Furcation Tubing, Sleeves, and Connector Caps

FTS61A

Stainless Steel Sleeve

for Ø6.1 mm Tubing

CAPF

Cap for Ø2.5 mm Ferrules,

Pack of 25

FT05SS

Ø5.0 mm Stainless Steel Tubing

FT061PS

Ø6.1 mm Stainless Steel Tubing,

Best Choice for Light-Sensitive Setups

CAPSM

Metal Threaded Cap

for SMA Connectors,

Pack of 4

- Tubing Protects Fiber and Provides Easy Identification

- Sleeves Join Stainless Steel Tubing to Connectors

- Fiber Connector Caps Protect Polished Faces of Fiber

FT023SS

Ø2.3 mm Stainless Steel Tubing

CAPX1

FC Plastic Connector Cap

CAPF1

FC Metal Connector Cap

FT080SSW

Ø8.0 mm Stainless Steel Tubing

Please Wait

| Furcation Tubing Selection Guide | |||

|---|---|---|---|

| Item # | Inner Diameter | Outer Diameter | Color |

| FT900Y | ≥400 µm | 900 µm | Yellow |

| FT900Ka | ≥400 µm | 900 µm | Yellow, Blue, or Black |

| FT020a | ≥1.0 mm | 2.0 mm | Orange, Yellow, or Black |

| FT023SS | 1.2 mm | 2.3 mm | Silver (Stainless Steel) |

| FT030DFa | ≥1.0 mm | 3.0 mm | Blue, Green, or Red (Polyvinylidene Fluoride) |

| FT030a | ≥1.0 mm | 3.0 mm | Orange, Yellow, Blue, or Black |

| FT038a | ≥1.8 mm | 3.8 mm | Red or Black |

| FT05SS | 3.5 mm | 5.0 mm | Silver (Stainless Steel) |

| FT061PS | 3.5 mm | 6.1 mm | Black (Coated Stainless Steel) |

| FT080SSW | 6.0 mm | 8.0 mm | Silver (Stainless Steel) |

Features

- Protect Fiber Optic Cables

- Colored Tubing for Quick Fiber Type Identification (See Color Choices in Table at Right)

- Black Furcation Tubing for Light-Sensitive Applications

- Stainless Steel Tubing Offers High Degree of Protection

- Sleeves Securely Join Stainless Steel Tubing to Fiber Connectors

- High-Temperature, Vacuum-Compatible Stainless Steel Sleeves Ideal for Use with Polyimide Fiber

- Connector Caps Keep Polished Fiber Tips Clean

Furcation Tubing

Furcation tubing, also commonly referred to as jacketing, is used to protect delicate optical fiber from damage. The color of tubing is typically chosen to represent the type of fiber patch cable. Yellow tubing is the industry standard for single mode fiber, orange designates multimode fiber, and blue is typically reserved for polarization-maintaining fiber. Black tubing prevents visible light from entering through the length of the fiber. Our FT030DF series furcation tubing has a polyvinylidene fluoride (PVDF) outer jacket and provides higher rigidity that can protect delicate fibers such as our fluoride fibers. For additional light blocking, our furcation tubing can be placed inside any of our stainless steel tubing with a sufficiently large inner diameter.

When selecting furcation tubing, please note its inner diameter, as this dimension must be larger than the outer diameter of the fiber you are using. Custom colors for furcation tubing are available. Additionally, as an alternative to jacketing your own fiber, Thorlabs offers custom pre-made patch cables. Please contact Tech Support for further information about Thorlabs' custom jacketing capabilities.

Stainless Steel Furcation Tubing and Sleeves

Thorlabs offers several stainless steel furcation tubing options that provide high rigidity but with a larger bend radius. Generally, the smallest tubing that fits the fiber is ideal, but it is sometimes beneficial to use larger tubing to protect a fiber with a larger bend radius. Our stainless steel sleeves effectively serve the same function as a strain relief boot and shield the connection from dust, dirt, and other external contaminants. We also offer a 304 stainless steel sleeve that can withstand environments with temperatures up to 250 °C or vacuum down to 10-10 Torr. It is intended to be used with our high-temperature, vacuum-compatible SMA905 multimode connectors and polyimide-coated fiber without furcation tubing.

