C-Band and L-Band High Power White Light Source

- Wavelength Range of 1530 to 1610 nm

- Over +15 dBm (30 mW) Output Power Across C-Band and L-Band Wavelengths

- Low Noise Operation

ASE730

Please Wait

| ASE730 Test Source Specifications | ||

|---|---|---|

| Total Output Power | >+15 dBm (30 mW) | |

| Spectral Power Density (Typical) | >-18 dBm/nm at 1530 nm; >-11 dBm/nm at 1540-1600 nm; >-18 dBm/nm at 1610 nm |

|

| Stability | Short Terma | ±0.001 dB |

| Long Termb | ±0.05 dB | |

| Wavelength Range | 1530 nm - 1610 nm | |

| Output Connector | FC/PC | |

| Output Fiber | SMF-28 | |

| Size (mm) | 88 (H) x 483 (W) x 352 (D); 19" Rack-Mount Compatible |

|

| Operation Temperature | 0 °C to 40 °C | |

| Storage Temperature | -10 °C to 45 °C | |

Features

- White Light Output over 1530 to 1610 nm

- High Power Output: 30 mW

- FC/PC Output Connector with SMF-28 Fiber

- Easy Operation

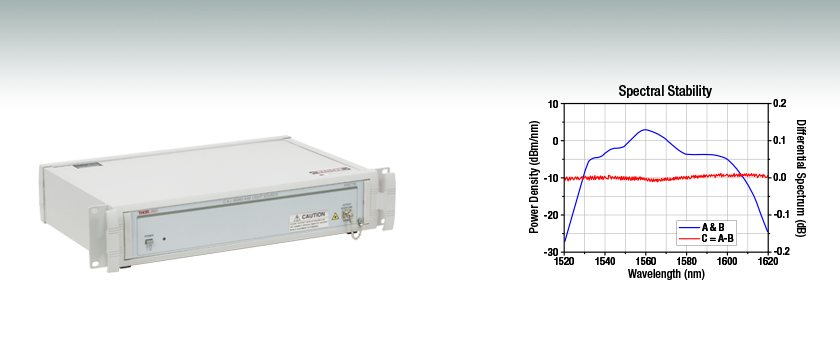

The ASE730 White Light Test Source is a low-noise, high-power C-Band and L-Band source that delivers more than +15 dBm of output power across the C-Band and L-Band wavelengths. Key features of the ASE730 source include low intensity noise, broadband output, and exceptional wavelength stability. Refer to the Graphs tab for test results.

This light source takes advantage of Erbium-doped fluoride fiber, pumped with a single 1480 nm laser diode, to produce 30 mW (15 dBm) of broadband "white light." This rare-earth fiber design allows for a higher degree of power and wavelength stability than conventional silica fibers with multiple pumping lasers. The output fiber is a standard SMF-28 silica fiber.

The ASE730 Source is supplied with an FC/PC output connector. Please keep this output connector covered with the attached cap and chain when not in use. Do not use an index matching gel with the ASE730 Source, as the use of an index matching gel will not improve the coupling of our standard ultra-polished FC/PC connector. The use of a gel will often lead to degradation of the performance of the connection because it will effectively trap contaminants that will damage the connectors.

The light source should be allowed to warm up for one hour prior to use. It supports input voltages of 115 and 230 VAC, but each unit comes preconfigured for 115 V. This can be changed via a switch on the back of the unit. The 115 V position allows operation from approximately 100 VAC to 120 VAC, while the 230 V position allows operation from approximately 200 V to 250 V. For the full list of operation instructions, please refer to the manual, found in the support documents (![]() ) below.

) below.

Thorlabs also offers Single Mode Benchtop SLD Sources as well as a Single Mode Benchtop ASE Source for NIR applications. This alternative may be suitable for some C-Band and L-Band applications.

Click to Enlarge

Spectral stability of the ASE730 light source. Trace C is the

difference between two scans (traces A and B) taken 15 minutes apart.

Click to Enlarge

Stability of ASE730 Output Power over 45 Hours

Laser Safety and Classification

Safe practices and proper usage of safety equipment should be taken into consideration when operating lasers. The eye is susceptible to injury, even from very low levels of laser light. Thorlabs offers a range of laser safety accessories that can be used to reduce the risk of accidents or injuries. Laser emission in the visible and near infrared spectral ranges has the greatest potential for retinal injury, as the cornea and lens are transparent to those wavelengths, and the lens can focus the laser energy onto the retina.

Safe Practices and Light Safety Accessories

- Laser safety eyewear must be worn whenever working with Class 3 or 4 lasers.

- Regardless of laser class, Thorlabs recommends the use of laser safety eyewear whenever working with laser beams with non-negligible powers, since metallic tools such as screwdrivers can accidentally redirect a beam.

- Laser goggles designed for specific wavelengths should be clearly available near laser setups to protect the wearer from unintentional laser reflections.

- Goggles are marked with the wavelength range over which protection is afforded and the minimum optical density within that range.

