45° Mounts

- Redirect Beam Paths with These Precision, Fixed 45° Mounts

- Compatible with a Wide Range of Optomechanical

Mounts and Rigid Construction Accessories

H45

H45E1

Shown Holding a

1" Elliptical Mirror

H45B2

H45CN

Shown Mounted in KS2

with Ø2" Mirror

MA45-2

45° Adapter for

KM100 and KM200

Mirror Mounts

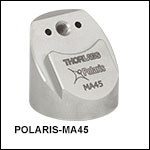

POLARIS-MA45

45° Adapter for

Ø1" Polaris

Mirror Mounts

Please Wait

Features

- Fixed 45° Mounts for 1/2", 1", or 2" Circular or Elliptical Optics

- 45° Mounting Adapters Compatible with Our KM05, KM100, KM200, or Standard Ø1" Polaris Kinematic Mounts

These mounts provide a precision, fixed, 45º mounting surface for optics and optomechanical mounts. Their rigid construction and low profile provide excellent stability when fastened to an optical table, and they are fabricated from black anodized aluminum with the exception of the POLARIS-MA45(/M) which is fabricated from 303 stainless steel.

Circular Optics

Thorlabs offers one 45° mount for standard Ø1/2" optics (H45A), two 45° mounts for standard Ø1" optics (H45B2 and H45), and one 45° mount for standard Ø2" optics (H45CN). The H45B2 is a complete assembly with a 45° mount, post, and base. The H45A, H45, and H45CN are 45° mounts that can be secured in any unthreaded Ø1/2", Ø1", or Ø2" kinematic mirror mount, respectively, to adapt to laboratory needs. The H45CN mount can also be secured to a Ø1.5" post using a BE1(BE1/M) Base Adapter, as shown in the image to the right.

Elliptical Optics

Our H45E1 and H45E2 mounts hold 1" and 2" elliptical optics, respectively. The H45E1 can be mounted in any Ø1" unthreaded kinematic mount or the BA2F Flexure Base. It can also be mounted on a 1/4"-20 (M6) tapped post or breadboard using a 1/4" washer and a 1/4"-20 (M6) cap screw. The H45E2 can be secured in any Ø2" unthreaded kinematic mirror mount and can also be mounted on a Ø1.5" post using a BE1(BE1/M) Base Adapter. For further mounting instructions, please see the Optic Installation tab on the 45° Elliptical Mirror Mounts page.

Mounting Adapters

Thorlabs also offers 45° mounting adapters for our KM100, KM200, or standard Ø1" Polaris kinematic mirror mounts.

POLARIS-MA45 Positional Repeatability After Thermal Shock

Polaris™ components have undergone extensive testing to ensure high-quality performance. Here, a Polaris mirror mount was secured to a POLARIS-MA45 which was then secured to a stainless steel rigid platform in a temperature-controlled environment. A beam from an independently temperature-stabilized laser diode was reflected by the mirror onto a position sensing detector.

Purpose: This testing was done to determine how reliably the mirror mount and 45° mounting adapter system returns the mirror, without hysteresis, to its initial position. These measurements show that the alignment of the optical system is unaffected by the temperature shock.

Procedure: The temperature of the Polaris mount and adapter system tested was raised to 37.5 °C. This temperature shock was maintained for approximately 60 minutes (soak time, see plots below). Then the temperature of the mirror mount system was returned to the starting temperature. The results of these tests are shown below.

Results: As can be seen in the plots below, when the Polaris mount and adapter system were returned to their initial temperature, the angular position (both pitch and yaw) of the mirrors returned to within 2 µrad of its initial position. The performance of the Polaris system was tested further by subjecting the mount to repeated temperature change cycles. After each cycle, the mirror mount system position reliably returned to within 2 µrad of its initial position.

Conclusions: The Polaris 45° mounting adapter paired with a Polaris mirror mount is a high-quality, ultra-stable system that will reliably return a mirror to its original position after cycling through a temperature change. As a result, this system is ideal for use in applications that require long-term alignment stability. This also shows that the addition of the POLARIS-MA45 to the Polaris mirror mount does not compromise the performance of the mirror mount alone.

Click to Enlarge

The plot above shows the pitch and yaw measured by a position-sensing detector before, while, and after a thermal shock was applied to the POLARIS-MA45 mounting adapter and Polaris mirror mount.

Click to Enlarge

The plot above shows the final angular position of the system for 10 consecutive thermal shock tests. The change in temperature is the difference between the starting temperature and the temperature at the end of the test and includes factors such as the variation in room temperature.

| Posted Comments: | |

user

(posted 2023-08-04 14:21:05.273) A 45 degree mount for 1/2" elliptical mirrors would be great jdelia

(posted 2023-08-07 01:52:14.0) Thank you for contacting Thorlabs. While this is not something we currently offer, I have submitted your feedback to our design engineers through our internal suggestion forum for consideration as a future catalog item. Nguyen Le

(posted 2023-05-10 11:49:23.273) Bonjour Thorlabs,

J'essaie de telecharger de fichier step, quand j'ouvris le fichier step, il n'a me pas donné le bon composant

Merci jdelia

(posted 2023-05-18 09:37:57.0) Thank you for contacting Thorlabs. I have reached out to you directly to clarify the issue that you are experiencing. Zachary Widel

(posted 2022-06-15 12:42:12.19) A 2" 45 deg mount that can be mounted in a 1" kinematic mirror mount would be great. cdolbashian

(posted 2022-06-21 11:55:52.0) Thank you for reaching out to us with this suggestion! While we do not have this as a stock part now, it is fairly straightforward to adapt the 2" mount to a 1" kinematic mirror mount. I suggest the combination of H45CN + BE1 + RS1G. The H45CN is the 2" mount, the BE1 allows the RS1G to be connected directly to the backside of the H45CN. This way you will have a 1" diameter post extending from the H45CN, allowing it to mount in something such as the KM100. Yelei Sun

(posted 2021-01-15 09:49:07.937) Hello, I have brough H45B2 for 45deg mounting of a mirror. But the height (Base to center of Mirror, 50.4 mm) is too large for our purpose. Would it be possible to order a customized mounting with a reduced height of 29.5mm and 19.5mm? Please also let me know if you have any other suggestions. Many thanks! YLohia

(posted 2021-01-27 10:32:43.0) Hello, thank you for contacting Thorlabs. Custom items can be requested by using the "Request Quote" button above or by contacting your local Thorlabs Tech Support team (in your case, europe@thorlabs.com). We will contact you directly to discuss the possibility of this customization. Jon Meyers

(posted 2020-06-24 13:27:18.933) Hello,

I've had great success using SLDPRT and STEP files for most products. Unfortunately this one isn't behaving like the others. I'm importing into Autocad and trying to export as STL, but it filters out during the process. Maybe it's not "water-tight?" Just thought I'd let you know.

Best,

Jon llamb

(posted 2020-06-29 08:25:59.0) Hello Jon, thank you for your feedback and bringing this to our attention. We will look to update the H45's Solidworks and Step files. user

(posted 2020-01-10 13:57:17.597) Would it be possible to make the H45A compatible with your SM05P05 optics mount? The base is currently slightly too large (12.9 mm) to fit into the SM05P05 opening (12.8 mm), it seems like a design flaw. YLohia

(posted 2020-01-23 08:30:24.0) Hello, thank you for bringing this design flaw to our attention. We are working on changing the outer diameter of the base to 1/2". Ben Garber

(posted 2019-07-15 19:01:52.52) Hi, looking at the drawing for H45E2, it doesn't show how far above the base the center of the mirror is. It is also not clear from the CAD model because the center of the elliptical mirror is not the same as the center of the bore in back. Could you please add that to the drawing? llamb

(posted 2019-07-19 01:43:45.0) Thank you for your feedback. While the location of the center of a mirror with respect to the base will depend upon the mirror's thickness, we are looking into updating the drawing with more details on the back thru port's height with respect to the base. christian.b.schmidt

(posted 2013-03-13 12:55:56.59) I would like to get the optic mount of the H45B2 and the H45 mount, but for/with metric screws. Is this possible? jlow

(posted 2013-03-14 11:22:00.0) Response from Jeremy at Thorlabs: These have #8-32 setscrews which uses 5/64 hex keys. However, since that is very close to 2mm (5/64" = 1.984mm), you should be able to use a 2mm hex key or ball driver with these. jlow

(posted 2012-11-06 16:08:00.0) Response from Jeremy at Thorlabs: Thank you very much for your feedback. I do agree that this would be a useful addition to our product line. We will look into adding this. ted.borger

