Optical Shutters

- Ø1/2" and Ø1" Beam Shutters

- Two Controller Options Available

- Interlock Mode Incorporated into Control Logic

SH1

Ø1" Beam Shutter,

10 ms (Typ.) Shutter Close Time

SC10

Benchtop Shutter Controller

KSC101

K-Cube Compact Shutter Controller

(Compatible with the SH05R(/M) Optical Beam Shutter)

SH05R

Ø1/2" Beam Shutter,

8.0 ms (Typ.) Shutter Close Time

Please Wait

| Shutter Selection Guide | |

|---|---|

| Diaphragm | Single-Blade |

| Ø1/4", Ø1/2", and Ø1" Motorized |

Ø0.29" Manual |

| Ø1/2" and Ø1" Motorized |

|

Features

- Ø1/2" and Ø1" Beam Shutters

- Typical Shutter Close Times:

- SH05R(/M) with KSC101 Controller: 8.0 ms (90% to 10% Exposure)

- SH1(/M) with SC10 Controller: 10 ms (80% to 20% Exposure)

- Passive Closure Mechanism Ideal for Laser Safety Applications

- 8-32 (M4) Taps for Ø1/2" Post Mounting

- SC10 Benchtop Controller and KSC101 Compact Controller (for SH05R(/M) Only) Available Separately Below

Thorlabs' Optical Shutters utilize a rotary, electro-mechanical actuator to provide millisecond shutter operation. During operation, these shutters remain in a closed position and then open when a pulse control signal is applied by an external controller. As long as the control voltage to the optical shutter remains high, the shutter stays open, but as soon as the voltage goes low, the shutter closes, providing inherent "fail-safe" operation. The frequency at which the device is opened and closed can be controlled. An optical sensor, which detects the shutter blade position in the housing, provides information that confirms the state of the optical shutter position. This makes it ideal in applications where a laser safety lockout is required.

In order to ensure that your optical shutter has a long lifetime, the aperture should not be located near the focus of a laser beam. Please note that the solenoid's performance is not guaranteed if the case temperature exceeds 50 °C. Significant heat buildup will occur if the aperture is closed for a long time while a high-power laser is incident on the shutter.

Controller Options

Thorlabs offers two controllers for use with our optical shutters: Item #s SC10 and KSC101. The SC10 controller can be used with both the Ø1/2" and Ø1" shutters below, while the KSC101 controller is only compatible with the Ø1/2" shutter. For information on the control requirements, please see the Specs tab. Both controllers include an "interlock mode" that is incorporated into the controller's logic; a physical key lock; and manual, triggered, or sofwtare controlled operation modes. The SC10 benchtop controller has an RS-232 computer connection that allows the controller to be operated using the included standalone software GUI. The KSC101 controller is a compact K-Cube™ controller with a USB 3.0 (2.0 Compliant) computer connection that allows the controller to be controlled using Thorlabs' Kinesis® software package. See the Specs tab for a comparison table of the two controller options.

A 10-foot-long cable with 6-way HRS connector is included for connecting the shutter to either the SC10 or KSC101 Shutter Controller. A replacement cable can also be purchased below.

| Controller Specifications | |||

|---|---|---|---|

| Item # | SC10 | KSC101 | |

| Maximum Exposure Ratea | 25 Hz | 20 Hz | |

| Minimum Exposure Timeb | 10 ms | 15 ms | |

| Typical Transfer Time | 1 ms | 1.5 ms | |

| Accuracy | 0.2 ms | 0.3 ms (at 15 ms Exposure) | |

| On/Off Timesb,c | 1 ms to 999.99 s | 10 ms to 1000 s | |

| Maximum Steady State Power | 5 W | 3.5 W | |

| Hold Voltage Range | 9 to 11.8 V | 6.5 to 7.5 Avg. Volts PWM | |

| Trigger Input/Output | TTL | TTL | |

| Voltage Output | 24 V Pulse (10 V Hold) | 15 V Max (7 V Avg. PWM Hold) | |

| Output Enable | Key Switch with Interlock Connector | Key Switch and Interlock Jack Plug | |

| Operating Modes | |||

| Manual | User Controlled On/Off | ||

| Single | Trigger Controlled Single On/Off Cycles | DSP Controlled Single On/Cycles | |

| Auto | Trigger Controlled Multiple On/Off Cycles | DSP Controlled Multiple On/Off Cycles | |

| X-Gate (Triggered) | Shutter Controlled by BNC Input Trigger | Externally Triggered On/Off | |

