XY Translation Mounts for 30 mm Cage Systems

- Mount Ø1/2" or Ø1" Optics

- Compatible with Our Lens Tubes

- Mounts with ±0.25 mm, ±1.0 mm, or ±3.0 mm of X and Y Adjustment

ST1XY-S

Mount with 6 mm X and Y Travel for Ø1" Optics

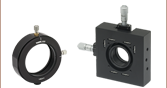

CP1XY

Stainless Steel Flexure Mount for Ø1/2" Optics

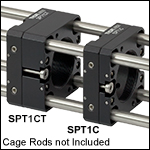

SPT1C

Slip Plate Positioner for Ø1" Optics

Application Idea

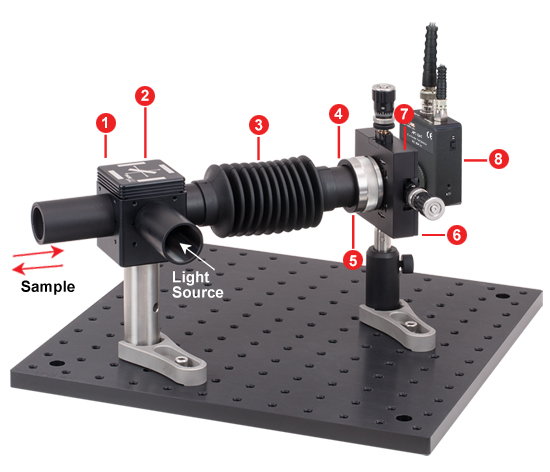

ST1XY-D and SM1ZM Zoom Housing for a Confocal Microscope Detector (See the Application Tab)

CXY1A

XY Translation Mount for Ø1" Optics

Please Wait

| Alternative Size Options |

|---|

| 16 mm Cage XY Translators |

| 30 mm Cage XY Translators |

| 60 mm Cage XY Translators |

Features

- Compatible with 30 mm Cage Systems

- SM05 (0.535"-40) or SM1 (1.035"-40) Threading

For Ø1/2" or Ø1" optical components mounted in a 30 mm cage system, Thorlabs offers several options for XY adjustment (orthogonal to the mechanical axis of the cage system). For experimental setups requiring fine adjustment, consider using our CP1XY Flexure Adjustment Plate, CXY1A Cage Mount, or CXY1QA Cage Mount with Quick-Release Plate. Our ST1XY Translation Mounts offer up to ±3.0 mm of XY translation controlled by either 100 TPI adjuster screws, micrometer drives, or differential drives. In cases where coarse adjustment is sufficient, the SPT1C(/M) and SPT1CT(/M) Slip Plate Mounts provide ±1.0 mm of manual XY adjustment.

Cage System Compatibility: Thorlabs offers 16 mm, 30 mm, and 60 mm cage systems designed primarily for Ø1/2", Ø1", and Ø2" optical components, respectively. The parts on this page are compatible with our 30 mm cage system and utilize Ø6 mm ER cage rods.

| # | Product Description | Qty. | Photo (Click to Enlarge) |

|---|---|---|---|

| 1 | DFM1 - Kinematic Dichroic Filter Cube |

1 |  |

| 2 | Microscopy Filters | 1 Set |  |

| 3 | SM1B3 - Lens Tube Bellows | 1 |  |

| 4 | SM1ZM - Non-Rotating SM1 Zoom Housing |

1 |  |

| 5 | Focusing Lens Inside Zoom Housing |

1 |  |

| 6 | ST1XY-D - XY Translator with Differential Drives |

1 |  |

| 7 | Precision Pinhole Between XY Translator and Photodetector |

1 |  |

| 8 | Photodetector SM1-Compatible Photodetector |

1 |  |

ST1XY XY Translation Mounts - Optic Alignment in a Confocal Microscope Detection Module

Thorlabs' ST1XY-A, ST1XY-S, and ST1XY-D XY Translation Mounts are useful when precise alignment of optics is necessary. In the following example of a partial confocal microscope, a light-tight connection is created between a DFM1 Dichroic Filter Cube (denoted by 1 in the image below) containing a Microscopy Filter Set (2) and an APD130A(/M) Photodetector (8). A lens (5) located inside the SM1ZM High-Precision Zoom Housing (4) focuses the beam onto a precision pinhole (7) located just before the avalanche photodetector's detector element. The SM1ZM zoom housing is mounted directly onto the ST1XY-D XY Translation Mount with Differential Adjusters (6), creating a compact XYZ mount. SM1 Lens Tubes and the SM1B3 Lens Tube Bellows (3) allow for a light-tight connection without inhibiting the free movement of the XYZ mount.

Components used in the configuration pictured below are listed in the table to the right. These parts, along with SM1 Lens Tubes and 1" Post Assemblies, are sold separately.

Cage System Overview

The Cage Assembly System provides a convenient way to construct large optomechanical systems with an established line of precision-machined building blocks designed for high flexibility and accurate alignment.

16 mm, 30 mm, and 60 mm Cage System Standards

Thorlabs offers three standards defined by the center-to-center spacing of the cage assembly rods (see image below). The 16 mm cage, 30 mm cage, and 60 mm cage standards are designed to accommodate Ø1/2", Ø1", and Ø2" optics, respectively. Specialized cage plates that allow smaller optics to be directly inserted into our larger cage systems are also available.

Standard Threads

The flexibility of our Cage Assembly System stems from well-defined mounting and thread standards designed to directly interface with a wide range of specialized products. The three most prevalent thread standards are our SM05 Series (0.535"-40 thread), SM1 Series (1.035"-40 thread), and SM2 Series (2.035"-40 thread), all of which were defined to house the industry's most common optic sizes. Essential building blocks, such as our popular lens tubes, directly interface to these standards.

An example of the standard cage plate measurements determining cage system compatibility.

| Standard Cage System Measurements | |||

|---|---|---|---|

| Cage System | 16 mm | 30 mm | 60 mm |

| Thread Series | SM05 | SM1 | SM2 |

| Rod to Rod Spacing | 16 mm (0.63") | 30 mm (1.18") | 60 mm (2.36") |

| Total Length | 25 mm (0.98") | 41 mm (1.60") | 71.1 mm (2.80") |

| Cage Components | ||

|---|---|---|

| Cage Rods | 16 mm | These rods are used to connect cage plates, optic mounts, and other components in the cage system. The SR Series Cage Rods are compatible with our 16 mm cage systems, while the 30 mm and 60 mm cage systems use ER Series Cage Rods. |

| 30 mm | ||

| 60 mm | ||

| Cage Plates | 16 mm | These serve as the basic building blocks for a cage system. They may have SM-threaded central bores, smooth bores sized for industry standard optics or to accommodate the outer profile of our SM Series Lens Tubes, or specialized bores for other components such as our FiberPorts. |

| 30 mm | ||

| 60 mm | ||

| Optic Mounts | 16 mm | Thorlabs offers fixed, kinematic, rotation, and translation mounts specifically designed for our Cage Systems. |

| 30 mm | ||

| 60 mm | ||

| Cage Cubes | 16 mm | These cubes are useful for housing larger optical components, such as prisms or mirrors, or optics that need to sit at an angle to the beam path, such as beamsplitters. Our cage cubes are available empty or with pre-mounted optics. |

| 30 mm | ||

| 60 mm | ||

| Replacement Setscrews | Replacement setscrews are offered for our 16 mm (SS4B013, SS4B025, and SS4B038) and 30 mm (SS4MS5 and SS4MS4) cage systems products. | |

| Post and Breadboard Mounts and Adapters | Mounting options for cage systems can be found on our Cage System Construction pages. Cage Systems can be mounted either parallel or perpendicular to the table surface. | |

| Size Adapters | Cage System Size Adapters can be used to integrate components from different cage system and threading standards. | |

| Specialized Components | Thorlabs also produces specialized cage components, such as Filter Wheels, a HeNe Laser Mount, and a FiberPort Cage Plate Adapter, allowing a wide range of our products to be integrated into cage-mounted optical systems. Explore our Cage Systems Visual Navigation Guide to see the full range of Thorlabs' cage components. | |

| Posted Comments: | |

user

(posted 2024-10-11 16:50:43.073) Are there any of xy translation mounts made with only non-magnetic material?

We are planning to build magnetic field sensing setup with those product. But we are not sure that the springs or other inner parts are made my magnets.

Also, we want to know whether the cage assembly rods are magnetic or not. spolineni

(posted 2024-10-18 06:37:59.0) Thank you for your inquiry. Unfortunately, we currently do not have any XY translation mounts made entirely of non-magnetic materials in our catalog, as some internal parts may contain magnetic materials. The cage assembly rods are also stainless steel, which may have slight magnetic properties. I will reach out to you to discuss your application and explore any possible offerings we can help you with. Daniel Connell

(posted 2022-07-28 13:31:22.44) You made it larger than the CXY1 and I do not recall seeing that this was the change. Thought it was just the set screws as was done with a number of other products recently. Do you have any of the CXY1 still available? We now have a lot of interference with the larger CXY1A and cannot use them without significant changes. jdelia

(posted 2022-07-28 02:14:48.0) Thank you for contacting Thorlabs. I have reached out to you directly to discuss quoting some of our older CXY1's out to you as a special. user

(posted 2020-02-05 11:30:34.02) Is there a way for the CP1XY to block the positionning screws ?

Does the mount keep its elasticity over time (go back to its initial form after a long period) ?

Also, is there a way to fix this mount by one of its side ?

Thank you DJayasuriya

(posted 2020-02-06 06:27:08.0) Hello, thank you for contacting Thorlabs. In reference to blocking the positioning screws, I presume that you want to lock the stage at a certain position. unfortunately this is not possible with the adjuster. This mount has a monolithic design which should return to its original location after use. Due to the design of the mount it is not side mountable. Yi Wei Ho

(posted 2019-07-19 06:19:28.25) I'm interested in motorizing CXY1 with resolution of 0.5 um, travel range of +- 0.5 mm or more. Thanks. YLohia

(posted 2019-07-19 10:27:45.0) Hello, thank you for contacting Thorlabs. For custom items, please email techsupport@thorlabs.com. I will reach out to you directly to discuss the possibility of offering this. user

(posted 2019-06-17 20:37:23.677) Do you have ST1XY mount with SM2 thread? i.e. ST2XY...Thanks. YLohia

(posted 2019-06-18 10:00:35.0) Hello, unfortunately, the 30mm cage mounts are incompatible with 2" (50.8mm) optics due to spatial constraints. The closest equivalent we currently offer is the CXY2 for the 60mm cage system. If use in a cage system is not critical to your application and you don't need the full clear aperture of the optic, you can also use the SM1A2 adapter with the ST1XY. S Y

(posted 2019-03-12 19:25:42.13) Is it possible to mount an objective to ST1XY and still be stable (i.e. no angular deviation or tilt)? The objective is ca. 240 g in weight (10X Mitutoyo objective). Equivalently, if you offer some alternative (XY adjustment for 30 mm cage) is also OK. llamb

(posted 2019-03-13 12:00:44.0) Thank you for contacting Thorlabs. This will depend on the angular deviation or tilt tolerances you have for your application, but the Mitutoyo objective is generally suitable and lightweight enough for mounting stably in the ST1XY mount. We do not have formal vibration stability testing on these mounts. If higher stability is needed, our CP1XY uses a flexure design to minimize the number of internal components susceptible to vibrations that cause instabilities, while the other XY translation mounts have multiple components in a spring-loaded carriage design. I have reached out to you directly to discuss your application's requirements further. user

(posted 2019-02-20 19:28:46.013) Please make a note in the PDF or the product webpage for the entire ST1XY series that the internal rings should NOT be threaded into the stationary thread (ST1CP) to avoid mismatch and ring stress during XY translation. mmcclure

(posted 2019-02-27 09:00:32.0) Hello, thank you for providing us with your valued feedback. We will consider adding this information to the web presentation. david.gherardi

(posted 2019-02-04 09:39:12.263) I haven't used this product before so don't know if this is possible, but I think it would be useful if the front plate on the SPT1/M had a tapped hole on it. The front plate could then be attached to an external micrometer driven xy stage for a fine "one time only" alignment. After the plate was locked down (and alignment verified), the external stage could be removed and freed up for other uses. llamb

(posted 2019-02-05 08:42:39.0) Thank you for your feedback. I have added this idea to our internal product forum for further discussion. colin.hebert

(posted 2018-07-12 20:40:21.023) Hello,

I am also interested in a motorized actuator that will work with the ST1XY-S. Could you please contact me?

Thank you in advance YLohia

(posted 2018-07-13 11:46:02.0) Hello, thank you for contacting Thorlabs. I see that you emailed us as well with a request for a ST1XY-S customized with motorized actuators. We will reach out to you to discuss this further. adm746

(posted 2017-11-02 19:15:21.58) Why isn't there a mounting hole on the bottom of the CXY1? similar to the CRM1P. you could combine the post mount and cage mount varieties to reduce manufacturing cost. nbayconich

(posted 2018-01-05 10:04:39.0) Thank you for your feedback. I have forwarded your request for future consideration. I will reach out to you directly with more information about our custom capabilities. gesuele

(posted 2017-09-06 11:45:04.39) Is there any motorized actuator which can work in combination with the ST1XY-S? tfrisch

(posted 2017-09-15 02:50:12.0) Hello, thank you for contacting Thorlabs. We can offer this as a custom, I will reach out to you with details for a quote. yunqing.tang

(posted 2017-08-26 08:54:39.927) If I use a ST1XY-D in a vertical setup (the direction of optical aix is the same with the gravity), and about 400 grams of objects was loaded centrally under it (without torque) with the SM1 threaded housing. Is this could damage the ST1XY-D/M? What is the maximum central load capacity of the ST1XY-D/M translator? tfrisch

(posted 2017-09-20 11:15:25.0) Hello, thank you for contacting Thorlabs. ST1XY-D is designed as an optic mount rather than a stage. While we don't have any performance testing for loads in this orientation, you may find that XYT1 is more suitable for your application. I will reach out to you directly to discuss this. user

(posted 2017-08-03 09:42:33.663) An SM1 threaded version of CP1XY would be very useful. It wouldn't necessarilty need to fit in the 30mm cage system - post mountable or 60mm cage would also be good. awebber-date

(posted 2017-08-07 09:34:58.0) Response from Alex at Thorlabs: Thank you for your feedback, we are always looking to expand our product range. I will convey this to our engineers. valter.zazubovits

(posted 2017-03-02 14:26:41.277) Good day!

I am wondering if it is possible to purchase a ST1XY-D without the actual differential adjusters? And without any other screws. Did the design of ST1XY-D change in the last couple years, is the thread on the adjusters the same as it used to be (I presume 1/4-80)? I am planning on using that translation stage with old ThorLabs motor actuators that have 1/4-80 thread on them...

Regards,

Valter. jlow

(posted 2017-03-08 09:15:40.0) Response from Jeremy at Thorlabs: Yes, we are able to sell the ST1XY series without adjusters. To order this, please contact techsupport@thorlabs.com. The bushing thread on the ST1XY-D is still 1/4"-80. user

(posted 2017-02-09 07:00:31.857) The CP1XY is a great product; very compact and appears to be very stable. It would be interesting to be able to add your multilayer piezo actuators for electronic control.

I have a question regarding the stainless - is it 304, 310 or 316?

Thanks bhallewell

(posted 2017-02-09 10:47:47.0) Response from Ben at Thorlabs: Thank you for your product suggestion. I will log this as an idea within our internal new product ideas forum. In terms of the material of the plate, this is 304 steel. cmar5964

(posted 2016-09-29 15:46:16.03) Am I correct that there is no 30 mm cage xy translation mount for transmissive optics that can be actuated by one of your piezo adjusters, or did I just not find the correct one?

Thanks jlow

(posted 2016-09-29 04:06:31.0) Response from Jeremy at Thorlabs: There's currently no 30mm cage XY mount with piezo. I will contact you directly to discuss about your application and see if any alternative could work. user

(posted 2015-05-18 15:31:24.773) Hi, why the CXY1 is not post-mountable? It would be useful to have it working with both traditional setups and cage-system ones.

Thank you cdaly

(posted 2015-06-01 10:24:49.0) Response from Chris at Thorlabs: The current housing of the CXY1 has only a wall less than 2 mm thick for adding a tapped mounting hole. It is not an option in the current version as this is not enough material. We do have post mountable equivalents such as LM1XY, or the ST1XY series which can be used in either the cage or on a post. user

(posted 2015-04-21 16:12:06.21) the CXY1 would be a much better value if it was possible to have a cantilevered load hanging off the front. Right now I am hanging a 0.5lb about 2 inches off of the mount and the mount is not usable. The load tilts the front plate leaving my camera at an angle. While I understand that the springs may not be able to accommodate this, I would expect that if the load is forced against the screw the plate would at least stay parallel to the body. rating a 1 for now but this would be a solid 3 if this could be addressed.

The SPT1 would be the ideal solution for my application if it has some crude xy adjustment screws cdaly

(posted 2015-04-29 03:42:31.0) Response from Chris at Thorlabs: Thank you for your feedback. I'm afraid the CXY1 is not designed to have a load cantilevered off of the front and is only intended to be used when centrally loaded within the SM1 threaded housing. I'd recommend combining two more rugged linear travel stages, such as MT1 if something like the weight of a camera needs to be supported. paulinio91

(posted 2015-03-30 16:04:49.71) Hi, will ST1XY be work without damage with connected via tube SM1L03 cube C4W (and to C4W connected 2 translators, 2 lenses). What a maximum load of ST1XY translator?

Looking like this:

ST1XY with lens in tube

|

fixed ST1XY-SM1L03-(C4W with B3CR)

|

ST1XY with lens in tube jlow

(posted 2015-07-24 04:39:23.0) Response from Jeremy at Thorlabs: We do not have a damage threshold for this. The stage will probably be able to handle this but there will be definitely be some angular deviation to the stage. As an example, with around 0.42 in-lb of torque, you can expect to see around 200µrad deviation. hugh.simons

(posted 2014-03-03 07:35:05.96) Hi,

Is it possible for any of the 30mm (or even 16mm) cage-mount XY stages to be motorized?

Thanks,

Hugh cdaly

(posted 2014-03-05 11:48:52.0) Response from Chris at Thorlabs: Thank you for you feedback. Yes, it is possible for the ST1XY series of translators, but it must be done during assembly. We have quoted this with Z806 actuators before. I will contact you directly about this. jlow

(posted 2012-08-17 12:16:00.0) Response from Jeremy at Thorlabs: Thank you for pointing this out to us. We will fix the solid model files for this part shortly. user

(posted 2012-08-17 09:43:41.0) Hi

The CAD (STEP) download for the CP1XY appears to be missing an adjustment knob on one axis. The PDF file shows the knob.

Thanks for making these avialable. bdada

(posted 2012-04-26 19:30:00.0) Response from Buki at Thorlabs to rjaculbia:

The ST1XY has three 8-32 (M4) tapped holes on the bottom surface to allow direct mounting on our TR Series Posts. The TR post can be placed in a post holder which is secured to the table with a post holder base like the BA2. Please use the link below to review our selection of our 1/2" post assembly products:

http://thorlabs.com/navigation.cfm?Guide_ID=52

If you want to mount the ST1XY closer to the optical table, please consider using the MA2 adapter instead of the BA2 (threads are not directly compatible). The MA2 has #8-32 mounting holes for the ST1XY and a center clearance hole for 1/4"-20 threads.

Another alternative is to mount the MA2 adapter on our 1.5" diameter P series posts. Please use the link below to see a picture of the ST1XY in our KT110 fiber launch system to see this configuration.

http://thorlabs.com/thorProduct.cfm?partNumber=KT110

There are just a few options for you to consider. Please contact TechSupport@thorlabs.com if you have any questions. user

(posted 2012-04-26 09:28:29.0) Hi, If I want to mount the ST1XY on an optical table, what are my options? Can I screw the ST1XY on a BA2 and mount the BA2 on the table or is there a better way? Thanks.

rjaculbia tcohen

(posted 2012-04-19 13:50:00.0) Response from Tim at Thorlabs: Retrofitting the ST1XY-S to have the differential drives is possible, but will include more than simply switching out one for the other. I will contact you with the parts, tools and information needed to make this alteration. doron.azoury

(posted 2012-04-18 10:14:10.0) Hi,

We have ST1XY-S. Is it possible to replace only the drivers, to differential driver (thorlabs model DM22),as in ST1XY-D? Thank you. bdada

(posted 2012-01-12 19:42:00.0) Response from Buki at Thorlabs:

Thank you for participating in our feedback forum and for your product suggestion on how to increase the mounting options for the ST1XY translation mounts. We would like to learn more about where the placement of the additional threaded holes would be beneficial to you but we do not have your contact information. Please contact TechSupport@thorlabs.com to discuss this further. user

(posted 2012-01-12 14:32:46.0) Can you please put a second M4&M6 thread on both sides of ST1XY products? This would be very helpful to mount them when an optical table is crowded. Thanks Thorlabs

(posted 2010-07-14 10:09:09.0) Response from Javier at Thorlabs to day: thank you for your feedback. You can certainly mount any of the ST1XY-*/M mounts onto the PT1/M translation stage. The mounting threads on the metric ST1XY mount are M4, while the PT1/M features M6 threads, so you can use the AP6M4M external M4 to external M6 thread adapter (http://www.thorlabs.com/NewGroupPage9.cfm?ObjectGroup_ID=1745). If height adjustment is needed, you can use our metric posts and post holders. day

(posted 2010-07-14 12:19:06.0) Can the ST1/M be mounted on the PT1/M to create an XYZ lens mount? (I would like finer resolution in the Z direction than the 50TPI of the SM1ZM). Which adapter would I need for this?

