Long-Travel Vertical Translation Stages

- Stages with 4" (101.6 mm) or 10" (254 mm) Travel

- Recommended Load Capacity of 50 lbs (23 kg)

- Dynamically Damped Post Construction

- Quick-Release Feature for Coarse Adjustment

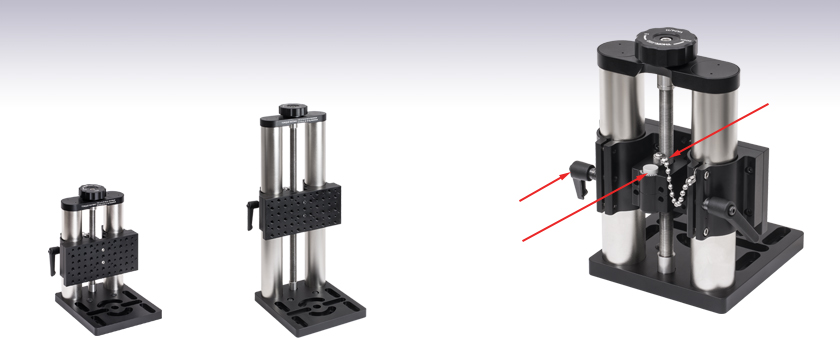

VAP4

4" Travel

Quick-Release Button

VAP10

10" Travel

Locking Handle

VAP4

Back View

Locking Pin and Chain

Please Wait

| Specifications | ||

|---|---|---|

| Item # | VAP4(/M) | VAP10(/M) |

| Travel Range | 4" (101.6 mm) | 10" (254 mm) |

| Adjustment per Revolution | 0.05" (1.27 mm) | |

| Load Capacity | 50 lbs (23 kg) | |

| Maximum Momenta | 150 in-lbs (16.9 N•m) | |

| Stabilityb | ≤15 µrad Drift Over 6 Hours | |

| Linearity | >90% | |

| Weight | 8.6 lbs (3.9 kg) | 11.0 lbs (5.0 kg) |

Features

- 4" (101.6 mm) or 10" (254 mm) of Vertical Travel

- Maximum Moment of 150 in-lbs (16.9 N•m)

- Quick-Release Button for Coarse Positioning

- Quick-Release Locking Pin

- C15QR Handles to Lock Stage Position

Thorlabs' Long Travel Vertical Translation Stages have been developed to accurately position optomechanical systems with moments as high as 150 in-lbs (16.9 N•m) at a recommended load of 50 lbs (23 kg). These stages are constructed using dynamically damped Ø1.5" posts to minimize mechanical vibration and ringing, making them ideal for alignment-sensitive applications.

Click to Enlarge

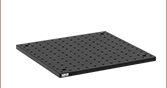

VAP4 Stage Supporting an Aluminum Breadboard and an Optical System

The VAP4(/M) and VAP10(/M) Vertical Stages allow for 4" (101.6 mm) or 10" (254 mm) of translation, respectively. The fine adjustment knob on the top of each stage can be actuated by hand or with a 3/16" (5 mm) hex key or balldriver to achieve a motion of 0.05" (1.27 mm) per revolution. The torque required to actuate the fine adjustment knob increases with the load on the stage. For coarse adjustment over a long travel range, the stage features a quick-release button. Holding down the button disengages the stage from the lead screw and allows the position of the mounting plate to be adjusted by hand.

A pin attached to the back of the stage by a ball chain can be placed in a quick-release lock to prevent the use of the coarse adjustment feature. We recommend keeping this locking pin engaged at all times except for when using the coarse adjustment. Both the quick-release button and the locking pin can be seen in the image above. Two bumpers on the base plate of the stage help to minimize damage if the mounting platform is dropped during coarse adjustment with the quick-release mechanism. Once the required stage height has been set, two included C15QR handles can be used to lock the post clamps holding the mounting plate for extra stability.

The translating vertical 3" x 6" (76.2 mm x 152.4 mm) mounting plate has an array of thirty-three 1/4"-20 (M6) and thirty-one 8-32 (M4) tapped holes. An Aluminum Breadboard can be attached to this plate using 90° mounting adapters (such as the AP90 or AB90), as shown in the photo to the left. The base plate of the stage features six linear counterbored slots and one counterbored hole for 1/4" (M6) mounting hardware. In addition, two counterbored 1/4" (M6) slots on a Ø2.00" (50 mm) circle are provided for rotational positioning. For other high load vertical translation applications, we also offer a selection of Lab Jacks.

| Posted Comments: | |

user

(posted 2021-10-28 19:14:39.893) Will a quarter turn give a vertical displacement of (1.27 \ 4) mm ? YLohia

