.

- Replacement Blades for the FWS100 Window Stripper

- Single-Sided 1.53" (38.9 mm) Long Blade

- Lifetime of 100 - 200 Strips

- User-Installable

- Pack of 100

The FWSBLADE is a pack of 100 replacement blades for the FWS100 Window Stripper. These blades are designed to cut polyimide-coated fiber at a specific angle with the FWS100. A single blade has a lifetime of 100 - 200 strips. Blade replacement instructions are provided in the FWS100 user manual. Be sure to use caution when handling a blade and dispose it in a proper container, such as our FTDU Disposal Unit.

Products Home

Products Home

Zoom

Zoom

Fiber Window Stripper

Fiber Window Stripper