| Trig IN (Trig 1d) | BNC, TTL, 2.2 - 5 V | SMA, TTL, Type 5 V | |

| Trig OUT (Trig 2d) | BNC, TTL, 2.2 - 5 V | SMA, TTL, Type 5 V | |

| Output (6 Way Hirose) | |||

| Solenoid Drive | 24 V Pulse (10 V Hold) | 15 V Regulated DC | |

| Position Feedback Sensor | - | Photodiode | |

| Input Power Requirements | |||

| Voltage | 100 - 240 VAC U.S. Power Cord Included |

15 V Regulated DC | |

| Current | - | 1 A Peak, 300 mA Steady State | |

| General | |||

| Instrument Weight | 5 lbs (2 kg) | 160 g (5.5 oz) | |

| Housing Dimensions (W x D x H) |

11.5" x 5.3" x 3.0" (292 mm x 135 mm x 76 mm) |

60.0 x 60.0 x 49.2 mm (2.36 " x 2.36 " x 1.94")e |

|

| Beam Shutter Specifications | ||

|---|---|---|

| Item # | SH05R(/M) | SH1(/M) |

| Aperture | Ø1/2" (12.7 mm) | Ø1.0" (25.4 mm) |

| Blade Material | 6061-T6 Aluminum | |

| Blade Thickness | 0.063" (1.6 mm) | 0.06" (1.6 mm) |

| Solenoid Coil Resistance | 28 Ω | 31.84 Ω |

| Initial State | Closed | |

| Operation | ||

| Actuation Pulse | 8 V to 50 V (Time Dependent) |

10 V to 75 V (Time Dependent) |

| Holding Voltage | 8 V to 12 V | 8 V to 15 V |

| Maximum Recommended Applied Solenoid Voltagea |

<12 VDC (Holding) <50 VDC (Pulse) |

15 VDC (Holding) 75 VDC (Pulse) |

| Maximum Pulse Rate | 10 Hz Steady, 25 Hz Burst |

12.5 Hz Steady, 16.6 Hz Burst |

| Duty Cycleb | Optimum @ 10 Hz = 40% | Optimum @ 8 Hz = 50% |

| Lifetime | 1,000,000 Cycles (Typical) | |

| Max Solenoid Power (20°C) | ||

| Steady State | 4 W @ Continuous | 9 W @ Continuous |

| 50% Duty Cycle | 8 W @ 100 s | 18 W @ 100 s |

| 25% Duty Cycle | 16 W @ 36 s | 36 W @ 36 s |

| 5% Duty Cycle | 80 W @ 2.5 s | 180 W @ 2.8 s |

Click to Enlarge

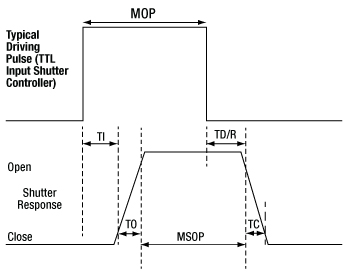

Click to EnlargeShutter Response Diagram

| Timing Specifications | |||

|---|---|---|---|

| Controller | Eventa | SH05R(/M)b | SH1(/M) |

| SC10 | TI | 8.0 ms | 10 ms |

| TO | 4.3 ms | 10 ms | |

| TD/R | 11.0 ms | 20 ms | |

| TC | 6.5 ms | 10 ms | |

| MOP | 10 ms | 40 ms | |

| MSOP | 14 ms | 40 ms | |

| KSC101 | TI | 11 ms | N/Ac |

| TO | 5.5 ms | ||

| TD/R | 26 ms | ||

| TC | 8.0 ms | ||

| MOP | 19 ms | ||

| MSOP | 24 ms | ||

| Timing Diagram Definitions | ||

|---|---|---|

| Event | SH05R(/M) | SH1(/M) |

| TI | Time Initialize: Time from Initialization pulse, to energizing of coil, to the initial movement of the shutter. | Transfer Initialize: the time delay between the application of the energizing voltage and the initial movement of the shutter. |

| TO | Time Open (Rise): Time of shutter blade movement to open from 10% exposurea to 90% exposure. | Transfer Open: the time for the shutter to move from 20% exposurea to 80% exposure. |

| TD/R | Time Delay Release: Time delay of release of the hold voltage or pulse at the moment the shutter blade starts to close. | Transfer Dwell/Release: the delay between the removal of the energizing voltage and the initial closing movement of the shutter. |

| TC | Time Close (Fall): Time of shutter blade movement to close from an 90% exposurea to 10% exposure. | Transfer Close: the time for the shutter to move from 80% exposurea to 20% exposure. |

| MOP | Minimum Open Pulse: Minimum pulse width as driven with the SC10 or KSC101 controller. | Minimum Open Pulse: the minimum pulse width supplied by the SC10 controller. |

| MSOP | Minimum Shutter Open Pulse: Minimum shutter open time (pulse) using the MOP time from the SC10 or KSC101 controller. | Minimum Shutter Open Time: the minimum time the shutter will remain open when using the minimum open pulse (MOP) from the SC10 controller. |

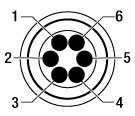

SH05R(/M) Interface Connector

HR10-7R-6S

| Pin | Description |

|---|---|

| 1 | Vsupply: 3.3 - 5 V, 20 mA |

| 2 | Solenoid |

| 3 | Solenoid |

| 4 | GND |

| 5 | GND |

| 6 | Sense Return Low: 0.11 V High: Vsupply - 0.11 V |

SH1(/M) Interface Connector

HR10-7R-6S

| Pin | Description |

|---|---|

| 1 | Monitor Opto Anode +V |

| 2 | Solenoid +V |

| 3 | Solenoid GND |

| 4 | Monitor Opto Cathode GND |

| 5 | Monitor Opto Emitter GND |

| 6 | Monitor Opto Collector +V |

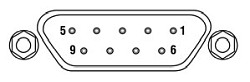

SC10 Pin Diagrams

Interface Connector

HR10-7R-6S

| Pin | Description |

|---|---|

| 1 | To Opto Anode (12 V limited to 20mA) |

| 2 | To Shutter Coil - 24 V Pulse - 10 V Steady State (0.4 A max) |

| 3 | To Shutter Coil - GND (on) - Open Ckt (off) |

| 4 | To Opto Cathode - GND |

| 5 | To Opto Emitter - GND |

| 6 | To Opto Collector (2.5V) |

Computer Connection

D-type Female

| Pin | Description |

|---|---|

| 1 | NC |

| 2 | TxD (from SC10) |

| 3 | RxD (to SC10) |

| 4 | NC |

| 5 | Signal Ground |

| 6 | NC |

| 7 | NC |

| 8 | NC |

| 9 | NC |

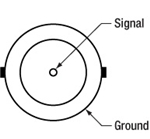

Trigger In*

BNC Female

*10K Input Impedance, 2.2 V Min, 5 V Max

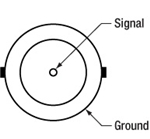

Trigger Out**

BNC Female

**2.2 V Min (500 Ohm Load), 5 V Max (Open Circuit)

KSC101 Pin Diagrams

Solenoid Connection

Hirose Female

| Pin | Description |

|---|---|

| 1 | Opto Anode (12 V limited to 20 mA) |

| 2 | Shutter Coil 15 V Pulse, 10 V steady state (0.4 A max) |

| 3 | Shutter Coil Ground (When ON) Open CCT (When OFF) |

| 4 | Opto Cathode Ground |

| 5 | Opto Emitter Ground |

| 6 | Opto Collector (2.5 V) |

Computer Connection*

*The USB 3.0 port is compatible with a USB 2.0 Micro B connector if the Micro B connector is plugged into the shaded region in the photo above. A USB 3.0 type A to type Micro B cable is included with the KSC101.