Fiber Connector Caps

Dirt on the fiber tip can result in permanent damage to the fiber connector. This can result in increased coupling losses or undesirable mode structure in the output light. To prevent damage to the fiber end face, clean the tip before each use and use a connector cap to protect the fiber end face when it is not in use (see our fiber optic cleaning products). Thorlabs offers caps for Ø1.25 mm, Ø2.5 mm, and Ø3.2 mm fiber connector ferrules; metal caps for FC and SMA connectors; metal caps for FC, SMA or ST®* bulkheads and mating sleeves; and plastic caps for FC bulkheads and mating sleeves. See below for more information.

*ST® is a registered trademark of Lucent Technologies, Inc.

| Posted Comments: | |

user

(posted 2024-04-04 12:21:53.067) Hi.

How do we use the pull string most efficiently? We need to pull 16m of fiber, and normally we glue with loctite 10 sec fast curing isocyanat. That is not strong enough for this long. OD of fiber is standard 250µm.

BR

Magnus cdolbashian

(posted 2024-04-26 08:59:19.0) Thank you for reaching out to us with this inquiry. While we do not have step-by-step advice for pulling fiber through jackets, we do have some tips. I have emailed you directly to discuss your application, and to perhaps give you some advice on pulling this fiber. Hans Olson

(posted 2023-12-19 14:26:59.627) Hello,

What is the preferred method for cutting the 5 mm stainless steel tubing, FT05SS, to length? Is there a tool that you can recommend?

Thanks,

Hans ksosnowski

(posted 2023-12-20 02:09:23.0) Hello Hans, thanks for reaching out to Thorlabs. Our team typically uses a Dremel tool or MicroLux Mini Miter to cut the stainless steel tubing. We would highly recommend using personal safety equipment including goggles if using hardware like this to process the tubing. I have reached out directly to discuss this application in further detail. Joshua Zaugg

(posted 2023-01-04 09:26:50.93) The smaller diameter section of the crimp sleeve does not crimp with the 0.128" setting on the CT042 crimp tool. I had to procure another crimp die with a 0.100" setting in order to actually crimp the sleeve onto a 2mm furcation tubing.

I've made this aware to some people in customer service though they just stopped replying to my follow-up emails.

I think perhaps changing the product description for the CT042 to reflect that customers will need to buy another specific die to use the 2mm crimp sleeves. jgreschler

(posted 2023-01-17 09:57:59.0) Thank you for reaching out to Thorlabs. We are aware of this concern and recommend using epoxy to fully secure the fiber when using 2mm tubing options. I have reached out to you directly to discuss this application. Lev Leontyev

(posted 2021-07-05 07:02:40.053) We would like to buy 20 meters FT023SS - Ø2.3 mm Stainless Steel Tubing with delivery to Novosibirsk, Russia. YLohia

(posted 2021-07-07 02:59:10.0) Hello, thank you for contacting Thorlabs. Orders for stock items can be placed on our website or with the Thorlabs Sales team (sales@thorlabs.com) / your local Thorlabs distributor. Lev Leontyev

(posted 2021-07-05 07:01:24.543) We would like to buy 20 meters FT023SS - Ø2.3 mm Stainless Steel Tubing with delivery to Novosibirsk, Russia. YLohia

(posted 2021-07-07 02:59:11.0) Hello, thank you for contacting Thorlabs. Orders for stock items can be placed on our website or with the Thorlabs Sales team (sales@thorlabs.com) / your local Thorlabs distributor. mahesh BN

(posted 2021-03-19 03:56:07.693) Hi,

can you please confirm the FT900Y is having the RoHS3 compliane. if so, please share the RoHS3 cerificate.

Thanks & Regards

Mahesh BN YLohia

(posted 2021-03-19 03:14:00.0) Hello Mahesh, I have reached out to you directly with this document. BRAHIM DAHMANI

(posted 2021-03-02 07:44:24.587) can we get the ROHS certificate for this product ??