(posted 2012-10-26 11:10:55.977) This for a 2 inch optic would be EXTREMELY useful!!!! bdada

(posted 2011-04-25 12:34:00.0) Response from Buki at Thorlabs:

Thank you for your feedback. The H45B2 45 degree optic holder includes a nylon tipped set screw to hold the optic in place along with a cap screw to hold the optic housing onto the aluminum post. If you ordered the H45B2-1-CT, this is simply the optic mount without any accessories. we can send you some extra set screws (nylon tipped 8-32 x 1/8 Stainless) to hold the optic in place. We have contacted you to get your contact information so we can send you the set screws. syim70

(posted 2011-04-25 17:04:53.0) I had been happy to get the top part separately, but I found that it does not have a set screw. In addition, the screw hole has Imperial thread. I would not mind the thread type if it came with a set screw. Adam

(posted 2010-03-23 09:50:59.0) A response from Adam at Thorlabs to paru: Thank you for the new product idea. I will present this to our engineering team as a customer-inspired idea. In the mean time, we can offer sell this part separately as a component part. I will contact you directly to see if you are interested in this option. paru

(posted 2010-03-23 09:22:57.0) You should sell the top part of this component as a product by itself. In many cases I only need the 45 degree holder. The additional post and mounting base is often necessary as they dont often fit the exact mounting scheme that I can accommodate.

Thanks,

--paru |

Click to Enlarge

Ø1/2" beamsplitter secured in the H45A 45° mount. This assembly is mounted in a KM05 kinematic mount with beam trajectories indicated by the red arrows.

- Fixed 45° Mount for Ø1/2" Optics at Least 0.12" (3.0 mm) Thick

- Compatible with Our Unthreaded Ø1/2" Kinematic Mirror Mounts

- Two Perpendicular Through Holes Allow Use with Our Ø1/2" Beamsplitters

- Back Side Clear Aperture: Ø0.32" (Ø8.1 mm)

- Bottom Clear Aperture: Ø0.25" (Ø6.4 mm)

This 45° mount directly accepts Ø1/2" optics. Two perpendicular through holes allow for the use of beamsplitters in addition to non-transmitting optics, such as mirrors. The optic is held in place with a nylon-tipped 4-40 setscrew, which accepts a 0.05" hex key. The back side through hole has a transmitted clear aperture of Ø0.32" (Ø8.1 mm), while the bottom through hole has a clear aperture of Ø0.25" (Ø6.4 mm).

Click to Enlarge

Ø1" beamsplitter secured in the H45 45° mount. This assembly is mounted in a KM100 kinematic mount with beam trajectories indicated by the red arrows.

Click for Details

Suggested Orientation for Beamsplitting

- Fixed 45° Mount for Ø1" Optics at Least 0.12" (3.0 mm) Thick

- Compatible with Our Unthreaded Ø1" Kinematic Mirror Mounts

- Two Perpendicular Through Holes Allow Use with Our Ø1" Beamsplitters

- Back Side Clear Aperture: Ø0.55" (Ø13.9 mm)

- Bottom Clear Aperture: Ø0.50" (Ø12.7 mm)

This 45° mount directly accepts Ø1" optics. Two perpendicular through holes allow for the use of beamsplitters in addition to non-transmitting optics, such as mirrors. The ideal orientation for light propagation through a beamsplitter is shown in the diagram to the right. The optic is held in place with a nylon-tipped 8-32 setscrew, which accepts a 5/64" (2 mm) balldriver. The rear through hole has a transmitted clear aperture of Ø0.55" (Ø13.9 mm), while the bottom through hole has a clear aperture of Ø0.50" (Ø12.7 mm).

Please note that the H45 mirror mount is not the optic mount used in the H45B2 mount assembly available below.

- 45° Mount Assembly for Ø1" Optics at Least 0.12" (3.0 mm) Thick

- Rear Through Hole Allows Use with Our Ø1" Beamsplitters

- Back Side Clear Aperture: Ø0.55" (Ø14.0 mm)

- Ships Assembled with Optic Housing, Post, and Mounting Base

This H45B2 ships fully assembled and consists of a 45° mount, post, and mounting base. The housing accepts Ø1" optics, such as mirrors. The rear through hole allows for use of Ø1" beamsplitters and has a transmitted clear aperture of Ø0.55" (Ø14.0 mm). The optic is held in place with a nylon-tipped 8-32 setscrew, which accepts a 5/64" (2 mm) balldriver.

- Fixed 45° Mount for Ø2" Optics

- Post Mountable using BE1(BE1/M) Base Adapter

- Compatible with All Unthreaded Ø2" Kinematic Mounts

- Two Perpendicular Through Holes Allow Use with Our Ø2" Beamsplitters

- Back Side Clear Aperture: Ø1.20" (Ø30.6 mm)

- Bottom Clear Aperture: Ø1.00" (Ø25.4 mm)

This 45° mount is ideal for holding Ø2" mirrors or beamsplitters at a 45° angle within an optical setup. Two through holes, located at a 90° angle with respect to each other, allow this mount to be used in applications where beamsplitters are needed. The rear through hole has a transmitted clear aperture of Ø1.20" (Ø30.6 mm), while the bottom through hole has a clear aperture of Ø1.00" (Ø25.4 mm). An 8-32 nylon-tipped setscrew [5/64" (2 mm) hex], located at the top of the mount, secures the optic in the bore. Optics must be at least 0.18" (4.6 mm) thick to be used in this mount.

This angled mount can be held in any of our unthreaded Ø2" kinematic mirror mounts, such as the KM200, via the setscrew included with the kinematic mount. The 45° mount can also be attached to a Ø1.5" post using a BE1 Ø1" post base. The image to the right illustrates the correct installation of the BE1. Please note that you must secure the H45CN mount to the post prior to installing the mirror, as the BE1 will only fit through the angled hole in the mount.

- Fixed 45° Mount for 1" Elliptical Optics

- Minimum Optic Thickness: 0.22" (5.5 mm)

- Two Perpendicular Through Holes Allow Use with Our Ø1" Elliptical Beamsplitters

- Back Side Through Port*: Ø0.66" (Ø16.7 mm)

- Bottom Clear Aperture: Ø0.40" (Ø10.2 mm)

The H45E1 Elliptical Mirror Mount is designed to hold 1" elliptical optics with a minimum thickness of 0.22" (5.5 mm), such as mirrors or beamsplitters. When used in beamsplitter or beam monitoring applications, the through hole on the back side has a diameter of Ø0.66" (Ø16.7 mm) while that on the bottom has a clear aperture of Ø0.40" (Ø10.2 mm).

This elliptical mount can be fastened in any unthreaded Ø1" kinematic mirror mount, such as the KM100 Mirror Mount, via the setscrew included with the kinematic mount (as shown to the right). It can also be mounted to a table or breadboard using a BA2F (BA2F/M) Flexure Base.

Alternatively, this angled mount can be secured to any 1/4"-20 (M6) tapped post or breadboard using a standard 1/4" washer and a 1/4"-20 (M6) cap screw. Place the 1/4" washer at the bottom of the mount, put the screw through the washer, and mount it into place. Please note that the mount must be secured to the post prior to installing the optic, as the washer and screw will only fit through the angled hole in the mount.

*The clear aperture of the back side port will be smaller than Ø0.66" (Ø16.7 mm).

- Fixed 45° Mount For Compatible 2" Elliptical Optics

- Minimum Optic Thickness: 0.47" (11.9 mm)

- Clear Aperture:

- Back Side Through Port* : Ø1.32" (Ø33.5 mm)

- Bottom Clear Aperture: Ø1.00" (Ø25.4 mm)

The H45E2 Elliptical Mirror Mount is designed to hold 2" elliptical optics with a minimum thickness of 0.47" (11.9 mm), such as mirrors or beamsplitters. When used in beamsplitter or beam monitoring applications, the through hole on the back side has a diameter of Ø1.32" (Ø33.5 mm) while that on the bottom has a clear aperture of Ø1.00" (Ø25.4 mm).

This angled mount can be held in any unthreaded Ø2" kinematic mirror mount, such as the KS2, via the setscrew included with the kinematic mount. The H45E2 can also be attached to a Ø1.5" post with a BE1 (BE1/M) post base using a 1/8" (3 mm) hex key. The image to the right illustrates the correct installation of the BE1. Please note the mount must be secured to the post prior to installing the optic, as the BE1 will only fit through the angled hole in the mount.

*The clear aperture of the back side port will be smaller than Ø1.32" (Ø33.5 mm).

Click to Enlarge A POLARIS-K1F Mirror Mount Held at 45° by a POLARIS-MA45 Mounted on a Ø1" Post which is Held by a POLARIS-CA1 Clamping Arm

- Designed for Use With All Ø1" or Ø25 mm Polaris Mirror Mounts

- Vacuum Compatible to 10-9 Torr at 25 °C with Proper Bake Out

- Bottom-Located 1/4"-20 (M6) Tap Allows for Attachment to Ø1" (Ø25.0 mm) Posts

- Two Ø2 mm Alignment Pin Holes in the Base for Precision Mounting in OEM Systems

- Heat-Treated 303 Stainless Steel

Click for Details

POLARIS-MA45(/M) Mechanical Drawing

The POLARIS-MA45(/M) 45° Mounting Adapters securely mount Ø1" or Ø25 mm Polaris Mirror Mounts at a 45° angle with respect to the optical table, breadboard, or working surface. The adapter has an 8-32 (M4) tap on the 45° face for securing the mirror mount, and a bottom-located 1/4"-20 (M6) tap for attachment to Ø1" (Ø25.0 mm) Posts. Two Ø2 mm alignment pin holes around each tap allow for direct, precision mounting within custom or OEM systems (see diagram to the bottom right for details).

Click to Enlarge

Each Polaris product undergoes extensive thermal testing to ensure high-quality performance. Please see the Polaris Test Data tab for additional test results.

When using our standard Ø1" or Ø25 mm Polaris mounts, the height to the center of the mirror will be 2" from the base of the mounting adapter when using the

This adapter is made from heat-treated 303 stainless steel, which has a relatively low coefficient of thermal expansion (CTE) and matches the material used in all of our Polaris mirror mounts. Matching the CTE of materials within an optical setup is essential to achieve optimal thermal repeatability. Heat treating the materials used removes the internal stresses that can cause temperature-dependent hysteresis. Therefore, when mounting, we only recommend using components fabricated from the same material. This is shown in the image above, where a

Cleanroom and Vacuum Compatibility

The POLARIS-MA45(/M) is designed to be compatible with cleanroom and vacuum applications. They are chemically cleaned using the Carpenter AAA passivation method to remove sulfur, iron, and contaminants from the surface. After passivation, they are assembled in a clean environment and double vacuum bagged to eliminate contamination when transported into a cleanroom. Please contact Tech Support for details.

- Designed for Use with Our KM100 and KM200 Kinematic Mirror Mounts

- Beam Height (to Center of Mounted Mirror):

- With KM100: 2.00" (50.8 mm)

- With KM200: 2.49" (63.2 mm)

- Bottom-Located 1/4"-20 (M6) Tap Allows for Attachment to Ø1" (Ø25.0 mm) Posts or Post Holder Bases

- Anodized Aluminum

The MA45-2 (MA45-50/M) 45° mounting adapter is designed to allow our KM100 and KM200 mirror mounts to be securely held at 45° with respect to the optical table, breadboard, or working surface. The beam height to the center of a mirror mounted in a KM100 on a MA45-2 is 2" (50.8 mm). The beam height of the same assembly using the KM200 is 2.49" (63.2 mm).

An 8-32 (M4) tap is provided on the 45° flat surface of the adapter so the KM100 can be directly fastened to that surface with a cap screw. This mounting adapter can be secured to our Ø1" (Ø25 mm) posts or post holder bases via a bottom-located 1/4"-20 (M6) cap screw.

- Top, Angled Surface has 8-32 (M4) Tapped Hole or #8 (M4) Counterbore for Attaching Optomechanical Components

- Bottom Surface has 8-32 (M4) Tapped Hole for Post Mounting

These blocks can mount optomechanical components, such as our Kinematic Platform Mounts and most of our Kinematic Mirror Mounts, at a 45° angle. The AM45T(/M) has an 8-32 (M4) tapped hole designed to mate with components that have a counterbored mounting hole. The AM45C(/M) has a #8 (M4) counterbore designed to mate with components that have a tapped mounting hole. Both designs have an 8-32 (M4) tapped hole on the bottom for post mounting.

Products Home

Products Home

Zoom

Zoom

45° Mounts

45° Mounts