TRIG 1

|

TRIG 2

|

|

|

| +5 V TTL | +5 V TTL |

| These connectors provide a 5 V logic level input and output that can be configured to support triggering into and out of external devices. Each port can be independently configured to control the logic level or to set the trigger as an input or output. |

|

Interlock

|

|

|

|

| A short circuit must be applied across the terminals of this connector before the unit can be enabled. An INTERLOCK jack plug is supplied with the unit. Alternatively, the contact can be controlled externally with a custom 3.5 mm jack plug connected to a switch, which must be closed before the unit can operate. | |

Software for the SC10 Shutter Controller

Software

Version 1.3.0 (July 31, 2023)

Standard full software application packages and graphical user interfaces.

OR

Firmware Update

Version 1.07 (July 25, 2013)

The firmware of the SC10 has been updated to address compatibility issues with our SH1 Shutter. For units purchased prior to October 2012, a firmware update is available to ensure compatibility with both SH1(/M) and SH05R(/M) shutters. The ability to query the status of the interlock on the device has been added. The latest update also addresses software communication bugs present in the former version.

The SC10 features a serial port for connection to a PC. In order to install the firmware update, a computer with a serial port is required. Alternately, a USB to serial adapter can be used.

Software

Kinesis Version 1.14.50

The Kinesis Software Package, which includes a GUI for control of Thorlabs' Kinesis system controllers.

Also Available:

- Communications Protocol

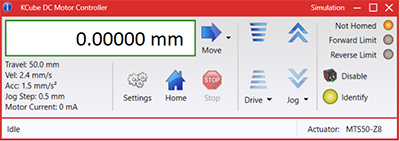

Kinesis GUI Screen

Thorlabs offers the Kinesis® software package to drive our wide range of motion controllers. The software can be used to control devices in the Kinesis family, which covers a wide variety of motion controllers ranging from small, low-powered, single-channel drivers (such as the K-Cubes™) to high-power, multi-channel benchtop units and modular 19" rack nanopositioning systems (the MMR60x Rack System).

The Kinesis Software features .NET controls which can be used by 3rd party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications. Low-level DLL libraries are included for applications not expected to use the .NET framework and APIs are included with each install. A Central Sequence Manager supports integration and synchronization of all Thorlabs motion control hardware.

By providing this common software platform, Thorlabs has ensured that users can mix and match any of our motion control devices in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from single-axis to multi-axis systems and control all from a single, PC-based unified software interface.

The software package allows two methods of usage: graphical user interface (GUI) utilities for direct interaction with and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

Legacy Software

Select products are still capable of running the legacy APT™ software package. Information on software compatibility can be found in the product documentation (![]() ), and additional details about the APT software can be found here.

), and additional details about the APT software can be found here.

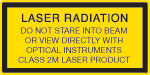

Laser Safety and Classification

Safe practices and proper usage of safety equipment should be taken into consideration when operating lasers. The eye is susceptible to injury, even from very low levels of laser light. Thorlabs offers a range of laser safety accessories that can be used to reduce the risk of accidents or injuries. Laser emission in the visible and near infrared spectral ranges has the greatest potential for retinal injury, as the cornea and lens are transparent to those wavelengths, and the lens can focus the laser energy onto the retina.

Safe Practices and Light Safety Accessories

- Laser safety eyewear must be worn whenever working with Class 3 or 4 lasers.

- Regardless of laser class, Thorlabs recommends the use of laser safety eyewear whenever working with laser beams with non-negligible powers, since metallic tools such as screwdrivers can accidentally redirect a beam.

- Laser goggles designed for specific wavelengths should be clearly available near laser setups to protect the wearer from unintentional laser reflections.

- Goggles are marked with the wavelength range over which protection is afforded and the minimum optical density within that range.

- Laser Safety Curtains and Laser Safety Fabric shield other parts of the lab from high energy lasers.

- Blackout Materials can prevent direct or reflected light from leaving the experimental setup area.

- Thorlabs' Enclosure Systems can be used to contain optical setups to isolate or minimize laser hazards.

- A fiber-pigtailed laser should always be turned off before connecting it to or disconnecting it from another fiber, especially when the laser is at power levels above 10 mW.

- All beams should be terminated at the edge of the table, and laboratory doors should be closed whenever a laser is in use.

- Do not place laser beams at eye level.

- Carry out experiments on an optical table such that all laser beams travel horizontally.

- Remove unnecessary reflective items such as reflective jewelry (e.g., rings, watches, etc.) while working near the beam path.

- Be aware that lenses and other optical devices may reflect a portion of the incident beam from the front or rear surface.

- Operate a laser at the minimum power necessary for any operation.

- If possible, reduce the output power of a laser during alignment procedures.

- Use beam shutters and filters to reduce the beam power.

- Post appropriate warning signs or labels near laser setups or rooms.

- Use a laser sign with a lightbox if operating Class 3R or 4 lasers (i.e., lasers requiring the use of a safety interlock).

- Do not use Laser Viewing Cards in place of a proper Beam Trap.

Laser Classification

Lasers are categorized into different classes according to their ability to cause eye and other damage. The International Electrotechnical Commission (IEC) is a global organization that prepares and publishes international standards for all electrical, electronic, and related technologies. The IEC document 60825-1 outlines the safety of laser products. A description of each class of laser is given below:

| Class | Description | Warning Label |

|---|---|---|

| 1 | This class of laser is safe under all conditions of normal use, including use with optical instruments for intrabeam viewing. Lasers in this class do not emit radiation at levels that may cause injury during normal operation, and therefore the maximum permissible exposure (MPE) cannot be exceeded. Class 1 lasers can also include enclosed, high-power lasers where exposure to the radiation is not possible without opening or shutting down the laser. |  |

| 1M | Class 1M lasers are safe except when used in conjunction with optical components such as telescopes and microscopes. Lasers belonging to this class emit large-diameter or divergent beams, and the MPE cannot normally be exceeded unless focusing or imaging optics are used to narrow the beam. However, if the beam is refocused, the hazard may be increased and the class may be changed accordingly. |  |

| 2 | Class 2 lasers, which are limited to 1 mW of visible continuous-wave radiation, are safe because the blink reflex will limit the exposure in the eye to 0.25 seconds. This category only applies to visible radiation (400 - 700 nm). |  |

| 2M | Because of the blink reflex, this class of laser is classified as safe as long as the beam is not viewed through optical instruments. This laser class also applies to larger-diameter or diverging laser beams. |  |

| 3R | Class 3R lasers produce visible and invisible light that is hazardous under direct and specular-reflection viewing conditions. Eye injuries may occur if you directly view the beam, especially when using optical instruments. Lasers in this class are considered safe as long as they are handled with restricted beam viewing. The MPE can be exceeded with this class of laser; however, this presents a low risk level to injury. Visible, continuous-wave lasers in this class are limited to 5 mW of output power. |  |

| 3B | Class 3B lasers are hazardous to the eye if exposed directly. Diffuse reflections are usually not harmful, but may be when using higher-power Class 3B lasers. Safe handling of devices in this class includes wearing protective eyewear where direct viewing of the laser beam may occur. Lasers of this class must be equipped with a key switch and a safety interlock; moreover, laser safety signs should be used, such that the laser cannot be used without the safety light turning on. Laser products with power output near the upper range of Class 3B may also cause skin burns. |  |

| 4 | This class of laser may cause damage to the skin, and also to the eye, even from the viewing of diffuse reflections. These hazards may also apply to indirect or non-specular reflections of the beam, even from apparently matte surfaces. Great care must be taken when handling these lasers. They also represent a fire risk, because they may ignite combustible material. Class 4 lasers must be equipped with a key switch and a safety interlock. |  |

| All class 2 lasers (and higher) must display, in addition to the corresponding sign above, this triangular warning sign. |  |

|

| Posted Comments: | |

Takeo Ejima

(posted 2024-05-28 08:49:46.273) いつもお世話になっております。

東北大の江島です。

早速ですが、SC10を用いた制御プログラムを開発中ですが、RS232Cの通信がうまくできません。こちらで調べたところ、送信はUTF-8を受付けて、受信はISO-8859-1とするとうまく通信できるようです。

通常、送受信の文字コードは一致しているのが普通ですので、かなり疑問に思っています。

お手数ですが、SC10で使用している文字コードをお教え願えないでしょうか?

取り急ぎ

江島 ksosnowski

(posted 2024-06-07 02:21:08.0) Hello Takeo, thanks for reaching out to us. We use UTF-8 when communcating with SC10, as can be seen in the Python examples included with the SC10 software installation folder. A member from your local tech support team has reached out to discuss this further. Alejandro Martinez Jimenez

(posted 2024-03-04 16:27:45.963) Hi,

I'm looking for an optical shutter that can be triggered with just a TTL signal. Do I need to buy the controller SC10 or KSC101 in this case? Or can I instead just send the signal to the SH05R(/M) Interface Connector PIN 6 for opening and closing? I understand that for further programming it will be beneficial to use SC10, but in the most basic case, would this be possible?

Best ksosnowski

(posted 2024-03-06 12:04:10.0) Hello Alejandro, thanks for reaching out to Thorlabs. Our shutters require a driving controller with sufficient current output to power the solenoid coil inside the device. Typical function generators will not be able to provide this type of power to an inductive load like a solenoid. Our controllers additionally provide a higher voltage opening signal to overcome any friction and inductance in the system then drop to a lower holding voltage to keep the shutter open against the internal return spring. The lower holding voltage helps prevent unnecessary heating and a lack of driving power can result in poor open-timing performance or potentially a failure to open at all. For a TTL input on SH05R(/M) it is recommended to use either our KSC101, or SC10 which has slightly better timing due to higher power output. Sergii bashchenko

(posted 2023-11-30 17:27:56.913) Hello,

I can't realize outer triggering mode by putting a few sec TTL pulse onto "IN1",

what is wrong?

Thanks, ksosnowski

(posted 2023-12-05 05:30:05.0) Thanks for reaching out to Thorlabs. I would recommend to start by making sure the device is set to external trigger mode and if using controller KSC101 then the KSC's top panel wheel must be moved down after startup to enable the controller. For troubleshooting questions like this, it is best to reach us directly at techsupport@thorlabs.com. A member from your local tech support team has reached out directly to discuss your issues in further detail. Dana Dlott

(posted 2023-10-17 09:43:39.043) What is the damage threshold for this shutter? I have a low repetition rate high energy 30 ns pulse laser and the pulse fluence is about 5 J/cm2. ksosnowski

(posted 2023-10-17 10:46:26.0) Hello Dana, thanks for reaching out to Thorlabs. While we have not formally tested the damage threshold for these shutters, some customers have reported damage close to energy density of 1J/cm2. Unfortunately in your case the shutter may not be suitable due to the high peak power of the pulses. I have reached out directly to discuss your application in further detail. Shuo Li

(posted 2023-08-16 10:09:53.383) Excuse me! I want to control the light shutter switch by using LABVIEW control KSC101. Do I need to add a sawtooth signal generator to the labview program? da ksosnowski

(posted 2023-08-18 10:42:17.0) Hello Shuo, thanks for reaching out to Thorlabs. With our Kinesis Motion Control Software, we include LabVIEW drivers to interface with the KSC101 directly over USB, without an external function generator signal. This allows the PC to communicate directly with the control board inside KSC101. We also have a KSC101 example in LabVIEW 2011 which I have reached out directly to share. We are working on adding more of these examples to Thorlabs' Github page. If you want to control the shutter state with a TTL signal, KSC101 also has a 5V TTL Trigger port you can use to apply a digital high/lo command. Many DAQs can provide such a signal and be configured in LabVIEW for automation. Frank Jin