Thanks, asundararaj

(posted 2021-03-03 10:30:49.0) Thank you for contacting Thorlabs. We have reached out to you directly via email with this information. Euan Dickson

(posted 2021-02-10 11:41:16.55) Hi

I am just enquiring about the above product and to see if I can be provided with more information. We currently use this sheathing for our range of optical sensor products. However I am just enquiring to see if you can tell me what material the actual sheathing is made of, and if this specific sheathing has a datasheet ?

Many thanks,

Euan Dickson. YLohia

(posted 2021-02-10 04:12:16.0) Hello, thank you for contacting Thorlabs. Are you referring to the FT900Y tubing or the black plastic sheath on the FT061PS? Assuming you're referring to the former (as selected on your form), please see this link for more information on the Hytrel 7246 material used in that tubing: https://www.materialdatacenter.com/ms/en/tradenames/Hytrel/DuPont+Engineering+Polymers/Hytrel%C2%AE+7246/1c9b70e9/800 Simon Ma

(posted 2021-02-04 13:14:10.86) Dear sir or madam,

My name is Simon and I'm looking for a PVC tubing.

I checked FT030-BK but seems the inner diameter is not big enough for us. The larger dimension (>3mm) is stainless only.

Do you have the PVC tubing (design features similar to FT030-BK) that has the inner diameter of >3mm?

Thank you very much!

Simon YLohia

(posted 2021-02-04 04:06:27.0) Hello Simon, thank you for contacting Thorlabs. Unfortunately, we don't have a PVC-based tubing option with ID > 3mm. The closest alternative is the FT061PS. Andreas Seifahrt

(posted 2019-07-30 16:00:32.107) FTS61B is listed as the correct sleeve for 30xxxxG3 type connectors. I think this is a typo in the table. The sleeve is much too large and in fact FTS50A is listed for the same connector. I tried and it fits much better. So I think FTS61A is the correct sleeve for 30xxxxG3. tcampbell

(posted 2019-08-01 12:56:44.0) Hello, thank you for contacting Thorlabs. You are correct, the 30xxxxG3 connectors should be used with FTSxxA sleeves. We have updated the tables accordingly. a.anderson

(posted 2017-05-22 13:20:11.07) Hi,

Can you please confirm the tooling needed to connect this part to the FT061PS tubing?

Thanks. nbayconich

(posted 2017-06-05 02:32:32.0) Thank you for contacting Thorlabs. The FT061PS tubing can be directly attached to the FTS61A mating sleeve using the F123 epoxy. Feed the connector/sleeve over the fiber, add a small amount of epoxy to the large inner diameter of the sleeve, then the furcation tubing. No crimping tools are needed to connect the FTS61A to the FT061PS tubing. A Techsupport representative will contact you directly. a1a

(posted 2015-11-05 11:55:42.477) Dear

I would like to know what is the attenuation of FT030 optical fiber to 710nm.

best

Andres Aragoneses besembeson

(posted 2015-11-05 01:28:57.0) Response from Bweh at Thorlabs USA: The FT030 is a furcation tubing or jacket used to protect delicate optical fiber. The It doesn't introduce any attenuation to the optical mode that propagates in the core of the fiber. It seems you would like to know the attenuation of a particular fiber at 710nm. I will follow-up with you to know which fiber you are referring to. marc-andre.lapointe

(posted 2013-11-01 14:44:42.367) The product FT030 from our last order is much different from our previous one. The inner tube is softer and it's much harder to feed the fiber in it. The color of the inner tube is not as white (not the same material?). Overall regidity is also lower. We are only able to feed a few meters of fiber in it. Cannot order anymore since we are not sure of what we will get.

Also, it would be useful to have a 25 pack of relief Boots and Crimp Sleeves for 3mm tubing like product 190066CP that already exist for 2mm tubing. pbui

(posted 2013-11-14 04:02:21.0) Response from Phong at Thorlabs: We are aware of the recent change to the characteristics of the inner tubing and are sorry to hear that you're experiencing some difficulty with it. Though this change has not impacted our usual production of patch cables, we will contact you directly to address your concerns regarding the inner tubing's rigidity. tilman.schmoll

(posted 2013-04-12 12:42:36.763) It would be nice, if you would also be offering splice sleeves.

