Kinesis® K-Cube™ Laser Sources

- Two Wavelengths Available: 635 nm and 1550 nm

- Single Mode Interface with FC/PC Output Connector

- Operates Using Top Panel Controls or Remote PC via USB

KLS1550

K-Cube™ 1550 nm Laser Source

Shown with Included Mounting Plate

(Power Supply Sold Separately)

Kinesis Software Included

Please Wait

Click to Enlarge

A KCH301 USB Controller Hub with Installed KLS1550 and KPC101 K-Cube Modules

| Compact Light Source & Driver Modules |

|---|

| K-Cube Modulesa |

| Laser Diode Driver |

| Laser Sources |

| T-Cube Modulesa |

| High Power LED Driver |

Click to Enlarge

Top and Back Views of KLS635 Laser Source

(See the Pin Diagrams Tab for More Information)

Features

- Compact Footprint: 121.0 mm x 60.0 mm x 47.0 mm

- 635 nm or 1550 nm Wavelengths Available

- Single Mode Fiber Interface with FC/PC Bulkhead

- LCD Display Screen and Controls for Standalone Operation

- USB Connection for Remote PC-Controlled Operation

- SMA Input for Laser Intensity Control from External Source

- Two Bidirectional I/O Triggers (5 V TTL Signal)

- Safety Enable Key Switch and Laser Safety Interlock Jack

- Includes the Kinesis® Software Control Suite

- Software Compatible with Other Kinesis Controllers for Integrated Systems Development

- Single-Channel PSU Options Available Separately

- USB Controller Hubs for Operating Multiple K-Cubes™ or T-Cubes™ (Sold Separately)

- Magnetic, Clip-On Optical Table Mounting Adapter Included

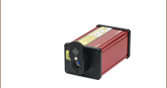

Thorlabs' K-Cube Laser Sources are fully functional, highly compact, fiber-coupled laser sources with a center wavelength of either 635 nm or 1550 nm. Each unit incorporates driver electronics and an FC/PC (2.1 mm wide key) fiber interface. The internally pigtailed Fabry-Perot laser diode is connected to the rear panel FC/PC output via a single mode fiber. With this fiber-to-fiber connection at the output, these devices deliver optical power more efficiently than air-to-fiber systems that use a receptacle with embedded optics. The laser can be operated independently via the top panel controls and display screen or remotely by PC via a USB connection. The output power is monitored continuously and a feedback circuit adjusts the laser power to achieve a constant output power.

The unit has a highly compact 121.0 mm x 60.0 mm x 47.0 mm footprint, allowing it to be positioned close to the rest of the system for added convenience when manually adjusting the laser output using the top panel controls. Tabletop operation also allows minimal cable lengths for easier cable management. A power switch on the front of the unit turns the K-Cube on and off. The top panel display screen enables operation as soon as the unit is turned on, without the need for connection to a PC. When the switch is turned off, the K-Cube saves all user-adjustable settings for the next session. Please note that the power switch should always be in the "off" position when plugging in or unplugging the unit. The laser must be turned off when connecting or disconnecting a fiber from the input. Please ensure the fiber tip and connector bulkhead are clean prior to use; the FBC250 Bulkhead and Connector Cleaner can be used to clean the bulkhead and connecting fiber.

USB connectivity provides easy 'Plug-and-Play' PC-controlled operation, and a suitable cable is included with each K-Cube laser source (USB 3.0 type A to USB 2.0 type Micro B). The Kinesis software package features .NET controls that can be used by third-party developers working in compatible languages such as C, C# and LabVIEW™ to create custom applications. For more details, please see the Kinesis Software and Kinesis Tutorials tabs.

Optical Table Mounting Plate

Each unit comes with a mounting plate that clips onto the base of the module. The plate contains two magnets for temporary placement on an optical table and two counterbored slots for 1/4"-20 (M6) cap screws for a more permanent placement on the tabletop.

Power Supply Options

The preferred power supply (single channel, multi-channel, or hub-based) depends on the end user's application and whether you already own compatible power supplies. To that end and in keeping with Thorlabs' green initiative, we do not ship these units bundled with a power supply.

Multiple units can be connected to a single PC by using the KCH301 or KCH601 USB Controller Hubs, available below, for applications involving multiple K-Cubes and/or T-Cubes. Please see the Mounting Options tab for more details. The KCH301 features three controller mounting bays while the KCH601 features six controller mounting bays. Note that these K-Cube laser sources occupy two mounting bays on the USB controller hubs.

All power supply options compatible with the K-Cube laser sources can be found below.

| Item # | KLS635 | KLS1550 |

|---|---|---|

| Wavelength | 635 nm | 1550 nm |

| Maximum Output Power | 8.0 mW | 7.0 mW |

| Output Fiber Connector | FC/PC (Wide 2.1 mm Key Compatible) | |

| Stability | ±0.1 dB | |

| Display Accuracy | ±10% | |

| Set Point Resolution | 0.01 mW | |

| Modulation Input | 0 to 10 V = 0 to Full Power | |

| Modulation Bandwidth | Sine Wave: 600 Hz at 3 dB 1 kHz at 6 dB |

|

| EXT IN Input Impedancea | 16 kΩ | |

| Input Voltage | 15 V | |

| Operating Temperature | 15 to 35 °C | |

| Storage Temperature | 0 to 50 °C | |

| USB Connector Type | USB 3.0 | |

| USB Connection Speed | USB 1.1 Full Speed (12 Mbps) | |

| Housing Dimensions (W x D x H) | 121.0 mm x 60.0 mm x 47.0 mm (4.76" x 2.36" x 1.85") | |

| Weight | 350 g | 300 g |

Computer Connection

The USB 3.0 port is compatible with a USB 2.0 Micro B connector if the Micro B connector is plugged into the shaded region in the photo above. A USB 3.0 type A to type Micro B cable is included with the K-Cube Laser Sources.

I/O 1 & 2

SMA Female

These connectors provide a 5 V logic level input and output that can be configured to support triggering into and out of external devices. Each port can be independently configured to control the logic level or to set the trigger as an input or output.

Ext In

SMA Female

Used to control the intensity of the laser output from an external source. This input can be driven from a 0 to 10 V voltage source. The input impedence is 16 kΩ.

Interlock

2.5 mm Pin

Interlock Jack must be shorted with included 2.5 mm pin or external user gate before laser may be enabled.

K-Cube Mounting Options

Two options are available to securely mount our K-Cube controllers onto an optical table. An optical table mounting plate, provided with every K-Cube, allows for a single controller to be attached to an optical table. Alternatively, three- and six-port USB controller hubs are offered (sold separately) that can mount and power our K-Cube controllers. These options are described in further detail below.

Optical Table Mounting Plate

Each K-Cube unit comes with a mounting plate that clips onto the base of the controller, as shown in the animation below. The plate contains two magnets for temporary placement on an optical table and two counterbores for 1/4"-20 (M6) cap screws for a more permanent placement on the tabletop. Please see the Specs tab for a mechanical drawing of the table mounting plate.

Kinesis USB Controller Hubs

Multiple units can be mounted and connected to a single PC by using the KCH301 or KCH601 USB Controller Hubs. They each consist of two parts: the hub, which can support up to three (KCH301) or six (KCH601) K-Cubes or T-Cubes, and a power supply that plugs into a standard wall outlet. K-Cubes simply clip into place using the provided on-unit clips, while current- and previous-generation T-Cubes require the KAP101 Adapter Plate, shown in the animation below. The hub vastly reduces the number of USB and power cables required when operating multiple controllers.

K-Cube Table Mounting Plate

Kinesis USB Controller Hubs

3- and 6-Port USB Controller Hubs allow multiple controllers to be connected to one PC for multi-axis applications. K-Cubes can be directly attached to the hubs while T-Cubes require a KAP101 Adapter Plate.

Software

Kinesis Version 1.14.50

The Kinesis Software Package, which includes a GUI for control of Thorlabs' Kinesis system controllers.

Also Available:

- Communications Protocol

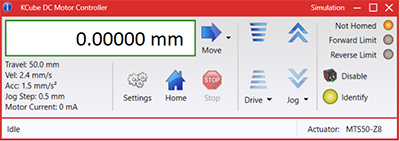

Kinesis GUI Screen

Thorlabs offers the Kinesis® software package to drive our wide range of motion controllers. The software can be used to control devices in the Kinesis family, which covers a wide variety of motion controllers ranging from small, low-powered, single-channel drivers (such as the K-Cubes™) to high-power, multi-channel benchtop units and modular 19" rack nanopositioning systems (the MMR60x Rack System).

The Kinesis Software features .NET controls which can be used by 3rd party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications. Low-level DLL libraries are included for applications not expected to use the .NET framework and APIs are included with each install. A Central Sequence Manager supports integration and synchronization of all Thorlabs motion control hardware.

By providing this common software platform, Thorlabs has ensured that users can mix and match any of our motion control devices in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from single-axis to multi-axis systems and control all from a single, PC-based unified software interface.

The software package allows two methods of usage: graphical user interface (GUI) utilities for direct interaction with and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

Legacy Software

Select products are still capable of running the legacy APT™ software package. Information on software compatibility can be found in the product documentation (![]() ), and additional details about the APT software can be found here.