(posted 2023-07-13 08:24:25.187) Hi, ksosnowski

I am using SC10, which works good as expected. I did find a SW bug. When I have a lot of serial ports ( like more than 10), the COM list goes to COM10, COM11, ... COM20 etc. The SC10 failed to populate the COM ports, and just closed itself without any error message. Basically the SW can't initiate itself, and fail to open it. I wish this will be a quick and easy fix. If you have a new version, I am more than to test it out. Thanks. cdolbashian

(posted 2023-08-04 11:06:41.0) Thank you for reaching out to us with this bug-find! Since you have reported this, we have provided you with a temporary fix immediately. In the meantime we are working to implement the same fix into the released software. Constant Schouder

(posted 2023-06-05 08:52:45.223) Hello,

I am using a KSC101 to control an optical shutter SH1M. I would like to give commands using a Python program. Would you have a library associated to it that I could use or some recommendations on how to properly start?

Thanks! ksosnowski

(posted 2023-06-12 04:27:02.0) Hello Constant, thanks for reaching out to Thorlabs. SH1(/M) shutters have a larger solenoid and are only intended for use on our SC10 controller which can provide proper power to actuate the shutter in time. SH05R(/M) does have a profile for operating KSC101 in our Kinesis software, however SH1 does not as it is meant for SC10. The Thorlabs GitHub has some examples for Kinesis in Python, including one for KSC101 using Pythonnet: https://github.com/Thorlabs/Motion_Control_Examples/tree/main/Python/KCube/KSC101 user

(posted 2023-04-12 16:09:50.817) Hi, I need two shutters operating simultaneously. Could I trigger both of them with a single SC10 unit using a T connector or would I require one SC10 per shutter? ksosnowski

(posted 2023-04-12 12:28:10.0) Thanks for reaching out to Thorlabs. The Shutter controllers SC10 and KSC101 are only intended to drive a single solenoid shutter. They do not have enough power to drive multiple shutters, and this could overload the controller. It is otherwise fine to use T connectors on the trigger input line to share one signal source to multiple controllers. Julia Sudyka

(posted 2022-12-19 09:04:41.133) Hello,what are the ambient temperature (operation and storage) limits for these shutters? cdolbashian

(posted 2023-01-10 03:26:28.0) Thank you for reaching out to us. We have not tested these parts for temperature extrema, as we intend for them to be operated at STP. I have contacted you directly to discuss your application and compatibility therein. Sonia Buckley

(posted 2022-12-02 06:21:37.397) This should be usb compatible- why do I need to buy another expensive and large piece of equipment to drive it? It was also unclear which equipment to buy to drive it. ksosnowski

(posted 2023-01-12 11:48:54.0) Thanks for reaching out to Thorlabs. Most PCs are not able to supply the proper driving conditions via USB alone. For the 1/2" shutter you can use the KSC101 KCube controller, and both 1/2" and 1" shutters will work with our SC10 Benchtop controller. Both of these controllers can connect to PC for control with our software, though the SC10 controller sources power directly from the wall, and KSC101 uses the KPS201 power supply. KSC101 is a fairly compact controller, however the SC10 allows for faster shutter timing performance. The SC10 ships with the cables needed for power and RS232 connection via DB9 plug, and KSC101 comes with the USB cable for connection. Some third-parties make DB9 serial to USB conversion cables which may work with SC10. I have reached out directly to discuss your application further. user

(posted 2022-07-27 17:20:21.037) We have ordered an SH1/M and will use it intra-cavity to prevent lasing in a production laser that will run continuously for several days at a time, using a hold voltage of 12V supplied by our own controller. I read fault reports below of shutters getting stuck half-way. Has this issue been investigated? Are there conditions/solenoid voltages to avoid in order to prevent this error? ksosnowski

(posted 2022-12-02 04:03:28.0) Thanks for reaching out to Thorlabs. This is a very rare occurrence that, if present from handling damage, would be apparent on arrival of the unit . Only in extreme case of misuse have we seen this happen in operation due to severe overheating. The SH1 and SH05R (and /M units) have a return spring to force the shutter closed in case of loss of power, and an optical monitor to observe if the shutter is open while operating. We recommend to remain within the Max Solenoid Voltages and Max Pulse Rate listed on the specifications for each shutter to avoid overheating. Increased heat will lead to shorter lifetime of the solenoid coil opening the shutter. I have reached out directly to discuss this application further. Chaman Gupta

(posted 2022-07-02 02:24:11.74) Is the SC10 controller compulsorily needed to control the SH1 or can it be connected and just controlled with a computer or some other form of remote? ksosnowski

(posted 2022-07-06 12:41:16.0) The controller will need to provide the driving power to the solenoid inside the SH1 to actuate and hold the shutter open as well as drive the optical emitter and sensor used to monitor the shutter state. We recommend the SC10, which acts as the power supply to the shutter head, and as the signal source. A PC alone cannot generally produce the proper driving power for the shutter, and our SC10 software is designed to work with our controller. The SH1 is compatible with 3rd party controllers however as long as they can provide the proper power to the device. Aaron Riede

(posted 2022-05-17 12:18:33.993) Dear Thorlabs, I want to run the TSC001 together with the SH05 shutter with a Python program. Do you have an example code for that?