Another product, which would be nice would be a plastic or metal box, with FC bulkhead connectors at one side. Similar to your interferometer housings but without the detectors and the interferometer inside. tcohen

(posted 2013-04-24 21:28:00.0) Response from Tim at Thorlabs: Thank you very much for your feedback! We will incorporate both of these suggestions into our catalog and I will contact you to keep you updated. klee

(posted 2009-10-29 17:48:40.0) A response from Ken at Thorlabs to qiangqiang.tai: FT030 is just the item number for the tubing and 973-579-7227 is actually our phone number in USA. There should be a white label on the cable with the item number of the cable itself on it. Please find out what that number is so we can determine which fiber you have. qiangqiang.tai

(posted 2009-10-29 10:42:02.0) Dear Ms. or Mr.

This is Philips Research Eindhoven. I am writing this letter for more information about your product FT030. The sery number of the fiber we are using is 973-579-7227 FT030.

1, Is this a single mode fiber which can maintain the states of polarization?

2, How many states of polarization would there be under the laser source of wavelength 780nm, linear polarized light?

3, What will be the alternative fiber for the purpose of getting linear polarized light regarding to the laser source we are using?

4, What would be the delievery time?

Best regards,

Qiangqiang Tai |

| Item # | Inner Diameter |

Outer Diameter |

Kevlar® Threads |

Color | Material | Operating Temperature |

|---|---|---|---|---|---|---|

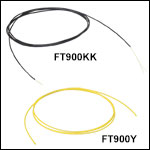

| FT900Y | ≥400 µm | 900 µm | Not Included | Yellow | Hytrel® (UL 94 HB) |

-40 to 70 °C |

| FT900KY | ≥400 µm | Included | Yellow | |||

| FT900KB | Blue | |||||

| FT900KK | Black |

Thorlabs' offers a wide variety of Hytrel® furcation tubing with a 900 µm outer diameter. They are most commonly used as a jacket for single mode fiber because the inner diameter may be too small for many multimode fibers. Our FT900KY, FT900KB, and FT900KK tubing include Kevlar® threads to be used as a pull string when feeding optical fiber. The interior of the yellow FT900Y tubing is empty. The tubing can be removed after installation by using the AFS900 Adjustable Fiber Buffer and Jacket Stripping Tool.

Thorlabs also offers the 190044P and 190044B Strain Relief Boots for covering connector ends when using Ø900 µm furcation tubing.

Hytrel® is a registered trademark of DuPont Polymers, Inc. Kevlar® is a registered trademark of DuPont Safety & Construction, Inc.

| Item # | Inner Diameter |

Outer Diameter |

Color | Operating Temperature |

|---|---|---|---|---|

| FT020 | ≥1.0 mm | 2.0 mm | Orange | -40 to 70 °C |

| FT020-Y | Yellow | |||

| FT020-BK | Black |

Our Ø2.0 mm protective tubing provides more protection than Ø900 µm tubing and fits optical fiber up to 900 µm in diameter. It has an internal structure similar to our Ø3.0 mm tubing pictured below, including a PVC outer jacket, Kevlar® threads, a polypropylene inner protective tube, and a pull string for fiber insertion. It is ideal for constructing patch cables for optogenetics or any other application where a lightweight, flexible, and durable patch cable is needed.

Feeding fiber through furcation tubing can be difficult, so the inner tube of the FT020(-BK) features a pull string to help guide the fiber. The furcation tubing can be removed from the fiber by using the AFS900 Adjustable Stripping Tool. We also offer connector boots and crimp sleeves to use Ø2.0 mm tubing with connectors. The 190066CP pack is for FC/PC-type connectors and the 190088CP pack is for SMA- or ST®-type* connectors. Our stock connectors do not include a boot compatible with Ø2.0 mm tubing. Please note that, due to the small size of this tubing, epoxy must be used after crimping a sleeve from the 190066CP or 190088CP packs to the tubing to ensure that it is properly secured to the tubing. For information on using this tubing with other connector styles, please contact Tech Support.