), and additional details about the APT software can be found here.

Thorlabs' Kinesis® software features new .NET controls which can be used by third-party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications.

C#

This programming language is designed to allow multiple programming paradigms, or languages, to be used, thus allowing for complex problems to be solved in an easy or efficient manner. It encompasses typing, imperative, declarative, functional, generic, object-oriented, and component-oriented programming. By providing functionality with this common software platform, Thorlabs has ensured that users can easily mix and match any of the Kinesis controllers in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from the low-powered, single-axis to the high-powered, multi-axis systems and control all from a single, PC-based unified software interface.

The Kinesis System Software allows two methods of usage: graphical user interface (GUI) utilities for direct interaction and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

For a collection of example projects that can be compiled and run to demonstrate the different ways in which developers can build on the Kinesis motion control libraries, click on the links below. Please note that a separate integrated development environment (IDE) (e.g., Microsoft Visual Studio) will be required to execute the Quick Start examples. The C# example projects can be executed using the included .NET controls in the Kinesis software package (see the Kinesis Software tab for details).

|

Click Here for the Kinesis with C# Quick Start Guide Click Here for C# Example Projects Click Here for Quick Start Device Control Examples |

|

LabVIEW

LabVIEW can be used to communicate with any Kinesis- or APT-based controller via .NET controls. In LabVIEW, you build a user interface, known as a front panel, with a set of tools and objects and then add code using graphical representations of functions to control the front panel objects. The LabVIEW tutorial, provided below, provides some information on using the .NET controls to create control GUIs for Kinesis- and APT-driven devices within LabVIEW. It includes an overview with basic information about using controllers in LabVIEW and explains the setup procedure that needs to be completed before using a LabVIEW GUI to operate a device.

|

Click Here to View the LabVIEW Guide Click Here to View the Kinesis with LabVIEW Overview Page |

|

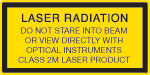

Laser Safety and Classification

Safe practices and proper usage of safety equipment should be taken into consideration when operating lasers. The eye is susceptible to injury, even from very low levels of laser light. Thorlabs offers a range of laser safety accessories that can be used to reduce the risk of accidents or injuries. Laser emission in the visible and near infrared spectral ranges has the greatest potential for retinal injury, as the cornea and lens are transparent to those wavelengths, and the lens can focus the laser energy onto the retina.

Safe Practices and Light Safety Accessories

- Laser safety eyewear must be worn whenever working with Class 3 or 4 lasers.

- Regardless of laser class, Thorlabs recommends the use of laser safety eyewear whenever working with laser beams with non-negligible powers, since metallic tools such as screwdrivers can accidentally redirect a beam.

- Laser goggles designed for specific wavelengths should be clearly available near laser setups to protect the wearer from unintentional laser reflections.

- Goggles are marked with the wavelength range over which protection is afforded and the minimum optical density within that range.

- Laser Safety Curtains and Laser Safety Fabric shield other parts of the lab from high energy lasers.

- Blackout Materials can prevent direct or reflected light from leaving the experimental setup area.

- Thorlabs' Enclosure Systems can be used to contain optical setups to isolate or minimize laser hazards.

- A fiber-pigtailed laser should always be turned off before connecting it to or disconnecting it from another fiber, especially when the laser is at power levels above 10 mW.

- All beams should be terminated at the edge of the table, and laboratory doors should be closed whenever a laser is in use.

- Do not place laser beams at eye level.

- Carry out experiments on an optical table such that all laser beams travel horizontally.

- Remove unnecessary reflective items such as reflective jewelry (e.g., rings, watches, etc.) while working near the beam path.

- Be aware that lenses and other optical devices may reflect a portion of the incident beam from the front or rear surface.

- Operate a laser at the minimum power necessary for any operation.

- If possible, reduce the output power of a laser during alignment procedures.

- Use beam shutters and filters to reduce the beam power.

- Post appropriate warning signs or labels near laser setups or rooms.

- Use a laser sign with a lightbox if operating Class 3R or 4 lasers (i.e., lasers requiring the use of a safety interlock).

- Do not use Laser Viewing Cards in place of a proper Beam Trap.

Laser Classification

Lasers are categorized into different classes according to their ability to cause eye and other damage. The International Electrotechnical Commission (IEC) is a global organization that prepares and publishes international standards for all electrical, electronic, and related technologies. The IEC document 60825-1 outlines the safety of laser products. A description of each class of laser is given below:

| Class | Description | Warning Label |

|---|---|---|

| 1 | This class of laser is safe under all conditions of normal use, including use with optical instruments for intrabeam viewing. Lasers in this class do not emit radiation at levels that may cause injury during normal operation, and therefore the maximum permissible exposure (MPE) cannot be exceeded. Class 1 lasers can also include enclosed, high-power lasers where exposure to the radiation is not possible without opening or shutting down the laser. |  |

| 1M | Class 1M lasers are safe except when used in conjunction with optical components such as telescopes and microscopes. Lasers belonging to this class emit large-diameter or divergent beams, and the MPE cannot normally be exceeded unless focusing or imaging optics are used to narrow the beam. However, if the beam is refocused, the hazard may be increased and the class may be changed accordingly. |  |

| 2 | Class 2 lasers, which are limited to 1 mW of visible continuous-wave radiation, are safe because the blink reflex will limit the exposure in the eye to 0.25 seconds. This category only applies to visible radiation (400 - 700 nm). |  |

| 2M | Because of the blink reflex, this class of laser is classified as safe as long as the beam is not viewed through optical instruments. This laser class also applies to larger-diameter or diverging laser beams. |  |

| 3R | Class 3R lasers produce visible and invisible light that is hazardous under direct and specular-reflection viewing conditions. Eye injuries may occur if you directly view the beam, especially when using optical instruments. Lasers in this class are considered safe as long as they are handled with restricted beam viewing. The MPE can be exceeded with this class of laser; however, this presents a low risk level to injury. Visible, continuous-wave lasers in this class are limited to 5 mW of output power. |  |

| 3B | Class 3B lasers are hazardous to the eye if exposed directly. Diffuse reflections are usually not harmful, but may be when using higher-power Class 3B lasers. Safe handling of devices in this class includes wearing protective eyewear where direct viewing of the laser beam may occur. Lasers of this class must be equipped with a key switch and a safety interlock; moreover, laser safety signs should be used, such that the laser cannot be used without the safety light turning on. Laser products with power output near the upper range of Class 3B may also cause skin burns. |  |

| 4 | This class of laser may cause damage to the skin, and also to the eye, even from the viewing of diffuse reflections. These hazards may also apply to indirect or non-specular reflections of the beam, even from apparently matte surfaces. Great care must be taken when handling these lasers. They also represent a fire risk, because they may ignite combustible material. Class 4 lasers must be equipped with a key switch and a safety interlock. |  |

| All class 2 lasers (and higher) must display, in addition to the corresponding sign above, this triangular warning sign. |  |

|

| Posted Comments: | |

Xiao Wang

(posted 2024-03-28 13:04:08.13) what's the spectrum bandwidth of 635nm laser source spolineni

(posted 2024-04-04 07:16:04.0) Thank you for contacting us. The diode used in the KLS635 is a single mode Fabry-Perot diode and the FWHM should be ~1nm. Simon Neves

(posted 2023-10-03 16:16:48.547) Dear support,We recently purchased a KLS1550. The source seems to have a sort of bug when we turn it on. The screen of the module loops on: 1. the "Thorlabs" intro image, 2. then very briefly shows the screen with written "Laser off", 3. goes immediately to "savings params & powering down...". It repeats these 3 displays indefinitly, apparently with no possibility of going out of the loop. Do you have any idea of how to fix this issue? Thank you for your consideration. do'neill

(posted 2023-10-10 09:08:11.0) Response from Daniel at Thorlabs. I am sorry to hear this. I will reach out to you directly to help troubleshoot this. user

(posted 2023-09-26 17:40:05.39) Dear Support,

We have been using KLS1550 laser for several years, and the maximum power was 7 mW as per specifications. When we launched the laser today the maximum power dropped to 1 mW.

This issue appeared a few days after we started using external modulation mode, although the maximum power is now 1 mW for all the control modes (wheel, software, external).

Thank you! do'neill

(posted 2023-09-27 11:00:45.0) Response from Daniel at Thorlabs. I will reach out to you directly to help troubleshoot this and see if we can isolate the issue and fix it for you. F Bess

(posted 2022-09-12 13:20:04.087) Hi! Is KLS1550 monomode (I mean for longitudinal mode)? DJayasuriya

(posted 2022-09-14 03:42:36.0) Thank you for your inquiry. The KLS has a single mode Fabry-Perot diode. Hope this helps. Please don't hesitate to get in touch with your local tech support team if you do require any assistance. Alexis Carlotti

(posted 2022-04-21 10:02:55.807) Hi! We purchased a KLS635 recently, and we observed a weird behavior: the wavelength of the laser changes between two values over a few seconds. This happens both when the laser is warming up, but also after waiting for some time, say, 10min. The transition between these two wavelengths is continuous, i.e., for a brief amount of time the laser is far from being really monochromatic.