Thanks and best regards,

Aaron ksosnowski

(posted 2022-05-23 03:08:34.0) While we don't have any Python examples for this specific TCube driver, we do have some examples for our other KCubes and with the Kinesis C API (installs by default) you can use these as a basis with the correct methods for your controller. I have contacted you directly to discuss this application further. CHANDRASEKHAR MUTYALA

(posted 2022-02-01 04:51:11.04) We would like to know whether the shutter is suitable for femtosecond lasers. If so, then mentioning damage threshold will be appreciable ksosnowski

(posted 2022-02-15 05:35:55.0) Thanks for reaching out to us Chandrasekhar, while we have not tested these shutters for ultrafast pulses, we have had cases where customers use these with some fs pulses without damage. If you are able to share the specifications of your laser, I can research with our team whether the shutter would be suitable for your laser. user

(posted 2021-09-21 12:26:33.253) Dear. The SC10 software crashes when I try to connect to the Shutter Controller. I already tried in 2 different computers and the problem persists. Can you advise what I can do to avoid that? Is there any log I can check what is going on? cdolbashian

(posted 2021-10-15 04:34:07.0) Thank you for reaching out to us at Thorlabs! When interfacing via the software, the most important first step is to ensure that the software and firmware versions are up to date. Please find the most recent version here: https://www.thorlabs.com/software_pages/viewsoftwarepage.cfm?code=SC10

I have reached out to you directly to engage in further troubleshooting steps. Shi-Yuan MA

(posted 2021-08-16 12:07:21.56) Hello,

I'm using a KSC101 to control the optical shutter SH05. The KSC101 is controlled via USB by the Kinesis software on a laptop. In the Kinesis interface, it shows that "Key Enabled" and "Is Ready", but the shutter has no responds when I click to start with a proper configuration and the "Active" is also green. How can I troubleshoot it? The shutter is only connected to KSC101 with the cable that came with it (I didn't see any other ports). cdolbashian

(posted 2021-08-27 09:12:08.0) Thank you for reaching out to us here at Thorlabs! Following our discussions via direct communication, it seems like you had not connected the interlock key, as outlined in sections 4.5.1 and 3.4.2 of the manual. Scott Beattie

(posted 2021-08-06 12:28:46.303) Would the KSC101 and SH1 work together if you only used manual mode? cdolbashian

(posted 2021-08-19 03:46:45.0) Thank you for reaching out to us with your inquiry! Based on previous customer experience, it seems like it is technically possible to do this. However, the performance is not guaranteed in any capacity. We really recommend using the SC10 to achieve the advertised and guaranteed performance! user

(posted 2021-07-21 03:33:35.713) Hello, by partial opening from previous post I meant its faulty behavior, and not partial opening by design. Is it possible that the shutter, due to some defect, gets partially open/closed? If yes, how likely it is? YLohia

(posted 2021-08-03 02:55:44.0) The default position of the electronic system is 'closed' so the shutter closes in case of electrical failure. We have received a few reports from other customers where mechanical failures led to the diaphragm shutters being stuck in half open/closed positions, but with the shutters on the page above we have only seen this occur in extreme case of misuse. We have reached out to you to discuss this further directly. user

(posted 2021-07-14 08:52:30.827) Is it possible that the shutter blade opens/closes only partially? YLohia

(posted 2021-07-15 11:03:21.0) Hello, thank you for contacting Thorlabs. Unfortunately, these shutters can only be in fully open or fully closed states. Susan Parker

(posted 2021-03-12 07:46:25.327) Can you tell me the expected lifetime in number of shutter operations.

In our case we are using it at 1 Hz.

Many thanks.

Best,

Susan. asundararaj

(posted 2021-03-12 10:01:08.0) Thank you for contacting Thorlabs. We spec the typical lifetime of the shutter as 1,000,000 open/close Cycles. Thomas Legbandt

(posted 2020-10-20 13:02:28.06) I think you need a way to make this into a shutter beam dump. Adding a beam tube alone is not sufficient. You need absorbent surface on the shutter to avoid specular reflection off the black anodized surface and low incident angle internal reflection from the inside of the beam tube. Internal baffles correctly placed would help. asundararaj

(posted 2020-10-22 04:43:54.0) Thank you for the valuable feedback. I have passed your suggestion along to our internal forum for consideration in a future product. Lingtian Diao

(posted 2020-07-20 09:13:20.52) Hello throlabs!

What is the operation temperature of the SH1/M? YLohia

(posted 2020-08-06 08:57:12.0) Hello, thank you for contacting Thorlabs. The solenoid in the SH1 shutter can be used at up to 120 C. Please note that a high power laser can damage the blades before the solenoid reaches an equilibrium temperature with the blades. LIDT information is given on Page 2 of the product manual. Claudia Ruiz

(posted 2020-05-29 06:14:50.26) Hello,

I see on the timing specifications of the web spec sheet of the SH* shutter that the KSC101 is not compatible with a SH1 shutter model. But I am using KSC101+SH1 system, so I do not understand very well this note ... could you please explain?

Thank you in advance,

Regards,

Claudia asundararaj

(posted 2020-07-14 03:56:34.0) Thank you for your feedback. The SH1 is not compatible for use with the KSC101 as it would not be able to provide the power needed to operate the SH1. The SH1 has a larger coil resistance and the KSC101 does not provide enough power to meet the higher duty cycles specified for the SH1. The reduced power will affect the open/close timings as well. Jason Thompson

(posted 2019-12-06 07:10:15.643) Hi, we buy optics from you, but buy a safety shutter in from Lasermet - their MS20 I think. We want to block a 30Khz, 3W, dia.1.2mm, 355nm UV laser. This laser is integrated into a customer cell and has a duty cycle of approx 5 seconds, so shutter would be open for roughly 4 seconds an close for 1 second per cycle. We are seeing reliability issues with the current unit so I am looking at alternatives.

I saw your SH05 unit and would like to know more, with quote please. If you want to chat about the application +44 1656 678009 for my direct line. Thanks,Jason asundararaj

(posted 2019-12-07 09:04:30.0) Thank you for contacting Thorlabs. I will reach out to you directly to discuss your application. techsupport

(posted 2009-05-14 08:50:31.0) A response from Erin in Tech Support to Andreas: For keeping the shutter open for a long period of time we recommend using 10 volts as the holding voltage. If you have any further questions please let us know. andreas.buehler

(posted 2009-05-14 05:09:33.0) We want to use the shutter as a safety interlock. I am wondering, what kind of generator to use i.e. what amount of current and voltage to keep the shutter open.