- Laser Safety Curtains and Laser Safety Fabric shield other parts of the lab from high energy lasers.

- Blackout Materials can prevent direct or reflected light from leaving the experimental setup area.

- Thorlabs' Enclosure Systems can be used to contain optical setups to isolate or minimize laser hazards.

- A fiber-pigtailed laser should always be turned off before connecting it to or disconnecting it from another fiber, especially when the laser is at power levels above 10 mW.

- All beams should be terminated at the edge of the table, and laboratory doors should be closed whenever a laser is in use.

- Do not place laser beams at eye level.

- Carry out experiments on an optical table such that all laser beams travel horizontally.

- Remove unnecessary reflective items such as reflective jewelry (e.g., rings, watches, etc.) while working near the beam path.

- Be aware that lenses and other optical devices may reflect a portion of the incident beam from the front or rear surface.

- Operate a laser at the minimum power necessary for any operation.

- If possible, reduce the output power of a laser during alignment procedures.

- Use beam shutters and filters to reduce the beam power.

- Post appropriate warning signs or labels near laser setups or rooms.

- Use a laser sign with a lightbox if operating Class 3R or 4 lasers (i.e., lasers requiring the use of a safety interlock).

- Do not use Laser Viewing Cards in place of a proper Beam Trap.

Laser Classification

Lasers are categorized into different classes according to their ability to cause eye and other damage. The International Electrotechnical Commission (IEC) is a global organization that prepares and publishes international standards for all electrical, electronic, and related technologies. The IEC document 60825-1 outlines the safety of laser products. A description of each class of laser is given below:

| Class | Description | Warning Label |

|---|---|---|

| 1 | This class of laser is safe under all conditions of normal use, including use with optical instruments for intrabeam viewing. Lasers in this class do not emit radiation at levels that may cause injury during normal operation, and therefore the maximum permissible exposure (MPE) cannot be exceeded. Class 1 lasers can also include enclosed, high-power lasers where exposure to the radiation is not possible without opening or shutting down the laser. |  |

| 1M | Class 1M lasers are safe except when used in conjunction with optical components such as telescopes and microscopes. Lasers belonging to this class emit large-diameter or divergent beams, and the MPE cannot normally be exceeded unless focusing or imaging optics are used to narrow the beam. However, if the beam is refocused, the hazard may be increased and the class may be changed accordingly. |  |

| 2 | Class 2 lasers, which are limited to 1 mW of visible continuous-wave radiation, are safe because the blink reflex will limit the exposure in the eye to 0.25 seconds. This category only applies to visible radiation (400 - 700 nm). |  |

| 2M | Because of the blink reflex, this class of laser is classified as safe as long as the beam is not viewed through optical instruments. This laser class also applies to larger-diameter or diverging laser beams. |  |

| 3R | Class 3R lasers produce visible and invisible light that is hazardous under direct and specular-reflection viewing conditions. Eye injuries may occur if you directly view the beam, especially when using optical instruments. Lasers in this class are considered safe as long as they are handled with restricted beam viewing. The MPE can be exceeded with this class of laser; however, this presents a low risk level to injury. Visible, continuous-wave lasers in this class are limited to 5 mW of output power. |  |

| 3B | Class 3B lasers are hazardous to the eye if exposed directly. Diffuse reflections are usually not harmful, but may be when using higher-power Class 3B lasers. Safe handling of devices in this class includes wearing protective eyewear where direct viewing of the laser beam may occur. Lasers of this class must be equipped with a key switch and a safety interlock; moreover, laser safety signs should be used, such that the laser cannot be used without the safety light turning on. Laser products with power output near the upper range of Class 3B may also cause skin burns. |  |

| 4 | This class of laser may cause damage to the skin, and also to the eye, even from the viewing of diffuse reflections. These hazards may also apply to indirect or non-specular reflections of the beam, even from apparently matte surfaces. Great care must be taken when handling these lasers. They also represent a fire risk, because they may ignite combustible material. Class 4 lasers must be equipped with a key switch and a safety interlock. |  |

| All class 2 lasers (and higher) must display, in addition to the corresponding sign above, this triangular warning sign. |  |

|

| Posted Comments: | |

Laurie

(posted 2008-08-13 10:14:18.0) Response from Laurie at Thorlabs to jhawkins: Weve been in contact with the vendor for the ASE-FL7002, and unfortunately, they have no data or specs on the lifetime of these. However, they did comment that it should be long because they are designed for telecommunication use. You mentioned that you have several units that appear to have varying outputs. Do you mean that the output power varies from unit to unit or that the output power of a given unit varies per day. The former would be somewhat expected. There will be some variation in output power from unit to unit. The latter, particularly if it is drastic, would not be expected. jhawkins

(posted 2008-08-04 00:57:52.0) Please let me know what the life expectency of the light source is. i.e., is there an approximate number of hours after which the power would be noticeably reduced? We have several ASE-FL7002 units that appear to have varying power outputs.

I look forward to your response.

John |

Products Home

Products Home

Er-Doped Fiber ASE Source

Er-Doped Fiber ASE Source