Is it normal? cwright

(posted 2022-04-22 06:47:22.0) Response from Charles at Thorlabs: Thank you for your query. This is mode-hopping and is not unexpected for diodes which are not thermally stabilised with a TEC. For best performance we recommend to wait approximately 30 mins for the unit to thermally stabilise to the environment. Akshay Singh

(posted 2021-05-20 19:18:50.62) hi, what is the linewidth (in nanometers) for KLS635 laser? Also, what is the output M2 os laser spot? cwright

(posted 2021-05-20 10:09:19.0) Response from Charles at Thorlabs: Thank you for your query. The diode used in the KLS635 is a single mode Fabry-Perot diode and while we do not have a specified linewidth for the KLS635 but, having looked at test data for a couple of diodes in stock, the FWHM should be ~1nm. We do not have an M2 value. Jaeduck Jang

(posted 2019-03-27 03:56:32.89) Dear Mr/Ms

I want to know optical bandwidth of KLS1550 laser.

Is it single frequency laser at 1550nm ?

Some laser diodes in THORLABS have 10~20nm optical bandwidth and the others are single frequency laser diodes. KLS1550 is in which case? user

(posted 2019-04-04 03:59:09.0) Response from Radu at Thorlabs. The laser diode inside KLS1550 is a distributed feedback diode. We consider them to be single frequency. Having looked in the test data obtained for one of the units that is currently in stock, I see that we measured a linewidth of ~ 70 pm. david.panak

(posted 2018-01-27 11:50:23.97) can the control panel be remoted, ~24" away from the unit? How many and what type of connections would be needed for a cable? bwood

(posted 2018-01-30 08:55:58.0) Response from Ben at Thorlabs: Thank you for your question. The TLS001-635 can only safely be used as a complete, enclosed unit as sold, so we cannot recommend any physical modifications to the unit. If you need to operate the device remotely, we would suggest using our software package. user

(posted 2017-05-25 12:32:16.563) Hello, thank you for nice product. Please, what is typical coherence lengh of this Laser source?

regards,Paul bwood

(posted 2017-05-26 06:52:20.0) Response from Ben at Thorlabs: Thank you for your feedback. We have not measured the coherence length of this laser source. In general, the coherence length of our laser diodes will be reasonably small (of the order of mm), and I would expect the same for this source |

- FC/PC-Coupled Output

- 635 nm or 1550 nm Center Wavelength

- Top Panel Display Screen and Controls for Standalone Operation

- USB Connectivity for PC Operation with the Kinesis® Software

- Power Supply Not Included (See Below)

The KLS635 and KLS1550 K-Cube laser sources are compact units with a fiber-coupled Fabry-Perot laser diode. The unit can be operated via the top panel display screen and controls as soon as the device is turned on. Alternatively, a USB connection allows for remote PC operation with the Kinesis software. An integrated feedback circuit maintains constant optical output power at the selected output intensity level.

The unit has a very small 121.0 mm x 60.0 mm x 47.0 mm (4.76" x 2.36" x 1.85") footprint and may be mounted directly to the optical table using the 1/4" (M6) counterbored slots in the base plate. This compact size allows the laser source to be positioned close to the rest of the system for added convenience when manually adjusting components. Tabletop operation also allows minimal cable lengths for easier cable management.

Please note that this controller does not ship with a power supply. Compatible power supplies are listed below.

Click for Details

Each KPS201 power supply includes one region-specific adapter, which can be selected upon checkout.

Click to Enlarge

The KPS201 Power Supply Unit

- Individual Power Supply

- KPS201: For K-Cubes™ or T-Cubes™ with 3.5 mm Jacks

- USB Controller Hubs Provide Power and Communications

- KCH301: For up to Three K-Cubes or T-Cubes

- KCH601: For up to Six K-Cubes or T-Cubes

The KPS201 power supply outputs +15 VDC at up to 2.66 A and can power a single K-Cube or T-Cube with a 3.5 mm jack. It plugs into a standard wall outlet.

The KCH301 and KCH601 USB Controller Hubs each consist of two parts: the hub, which can support up to three (KCH301) or six (KCH601) K-Cubes or T-Cubes, and a power supply that plugs into a standard wall outlet. The hub draws a maximum current of 10 A; please verify that the cubes being used do not require a total current of more than 10 A. In addition, the hub provides USB connectivity to any docked K-Cube or T-Cube through a single USB connection.

For more information on the USB Controller Hubs, see the full web presentation.

Products Home

Products Home

Zoom

Zoom

Single Channel, K-Cube

Single Channel, K-Cube