Thanks

Andreas Laurie

(posted 2009-03-20 12:31:18.0) Response from Laurie at Thorlabs to larrs-erik.nilsson: Thank you for your feedback. The SH05 shutter vane is made of anodized aluminum, so it should be suitable for handling and blocking the amount of power you suggest. Generally, shutters are not placed at the focal point of a light source; under such conditions and with sufficient power, the shutter vane will heat up. Laser powers in excess of 1000 W with a beam diameter of 0.2 mm is generally necesssary to cause burning or cutting. We do not have any lasers in our facility powerful enough to promote any ablation or damage. For high powers, it is advisable (for safety reasons) to periodically check the vane for any damage. If you have additional questions, please let us know. larrs-erik.nilsson

(posted 2009-03-20 07:28:45.0) We would like to use this product as a safety intelock to frequency doubled YAG-laser.

Will it sustain continous operation at:

532 nm

20 mJ/puls (10 ns)

100 Hz

Looking forward to your answer

Sincerely

Lars-Erik Nilsson jlm

(posted 2009-03-10 09:40:59.0) We want to use the TSC001 Shutter Controller in a prototype, ideally we would like to place the controller in a closed package and use an external trigger signal, unfortunately the “Enable” bottom must be pressed at power on. Is there any way to circumvent this problem? Laurie

(posted 2009-02-26 14:51:56.0) Response from Laurie at Thorlabs to benoit.mangote: Thank you for your interest in our SH05 shutter. The shutter vane is made of .05" (2.54 mm) anodized aluminum. There is no specific damage threshold value. Significant power may ablate the anodized surface on the aluminum. If your incoming laser beam can cut aluminum (typically a focused > 500 W CO2 laser ) then this shutter cannot be used. The shutter vane can be easily replaced, although weve never seen damage to it due to burning. For most applications, the laser beam at the location of the shutter is not focused. benoit.mangote

(posted 2009-02-26 09:17:57.0) What is the damage threshold of the SH05 ? Laurie

(posted 2009-02-23 08:05:47.0) Response from Laurie at Thorlabs to jwsickler: You are correct that the SH05 will not be suitable for you application. You could try an optical chopper. The description can be found via this link: http://www.thorlabs.com/NewGroupPage9.cfm?ObjectGroup_ID=287. If you choose this route, your blocked/unblocked durations will be identical. Please let us know if you have additional questions. jwsickler

(posted 2009-02-20 16:58:55.0) Interested in the capabilities of this shutter for modulating a 1 kHz repetition rate high power (up to 1 W) ultrafast pulse train, ideally with the capability to select every other pulse (i.e. 500 Hz modulation). From what I understand, this shutter can only cycle at up to 10 Hz, 25 Hz in bursts, and would not serve my needs. Is that correct? If so, are there any other solutions you can suggest? Tyler

(posted 2008-05-21 08:43:43.0) Response from Tyler at Thorlabs to hansknec: We have not tested the SH05 shutter to determine the damage threshold. I can tell you that the shutter blade is made from 1.6 mm thick black anodized aluminum. Please consider contacting one of our application engineers to discuss your intended application. Since we use this product in our own research labs, we might have used the product in a similar situation to your application. hansknec

(posted 2007-10-29 09:14:00.0) Dont you think it would be appropriate for you to show the beam power handling ability? Wavelength? Power? |

Click to Enlarge

An example measurement of the open and close times of the SH05R(/M) shutter when driven with the KSC101 controller. A collimated LED light was used to overfill the shutter aperture, and as the shutter opened and closed the amount of light transmitted was measured.

- Ø1/2" Aperture

- Shutter Close Time (90% to 10% Exposure):

- 6.5 ms (Typ.) with SC10 Controller

- 8.0 ms (Typ.) with KSC101 Controller

- SM05-Threaded (0.535"-40) Aperture for SM05 Lens Tube Compatibility

- Default Position: Closed

- Compatible with the SC10 and KSC101 Controllers (Sold Separately Below)

The SH05R(/M) Optical Beam Shutter has a single blade that slides across a Ø1/2" aperture. The typical shutter close time, defined as the time it takes for the shutter to go from 90% to 10% of the aperture area exposed, is 6.5 ms when the shutter is driven with the SC10 controller or 8.0 ms with the KSC101 controller. The graph to the right shows a sample measurement of open and close times for an SH05R optical shutter driven with the KSC101 controller. Please see the Specs tab for additional specifications.

Both sides of this shutter's aperture are internally SM05 (0.535"-40) threaded for compatablity with our SM05 Lens Tubes. Two 8-32 (M4) tapped holes, located on the side and bottom of the shutter housing, can be used for post mouting.

For applications requiring blades that open from the center, we offer a Ø1/2" diaphragm shutter and controller with five stainless steel blades.

Click to Enlarge The SH1 is compatible with SM1 Lens Tubes and 30 mm Cage Systems.

- Ø1" Aperture

- Shutter Close Time (80% to 20% Exposure): 10 ms (Typ.) with SC10 Controller

- SM1-Threaded (1.035"-40) Aperture for SM1 Lens Tube Compatibility

- Default Position: Closed

- Compatible with the SC10 Controller (Sold Separately Below)

The SH1(/M) Optical Beam Shutter has a single blade that slides across a Ø1" aperture. The typical shutter close time, defined as the time it takes for the shutter to go from 80% to 20% of the aperture area exposed, is 10 ms when used with the SC10 Shutter Controller (sold separately below). Please note that this optical shutter is not compatible with the KSC101 controller. This shutter can be used with third-party controllers, as long as they fall within the solenoid power requirements given in the Beam Shutter Specifications table of the Specs tab. For further details, see Chapter 4 of the manual.

Both sides of the aperture are internally SM1 (1.035"-40) threaded for compatibility with our SM1 Lens Tubes. The SH1(/M) has three 8-32 (M4) tapped holes for post mounting and 4-40 taps for use with our 30 mm Cage Components.

For applications requiring blades that open from the center, we offer a Ø1" diaphragm shutter and controller with five stainless steel blades.