(posted 2021-12-23 11:14:01.0) Yes, a quarter turn would yield a displacement of (Adjustment per revolution / 4) = 0.3175 mm. Brian Patton

(posted 2021-08-02 12:23:08.183) We are using two of these units to raise and lower a microscope stage for sample loading and then imaging. They are performing very well and we have been very happy with them in general. However, the mass being supported means that some of the smaller team members can't use the quick release function without risking dropping the stage and the turn-screw is very laborious to run by hand while avoiding the risk of raising one side more than the other and locking the stage in position by accident. Is there a way in which we could remove the upper knob to allow us to replace it with a pulley for a belt drive system? We could then use appropriate stepper motors to raise and lower the stage. cdolbashian

(posted 2021-08-19 04:10:06.0) Thank you for reaching out to us here at Thorlabs! We do not recommend motorizing this unit: excessive speed could lead to accelerated wear on the lead screw and nut which can in turn lead to a failure of the unit. This has not been tested and Thorlabs cannot be held responsible for any damage or injury as a result of modifying this part. I have contacted you directly to discuss this further. er

(posted 2017-11-16 14:22:06.67) Is it possible to turn the base plate 180 degrees? So that if you mount something on the stage you can move it all the way down without touching the base? Is it possible to have it longer the stage ? (maybe 350mm or more?) tfrisch

(posted 2017-11-20 04:39:22.0) Hello, thank you for contacting Thorlabs. Flipping the mounting base is possible, we've offered this as a custom several times before. As for the longer travel, that would be limited by the lead screw. Unfortunately, we are currently limited to 10" travel. I will reach out to you directly to discuss your application. fgr

(posted 2016-08-24 10:45:48.987) Hej

You name a max. moment of 16.9 Nm in the specs. For my calculations: Where do I have to apply it?

1) Where the posts touch the base-plate?

2) On the mounting plate?

Thanks! tcampbell

(posted 2016-08-24 02:53:18.0) Response from Tim at Thorlabs: Thank you for your question. The moment load is measured from the mounting plate, not the base of the posts. We have updated the web with this information. konstantin.sukharnikov

(posted 2016-07-27 06:26:00.097) Dear Sir or Madam

Is it possible to have a vacuum compatible (10^(-8) mBar) version of this stage? |

Manual Linear Translation Stages

Thorlabs' manual translation stages are offered in a range of maximum travel distances, from less than 1/4" (6 mm) to 2" (50 mm) and longer for our long travel, large area platforms. Many of these stages can be ordered in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our Multi-Axis Stages, which offer finer adjustment than our standard manual translation stages. In addition to linear translation stages, we offer rotation stages, pitch and yaw platforms, and goniometers. We also offer motorized translation stages that are powered by DC Servo motors, stepper motors, or direct drive technology.

Crossed-Roller Bearing Stages

These linear translation stages feature crossed-roller bearing travel mechanisms for precision motion, high load capacity, and low angular deviation. The LNR Series stages feature all-steel body construction, while the LX, XRN, and XR Series stage bodies are constructed of cast tool and jig aluminum. We also offer several vertical crossed-roller bearing stages (see below).

| Crossed-Roller Bearing Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | LNR Series 25 mm Stages | LX Series 25 mm Stages |

XRN Series 25 mm Stages | XR Series 25 mm Stages | XR Series 50 mm Stages | LNR Series 50.8 mm Stages |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 50 mm (1.97") | 50.8 mm (2") |

| Drive Type | Multiple | Micrometer | Micrometer | Micrometer | Micrometer | Multiple |

| Platform Size | 2.34" x 2.36" (59.4 mm x 60.0 mm) |

2.56" x 2.56" (65.0 mm x 65.0 mm) |

2.00" x 3.35" (50.7 mm x 85.0 mm) |

2.98" x 4.33" (75.7 mm x 110.0 mm) |

2.98" x 5.51" (75.7 mm x 140.0 mm) |

3.94" x 3.94" (100.0 mm x 100.0 mm) |

| Possible Axis Configurations |

X, XZ, XY, XYZ | X, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, XY, XYZ |

| Additional Details | ||||||

Ball Bearing Stages

These translation stages feature hardened steel linear bearings for precise motion and long life. They are available with a variety of actuators and in single-axis or preassembled multi-axis configurations.

