BBO Crystals for Spontaneous Parametric Down Conversion (SPDC)

- Optimized for Type I and Type II Spontaneous Parametric Down Conversion

- Source for Polarization Entangled Photons or Heralded Single Photons

- Cut for Normal Incidence with 405 nm, 532 nm, or 775 nm Pump Lasers

- Available in Thicknesses of 1.00 mm, 2.00 mm, and 3.00 mm

When one of these β-BBO Crystals is mounted in the RSP1 mount, the crystal will be centered over the 8-32 (M4) hole in the mount's base without the need for spacers.

NLCQ1

1.00 mm Thick, θ = 29.2°

5.0 mm Aperture

Please Wait

| Key Common Specificationsa | |

|---|---|

| Material | β-BBO (beta-BaB2O4) |

| Aperture | Ø5.0 mm |

| Clear Aperture | >Ø4.0 mm |

| Transmitted Wavefront Error | λ/3 @ 632.8 nm Over Clear Aperture |

| Surface Quality | 20-10 Scratch-Dig |

| Optic Axis Angleb Tolerance | ±0.5° |

Features

- β-BBO (beta-BaB2O4) Crystals Optimized for Spontaneous Parametric Down Conversion (SPDC)

- Type-I or Type-II SPDC

- Collinear and Noncollinear SPDC

- Designed for Use with 405 nm, 532 nm, or 775 nm Pump Lasers

- Markings on Housing Indicate Rotation Axis and Polarization Orientations

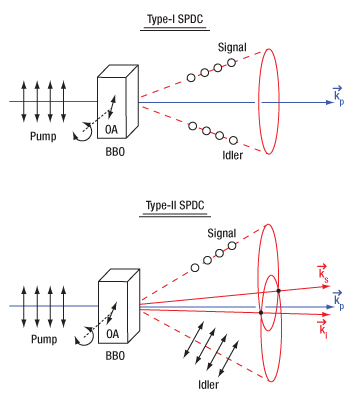

Thorlabs' β-BBO crystals for Spontaneous Parametric Down Conversion (SPDC) are designed for Type-I or Type-II SPDC, a nonlinear process where a single high-energy pump photon is down converted into a signal and idler pair of lower-energy photons, conserving both energy and momentum in the process. SPDC is commonly used as a source for polarization-entangled photon pairs or as a heralded single-photon source. Type-I SPDC outputs signal and idler photons with the same polarization, perpendicular to the pump polarization. Type-II SPDC outputs signal and idler photons with polarizations perpendicular to each other. See the SPDC Tutorial tab for more detailed information about SPDC. Crystals are available for Type-I or Type-II SPDC, both collinear and noncollinear, designed for pump wavelengths of 405 nm, 532 nm, or 775 nm.

SPDC is the reverse process of sum frequency generation (SFG) and, in the degenerate case, second harmonic generation (SHG). As such, these BBO crystals are very similar to crystals designed for second harmonic generation. The primary difference is in the crystal lengths. Crystals for SHG are designed to match the group velocity walk-off of typical pulse durations. By contrast, the SPDC process is not limited in the same way. This allows for the use of thicker crystals that can provide greater efficiency (more signal/idler photon counts) at the cost of a blurring of the wavelength-position correlation of the photons. In order to support applications with differing requirements, these SPDC-optimized BBO crystals are available in thicknesses of 1.00 mm, 2.00 mm, and 3.00 mm.

Each crystal has an antireflection (AR) coating to provide low reflectance over the pump, signal, and idler wavelengths. For plots of the antireflection performance, see the Specs tab. The crystals are mounted in Ø1" housings that have a Ø5.0 mm aperture and engravings to aid in aligning the crystal with the polarization state and propagation direction of the input pump beam for phase matching (see Alignment for Optimal SPDC).

To distinguish between pump and signal/idler photons (especially for collinear SPDC), a high optical density long-pass filter should be used. An optical density of 7 or greater is recommended which typically precludes the use of just a single filter. These crystals produce signal and idler photons with wavelengths in the visible to near infrared where single-photon detection is practical with detectors like the SPDMA Single Photon Detection Module.

Alignment for Optimal SPDC

The front of each crystal’s housing is engraved with the polarization orientations for the pump input beam (marked 2ω) and resulting orthogonally polarized SPDC-generated signal/idler beams (marked 1ω). A zero-order half-wave plate prior to the BBO crystal can be used to rotate the polarization of a linearly polarized pump beam to match the 2ω axis of the crystal. A line across the middle of the housing, labeled Rotation Axis, indicates the axis around which the crystal can be rotated in order to adjust the angle between the pump beam’s propagation direction and the optic axis of the crystal.

Thorlabs recommends mounting these crystals in an RSP1(/M) rotation mount attached to a manual rotation stage, such as our XRNR1(/M) or RP01(/M) stages, as seen in Figure 1.1. When the crystal's housing is installed in the RSP1(/M) mount, the crystal will be centered over the 8-32 (M4) threaded hole in the bottom of the mount without the need to use spacers or additional retaining rings. This allows the crystal to be centered on the RP01(/M) rotation stage, which provides the fine control needed to optimize the phase matching angle by adjusting the angle of incidence. In this example case, the crystal is oriented for a horizontally polarized input pump beam.

To optimize the SPDC process in β-BBO, phase matching can be achieved by aligning the polarization of the pump input beam parallel to the crystal's principal extraordinary axis (marked 2ω), and then adjusting the angle between the optic axis and propagation direction to tune the phase matching, and thus the efficiency of the SPDC process. For each of the crystals below, the angle between the optic axis and the normal to the crystal surface was chosen so that phase matching would be optimized for normally incident light at the design wavelength listed in Tables G1.1 through G5.1. Fine tuning in the range of ±1° around normal incidence will be necessary to achieve the desired collinear or non-collinear phase matching condition. Tuning to a greater angle allows for phase matching with a different wavelength pump laser; see the Specs tab for plots of tuning sensitivity.

Usage, Handling, and Care

Use care and always wear gloves when handling BBO crystals. These crystals scratch easily and the BBO is hygroscopic. Protect the crystals from excess moisture such as high humidity environments. In high-humidity environments, desiccant can help prolong the lifespan of the crystal. If needed, we recommend removing dust by gently puffing with clean dry air only, as detailed in the Blowing Off the Surface of an Optic section in our Optics Handling and Care Tutorial.

| Item # | NLCQ1 | NLCQ2 | NLCQ3 | NLCQ4 | NLCQ5 | NLCQ6 | NLCQ7 | NLCQ8 | NLC07 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Material | β-BBO (beta-BaB2O4) | |||||||||

| Crystal Thickness | 1.00 mm | 2.00 mm | 3.00 mm | 1.00 mm | 2.00 mm | 3.00 mm | 3.00 mm | 3.00 mm | 3.00 mm | |

| Crystal Thickness Tolerance | ±0.05 mm | ±0.05 mm | ±0.05 mm | ±0.05 mm | ±0.05 mm | |||||

| Angle of Optic Axisa (θ) | 29.2° | 41.8° | 26.9° | 22.2° | 19.8° | |||||

| Optic Axis Anglea (θ) Tolerance | ±0.5° | ±0.5° | ±0.5° | ±0.5° | ±0.5° | |||||

| Application | Type-I SPDC | Type-II SPDC | Type-I SPDC | Type-I SPDC | Type-I SPDC | |||||

| Collinear vs Noncollinear | Both | Both | Collinear | Collinear | Both | |||||

| Pump Wavelength at AOI = 0° | 405 nm | 405 nm | 405 nm | 532 nm | 775 nm | |||||

| Signal Wavelength at AOI = 0° | 810 nm | 810 nm | 586 nm | 810 nm | 1550 nm | |||||

| Idler Wavelength at AOI = 0° | 810 nm | 810 nm | 1310 nm | 1550 nm | 1550 nm | |||||

| Angle of Incidence Tuning Sensitivityb | ||||||||||

| AR Coating, Entrance Face, 0° AOI | R<0.5% at 405 and 810 nm | R<0.5% at 405 nm | R<1% at 532 nm | Ravg<4% 650 - 850 nm and 1300-1700 nm |

||||||

| AR Coating, Exit Face, 0° AOI | R<3% at 586 and 1310 nm | R<2.5% at 810 and 1550 nm | ||||||||

| AR Coating Curves | Raw Data |

Raw Data |

Raw Data |

Raw Data |

||||||

| Laser Induced Damage Threshold | 9.5 J/cm2 (532 nm, 5.3 ns, 100 Hz, Ø218 μm) | 0.6 J/cm2 (1550 nm, 52 fs FWHM, S-Pol, 104 Pulses) |

||||||||

| Aperture Diameter | Ø5.0 mm | |||||||||

| Clear Aperture | >Ø4.0 mm | |||||||||

| Mounted Diameter | 1" (25.4 mm) | |||||||||

| Surface Quality | 20-10 Scratch-Dig | |||||||||

| Transmitted Wavefront Error | λ/3 @ 632.8 nm Over Clear Aperture | |||||||||

| Physical and Optical Properties | ||

|---|---|---|

| Material | β-BBO (beta-BaB2O4) | |

| Crystal Structure | Trigonal, Space Group R3c | |

| Transparency Range | 189 - 3500 nm | |

| Second-Order Nonlinear Coefficients | d21 = 2.2 pm/V d31 = 0.08 pm/V d22 = 2.2 pm/V |

|

| Nonlinear Refractive Index (Kerr Index)a | 4.9 x 10−20 m2/W @ 1032 nm | |

| Sellmeier Coefficientsb | Ordinary Ray | |

| Extraordinary Ray | ||

| Thermal Conductivity | 1.2 W / m ⋅ K (⊥ C) 1.6 W / m ⋅ K (|| C) |

|

| Mohs Hardness | 4.5 Mohs | |

| Density | 3.85 g/cm3 | |

Spontaneous Parametric Down Conversion and Phase Matching

Spontaneous Parametric Down Conversion (SPDC) is a common process for generating correlated photon pairs. In SPDC, a single pump photon generates two photons inside a nonlinear crystal, conserving both energy and momentum. These photons are created virtually simultaneously, so that one of the photons can be used to signal the existence of the other, making it possible to perform measurements on single photons. For this reason, the signal and idler photons are referred to as a herald (or heralding) and heralded photon. Additionally, degenerate Type-II SPDC can be used to create polarization entangled photon pairs.

Optimizing for SPDC in these β-BBO crystals requires choosing a crystal cut angle appropriate to the wavelength of the pump laser and the phase matching conditions for the desired down conversion process. Tuning curves for each crystal offered are provided by the graphs in the Specs tab. Additional information and background, which can be helpful for interpreting the graphed data as well as more effectively using the crystals to generate down converted photons, is included in the expandable sections below.

Click on a question to expand the corresponding passage that provides an answer, and then click again to contract the section.

What is nonlinear optics?

Click to Enlarge

Figure 3.1 A beam of light accumulates phase and is attenuated as it propagates through a linear medium, but the photons of the beam do not interact with each other. Due to this, the input (Ein) and output (Eout) electric fields have the same frequency (ω) and are directly proportional.

Click to Enlarge

Figure 3.2 This nonlinear optical medium supports second harmonic generation and the input light is the same as in Figure 3.1. In addition to providing fundamental-frequency electric fields, as in Figure 3.1, the light output from this nonlinear medium also includes frequency doubled light, whose electric field Eout(2ω) is proportional to the square of the total input electric field.

The field of nonlinear optics refers to different optical phenomena that can occur when light alters the properties of the surrounding material. These phenomena are called nonlinear optics because the strength of the material's response is proportional to the square, cube, or other higher power of the light's total electric field. Since the light usually must be intense to produce a measurable nonlinear response, laser light is often used to generate desired nonlinear effects.

A material's nonlinear response occurs in addition to the linear response, which is proportional to only the first power of the light's electric field. The interaction between the light and the material is completely conventional (linear) when optical and material conditions are not appropriate for generating nonlinear phenomena. Then, light waves in a material propagate together without affecting one another, whether or not they are part of the same beam or pulse.

An example of a material's linear response to light is illustrated in Figure 3.1, in which an input beam is described by its electric field amplitude (Ein), frequency (ω), and polarization orientation (vertical). The beam accumulates phase and experiences conventional losses from effects like reflection and material absorption before it is output, but otherwise the beam is unaffected. The total electric field (Eout) output by the material has an amplitude that is directly proportional to the that of the input beam. In addition, the input and output light has the same frequency and polarization direction.

Nonlinear processes occur when the presence of the light in the material creates conditions in which different light waves can interact with one another. In some cases, light waves from the same beam or pulse interact, and in other cases light waves with significantly different frequencies and / or polarizations interact. Nonlinear phenomena include the generation of new frequencies of light, lensing of laser light propagating in uniform materials, and modulation effects. In the case of frequency generation, the light output by the nonlinear material will include a frequency of light different than any of the input beams' frequencies.

An example of nonlinear frequency generation is illustrated in Figure 3.2, in which the light is incident on a nonlinear optical material. While the incident light is the same as in Figure 3.1, the material supports second harmonic generation, and the electric field output from this crystal includes a new color, which has double the frequency of the input beams. The amplitude of this frequency-doubled light is proportional to the square of the total input electric field, and the losses accumulated by the two fundamental-frequency beams include the photons converted into frequency-doubled light.

What is spontaneous parametric down conversion (SPDC)?

Click to Enlarge

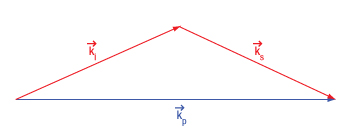

Figure 3.3 Conservation of momentum in non-collinear spontaneous parametric down conversion requires an angular deviation of the signal (ks) and idler (ki) photons to compensate for the larger magnitude of the sum of their momenta.

Click to Enlarge

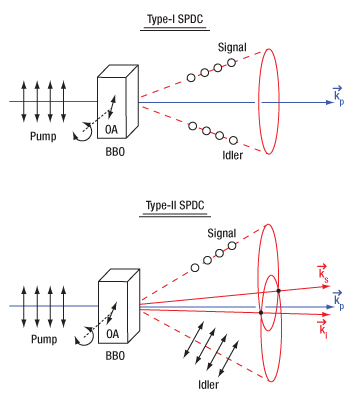

Figure 3.4 The signal and idler photons emitted during spontaneous parametric down conversion form either a cone (Type-I SPDC) or a pair of cones (Type-II SPDC). The two intersection lines between the signal and idler emission cones in Type-II SPDC (labeled ks and ki, respectively) are the wavevectors that correspond to polarization entangled photons. The optical axis (OA) of the crystal can be changed by rotating the crystal, altering the phase matching conditions. This diagram shows noncollinear SPDC emission, but collinear emission with a gaussian profile is also possible.

Spontaneous Parametric Down Conversion

Spontaneous parametric down conversion (SPDC) is the reverse process to sum frequency generation (SFG). One common example of degenerate SFG, called second harmonic generation (SHG), is used to generate 532 nm wavelength photons from a 1064 nm pump laser. Unlike SFG, however, SPDC cannot be explained by classical fields. The SPDC process is called spontaneous (as opposed to stimulated) because the photon pair is created without the presence of an external electromagnetic field at the signal wavelength. Classical theories only allow for the generation of an idler and signal beam if a weak signal beam already exists, a process called parametric amplification. Therefore, the existence of the SPDC process can only be explained with quantum mechanics.

Conservation of Energy and Momentum in SPDC

Since energy and momentum are conserved in the SPDC process, the energy and momentum of the photon being down converted must be equal to the energy and momentum of the pair of output photons. The implication of this conservation is that experimental parameters must be set up to allow for conservation of energy and momentum during SPDC or else the process cannot proceed. The following example demonstrates how this conservation determines experimental parameters such as the photon output angles, polarization states of the output photons, and the nonlinear crystal cut angle.

In general, the output idler and signal photons will have propagation directions that fall on the surface a cone (Type-I SPDC) or a pair of cones (Type-II SPDC), as shown in Figure 3.4. These conical emission patterns can be observed as annuluses when viewed on a plane. Conservation of momentum requires that the sum of the wave vectors for these resulting output photons be equal to that of the input pump photon.

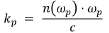

To simplify the calculations, let's look at the collinear case of SPDC, where the pump, signal, and idler photons are all propagating in the same direction. In this case, both the energy and momentum conservation relations simplify to scalar equations:

and

Here, ω represents the angular frequency of the photon and k the magnitude of the wave vector. The indices p, s, and i stand for pump, signal, and idler, respectively. The frequencies and wavevectors of each of these three photons are not independent but linked via the expression

where n(ωp) is the frequency-dependent index of refraction of the crystal at the pump frequency ωp, and c is the speed of light in vacuum. The signal and idler photons have analogous relations which together allow for the conservation of momentum expression to be rewritten as:

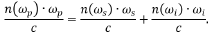

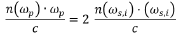

Degenerate SPDC

For the further simplifying case of degenerate SPDC, we can assume the wavelength (and thus frequency ω) of the signal and idler photons are the same and thus the previous expression simplifies to:

where (ωs,i) is the frequency of the degenerate signal and idler photons. Since ωp = 2 (ωs,i) for energy conservation, this demonstrates that we need the same index of refraction for both the short-wavelength pump and long-wavelength signal/idler photons, i.e. n(ωp) = n(ωs,i). This can be accomplished through the use of birefringent crystals, which have different indices of refraction for different polarizations of light. The crystal orientation can be rotated with respect to the input polarization of the pump beam to create the appropriate phase matching conditions to conserve energy and momentum and allow for spontaneous parametric down conversion.

Categories of SPDC

Stepping back from the simple case above, SPDC can be broken down into three categories all dealing with how the process is phase matched: collinear vs non-collinear wavevector orientations,

Additional discussion on the SPDC categories and tuning between them is found in the How is the SPDC process tuned in nonlinear crystals? section.

Can all crystals be used for SPDC?

Only optical materials which have a non-zero χ(2) parameter support SPDC, and not all crystals fulfill this requirement. An example of a crystal that can be used for SPDC is β-BBO. A material is crystalline when its atoms, ions, or molecules are arranged in a repeating pattern. If there is no central point around which the crystal pattern is symmetric (i.e. if the crystal is not centrosymmetric), the crystal has a non-zero χ(2) parameter and can be used for SPDC.

Click to Enlarge

Figure 3.6 When light's oscillating electric field interacts with a centrosymmetric material, an electron's induced potential energy, which is illustrated as a function of the electron's displacement (x) from its equilibrium position, is symmetric and described by a polynomial function consisting of even powers of x.

Click to Enlarge

Figure 3.5 This cubic crystal structure includes two different ions, A and B, in a repeating pattern. The crystal structure is centrosymmetric since the crystal at point (x, y, z) and its inverse (-x, -y, -z) are identical.

Click to Enlarge

Figure 3.8 When light's oscillating electric field interacts with a non-centrosymmetric material, an electron's induced potential energy, which is illustrated as a function of the electron's displacement (x) from its equilibrium position, is asymmetric for larger displacements. This curve is described by a polynomial function consisting of even and odd powers of x.

Click to Enlarge

Figure 3.7 This wurtzite crystal structure includes two different ions, A and B, in a repeating pattern. The crystal structure is not centrosymmetric since there is at least one point (u, v, w) which is not identical to its inverse (-u, -v, -w).

Centrosymmetric Crystal

The repeating crystalline pattern of one type of centrosymmetric crystal is illustrated in Figure 3.5. As is true for all centrosymmetric crystals, the structure at point (x, y, z) is identical to the structure at the inverse location (-x, -y, -z). Due to the crystal's structural symmetry, the material's response is the same whether the incident light's electric field vector points in one direction or in the opposite direction.

The material’s response to light occurs due to interactions between the light’s oscillating electric field and the electrons in the material. An electron bound to an atom in the material experiences forces contributed by the atom and the light’s electric field, as well as the surrounding atoms in the material. The blue curve in Figure 3.6 was calculated using the Lorentz model of an atom, which takes these forces into account using a classical mechanics approach. This model can also be used to estimate the χ(2) parameter.

In Figure 3.6, the X-axis corresponds to the position of the electron, which is in equilibrium at x = 0. The input light’s oscillating electric field moves the electron back-and-forth between positive and negative displacements. The greater the intensity of the electric field, the larger the displacement of the electron. The central and surrounding atoms exert a restoring force on the displaced electron, returning it to equilibrium. This restoring force provides the electron with potential energy, which is plotted on the Y-axis and increases as the electron moves further from equilibrium.

At moderate displacements, the central atom exerts the majority of the restoring force, and the electron’s corresponding potential energy is symmetric and approximately parabolic (the dashed gray curve is a parabolic fit). At larger displacements, achieved using higher-intensity light, surrounding atoms contribute more to the restoring force, as well as the electron’s potential energy. At these larger displacements, the electron’s potential energy deviates from parabolic but remains symmetric.

The symmetric material response is a consequence of the centrosymmetric structure of the crystal. In order to support SPDC, this curve would have to be asymmetric. Mathematically, a non-zero χ(2) parameter requires the polynomial describing the curve to include odd powers of x, while the polynomial describing the curve in Figure 3.6 includes only even powers of x.

Non-Centrosymmetric Crystal

An example of a non-centrosymmetric material is shown in Figure 3.7. In the case of these materials, there is aways at least one location (u, v, w) for which the crystal structure differs from the crystal structure at the inverse location (-u, -v, -w).

The potential energy of an electron, as a function of its displacement from its equilibrium position, has been calculated for a non-centrosymmetric material using the Lorentz model of the atom (Figure 3.8). When the incident light has low intensity, the displacement of the electron from its equilibrium position is small, and the majority of the restoring force is provided by the central atom. Within this limited region, the electron's corresponding potential energy function is symmetric and approximately parabolic, which indicates a linear optical material response. When illuminated by higher-intensity light, the electron's displacement is greater and the surrounding atoms contribute more to the restoring force. Since the distribution of the surrounding atoms is not symmetric, neither is the restoring force nor the potential energy well confining the electron for these higher displacements.

The polynomial needed to model this asymmetric curve includes even, as well as odd, powers of x. It is the non-zero cubic (x3) terms in this polynomial that provide a non-zero χ(2) parameter. A third-order polynomial term is required for the generation of the second-order nonlinearities quantified by the χ(2) parameter, since the x3 term is the lowest-order correction to the linear optics model. Because the asymmetric response only becomes significant for larger electron displacements, high-intensity light is required to induce SPDC.

Uniaxial Crystal

A secondary requirement for efficient production of light through nonlinear processes, which is discussed in more detail in the How is the SPDC process tuned in nonlinear crystals? section, is the so-called phase matching condition. At a high level, phase matching is the conservation of momentum between the input and output photons of the nonlinear process. This is frequently accomplished by utilizing the birefringence of anisotropic optical materials.

Uniaxial crystals are a specific type of anisotropic material, where two of the three principal refractive indices are the same. The name “uniaxial” is derived from there being a single propagation axis in these crystals, known as the optical axis or c-axis, on which the index of refraction is the same for all polarization orientations. Many common optical materials belong to the uniaxial class: calcite, quartz, sapphire, and β-BBO.

Reference:

Robert W. Boyd, Nonlinear Optics (Academic Press, New York, 1992) pp. 17 - 52.

Can a crystal's refractive index depend on the light's polarization orientation within the crystal?

Certain materials have a refractive index that depends on the orientation of the light's electric field polarization. An example is birefringent materials, which include uniaxial crystals like β-BBO. Uniaxial crystals characteristically have two principal refractive indices, which are called the ordinary (no) and extraordinary (ne) refractive indices. The principal refractive indices are the maximum and minimum the material can provide. Since light’s electric field (E) is always polarized perpendicular to the propagation direction (k), both the propagation direction and polarization state must be known to determine the refractive indices experienced by the light's polarization components.

A Cartesian coordinate system, with the Z-axis aligned along the crystal’s optic axis (c), can be used to relate the light's polarization components (Ex, Ey, and Ez) to a birefringent crystal's geometry.

In uniaxial crystals, the refractive index can be determined by referencing the angles of the propagation direction and polarization orientation relative to the crystal's optic axis (c).

Since the crystal is uniaxial, the refractive index for fields polarized orthogonal to the crystal's optic axis is no. For fields parallel to the crystal's optic axis, the refractive index is ne. The two components (Ex and Ey) of light polarized orthogonal to the crystal's optic axis have refractive indices equal to no, since the crystal is uniaxial. Light polarized parallel (Ez) to the crystal’s optic axis has a refractive index equal to ne.

It is also possible for birefringent materials to provide a refractive index value between no and ne, which is discussed in a following section.

Click to Enlarge

Figure 3.9 The diagram on the left indicates the propagation direction (k) of the incident light is along the optic axis (c) of the crystal. The incident light can be decomposed into orthogonal polarization components Ex and Ey. The diagram on the right is a refractive index ellipsoid, with a conic section (red circle) at the XY-plane. This constant-radius circle shows the refractive index is always no in this case and the crystal does not affect the light's polarization.

Light Propagating Parallel to the Optic Axis

(Example: Optical Windows)

Light propagating along the optic axis (Z-axis) of a birefringent material always has a refractive index equal to no. This is a defining trait of the optic axis.

The left side of Figure 3.9 illustrates the electric field components of light propagating along the crystal's optic axis. These polarization state components can include Ex and Ey, but not Ez. In other words, the electric field vector is orthogonal to the Z-axis, so the angle φ equals 90°. The relative magnitude of Ex and Ey depends on angle α.

The right side of Figure 3.9 uses an ellipsoidal volume, the so-called index ellipsoid, to map all possible refractive indices provided by the material for all combinations of light propagation directions and polarization orientations. In the case of this material, the maximum possible refractive index is ne and the minimum is no. The opposite can be true for other materials. The red circle drawn on the ellipsoid is a conic section that marks the refractive indices that light propagating along the optic axis will experience. The refractive index of both Ex and Ey components equals no. Due to this, E has a refractive index of no, regardless of the orientation of the E vector in the XY-plane. Therefore, the Ex and Ey components travel with the same phase velocity, and the polarization state stays the same as the light propagates.

Optical windows made from uniaxial crystals, such as sapphire (for example Item # WG31050), are typically cut or polished so that normally incident light propagates parallel to the optic axis. This is done so that the window has no effect on the polarization state of the transmitted light, as described above. When the end faces are orthogonal to the optic axis like this, the crystal is often described as Z-cut or C-cut.

Click to Enlarge

Figure 3.10 The diagram on the left indicates the incident light's propagation direction (k) and polarization state orientation (E), which can be decomposed into orthogonal components Ex and Ez. The propagation direction is aligned to the Y-axis and is orthogonal (θ = 90°) to the optic axis (c) of the crystal. The diagram on the right is a refractive index ellipsoid, with conic sections (red ellipses) drawn in the XZ- and XY-planes. The refractive index (ne) of the extraordinary component (Ee = Ez) is indicated by the intersection of the Z-axis and ellipse, while the refractive index (no) of the ordinary component (Eo = Ex) is indicated by the intersection of the X-axis and the ellipse. The angle φ determines the two components' relative magnitudes.

Click to Enlarge

Figure 3.11 The diagram on the left indicates the incident light's propagation direction (k), which is aligned to the Y-axis, which is orthogonal (θ = 90°) to the optic axis (c) of the crystal. Since φ is 0°, the only polarization component is Ez, which is also the extraordinary component. The diagram on the right indicates this component has a refractive index of ne.

Click to Enlarge

Figure 3.12 The diagram on the left indicates the incident light's propagation direction (k), which is aligned to the Y-axis, which is orthogonal (θ = 90°) to the optic axis (c) of the crystal. Since φ is 90°, the only polarization component is Ex, which is also the ordinary component. The diagram on the right indicates this component has a refractive index of no.

Light Propagating Perpendicular to the Optic Axis

(Example: Wave Plate)

When linearly polarized light incident on a birefringent material propagates in a direction orthogonal to the optic axis (θ = 90°), the light may have components polarized both parallel and perpendicular to the optic axis (Z-axis). This is illustrated in Figure 3.10, in which the light’s propagation direction is aligned to the Y-axis for convenience. The refractive index of the electric field component parallel to the optic axis (Ez) is ne, and the component perpendicular to the optic axis (Ex) is no. This is the largest refractive index difference that can exist between two polarization components in the material.

The vertical, red circle on the right side of Figure 3.10 is the conic section of the index ellipsoid in a plane perpendicular to the k-vector. The horizontal, red elliptical conic section indicates a difference between the refractive indices of the orthogonal principal polarization axes of  and

and  .

.

Due to different refractive indices, the two polarization components travel at different velocities as they propagate through the material. This causes a phase shift between the two polarization states Ez and Ex.

Wave plates are often fabricated from uniaxial birefringent materials, with the optic polished and mounted so that normally incident light propagates orthogonal to the optic axis. Markings on the wave plate housing, such as the ones on Item # WPQ05M-266, or flat features on the perimeter of the optic, identify the orientations of the ordinary and extraordinary axes, or for a typical waveplate made of crystal quartz the so-called fast and slow axes, respectively.

Light polarized parallel to the fast axis travels with a faster velocity in the material due to the lower refractive index, compared with light polarized parallel to the slow axis. Quartz, a commonly used waveplate material, is a positively uniaxial crystal with a smaller ordinary refractive index compared to its extraordinary index. For quartz, the fast axis is the ordinary axis.

Tuning a wave plate requires rotating the optic in the XZ-plane, around the Y-axis, so that the light's propagation direction is maintained perpendicular to the optic axis. This rotation changes the angle φ, while keeping θ = 90°.

When the angle φ is between 0° and 90°, the linear polarization state has both orthogonal Ex and Ez components, and the wave plate will delay one component relative to the other. However, note that since θ is unchanged, there is no change in the indices of refraction of the two principal orthogonal polarization orientations along  and

and  .

.

When φ = 0°, as illustrated in Figure 3.11, the light's polarization state is oriented along the optic axis. This provides an extraordinary component (Ez = Ee) without an ordinary component. This component has a refractive index equal to ne. Since there is only one polarization component, the wave plate does not affect the polarization state.

The polarization state is similarly unaffected when the linear polarization state is aligned with the X-axis (φ = 90°), as seen in Figure 3.12. In this case, there is an ordinary component (Ex = Eo) without an extraordinary component and the refractive index is no.

Click to Enlarge

Figure 3.13 In the diagram on the left, the propagation direction (k) of the incident light and the optic axis (c) of the uniaxial birefringent crystal are in the same plane (XZ plane). The angle (θ) between k and c is arbitrary. The input fundamental field, represented by the red vector, is parallel to the Y-axis. The SHG light is polarized perpendicularly, represented by the green vector in the XZ plane. Rather than decompose the SHG polarization into components Ex and Ez, the light is typically described as an extraordinary wave (E'e) with a refractive index, n'e. In the diagram on the right, n'e, which depends on θ, is indicated by the intersection of the conic section illustrated by the red ellipse with the XZ plane.

Click to Enlarge

Figure 3.15 How θ and γ are defined in a laboratory setup.

Click to Enlarge

Figure 3.14 In this diagram, the propagation direction (k) of the incident light and the optic axis (c) of the uniaxial birefringent crystal are in the same plane (XZ-plane). The angle (θ) between k and c is arbitrary. In this case, the incident fundamental field (E), represented by the red vector, is rotated off of the laboratory reference frame by an angle γ, and thus only a portion of the fundamental (Eoγ) is converted by SHG into the resulting polarization E'e, represented by the green vector.

Light Propagating at an Arbitrary Angle

(Example: Nonlinear Crystals)

This is a case study using Type-I second harmonic generation (SHG) as an example of an application of birefringent crystals in nonlinear optics. SHG is the reverse case of degenerate SPDC, so this treatment will be instructive.

In uniaxial crystals, the field polarizations are arranged as in Figure 3.13 for Type-I second harmonic generation (SHG). The k-vector is at an angle θ from the optic axis,  , and in the XZ plane. The input fundamental electric field (Eo) is polarized parallel to one of the principal ordinary axes, in this case the Y-axis, and has a refractive index of no. The index of refraction for light polarized in the ordinary direction, parallel to

, and in the XZ plane. The input fundamental electric field (Eo) is polarized parallel to one of the principal ordinary axes, in this case the Y-axis, and has a refractive index of no. The index of refraction for light polarized in the ordinary direction, parallel to  , is independent of changes to θ.

, is independent of changes to θ.

The SHG light is polarized in the XZ plane and is orthogonal to both the Eo and the k-vector. Rather than decompose the polarization of the SHG light into Ex and Ez components, the electric field is typically described as an extraordinary wave (E'e). The refractive index for this extraordinary wave, n'e, changes as a function of θ. n'e(θ) can be calculated using the equation in Figure 3.13. The ellipse defining the extraordinary index of refraction as a function of θ is a conic section of the index ellipsoid. The two extreme cases are 1) θ = 0°, where the field is polarized along the other principal ordinary axis,  , and the index of refraction is no, or 2), θ = 90°, where the field is polarized along the principal extraordinary axis,

, and the index of refraction is no, or 2), θ = 90°, where the field is polarized along the principal extraordinary axis,  , and the index of refraction is ne. The prime (') notation is used to denote index of refraction for cases in between the two extreme cases of θ.

, and the index of refraction is ne. The prime (') notation is used to denote index of refraction for cases in between the two extreme cases of θ.

Figure 3.14 shows a departure from an ideal polarization orientation for  . The fundamental field now driving the Type-I SHG process is the Eoγ component of the incident field. At γ = 90°, there would be zero SHG output, since the drive field Eoγ = 0.

. The fundamental field now driving the Type-I SHG process is the Eoγ component of the incident field. At γ = 90°, there would be zero SHG output, since the drive field Eoγ = 0.

In practice, γ is nonzero when the polarization states of light in a laboratory reference frame are not matched to the intrinsic principal axes in the crystal frame. To orient the two reference frames together, e.g. the vertically polarized light from the laser on the optical table is parallel to  in the crystal, we mount the nonlinear crystal in a rotation stage to finely adjust γ to zero, first by eye using the markings on the housing and then further, if necessary, using the SHG output power as feedback. Figure 3.15 shows the orientation of γ in a laboratory frame rotation of the crystal. In this example case, the nonlinear crystal is mounted in an RSP1 rotation mount on top of an RP01 rotation stage. Changes in γ and θ adjust the orientation of the optic axis,

in the crystal, we mount the nonlinear crystal in a rotation stage to finely adjust γ to zero, first by eye using the markings on the housing and then further, if necessary, using the SHG output power as feedback. Figure 3.15 shows the orientation of γ in a laboratory frame rotation of the crystal. In this example case, the nonlinear crystal is mounted in an RSP1 rotation mount on top of an RP01 rotation stage. Changes in γ and θ adjust the orientation of the optic axis,  . In this case, adjustments in γ have been used to align

. In this case, adjustments in γ have been used to align  with the horizontal plane and one of the principle ordinary axes vertically. For a vertically polarized input beam, this orientation allows the rotation stage to be used to adjust θ.

with the horizontal plane and one of the principle ordinary axes vertically. For a vertically polarized input beam, this orientation allows the rotation stage to be used to adjust θ.

How is the SPDC process tuned in nonlinear crystals?

Click to Enlarge

Figure 3.16 The signal and idler photons emitted during noncollinear spontaneous parametric down conversion form either a cone (Type-I SPDC) or a pair of cones (Type-II SPDC). The two intersection lines between the signal and idler emission cones in Type-II SPDC (labeled ks and ki, respectively) are the wavevectors that can correspond to polarization entangled photons. This Type-II SPDC diagram shows noncollinear SPDC emission, but collinear emission with a gaussian profile is also possible.

Click to Enlarge

Figure 3.17 For SPDC, it is necessary for the pump and signal/idler photons to experience the same index of refraction despite their different wavelengths. Birefringent materials like β-BBO allow for this by having different indices of refraction for two crystal axes so that photons with different polarizations and different wavelengths can be phase matched.

Tuning Type-I, Degenerate, Non-Collinear SPDC

In the following example, degenerate non-collinear spontaneous parametric down conversion (SPDC) with a 405 nm pump is used to demonstrate how tuning is performed. Using the same logic, degenerate and non-degenerate SPDC tuning can be achieved for any pump wavelength. This example, where the degenerate signal and idler have the same polarization, perpendicular to that of the pump, is called Type-I SPDC, as shown in the upper panel of Figure 3.16. In contrast, for Type-II SPDC, the signal and idler have polarizations perpendicular to each other, with one being parallel to the pump polarization, as shown in the lower panel of Figure 3.16.

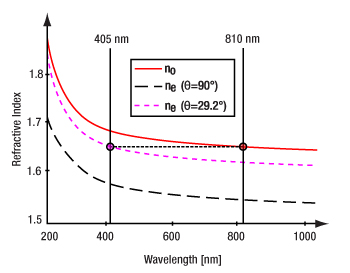

As discussed previously, for SPDC to occur, the index of refraction within the nonlinear crystal for the pump at 405 nm must be the same as the index of refraction for both the signal and idler at 810 nm. The refractive index as a function of wavelength for β-BBO is shown in Figure 3.17. The red solid curve indicates the refractive index for the ordinary beam (no). The black dashed curve is the refractive index for the extraordinary beam (ne) if the input beam is orthogonal to the crystal plane. By rotating the crystal axes relative to the wavevector of the incident pump, the refractive index curve can be moved until ne (405 nm, pump) = no (810 nm, signal/idler). This is called phase matching and allows for efficient SPDC from pump photons at 405 nm to signal and idler photon pairs at about 810 nm each. In this example, the optic axis of the crystal must be at an angle of 29.2° relative to the incident 405 nm pump beam to allow for optimal phase matching. Typically, a crystal cut to a similar angle (like our NLCQ1, NLCQ2, or NLCQ3 crystals for this example) would be used to allow for near-normal incidence and maximizing of the clear aperture.

Thorlabs' β-BBO crystals are designed to provide near-phase-matched conditions for normally incident input light for a specified set of wavelengths. The faces of the β-BBO crystals are cut such that the angle between the normally incident light and the optic axis is approximately the phase-matching angle for the specified frequencies. See the Specs tab for detailed specifications for the crystals currently available. The phase matching angle can be tuned by rotating the crystal to alter the angle between the optical axis (OA) and the incident pump as shown in Figure 3.16. An adjustment of typically only a few degrees can either optimize the performance of the crystal in the setup or match another wavelength within the crystal's operating range.

Tuning Between Type-I and Type-II SPDC

Depending on the exact phase matching parameters, the signal and idler photon pairs either leave the crystal either collinearly with the same mode as the pump beam, or non-collinearly on a cone with a small opening angle. The angle of the cone and wavelengths of the signal/idler pair can be tuned by adjusting the angle of incidence to the crystal.

For Type-I SPDC (see the upper panel of Figure 3.16), in the specific example discussed above, the degenerate noncollinear signal and idler photons emit in a singular annular cone with a half angle of 2.88°. Rotating the crystal's optical axis to an angle of 28.64° changes the degenerate phase matching condition from non-collinear to collinear, collapsing the conical emission pattern to a Gaussian spatial mode collinear with the pump.

Due to the large difference in angle between Type-I and Type-II SPDC, it is often necessary to use crystals with different cut angles. For example, Thorlabs' NLCQ1 β-BBO crystal is cut at 29.2° to enable Type-I phase matching with a 405 nm pump and degenerate 810 nm output at near-normal incidence. For Type-II SPDC at the same wavelengths, Thorlabs' NLCQ4 BBO crystal cut at 41.8° would allow for phase matching at near normal incidence.

For Type-II SPDC (see the lower panel of Figure 3.16), the signal and idler have distinct noncollinear emission cones each with a half angle of 5°. The signal and idler emission cones are separated from each other by a half angle of 1.7°. This results in the two cones intersecting at two lines. For larger increased negative angular offset (larger optic axis angle relative to the pump propagation), the individual cone half angles increase but the separation is relatively un-changed. Due to the increased cone half angle, the intersection lines of the two emission cones move outwards (transverse). As the AOI is tuned towards the collinear case, the two noncollinear annular emission cones separate and then collapse back to the collinear Gaussian modes.

It is important to note that for a pump wavelength of 405 nm, the wavelength of the signal and idler photons will not always be exactly 810 nm. It is also allowed that photon pairs can be of differing wavelengths, such as 812 nm and 808 nm. In those cases, the photon with the longer wavelength (lower energy) makes a slightly larger angle with the pump beam and vice versa. This wavelength deviation is limited by how well the phase matching is fulfilled at the different wavelengths, as the efficiency of the SPDC process will drop sharply with non-optimal phase matching.

The broad phase matching criteria for these crystals allows for photon pairs to be emitted under a vast range of wavelengths and angles. This means that photons generated by SPDC are distributed over a large spatial region. When measuring with two detectors in coincidence, one must be careful that detectors are positioned in the correct location so that they are able to detect photons from the same signal/idler pair.

The Effect of Crystal Thickness on SPDC

While phase matching can be achieved with a wide variety of wavelengths, crystals, and geometries, optimizing the system for the desired output introduces many more variables that should be considered. One such factor is the thickness of the crystal. Thicker crystals can provide a higher photon pair generation rate for a given pump power as there is a longer path for the light to interact with the crystal. However, increasing thickness also blurs the wavelength-position correlation of the SPDC photons, as pairs created at different spots in the crystal have different points of origin for the cone on which they are emitted. In Type-II SPDC, the birefringent material of β-BBO causes differing group velocities in the ordinary and extraordinary axes due to different indices of refraction, causing temporal walk-off between the perpendicularly polarized signal and idler photons. This effect acts to label the signal and idler photons, reducing the quality of entanglement. As this temporal walk-off is a propagation effect, it scales linearly with increasing crystal thickness.

Thicker crystals also tighten the pump bandwidth for a given set of phase matching conditions as seen in Figure 3.18. More consequentially, the thicker crystals also result in tighter angular bandwidth for the emitted signal and idler photons, see Figure 3.19. This tighter angular distribution reduces the wavelength-position correlation and can make it more challenging to isolate specific photon pairs, since in an actual experiment an iris is typically used to spatially filter the output signal and idler beams, thus passing a more restricted range of wavelengths.

Click to Enlarge

Figure 3.18 As crystal thickness increases, the pump bandwidth that is phase-matched gets narrower. In this series of calculations, a fixed output wavelength was chosen and the resulting pump wavelengths that can achieve phase matching are plotted. This theoretical data was calculated with the web tool SPDCalc.

Click to Enlarge

Figure 3.19 The angular dispersion of the emitted signal and idler photons becomes tighter with increasing crystal thickness. This theoretical data was calculated with the web tool SPDCalc.

| Posted Comments: | |

user

(posted 2025-07-22 16:07:50.15) Hi, I want to confirm that although NLCQ8 gives signal and idler of different wavelength, I can use this for 515 nm input with certain angle tuning to get degenerate signal at 1030nm, right? EGies

(posted 2025-07-24 04:50:24.0) Thank you for contacting Thorlabs. When using the NLCQ8, tuning to a larger angle of incidence allows for phase matching with a different wavelength pump laser. I have reached out to you directly regarding this. Hamza Hussain

(posted 2025-07-03 15:21:14.31) Hi, I have recently purchased a 500mW laser to use for SPDC using type 2 BBO crystal NLCQ6. Could this damage the crystal in anyway? We have been using a 50mW laser as of now. tdevkota

(posted 2025-07-10 01:30:48.0) Thank you for contacting Thorlabs. The coating on those crystals should easily withstand 500 mW of 405 nm CW light with typical focal conditions (several 10s to 100s of micron spot size). David Mugglin

(posted 2025-04-21 15:36:43.653) Hello,

I was wondering what kind of efficiency one can expect with the NLCQ5 or NLCQ6 crystal. Is one out a 10^6 photons down converted? Is it more like one out of 10^12 or even less? Just wondering if you have any estimates.

Thanks so much.

PS-we have already purchased the NLCQ5 and the NLCQ6. tdevkota

(posted 2025-04-28 12:21:26.0) Thank you for contacting Thorlabs. Due to the many variables involved in the user setup, it’s difficult to provide a meaningful estimate of the photon efficiency. I have reached out to you directly to discuss this further. |

| Table G1.1 Key Specifications for SPDC Applicationsa | ||||

|---|---|---|---|---|

| Item # | NLCQ1 | NLCQ2 | NLCQ3 | |

| Crystal Thickness | 1.00 mm | 2.00 mm | 3.00 mm | |

| Angle of Optic Axis (θ)b | 29.2° ± 0.5° | |||

| Application | Type-I SPDC | |||

| AR Coating (AOI = 0°) | R<0.5% at 405 and 810 nm | |||

| AR Coating Curves | Raw Data |

|||

| Pump Wavelength (2ω) | AOI = 0° | 405 nm | ||

| SPDC Signal / Idler Wavelength (1ω) | AOI = 0° | 810 nm / 810 nm | ||

- Mounted Crystal with Antireflection (AR) Coating for 405 nm and 810 nm

- Optic Axis Angle of 29.2°

- Cut for a 405 nm Pump Wavelength and 810 nm Signal/Idler Wavelength at Normal Incidence

These β-BBO crystals are designed to produce 810 nm Type-I SPDC emission from an input beam with a center wavelength of 405 nm. They are available with thicknesses of 1.00, 2.00, or 3.00 mm and feature an AR coating to reduce surface reflections over the pump, signal, and idler wavelength ranges. These mounted crystals can be pumped with a pulsed laser like the NPL41B nanosecond pulsed laser diode, the frequency doubled output of a Ti:sapphire laser, or a 405 nm diode laser such as the L405P20 diode.

| Table G2.1 Key Specifications for SPDC Applicationsa | ||||

|---|---|---|---|---|

| Item # | NLCQ4 | NLCQ5 | NLCQ6 | |

| Crystal Thickness | 1.00 mm | 2.00 mm | 3.00 mm | |

| Angle of Optic Axis (θ)b | 41.8° ± 0.5° | |||

| Application | Type-II SPDC | |||

| AR Coating (AOI = 0°) | R<0.5% at 405 and 810 nm | |||

| AR Coating Curves | Raw Data |

|||

| Pump Wavelength (2ω) | AOI = 0° | 405 nm | ||

| SPDC Signal / Idler Wavelength (1ω) | AOI = 0° | 810 nm / 810 nm | ||

- Mounted Crystal with Antireflection (AR) Coating for 405 nm and 810 nm

- Optic Axis Angle of 41.8°

- Cut for a 405 nm Pump Wavelength and 810 nm Signal/Idler Wavelength at Normal Incidence

These β-BBO crystals are designed to produce 810 nm Type-II SPDC emission from an input beam with a center wavelength of 405 nm. They are available with thicknesses of 1.00, 2.00, or 3.00 mm and feature an AR coating to reduce surface reflections over the pump, signal, and idler wavelength ranges. These mounted crystals can be pumped with a pulsed laser like the NPL41B nanosecond pulsed laser diode, the frequency doubled output of a Ti:sapphire laser, or a 405 nm diode laser such as the L405P20 diode.

| Table G3.1 Key Specifications for SPDC Applicationsa | ||||

|---|---|---|---|---|

| Item # | NLCQ7 | |||

| Crystal Thickness | 3.00 mm | |||

| Angle of Optic Axis (θ)b | 26.9° ± 0.5° | |||

| Application | Type-I SPDC | |||

| AR Coating (AOI = 0°) | R<0.5% at 405 nm R<3% at 586 and 1310 nm |

|||

| AR Coating Curves | Raw Data |

|||

| Pump Wavelength (2ω) | AOI = 0° | 405 nm | ||

| SPDC Signal / Idler Wavelength (1ω) | AOI = 0° | 586 nm / 1310 nm | ||

- Mounted Crystal with Antireflection (AR) Coating for 405 nm, 586 nm, and 1310 nm

- Optic Axis Angle of 26.9°

- Cut for a 405 nm Pump Wavelength and 586/1310 nm Signal/Idler Wavelength at Normal Incidence

This β-BBO crystal is designed to produce 586 nm and 1310 nm Type-I SPDC emission from an input beam with a center wavelength of 405 nm. It is available with a thicknesses of 3.00 mm and features an AR coating to reduce surface reflections over the pump, signal, and idler wavelength ranges. This mounted crystal can be pumped with a pulsed laser like the NPL41B nanosecond pulsed laser diode, the frequency doubled output of a Ti:sapphire laser, or a 405 nm diode laser such as the L405P20 diode.

| Table G4.1 Key Specifications for SPDC Applicationsa | ||||

|---|---|---|---|---|

| Item # | NLCQ8 | |||

| Crystal Thickness | 3.00 mm | |||

| Angle of Optic Axis (θ)b | 22.2° ± 0.5° | |||

| Application | Type-I SPDC | |||

| AR Coating (AOI = 0°) | R<1% at 532 nm R<2.5% at 810 and 1550 nm |

|||

| AR Coating Curves | Raw Data |

|||

| Pump Wavelength (2ω) | AOI = 0° | 532 nm | ||

| SPDC Signal / Idler Wavelength (1ω) | AOI = 0° | 810 nm / 1550 nm | ||

- Mounted Crystal with Antireflection (AR) Coating for 532 nm, 810 nm, and 1550 nm

- Optic Axis Angle of 22.2°

- Cut for a 532 nm Pump Wavelength and 810/1550 nm Signal/Idler Wavelength at Normal Incidence

This β-BBO crystal is designed to produce 810 nm and 1550 nm Type-I SPDC emission from an input beam with a center wavelength of 532 nm. It is available with a thicknesses of 3.00 mm and features an AR coating to reduce surface reflections over the pump, signal, and idler wavelength ranges. This mounted crystal can be pumped with frequency doubled lasers at 532 nm and diode-pumped solid state lasers such as our DJ532-40 laser.

| Table G5.1 Key Specifications for SPDC Applicationsa | ||||

|---|---|---|---|---|

| Item # | NLC07 | |||

| Crystal Thickness | 3.00 mm | |||

| Angle of Optic Axis (θ)b | 19.8° ± 0.5° | |||

| Application | Type-I SPDC | |||

| AR Coating (AOI = 0°) | Ravg<4%, 650 - 850 nm and 1300-1700 nm | |||

| AR Coating Curves | Raw Data |

|||

| Pump Wavelength (2ω) | AOI = 0° | 775 nm | ||

| SPDC Signal / Idler Wavelength (1ω) | AOI = 0° | 1550 nm / 1550 nm | ||

- Mounted Crystal with Antireflection (AR) Coating for 775 nm and 1550 nm

- Optic Axis Angle of 19.8°

- Cut for a 775 nm Pump Wavelength and 1550 nm Signal/Idler Wavelength at Normal Incidence

This β-BBO crystal is normally used for second harmonic generation (SHG) but in the reverse process also produces 1550 nm Type-I SPDC emission from an input beam with a center wavelength of 775 nm. It is available with a thicknesses of 3.00 mm and features an AR coating to reduce surface reflections over the pump, signal, and idler wavelength ranges. This mounted crystal can be pumped with a Ti:sapphire laser, a frequency doubled 1550 nm laser like our FSL1550 femtosecond laser, or diode lasers like the DBR780PN laser. This crystal can also be found on the BBO Crystals for Second Harmonic Generation page.

Products Home

Products Home

Zoom

Zoom

β-BBO Crystals for SPDC

β-BBO Crystals for SPDC