Thanks apalmentieri

(posted 2010-01-05 09:22:05.0) A response from Adam at Thorlabs to amy peng: I am sorry for the delayed resonse. Thank you for the suggestion that we had a version of the HPT1 designed for the 60mm cage system. We are currently looking to add this to our design plan. While we do not have this readily available, we hope to add to our wide variety of products soon. amypeng

(posted 2009-12-02 07:07:18.0) Can you make equivalent of this product but for 60mm cage mounts? |

- Flexure Design for Maximum Stability

- Stainless Steel Construction

- SM05 (0.535"-40) Compatible

- ±0.25 mm Range in X and Y Directions

- Resolution: 200 µm/rev

The CP1XY offers ±0.25 mm of XY travel manipulated by M2.5 x 0.20 fine pitch adjusters. The stainless steel flexure design provides excellent long-term stability and is ideal for fiber coupling applications or experiments that use spatial filters or pinholes, which require fine positioning. The 0.35" (8.89 mm) long center bore is tapped through with an SM05 (0.535"-40) thread to allow the integration of our extensive SM05-threaded family of products. The CP1XY is vacuum compatible to 10-5 Torr. We recommend using two POLARIS-SM05RR vacuum-compatible, stainless steel retaining rings (sold separately) to secure an optic in the bore while under vacuum conditions. Alternatively, for non-vacuum applications, we offer SM05RR anodized aluminum retaining rings.

| Item # | Travel | Drive | Optic Mounting | ER Cage Rod Connection |

|---|---|---|---|---|

| CP1XY | ±0.01" (±0.25 mm) | M2.5 x 0.20 Fine Pitch Adjusters | SM05 (0.535"-40) Thread | 4 Through Holes with Side-Located Locking Screws |

Click to Enlarge

CXY1A XY Translator Coupled to a CT1A Z-Axis Translation Mount Using an SM1S15 Lens Tube

- Accepts Ø1.00" (Ø25.4 mm) Optics up to 0.39" (10.0 mm) Thick

- ±1 mm Travel in X and Y via 3/16"-100 Adjusters

- Compatible with 30 mm Cage Systems

- SM1 (1.035"-40) Threading for Compatibility with Our Extensive Line of SM1 Lens Tubes

The CXY1A XY Translator provides ±1 mm of travel perpendicular to the optical axis of a 30 mm cage system. This translation is actuated by two 3/16"-100 adjusters, which are lockable via a 0.035" hex key. The movable carriage is internally SM1 (1.035"-40) threaded and directly accepts Ø1" optics up to 0.39" (10.0 mm) thick when secured using the included SM1RR retaining ring. The fixed back side is also threaded to allow SM1 lens tubes to be attached. The center carriage has been designed to offer pure X and Y translation. The mount features engraved vertical and horizontal tick marks to use as an alignment aid for the mounting carriage.

The translation mount also features four through holes for use with our ER cage rods. One side-located M4 x 0.7 locking setscrew in each bore can be tightened using a 5/64" (2.0 mm) hex key to secure a cage rod.

For applications requiring a greater travel range, we offer XY translators with ±2.5 mm travel.

| Item # | Travel | Drive | Optic Mounting | ER Cage Rod Connection |

|---|---|---|---|---|

| CXY1A | ±1 mm | 100 Threads per Inch (TPI) Adjusters | SM1 (1.035"-40) Thread | Through Holes with Side-Located Locking Screws |

Click to Enlarge

Click to EnlargeThe CXY1QA mount integrated into a cage system.

- Accepts Ø1.00" (Ø25.4 mm) Optics

- ±1 mm Travel in X and Y via 3/16"-100 Adjusters

- Magnetically Coupled, Quick-Release Mounting Carriage (Extra Carriages Sold Separately)

- Compatible with 30 mm Cage Systems

- SM1 (1.035"-40) Threading for Compatibility with Our Extensive Line of SM1 Lens Tubes

The CXY1QA XY Translation Mount is similar to the CXY1A mount sold above, but features a quick-release mounting carriage for easy exchange of components within a 30 mm Cage System. This mount provides ±1 mm of travel perpendicular to the optical axis of a 30 mm cage system. This translation is actuated by two 3/16"-100 lockable adjusters. The movable center carriage and magnetically coupled mounting carriage are internally SM1 (1.035"-40) threaded and directly accept Ø1" optics up to 0.39" (10.0 mm) and 0.20" (5.0 mm) thick, respectively, when secured using the included SM1RR retaining ring. The fixed back side is also threaded to allow SM1 lens tubes to be attached. The center carriage has been designed to offer pure X and Y translation.

The mount features engraved vertical and horizontal tick marks to use as an alignment aid for the movable carriage. A dot is engraved on both pieces of the mount to indicate the correct orientation of the quick-release carriage. Aligning the dots ensures the quick-release carriage is properly secured. The quick-release carriage also features a dedicated white space for denoting the optic that has been mounted within it. This allows for easy identification if more than one carriage is being used in a setup, as extra CXY1QF quick-release carriages can be purchased separately.

The translation mount also features four through holes for use with our ER cage rods. One side-located M4 x 0.7 locking setscrew in each bore can be tightened using a 5/64" (2.0 mm) hex key to secure a cage rod.

To remove the quick-release carriage from the mount when in a closed cage system, detach the carriage, rotate it 90°, and then take it out of the system. There must be at least 1.60" (40.6 mm) separating the edge of the quick-release carriage and the next component in the system to provide enough clearance during removal.

| Item # | Travel | Drive | Optic Mounting | Torque Applied to CXY1QF | ER Cage Rod Connection |

|---|---|---|---|---|---|

| CXY1QA | ±1 mm | 100 Threads per Inch (TPI) Adjusters | SM1 (1.035"-40) Thread | 0.58 in-lb (0.0655 N•m)a | Through Holes with Side-Located Locking Screws |

- Accepts Ø1.00" Optics up to 0.48" (12.2 mm) Thick

- Compact Design; ±0.12" (±3.0 mm) Travel

- Compatible with Our Ø1" SM1 Lens Tubes

- 4-40 Taps on Front and Back Provide 30 mm Cage Compatibility

The ST1XY translation mounts offer ±3.0 mm of travel provided by one of three drive types: adjuster screw, micrometer, or differential drive. They utilize hardened tool steel components on all moving parts to ensure long-term, drift-free operation. The ST1XY is designed to connect with our extensive line of Ø1" SM1 Lens Tubes as well as our 30 mm cage assemblies to offer great flexibility when building optical systems.

The translating SM1-threaded carriage accepts optics up to 0.48" (12.2 mm) thick when using two SM1RR retaining rings (included). A stationary internal SM1 thread with 0.14" (3.5 mm) depth is present on the other side of the mount that allows for coupling to stationary SM1 Lens Tubes. Three 8-32 (M4) tapped holes are provided on the bottom surface to allow direct mounting on our Ø1/2" Posts.

Thorlabs also offers the CXY1A XY Translator, which has Ø6 mm through holes for cage rods, as opposed to the 4-40 taps on the ST1XY translation mounts. These through holes permit the CXY1A to slide along the optic axis.

The ST1XY-D(/M) features DM22 differential drives. For more information about this drive, including operation and adjustment knob reattachment, please visit our DM22 differential drive page.

| Item # | Travel | Drive Type |

Drive Mechanism | Optic Mounting |

Post Mounting |

ER Cage Rod Connection |

|---|---|---|---|---|---|---|

| ST1XY-A(/M) | ±0.12" (±3.0 mm) |

100 TPI | 0.01" (0.25 mm) per Revolution and 100 Threads per Inch Adjusters (Locking Set Screw on Each Adjuster Uses 0.035" Hex Key) |

SM1 (1.035"-40) Thread |

Three 8-32 (M4) Tapped Holes on Bottom Surface |

4-40 Tapped Holes or Counterbored Mounting Using ST1CP |

| ST1XY-S(/M) | Micrometer | 0.5 mm per Revolution and 10 µm per Graduation Micrometer Screws | ||||

| ST1XY-D(/M) | Differential | 0.4 mm per Revolution Coarse and 25 µm per Revolution Fine Control with 0.5 µm per Graduation Differential Micrometers |

- Designed Specifically for Use with the ST1XY Series of XY Translators (Featured Above)

- Connect Two Internally Threaded Cage Components with ER Rods

- SM1 (1.035"-40) Threaded Through Hole

- Four 4-40 Screws Included

The ST1CP is a bolt-on adapter designed specifically for use with the ST1XY-series of XY translators. Like our ERSCB adapter, this plate can be used to connect two internally threaded cage components with ER rods. First thread the four included 4-40 screws through the ST1CP through hole and into the internally bored side of the ER rod (as shown in the figure to the left). Then, remove the back plate on an ST1XY stage and secure this adapter plate in its place using the four outer 2-56 counterbored through-holes. Once attached, this adapter plate keeps the cage and any SM1-threaded component attached to the adapter plate stationary, while enabling an optic inside the ST1XY stage to move relative to these fixed components.