- Local Operation or Remote Control via LabVIEW™, LabWindows™, RS-232, or BNC

- Programmable with Repeating Open/Close Sequences at Millisecond Intervals

- LCD Front Panel with Dedicated Shutter Status Indicators

- Safety Alarm When Coupled with SH05R(/M) or SH1(/M) Beam Shutter

- Key Switch Provides Additional Safety

Thorlabs' SC10 Shutter Controller provides an easy-to-use control interface for our SH05R(/M) and SH1(/M) Optical Shutters. The shutter can be controlled by hand using the buttons on the front of the unit, and the back includes a BNC input for external triggering, a BNC output for synchronization with other equipment, and an RS-232 port for remote computer control. Dedicated lights on the front panel reveal if the shutter is enabled and if the shutter is open. It also features a keyswitch that enables opening of the shutter, helping to comply with lab laser safety requirements. In addition, it incorporates a safety interlock that overrides all system commands and closes the shutter. If the interlock is tripped, the keyswitch must be cycled to resume operations.

The easy-to-read LCD front panel provides access to the same commands as the included LabVIEW and LabWindows software packages. In addition to simply opening or closing the shutter, a repeating sequence of open and close events with exposure times as low as 10 ms can be set up and initiated either by a front panel button, a TTL pulse (+5 V), or a computer command via RS-232. Alternatively, the shutter can be synchronized to follow the rising and falling edges of an external voltage supplied over BNC.

The optical shutter controller includes LabVIEW VI's suitable for integrating into existing LabVIEW applications. A standalone executable written in LabWindows/CVI is also provided, allowing remote computer control of the SC10 without any additional programming. See the SC10 Software tab to download these packages.

The shutter controller's BNC output allows it to double as a standalone digital delay generator with 1 ms resolution and 0.1 ms accuracy.

In October 2012, the firmware of the SC10 was updated to address compatibility issues with our SH1 Shutter. For units purchased prior to that date, a free firmware update is available; please see the SC10 Software tab for details.

Click to Enlarge

Back and Top Views of the KSC101 K-Cube

(See the Pin Diagrams Tab for More Information)

Click to Enlarge KCH301 USB Controller Hub (Sold Separately) with Installed K-Cube™ Modules

- Local Operation or Remote Control via USB or SMA

- Full Kinesis® Software Control Suite (See Kinesis Software Tab for Details)

- Programmable with Repeating Open/Close Sequences at Millisecond Intervals

- Manual Controls and Digital Display Allow for Mode Selection and On/Off Time Control

- Laser Safety Interlock Jack and Safety Enable Key Switch

- Single-Channel Power Supply Unit Sold Separately

- Multi-Unit Operation Using USB Controller Hubs (Sold Separately)

Thorlabs' KSC101 K-Cube™ Optical Shutter Controller is a compact, 60.0 mm x 60.0 mm x 49.2 mm controller that is designed for use with our SH05R(/M) Shutter. The controller features an embedded digital signal processor (DSP) to provide a multitude of flexible operating modes; see the Specs tab for details. Embedded software functionality allows this unit to control solenoid devices using the on-unit menu button, display, and control wheel; using DSP timed operations; or using external trigger signals for operation with third-party equipment. The trigger out connection, defaulted on Trigger 2, allows multiple K-Cube controllers to be connected together for synchronized multi-channel system operation.

The KSC101 is also equipped with built-in safety interlock functionality in the form of a 3.5 mm stereo jack. A shorted connector is included for overriding this connection, while a custom circuit may be created for lab safety applications using the included 3.5 mm stereo connector. The circuit must be closed for the controller to be able to open the shutter. To comply with laser safety requirements, the controller also features a key switch that enables or disables opening of the shutter.

The easy-to-read digital display provides access to the same commands as the included Kinesis® software package. In addition to simply opening or closing the shutter, a repeating sequence of open and close events with exposure times as low as 15 ms can be set up and initiated either by the top panel controls, a TTL pulse (+5 V), or a computer command via USB 3.0.

USB connectivity provides easy 'Plug-and-Play' PC-controlled operation with our Kinesis software package. For more details, please see the Kinesis Software tab. For convenience, a 1.5 m long Type A to Type Micro B USB 3.0 cable is included with the KSC101 cube.

Power Supply Options

The preferred power supply (single channel or hub-based) depends on the end user's application and whether you already own compatible power supplies. To that end and in keeping with Thorlabs' green initiative, we do not ship these units bundled with a power supply.

Multiple units can be connected to a single PC by using the KCH301 or KCH601 USB Controller Hubs, available below, for multi-axis motion control applications. The KCH301, shown in the image above, allows up to three T- or K-Cube controllers to be used while the KCH601 allows up to six controllers to be used.

All power supply options compatible with the KSC101 Controller can be found below. For more information on the KSC101, please see the full web presentation.

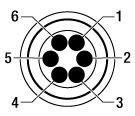

Click to Enlarge

Male Hirose Connector

Click to Enlarge

Wire Diagram

- 6-Pin, Male-to-Male Hirose Connector Cable

- Replacement Cable to Connect Shutter and Controller

- Cut Cable to Expose Wires for Custom Applications

- HR10AD1 Cable with Breakout Box Also Available for Custom Connections to Shutters

The HR10CAB1 is a 3.0 m long, 6-pin, male-to-male Hirose connector cable that is compatible with the shutters and controllers on this page.

If a custom soldered connection is desired, this Hirose connector cable can also be cut to any length leaving one connectorized end and one bare end. The colored wire diagram to the right shows the relationship between the six colored wires and the pins in the connector, allowing the cut cable to be incorporated into a variety of custom applications. Note that the wires in this cable cross over the length of the cable, so the insulation color should be used for pin identification.

For more information on the HR10CAB1, please see the full web presentation.

For custom shutter driving configurations, our HR10AD1 cable with breakout box allows for easy connection to bare wire components without the need for soldering.

Products Home

Products Home

Zoom

Zoom

Single-Blade Optical Beam Shutters

Single-Blade Optical Beam Shutters