These furcation tubings can be used with MM (orange standard) and SM (yellow standard) fiber. Additionally, the FT020-BK black furcation tubing is especially useful for preventing ambient visible light from entering the patch cable. For additional light blocking, the FT020-BK tubing can be placed inside FT05SS, FT061PS, or FT080SSW stainless steel tubing.

*ST® is a registered trademark of Lucent Technologies, Inc.

| Item # | Inner Diameter | Outer Diameter | Min Bend Radiusa | Material | Color | Operating Temperatureb |

|---|---|---|---|---|---|---|

| FT023SS | 1.2 ± 0.1 mm | 2.3 ± 0.1 mm | 23 mm | SUS304 | Silver | -60 to 527 °C (-76 to 981 °F) |

Click to Enlarge

Sleeve with Fiber Connector and Stainless Steel Tubing

Click to Enlarge

Sleeve Schematic

Thorlabs' FT23SS Stainless Steel Tubing and FTS23x Sleeves provide a high degree of fiber protection. This thin, lightweight stainless steel tubing provides added protection for more rigorous optogenetics experiments. Its all-metal jacket also prevents visible and IR light from entering through the length of the patch cable. The FTS23x sleeves effectively replace the strain relief boot used with our standard furcation tubing and shield the connection from dust, dirt, and other external contaminants. Please refer to the Compatibility Guide table below to ensure the proper match between the fiber connector and sleeve.

To create a fiber connection, our F112 or F123 Epoxy is used to secure the sleeve along the same central axis as the fiber connector, tubing, and bare fiber. Each sleeve is engraved with a part number ending in an A, B, or D that indicates the inner diameter of the connector side of the sleeve, as shown in the table below. When the fiber connector and tubing are fed into the sleeve, they each encounter a hard stop once they are completely inserted, making it easy to create reliable connections.

The bare fiber can be fed directly into the tubing, which does not contain an inner tube, Kevlar® threads, or a pull string.

Please note that the maximum continuous length we can provide for this tubing is 200 m.

| Compatibility Guide | ||||||

|---|---|---|---|---|---|---|

| Item # | Inner Diameter of Fiber Connector Side |

FC/PC Connectors |

FC/APC Connectors |

SMA Connectors |

ST®a Connectors |

LC Connectorsb |

| FTS23A | 0.138" - 0.150" (3.50 - 3.81 mm) |

30126C3, 30128C3, 30126C9, 30xxxxG3 | 30126A3, 30126A9 | 1xxxxA | 30126B1 | - |

| FTS23B | 0.153" - 0.165" (3.89 - 4.19 mm) |

- | - | - | 10140G1 10127C |

- |

| FTS23D | 0.178" - 0.190" (4.52 - 4.83 mm) |

30xxxC1, 30125D2, 30126G2-xxxx, 30140E1 | 30080K2, 30127A3 | - | - | - |

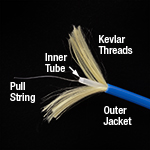

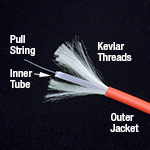

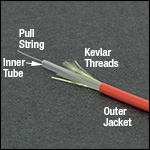

Click to Enlarge

Components of Furcation Tubing

| Item # | Inner Diameter | Outer Diameter | Color | Operating Temperature | Min. Bend Radius |

|---|---|---|---|---|---|

| FT030DF-B | ≥1.0 mm | 3.0 mm | Blue | -40 to 85 °C (-40 to 185 °F) | 2.9 cm |

| FT030DF-G | Green | ||||

| FT030DF-R | Red |

Thorlabs' FT030DF Series Furcation Tubing consists of an outer polyvinylidene fluoride (PVDF) jacket, Kevlar® protective threads, a polypropylene inner fiber tube, and a pull string for fiber insertion, as shown in the photo to the right. Compared to our furcation tubing with a polyvinyl chloride (PVC) outer jacket, the PVDF construction provides additional mechanical strength, making this tubing ideal for use with fragile fibers such as our fluoride fibers. Because of its higher mechanical strength, the flexibility of this tubing is lowered, so our PVC tubing may be preferred in applications where a small bend radius is needed.

The Kevlar® threads that surround the inner tube protect the fiber from damage by cushioning any impact incurred by the PVDF outer jacket. Feeding fiber through furcation tubing can be difficult, so the inner tubes of these tubings feature a pull string to help guide the fiber. The tubing can be removed from the fiber by using the FTS3 Stripping Tool and the T186 Kevlar® Cutting Shears.

This tubing can be used with single mode, polarization-maintaining, or multimode fibers. In applications where preventing light from entering the patch cable, the tubing can be placed inside FT05SS, FT061PS, or FT080SSW stainless steel tubing.

Click to Enlarge

Components of Furcation Tubing

| Item # | Inner Diameter | Outer Diameter | Color | Operating Temperature |

|---|---|---|---|---|

| FT030 | ≥1.0 mm | 3.0 mm | Orange | -20 to 70 °C (-4 to 158 °F) |

| FT030-Y | Yellow | |||

| FT030-BLUE | Blue | |||

| FT030-BK | Black | |||

| FT038 | ≥1.8 mm | 3.8 mm | Red | |

| FT038-BK | Black |

Thorlabs' FT030 and FT038 Furcation Tubings consist of an outer PVC jacket, Kevlar® protective threads, a polypropylene inner fiber tube, and a pull string for fiber insertion, as shown in the photo to the right. The Kevlar® threads that surround the inner tube protect the fiber from damage by cushioning any impact incurred by the PVC outer jacket. Feeding fiber through furcation tubing can be difficult, so the inner tubes of the FT030 and FT038 feature a pull string to help guide the fiber. The tubing can be removed from the fiber by using the FTS3 Stripping Tool and the T186 Kevlar® Cutting Shears.

These furcation tubings can be used with SM (yellow standard), PM (blue standard), and MM (orange standard) fibers. Our FT030-BK and FT038-BK Black Furcation Tubing are especially useful for preventing ambient visible light from entering the patch cable. For additional light blocking, the FT030-BK tubing can be placed inside FT05SS, FT061PS, or FT080SSW stainless steel tubing.

| Item # | Inner Diameter | Outer Diameter | Min Bend Radiusa | Material | Color | Operating Temperatureb |

|---|---|---|---|---|---|---|

| FT05SS | 3.5 mm | 5.0 ± 0.2 mm | 19 mm | SUS304 | Silver | -60 to 527 °C (-76 to 981 °F) |

Click to Enlarge

Sleeve with Fiber Connector and Stainless Steel Tubing

Click to Enlarge

Sleeve Schematic

Thorlabs' FT05SS Stainless Steel Tubing and FTS50x Sleeves provide a high degree of fiber protection. The FT05SS is the same tubing used in our SMA Fiber Bundles. Its all-metal jacket prevents visible and IR light from entering through the length of the patch cable. The FTS50x sleeves effectively replace the strain relief boot used with our standard furcation tubing and shield the connection from dust, dirt, and other external contaminants. Please refer to the Compatibility Guide table below to ensure the proper match between the fiber connector and sleeve.

To create a fiber connection, our F112 or F123 Epoxy is used to secure the sleeve along the same central axis as the fiber connector, tubing, and bare fiber. Each sleeve is engraved with an A, B, or D that corresponds to the suffix of the part number and indicates the inner diameter of the connector side of the sleeve, as shown in the table below. When the fiber connector and tubing are fed into the sleeve, they each encounter a hard stop once they are completely inserted, making it easy to create reliable connections.

The bare fiber can be fed directly into the tubing, which does not contain an inner tube, Kevlar® threads, or a pull string. If desired, the fiber can be fed into our FT030 tubing (which does feature a pull string) before being put into the stainless steel tubing for added convenience and protection.

Please note that the maximum continuous length we can provide for this tubing is 100 m.

| Compatibility Guide | ||||||

|---|---|---|---|---|---|---|

| Item # | Inner Diameter of Fiber Connector Side |

FC/PC Connectors |

FC/APC Connectors |

SMA Connectors |

ST®a Connectors |

LC Connectors |

| FTS50A | 0.138" - 0.150" (3.50 - 3.81 mm) |

30126C3, 30128C3, 30126C9, 30xxxxG3 | 30126A3, 30126A9 | 1xxxxA | 30126B1 | 30126L9 |

| FTS50B | 0.153" - 0.165" (3.89 - 4.19 mm) |

- | - | - | 10140G1 10127C |

- |

| FTS50D | 0.178" - 0.190" (4.52 - 4.83 mm) |

30xxxC1, 30125D2, 30126G2-xxxx, 30140E1 | 30080K2, 30127A3 | - | - | - |

| Item # | Inner Diameter | Outer Diameter | Min Bend Radiusa | Color | Operating Temperatureb |

|---|---|---|---|---|---|

| FT061PS | 3.5 mm | 6.1 mm | 19 mm | Black | -50 to 60 °C (-58 to 140 °F) |

Click to Enlarge

Sleeve with Fiber Connector and Stainless Steel Tubing

Click to Enlarge

Sleeve Schematic

Thorlabs' FT061PS Stainless Steel Tubing and FTS61x Sleeves provide a high degree of fiber protection. The FT061PS has a black plastic coating (olefin elastomer) that is lead-free, halogen-free, and provides chemical, water, and heat resistance. The black coating and all-metal jacket prevent visible and IR light from entering through the length of the patch cable. The FTS61x sleeves effectively replace the strain relief boot used with our standard furcation tubing and shield the connection from dust, dirt, and other external contaminants. Please refer to the Compatibility Guide table below to ensure the proper match between the fiber connector and sleeve.

To create a fiber connection, our F112 or F123 Epoxy is used to secure the sleeve along the same central axis as the fiber connector, tubing, and bare fiber. Each sleeve is engraved with an A, B, or D that corresponds to the suffix of the part number and indicates the inner diameter of the connector side of the sleeve, as shown in the table below. When the fiber connector and tubing are fed into the sleeve, they each encounter a hard stop once they are completely inserted, making it easy to create reliable connections.

The bare fiber can be fed directly into the tubing, which does not contain an inner tube, Kevlar® threads, or a pull string. If desired, the fiber can be fed into our FT030 tubing (which does feature a pull string) before being put into the stainless steel tubing for added convenience and protection.

Please note that the maximum continuous length we can provide for this tubing on a spool is 70 m. Longer maximum continuous lengths up to 100 m are also available, packaged instead as a plastic-wrapped coil.

| Compatibility Guide | ||||||

|---|---|---|---|---|---|---|

| Item # | Inner Diameter of Fiber Connector Side |

FC/PC Connectors |

FC/APC Connectors |

SMA Connectors |

ST®a Connectors |

LC Connectors |

| FTS61A | 0.138" - 0.150" (3.50 - 3.81 mm) |

30126C3, 30128C3, 30126C9, 30xxxxG3 | 30126A3, 30126A9 | 1xxxxA | 30126B1 | 30126L9 |

| FTS61B | 0.153" - 0.165" (3.89 - 4.19 mm) |

- | - | - | 10140G1 10127C |

- |

| FTS61D | 0.178" - 0.190" (4.52 - 4.83 mm) |

30xxxC1, 30125D2, 30126G2-xxxx, 30140E1 | 30080K2, 30127A3 | - | - | - |

| Item # | Inner Diameter | Outer Diameter | Min Bend Radiusa | Material | Color | Operating Temperatureb |

|---|---|---|---|---|---|---|

| FT080SSW | 6.0 ± 0.2 mm | 8.0 ± 0.3 mm | 110 ± 30 mm | SUS304 | Silver | -60 to 527 °C (-76 to 981 °F) |

Click to Enlarge

Stainless Steel Sleeve with Fiber Connector

Click to Enlarge

Sleeve Schematic

Thorlabs' FT080SSW Stainless Steel Tubing and FTS80x Sleeves provide a high degree of fiber protection. The tubing's all-metal jacket prevents visible and IR light from entering through the length of the patch cable. Additionally, the tubing's minimum bend radius of 110 ± 30 mm can help protect fibers that have large bend radii, such as fluoride or large-core fibers. The FTS80x sleeves effectively replace the strain relief boot used with our standard furcation tubing and shield the connection from dust, dirt, and other external contaminants. Please refer to the Compatibility Guide table below to ensure the proper match between the fiber connector and sleeve.

To create a fiber connection, our F112 or F123 Epoxy is used to secure the sleeve along the same central axis as the fiber connector, tubing, and bare fiber. Each sleeve is engraved with a part number ending in an A, B, or D that indicates the inner diameter of the connector side of the sleeve, as shown in the table below. When the fiber connector and tubing are fed into the sleeve, they each encounter a hard stop once they are completely inserted, making it easy to create reliable connections.

The bare fiber can be fed directly into the tubing, which does not contain an inner tube, Kevlar® threads, or a pull string. If desired, the fiber can be fed into our FT030 tubing (which does feature a pull string) before being put into the stainless steel tubing for added convenience and protection.

Please note that the maximum continuous length we can provide for this tubing is 10 m.

| Compatibility Guide | ||||||

|---|---|---|---|---|---|---|

| Item # | Inner Diameter of Fiber Connector Side |

FC/PC Connectors |

FC/APC Connectors |

SMA Connectors |

ST®a Connectors |

LC Connectorsb |

| FTS80A | 0.138" - 0.150" (3.50 - 3.81 mm) |

30126C3, 30128C3, 30126C9, 30xxxxG3 | 30126A3, 30126A9 | 1xxxxA | 30126B1 | - |

| FTS80B | 0.153" - 0.165" (3.89 - 4.19 mm) |

- | - | - | 10140G1 10127C |

- |

| FTS80D | 0.178" - 0.190" (4.52 - 4.83 mm) |

30xxxC1, 30125D2, 30126G2-xxxx, 30140E1 | 30080K2, 30127A3 | - | - | - |

| Compatible SMA905 Connectors | |

|---|---|

| Item # | Bore Diameter |

| 10128V | 128 +5/-0 µm |

| 10145V | 145 +5/-0 µm |

| 10245V | 245 +10/-0 µm |

| 10380V | 380 +15/-0 µm |

| 10490V | 490 +15/-0 µm |

| 10720V | 720 +15/-0 µm |

- Stainless Steel Sleeve for Temperatures up to 250 °C or Vacuum up to 10-10 Torr

- Intended for Use with 353NDPK Epoxy and High-Temperature, Vacuum-Compatible SMA905 Multimode Connectors

- Ideal for Use with Polyimide-Coated Fiber

The FTSB1 Stainless Steel Sleeve fits fiber outer diameters up to 720 µm, such as polyimide-coated fiber. It is intended to be used with our high-temperature SMA905 multimode connectors and can withstand environments with temperatures up to 250 °C or vacuum down to 10-10 Torr.

- Cap Protects End Face of Fiber

- Options Available for LC, FC, ST®, and SMA Connectors

- Plastic, Nickel-Plated Brass, and Rubber Versions Available

| Item # | Ferrule Size | Compatible Connector Types | Material | Number of Caps per Pack | |

|---|---|---|---|---|---|

| CAPL | Ø1.25 mma | LC | White Plastic | 25 | |

| CAPF | Ø2.5 mma | FC or ST®b | Clear Plastic | 25 | |

| CAPFM | Ø2.5 mm | FC (Narrow Key) | Nickel-Plated Brass | 4 | |

| CAPM | Ø3.2 mma | SMA | Black Rubber | 10 | |

| CAPSM | Ø3.2 mm | SMA | Nickel-Plated Brass | 4 | |

- Threaded Caps Protect Bulkheads and Mating Sleeves

- CAPX1: Plastic Caps for FC/PC and FC/APC Bulkheads and Mating Sleeves, Pack of 10

- CAPF1: Metal Cap and Chain for FC/PC and FC/APC Bulkheads and Mating Sleeves

- CAPN1: Metal Cap and Chain for SMA Bulkheads and Mating Sleeves

- CAPT1: Metal Cap and Chain for ST®* Bulkheads and Mating Sleeves

*ST® is a registered trademark of Lucent Technologies, Inc.

Products Home

Products Home

Zoom

Zoom

Furcation Tubing, Sleeves, and Connector Caps

Furcation Tubing, Sleeves, and Connector Caps