| Ball Bearing Stages | |||||

|---|---|---|---|---|---|

| Product Family | MS Series 1/4" Stages | T12 Series 1/2" Stages | MT Series 1/2" Stages | PT Series 1" Stages | LT Series 2" Stages |

| Click Photo to Enlarge |  |

|

|

|

|

| Travel | 1/4" (6.4 mm) | 1/2" (12.7 mm) | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50 mm) |

| Drive Type | Multiple | Thumbscrew | Multiple | Multiple | Differential Micrometer |

| Platform Size | 1.17" x 1.17" (29.7 mm x 29.7 mm) |

0.76" x 0.81" (19.3 mm x 20.6 mm) |

2.40" x 2.41" (61.0 mm x 61.2 mm) |

3.00" x 4.00" (76.2 mm x 101.6 mm) |

3.75" x 3.75" (95.3 mm x 95.3 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | |||||

Dovetail Stages

These compact stages incorporate dovetails and a leadscrew for the translation mechanism. They are suitable in general purpose motion control applications.

| Dovetail Stages | |||

|---|---|---|---|

| Product Family | DT Series 1/2" Stages | DTS Series 1" Stages (Vacuum-Compatible Version Available) |

DTS Series 2" Stage |

| Click Photo to Enlarge |  |

|

|

| Travel | 1/2" (12.7 mm) | 1" (25 mm) | 2" (50 mm) |

| Drive Type | Thumbscrew | Thumbscrew | Thumbscrew |

| Platform Size | 1.00" x 1.00" (25.4 mm x 25.4 mm) | 2.68" x 2.95" (68.0 mm 75.0 mm) | 2.68" x 3.74" (68.0 mm x 95.0 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZa | X, XY, XYZ |

| Additional Details | |||

Flexure Stages

Thorlabs' Nanoflex™ translation stages feature frictionless flexure mechanisms for improved positioning and resolution when compared to similar stages made using bearings. The translation of the stage is accomplished by the elastic deformation (flexing) of a linkage attached to the mounting platform. Most models also include piezo actuators for small position adjustments.

| Flexure Stages | ||||

|---|---|---|---|---|

| Product Family | Nanoflex™ 1.5 mm Stage | Nanoflex™ 5 mm Stages | ||

| Click Photo to Enlarge |  |

|

|

|

| Travel | 1.5 mm (0.06") + 25 µm Piezo | 5 mm (0.20") | 5 mm (0.20") + 20 µm Piezo | |

| Drive Type | Thumbscrew and Piezo Actuator | Differential Micrometer | Differential Micrometer and Open-Loop Piezo Actuator |

Differential Micrometer and Closed-Loop Piezo Actuator |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) | 2.95" x 2.95" (75.0 mm x 75.0 mm) | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | ||||

Vertical Stages

We offer vertical translation stages with crossed-roller bearings for precise motion as well as long travel vertical stages for heavy-duty applications.

| Vertical Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | XRN Series 9 mm Vertical Stage | XR Series 14 mm Vertical Stage | MVS Series 1/2" Vertical Stage | MVS Series 1" Vertical Stage | VAP Series 4" Vertical Stage | VAP Series 10" Vertical Stage |

| Click Photo to Enlarge |  |

|

|

|

|

|

| Travel | 9.0 mm (0.35") | 14.0 mm (0.55") | 1/2" (13.0 mm) | 1" (25.0 mm) | 4" (101.6 mm) | 10" (254 mm) |

| Drive Type | Worm-Gear Driven Lift Screw | Micrometer | Adjuster Knob and Coarse Manual Positioning | |||

| Platform Size | 2.00" x 2.00" (50.7 mm x 50.7 mm) |

2.98" x 2.98" (75.7 mm x 75.7 mm) |

2.36" x 2.36" (60.0 mm x 60.0 mm) | 3.00" x 6.00" (76.2 mm 152.4 mm) | ||

| Additional Details | ||||||

- Attach Aluminum Breadboards to our VAP4(/M) or VAP10(/M) Vertical Stages

- One-Piece Aluminum Construction for Excellent Rigidity

- Parallel and Perpendicular to Within 0.002" (0.05 mm)

The AP90(/M) and AB90 Right-Angle Adapters are ideal for mounting aluminum breadboards on the VAP4(/M) and VAP10(/M) Vertical Translation Stages. The AP90(/M) plate provides four 1/4"-20 (M6) clearance slots, seven 1/4"-20 (M6) tapped holes, and two 1/4"-20 (M6) counterbores on one face. The other face contains two 1.30" (34 mm) long, 1/4"-20 (M6) clearance slots and two 1/4"-20 (M6) counterbores for attaching it to the mounting plate of these stages. The AB90 Right-Angle Bracket has two counterbored slots at 90° for 1/4" (M6) mounting hardware.

For alternative 90° mounting options, please see our full selection of 90° Mounting Adapters. We also offer 45° and 30°/60° mounting plates.

Products Home

Products Home

Zoom

Zoom High-Load Vertical Stages:

High-Load Vertical Stages: