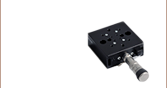

1/4" Travel Translation Stage

- Modular X Y Z Configurable Translation Stages with Hardened Steel Guide Pins

- Ball Bearing Design for Precision Motion and Long Life

- Actuator Screw- or Micrometer-Driven Versions

MS1

Single-Axis Stage with

Actuator Screw

MS101

Stage Base Plate

MS1S

Single-Axis Stage

with Side-Mounted

Micrometer

MS3

Please Wait

| Ball Bearing-Mechanism Manual Translation Stages |

|---|

| 1/4" (6 mm) Travel |

| 1/2" (13 mm) Travel |

| 1/2" (13 mm) Travel, Miniature |

| 1" (25 mm) Travel |

| 2" (50 mm) Travel |

Thorlabs offers two designs for 1/4" travel translation stages. The MS1 single-axis stage is actuated by an end-mounted 0.25 mm pitch thumbscrew. This stage is also the basis for our three-axis MS3 translation stage. The MS1S single-axis stage is actuated by a side-mounted micrometer. Since the MS1S removes the actuator from the translation axis, the MS1S is suitable for situations where it is necessary to mount the stage in close proximity to other components.

The modular design of these translation stage allows the user to quickly and precisely create multi-axis stage configurations using multiple MS1 or MS1S stages and stage plates. Each MS1 or MS1S stage has precision machined dowel holes in its top and bottom surfaces that allow two MS1 or MS1S stages to be connected together orthogonally within 2 mrad when the dowel pins are used. The MS series plates also have precision machined dowel holes. Each stage also features a side-located mounting plate that allows the stage to be locked in position using a 0.05" (1.3 mm) hex key.

Click to Enlarge

MS3 Packaging

Smart Pack

- Reduce Weight of Packaging

- Increase Usage of Recyclable Materials

- Improve Packing Integrity

- Decrease Shipping Costs

Thorlabs' Smart Pack Initiative is aimed at minimizing waste while providing adequate protection for our products. By eliminating any unnecessary packaging, implementing design changes, and utilizing eco-friendly materials, this initiative seeks to reduce the environmental impact of our product packaging.

The updated MS3(/M) packaging primarily consists of recycled paper and cardboard and weighs 8.22% less than the original packaging. This weight change results in a 0.55 kg reduction in travel-based CO2 emissions per year, based on typical product sales.

As we move through our product line, we will indicate re-engineered, eco-friendly packaging with our Smart Pack logo, which can be seen above.

| Posted Comments: | |

Carlos Villegas

(posted 2021-09-09 13:34:25.667) The link to the Auto CAD PDF file in the MS1S page is not leading to the correct diagram. Instead, it is leading to the diagram of a different product. I don't know if the other files in Drawings and Documents also have incorrect links, but at least the one for the Auto CAD PDF is wrong. Could you correct that, please? msinger

(posted 2021-10-11 08:58:41.0) Hello Carlos, thank you for your feedback. We have corrected the Auto CAD PDF for the MS1S page and checked that the remaining documents are correct as well. Simon Lane

(posted 2020-01-31 08:21:36.88) Is there a metric version of this part with slots spaces at 50mm? llamb

(posted 2020-01-31 03:50:31.0) Thank you for contacting Thorlabs. We do not have a metric version of the MS101. However, the counterbored slots on this base plate are wide enough to accommodate mounting to tables/breadboards with both metric and imperial spacing. Paul Marshall

(posted 2019-12-13 12:37:58.237) Hi!

Do you know if the lubricant used in the stage(s) and the micrometer are able to handle minus 20 celsius conditions?

Thanks,

Paul llamb

(posted 2019-12-16 11:21:15.0) Hello Paul, thank you for your feedback. The micrometer head alone is rated for 5-40°C, and the lubricants used in these stages are only recommended for down to about 10-20°C at a minimum operating temperature. We would not recommend using these stages at -20°C. Marcel Krieg

(posted 2019-10-15 10:40:26.247) A metric version would be helpful YLohia

(posted 2019-10-15 12:32:36.0) Hi Marcel, thank you for contacting Thorlabs. May I ask what the reason for requesting a special metric version of the MS101 is? This is a universal design, intended to work with both imperial and metric MS1 stages as well as both types of breadboards/tables. The MS101 base plate has a central 8-32 (M4) through hole and four precision machined dowel holes that allow for the MS1(/M) translation stage to be secured in two orthogonal orientations when the dowels are being used. The two sides of the plate have 1/4"-20 (or M6) clearance slots for mounting to imperial and metric boards. While the nominal center-to-center distance of the slots is 50.8mm, due to the nature of the slot, this can be used with 50mm hole spacing on metric boards as well. user

(posted 2019-06-19 09:21:10.41) Could I use MS1/M with the micrometer 148-205ST? Thanks YLohia

(posted 2019-06-19 09:41:22.0) Hello, thank you for contacting Thorlabs. Unfortunately, the MS1 stage cannot be used with the 148-205ST due to the incompatible bushings. Perhaps the MS1S/M may work for your application? It comes with the 148-205ST installed by default. cwong3

(posted 2018-06-18 18:42:52.913) Hi there - Is it possible to purchase the MS1S stage (imperial) but with the metric micrometer (148-205ST) installed instead of the imperial micrometer? YLohia

(posted 2018-06-26 10:09:28.0) Hello, we will contact you directly regarding this. Alternately, you could consider using the MS103 plate (imperial) on the MS1S/M stage (metric), so that way you get metric micrometer with imperial taps on top. We also have a selection of screw adapters that you could use on the metric stage to adapt to imperial optics here: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=1745. prathmesh

(posted 2017-09-11 22:33:22.983) How can the vertical and horizontal load capacities for MS1 and MS3 be the same, since MS3 is made out of 3 MS1, shouldn't they be a bit lower for MS3?

Kindly clafiry. Thanks. tfrisch

(posted 2017-09-21 10:06:56.0) Hello, thank you for contacting Thorlabs. In an XYZ configuration, there will typically be two stages in horizontal and one in vertical orientation, so the vertical orientation will be the limiting factor. I will contact you directly about the orientation you intend to use your MS3 in, but in most cases, the topmost stage is vertical and where the load is placed, so the vertical stage often does not bear the weight of the other two stages. user

(posted 2017-07-12 20:26:33.397) yesterday I asked about the compatibility of MS101 and MS102 with MS1S, not MS1. tcampbell

(posted 2017-07-13 12:21:10.0) Hello, thank you for contacting Thorlabs again. I apologize for the confusion. The MS1 and MS1S stages have the same hole pattern, and thus both are compatible with with the MS101 base plate and MS102 angle bracket. The metric versions, MS1/M and MS1S/M, are also compatible with these items. user

(posted 2017-07-11 16:44:25.0) I want to use three MS1S/M in xyz configurations. is it true that for this reason i should buy MS101 and MS102? you didn't mentioned that these two pieces are compatible with MS1S/M. tcampbell

(posted 2017-07-11 03:14:11.0) Hello, thank you for contacting Thorlabs. The MS101 and MS102 are both compatible with imperial and metric versions of the MS1 stage. We have updated the text on the webpage to clarify this. tcohen

(posted 2012-04-20 14:06:00.0) Response from Tim at Thorlabs: Thank you for your feedback. We apologize for the inconvenience. I will contact you to provide you more alignment dowels. igkiou

(posted 2012-04-20 09:21:43.0) Hi, I recently purchased a MS101+MS102+MS1+MS103 combination. I was disappointed to see that the whole thing came with only 2 dowels, which are hardly enough. Do you provide these dowels as a separate part somewhere, so that I could purchase some more separately? Thank you in advance. |

Manual Linear Translation Stages

Thorlabs' manual translation stages are offered in a range of maximum travel distances, from less than 1/4" (6 mm) to 2" (50 mm) and longer for our long travel, large area platforms. Many of these stages can be ordered in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our Multi-Axis Stages, which offer finer adjustment than our standard manual translation stages. In addition to linear translation stages, we offer rotation stages, pitch and yaw platforms, and goniometers. We also offer motorized translation stages that are powered by DC Servo motors, stepper motors, or direct drive technology.

Crossed-Roller Bearing Stages

These linear translation stages feature crossed-roller bearing travel mechanisms for precision motion, high load capacity, and low angular deviation. The LNR Series stages feature all-steel body construction, while the LX, XRN, and XR Series stage bodies are constructed of cast tool and jig aluminum. We also offer several vertical crossed-roller bearing stages (see below).

| Crossed-Roller Bearing Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | LNR Series 25 mm Stages | LX Series 25 mm Stages |

XRN Series 25 mm Stages | XR Series 25 mm Stages | XR Series 50 mm Stages | LNR Series 50.8 mm Stages |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 50 mm (1.97") | 50.8 mm (2") |

| Drive Type | Multiple | Micrometer | Micrometer | Micrometer | Micrometer | Multiple |

| Platform Size | 2.34" x 2.36" (59.4 mm x 60.0 mm) |

2.56" x 2.56" (65.0 mm x 65.0 mm) |

2.00" x 3.35" (50.7 mm x 85.0 mm) |

2.98" x 4.33" (75.7 mm x 110.0 mm) |

2.98" x 5.51" (75.7 mm x 140.0 mm) |

3.94" x 3.94" (100.0 mm x 100.0 mm) |

| Possible Axis Configurations |

X, XZ, XY, XYZ | X, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, XY, XYZ |

| Additional Details | ||||||

Ball Bearing Stages

These translation stages feature hardened steel linear bearings for precise motion and long life. They are available with a variety of actuators and in single-axis or preassembled multi-axis configurations.

| Ball Bearing Stages | |||||

|---|---|---|---|---|---|

| Product Family | MS Series 1/4" Stages | T12 Series 1/2" Stages | MT Series 1/2" Stages | PT Series 1" Stages | LT Series 2" Stages |

| Click Photo to Enlarge |  |

|

|

|

|

| Travel | 1/4" (6.4 mm) | 1/2" (12.7 mm) | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50 mm) |

| Drive Type | Multiple | Thumbscrew | Multiple | Multiple | Differential Micrometer |

| Platform Size | 1.17" x 1.17" (29.7 mm x 29.7 mm) |

0.76" x 0.81" (19.3 mm x 20.6 mm) |

2.40" x 2.41" (61.0 mm x 61.2 mm) |

3.00" x 4.00" (76.2 mm x 101.6 mm) |

3.75" x 3.75" (95.3 mm x 95.3 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | |||||

Dovetail Stages

These compact stages incorporate dovetails and a leadscrew for the translation mechanism. They are suitable in general purpose motion control applications.

| Dovetail Stages | |||

|---|---|---|---|

| Product Family | DT Series 1/2" Stages | DTS Series 1" Stages (Vacuum-Compatible Version Available) |

DTS Series 2" Stage |

| Click Photo to Enlarge |  |

|

|

| Travel | 1/2" (12.7 mm) | 1" (25 mm) | 2" (50 mm) |

| Drive Type | Thumbscrew | Thumbscrew | Thumbscrew |

| Platform Size | 1.00" x 1.00" (25.4 mm x 25.4 mm) | 2.68" x 2.95" (68.0 mm 75.0 mm) | 2.68" x 3.74" (68.0 mm x 95.0 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZa | X, XY, XYZ |

| Additional Details | |||

Flexure Stages

Thorlabs' Nanoflex™ translation stages feature frictionless flexure mechanisms for improved positioning and resolution when compared to similar stages made using bearings. The translation of the stage is accomplished by the elastic deformation (flexing) of a linkage attached to the mounting platform. Most models also include piezo actuators for small position adjustments.

| Flexure Stages | ||||

|---|---|---|---|---|

| Product Family | Nanoflex™ 1.5 mm Stage | Nanoflex™ 5 mm Stages | ||

| Click Photo to Enlarge |  |

|

|

|

| Travel | 1.5 mm (0.06") + 25 µm Piezo | 5 mm (0.20") | 5 mm (0.20") + 20 µm Piezo | |

| Drive Type | Thumbscrew and Piezo Actuator | Differential Micrometer | Differential Micrometer and Open-Loop Piezo Actuator |

Differential Micrometer and Closed-Loop Piezo Actuator |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) | 2.95" x 2.95" (75.0 mm x 75.0 mm) | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | ||||

Vertical Stages

We offer vertical translation stages with crossed-roller bearings for precise motion as well as long travel vertical stages for heavy-duty applications.

| Vertical Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | XRN Series 9 mm Vertical Stage | XR Series 14 mm Vertical Stage | MVS Series 1/2" Vertical Stage | MVS Series 1" Vertical Stage | VAP Series 4" Vertical Stage | VAP Series 10" Vertical Stage |

| Click Photo to Enlarge |  |

|

|

|

|

|

| Travel | 9.0 mm (0.35") | 14.0 mm (0.55") | 1/2" (13.0 mm) | 1" (25.0 mm) | 4" (101.6 mm) | 10" (254 mm) |

| Drive Type | Worm-Gear Driven Lift Screw | Micrometer | Adjuster Knob and Coarse Manual Positioning | |||

| Platform Size | 2.00" x 2.00" (50.7 mm x 50.7 mm) |

2.98" x 2.98" (75.7 mm x 75.7 mm) |

2.36" x 2.36" (60.0 mm x 60.0 mm) | 3.00" x 6.00" (76.2 mm 152.4 mm) | ||

| Additional Details | ||||||

| Item # | MS1 & MS3 |

|---|---|

| Drive Type | M3 x 0.25 Fine-Adjustment Screw; Provides 250 µm/rev |

| Stage Height | 0.60" (15.2 mm) |

| Horizontal Load | 7 lbs (3.2 kg) (Max) |

| Vertical Load | 2.5 lbs (1.1 kg) (Max) |

| Maximum Stage Travel | 1/4" (6.4 mm) |

| Orthogonality | <2 mrad (with Alignment Pins) |

| Bearing Type | Ball Bearing |

| Material | Aluminum with Hardened Steel Dowel Pins |

Click to Enlarge

The MS1/M can be identified by the small dimple under the center tap on the underside of the stage.

- End-Mounted Adjustment Screw

- Lockable

- XYZ Configurable

The MS1(/M) series translation stage provides one axis of translation, and features an end-mounted adjustment screw. Components may be mounted to the top of the translation stage via five 8-32 (M4) tapped holes. The stage can be secured to the MS101 base plate or a Ø1/2" post using the 8-32 (M4) threaded hole located on the underside of the translation stage. Alternatively, there are two through holes accessible from the top of the stage that can be used to attach one MS1 translation stage to another MS1 translation stage. Two alignment dowels are provided with each stage; the dowels are used to precisely align two MS1 stages in an XY configuration or align the stage to the mounting plates available below.

The MS3(/M) is a 3-axis translation stage that comes completely assembled. The MS3 is built from three MS1 translation stages, one MS101 base plate, one MS102 right angle plate, and one adapter plate. The imperial version of the adapter plate includes four 6-32 and four 8-32 mounting holes for mounting various components; the metric version includes eight M4 mounting holes. Both the imperial and metric versions also include a 4 mm keyway lined with 4-40 (M3) tapped mounting holes to secure the optic mounts below to the stage.

| Item # | MS1S |

|---|---|

| Drive Type | Micrometer; Provides 0.025" (0.5 mm) per Rev |

| Stage Height | 0.73" (18.4 mm) |

| Horizontal Load | 7 lbs (3.2 kg) (Max) |

| Vertical Load | 2.5 lbs (1.1 kg) (Max) |

| Maximum Stage Travel | 1/4" (6.5 mm) |

| Orthogonality | <2 mrad (with Alignment Pins) |

| Bearing Type | Ball Bearing |

| Material | Aluminum with Hardened Steel Dowel Pins |

- Side-Mounted Micrometer

- Lockable

- XYZ Configurable

The MS1S(/M) translation stage provides one axis of translation and features a side-mounted micrometer. Since the MS1S removes the actuator from the translation axis, the MS1S is suitable for situations where it is necessary to mount the stage in close proximity to other components. The MS1S stage is actuated with the 148-206ST (1/4" travel micrometer), while the MS1S/M is actuated with the 148-205ST (6.5 mm travel micrometer).

Components may be mounted to the top of the translation stage via five 8-32 (M4) tapped holes. The stage can be secured to the MS101 base plate or a Ø1/2" post using the 8-32 (M4) threaded hole located on the underside of the translation stage. Alternatively, there are two through holes accessible from the top of the stage that can be used to attach one MS1S translation stage to another MS1S translation stage. Two dowel pins are provided with each stage; the dowel pins are used to precisely align two MS1S stages in an XY configuration or align the stage to the mounting plates available below.

Click to Enlarge

The MS103/M is marked as a metric component by a small dimple located next to the center tap.

The MS101 base plate has a central 8-32 (M4) through hole and four precision machined dowel holes that allow for the MS1(/M) translation stage to be secured in two orthogonal orientations when the dowels are being used.

The MS102 right angle plate has a central #8 (M4) through hole and four precision machined dowel holes on each of its two mounting surfaces. The MS102, with the use of the dowels, allows an MS1(/M) to be vertically mounted so that the surface of the stage is orthogonal, within 2 mrad, to the horizontal plane. Two hardened steel alignment dowel pins are provided with each bracket.

The MS103(/M) adapter plate has a central #8 (M4) through hole to secure the plate to the MS1(/M) translation stage. The four precision machined dowel holes on the underside of the plate allow the MS103 adapter to be mounted so that the key way on the top surface is either orthogonal or parallel, within 2 mrad, to the direction of the translation if the dowel pins are used. Two hardened steel alignment dowel pins are included with MS103(/M). The CT series of mounts are designed to fit into the keyway on the MS103 adapter plate, thus ensuring the orientation of the mounted component. The metric version can be identified by a small dimple on the underside of the plate located next to the central bore, shown in the photo to the right.

- SM1 (1.035"-40) Threaded Bore Directly Accepts Ø1" Optics up to 6.9 mm (0.27") Thick

- Compatible with Our Line of SM1 Lens Tubes

- Finger Groove Recess Allows for Ease of Alignment

- Beam Height: 0.72" (18 mm)

- Compatible with MS-Series Translators and 30 mm Cage Translation Stages

The CT101 has an internal SM1 threading for mounting Ø1" components or externally threaded SM1 components, which includes the SM1 lens tubes. The mount is compatible with the MS103(/M) adapter plate and with the CT1A(/M) 30 mm cage Z-axis translation stage. One SM1RR retaining ring, two 4-40 and two M3 cap screws for securing the mount, and two removable dowel pins for alignment are included with each unit.

- Provides ±0.04" (±1.0 mm) of Travel in X and Y Directions

- SM05 (0.535"-40) Threaded Bore Directly Accepts Ø1/2" Optics up to 9.9 mm (0.39") Thick

- Wobble: <100 µrad

- Resolution: 250 µm/rev

- Beam Height: 0.72" (18 mm)

- Compatible with MS-Series Translators and 30 mm Cage Translation Stages

The CT102 has an internal SM05 (0.535"-40) threading for mounting Ø1/2" components up to 0.39" (9.9 mm) thick or externally SM05-threaded components. The CT102 allows for ±1 mm of travel in the X and Y direction using M3 x 0.25 fine adjusters. The mount is directly compatible with the CT1A(/M) 30 mm cage Z-axis translation stage and the MS1(/M) translation stage when it is used with the MS103(/M) adapter plate. One SM05RR retaining ring, which secures a component by sandwiching it between the ring and the back lip on the mount. Two 4-40 and two M3 cap screws for securing the mount are included with each unit.

- Coarse Rotation: 360° Continuously Adjustable

- Graduations: 2° Increments

- Mount Ø1/2" (Ø12.7 mm) Optics up to 0.29" (7.4 mm) Thick

- Runout: <0.0001" Along Optical Axis

- Maximum Clear Aperture: 0.43"

- Beam Height: 0.72" (18 mm)

- Lockable Design

- Compatible with MS-Series Translators and 30 mm Cage Translation Stages

The CT104 has an internal SM05 threading for mounting Ø1/2" (Ø12.7 mm) optics and externally threaded SM05 threaded components. The CT104 mount provides 360° of continuous rotation for the mounted components. The 2° graduation allows for precise positioning of components such as linear polarizers and waveplates. A top-mounted, nylon-tipped setscrew is used to lock the position of the component. The mount is compatible with the MS103(/M) adapter plate and with the CT1A(/M) 30 mm cage Z-axis translation stage. One SM05RR retaining ring, which secures a component by sandwiching it between the ring and the back lip on the mount. Two 4-40 and two M3 cap screws for securing the mount are included with each unit.

- Ideal for Custom Machining

- Center-Drilled Dimple Allows for User to Precisely Align Along the Cage's Optical Axis

- Finger Groove Recess Allows for Ease of Alignment

- Compatible with MS-Series Translators and 30 mm Cage Translation Stages

The CT103 blank device mount has a solid surface to allow the end user to tailor the mount for custom applications and is compatible with the MS103(/M) adapter plate and CT1A(/M) 30 mm Z-axis translation stage. Custom hole sizes and threads can be machined using any size drill bits and taps. A center-drilled dimple is provided to help in aligning with the optical axis during the machining process. Two 4-40 and two M3 cap screws for securing the mount are included with each unit.

Products Home

Products Home

Zoom

Zoom

Linear: 1/4" (6 mm)

Linear: 1/4" (6 mm)