Alternatively, this adapter can also be attached to the front side (i.e., the side without the removable mount) of an ST1XY stage using the included 4-40 screws. In this case, the front side of the ST1XY stage will no longer be cage compatible (although the back side still is). However, the advantage of this configuration is that two SM1-compatible components can be attached to the ST1XY stage (one on each side) and an optic inside the stage can be moved relative to these fixed components.

Click to Enlarge

The SPT1CT and SPT1C Slip Plates assembled in a cage system using the ER series cage rods.

- ±0.04" (±1.0 mm) of Adjustment in Both X and Y Directions

- Center-Located SM1 (1.035"-40) Threaded Hole in Front Slip Plate and Smooth Bore in Fixed Back Plate

- Position Front Plate by Hand and Lock in Place by Tightening Locking Screws

- Secure Back Plate to Four Cage Rods via Side-Located Setscrews

- 8-32 (M4) Threaded Hole in Base of Back Plate for Post Mounting

The SPT1C(/M) and SPT1CT(/M) Slip Plate Positioners are designed to provide coarse XY positioning of optical components within our 30 mm Cage Assembly System. This design provides for manual adjustment only and is best utilized in conjunction with an alignment laser to monitor centricity. The front plate can be locked into position against the fixed plate via two locking screws, which can be tightened using a 5/64" (2 mm) hex key.

The SPT1C(/M) slip plate accomodates Ø1" optics up to 0.08" (2.0 mm) thick, while the thicker front plate on the SPT1CT(/M) can hold Ø1" optics up to 0.34" (8.6 mm) thick. Unmounted optics can be secured with SM1RR Retaining Rings, two of which are included with the SPT1CT(/M). The center-located SM1 (1.035"-40) tapped through hole also directly accepts externally SM1-threaded components. Four through holes in the back plate of each mount with side-located locking screws accept ER series cage rods for compatibility with our 30 mm cage systems.

| Item # | Travel | Slip Plate Thickness | Maximum Optic Thickness | Optic Mounting | Post Mounting | ER Cage Rod Attachment |

|---|---|---|---|---|---|---|

| SPT1C(/M) | ±0.04" (±1.0 mm) |

0.23" (5.8 mm) | 0.08" (2.0 mm) | SM1 (1.035"-40) Thread |

8-32 (M4 x 0.7) Tap on Bottom Surface |

4 Through Holes with Side-Located Locking Screws, 5/64" (2 mm) Hex |

| SPT1CT(/M) | 0.50" (12.7 mm) | 0.34" (8.6 mm) |

Click to Enlarge

Front View of VRC1CPT Drop-In Alignment Plate

- Drop-In Beam Alignment Tools

- Small Through Hole Aligned at Center of 30 mm Cage Assembly

The CPA1 and CPA2 Alignment Plates are convenient tools for aligning cage-based optical systems. These drop-in plates feature a small through hole at the exact center of the 30 mm cage assembly that is used for aligning visible beams. For easy alignment, the through hole is surrounded by engraved rings, which indicate Ø4 mm, Ø7 mm, Ø10 mm, and Ø13 mm. The CPA1 provides a Ø0.9 mm through hole, while the CPA2 provides a Ø5 mm through hole.

The VRC1CPT, VRC2CPT, VRC4CPT, and VRC6SCPT Alignment Plates are specifically designed to align UV to MIR beams in a cage-based optical assembly. These plates have concentric alignment ring engravings identical to the CPA1 (shown to the left) plate on the back. The fronts of the VRC1CPT, VRC2CPT, and VRC4CPT plates each include a Ø1/2" (Ø12.7 mm), non-rotating fluorescing alignment disk made of the same material used in our VRC1, VRC2, and VRC4 Viewing Cards, respectively. Alternatively, the front of the VRC6SCPT plate includes a Ø0.39" (Ø10.0 mm), non-rotating MIR alignment disk made of the same thermochromic liquid crystal material used in our VRC6S Viewing Card. The disk on the VRC1CPT, VRC2CPT, or VRC4CPT plate has a Ø1.5 mm hole centered on the plate's Ø0.9 mm hole, and the disk on the VRC6SCPT plate has a Ø2.0 mm hole centered on the plate's Ø0.9 mm hole.

Products Home

Products Home

Zoom

Zoom

XY Translation Mounts

XY Translation Mounts