Lens Tube / Beam Path Covers

- Span Gaps Between Lens Tubes

- Enclose Light Path in Optical Systems

- Options for Light-Tight Lens Tube Systems

SC2L24

for Ø2" Lens Tubes

SC1L24

for Ø1" Lens Tubes

Slip-On Covers

SC05L24

for Ø1/2" Lens Tubes

SM1CPL

Flexure Sleeve Coupler

for Ø1" Lens Tubes

SM1B3

Rubber Bellows for Ø1" Lens Tubes

SC1800RL

for Ø1" Lens Tubes

The C128CC Clamp Secures an Aluminum Cover Over a Beam Path

Please Wait

| Quick Links | |

|---|---|

| Lens Tube Covers | Compatible Lens Tubes |

| Flexure Sleeve Couplers | SM1, C-Mount, SM2 |

| Rubber Bellows | SM1, C-Mount, SM2 |

| PTFE Bellows | SM1 |

| Slip-On Covers | SM05, SM1, SM2 |

| Aluminum Covers | SM1 |

| Slip Rings and Clamps for Aluminum Lens Tube Covers | |

Features

- Covers for Spanning Gaps in Lens Tube or Cage Systems

- Flexure Clamping Covers Provide Light-Tight Seal and Structural Rigidity

- Rubber and PTFE Bellows Provide a Flexible Light-Tight Solution

- Non-Flammable, Anodized or Unanodized Aluminum Tubing can be Cut to Desired Length

- Keep Optical Systems Clean of Dust and Other Contaminants

- Slip Rings and Clamps to Mount Aluminum Covers onto Posts or Between Cage System Components

We offer four varieties of lens tube covers. The Flexure Sleeve Couplers are aluminum, flexure-based couplers that clamp onto two lens tubes, providing structural rigidity and a light-tight enclosure. The Lens Tube Bellows are adjustable in length and provide a light-tight connection for lens tubes. The Plastic Slip-On Covers can be cut to any desired length and slipped on fixed lens tubes to enclose the light path. Finally, the Lens Tube Covers can be cut to size by the user (see the Cutting Tutorial tab) and crimped onto lens tubes to create customized lengths of non-flammable lens tube couplers. See the table to the right for the lens tube sizes compatible with each coupler type.

Slip rings and mounting clamps are available that are designed to enable easy placement and removal of aluminum lens tube covers in optical systems. Our C127RC(/M) Slip Ring has a 8-32 (M4) tap for compatability with our Ø1/2" posts. The C127TC Clamp includes a counterbore for post mounting, while the C128CC Clamp can be mounted onto 30 mm cage system components to create an enclosed beam path in a cage system.

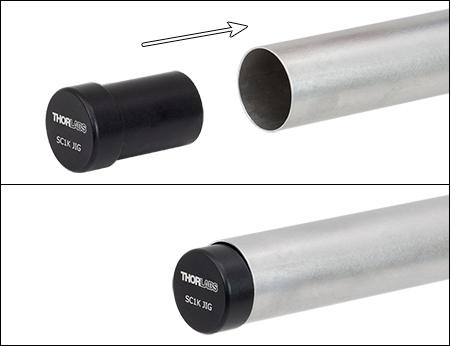

The SC600 and SC1800RL Aluminum Lens Tube Covers can be easily cut to custom lengths using our SC1K Tool Kit, pictured below. This kit contains a tubing cutter and de-burring tool, jig, and pliers, allowing the user to cut the aluminum covers and then crimp the edges to form a light press fit. These lens tube covers, sold at the bottom of this page, can be cut to a desired length up to 1828.8 mm (for the unanodized aluminum version) or 609.6 mm (for the anodized aluminum version).

To Cut the Aluminum Cover Tubing:

Click to Enlarge

Step 1: Rotate the knob on the tubing cutter counterclockwise to open the cutter far enough to insert the tubing between the rollers and the blade.

Click to Enlarge

Step 2: Slide the tubing into the tubing cutter between the rollers and the circular blade. Position the blade along the tubing such that a cut will produce the desired length of tubing.

Click to Enlarge

Step 3: Rotate the knob on the tubing cutter clockwise until it begins to lightly cut into the tubing. Although you want the blade to be in good contact with the tubing, do not overtighten the cutter, as that may cause tube cover deformation.

Click to Enlarge

Step 4: Slowly rotate the tubing cutter to score the tubing, rotating the tool, blade first. Take care that the cutter completes its rotation where it began, making a closed ring around the tubing rather than a spiral that will fail to cut the tubing. Continue to carefully rotate the cutter around the tube until the blade has cut all the way through the thickness of the tubing. With each rotation, tighten the knob on the top of the cutter so that the blade remains in good contact with the tubing but avoid over tightening. Note that the knob will only need to be tightened about a half of a turn from its initial scoring position to cut through the tubing.

Click to Enlarge

Step 5: After the tubing is cut through, pull the deburring tool out of the body of the tubing cutter to debur the cut edges.

Click to Enlarge

Step 6: Lightly press the flat edge of the deburring tool against the inside of the cut edge of the tubing. Maintaining pressure, rotate the tool around the inner edge of the tubing to remove any rough spots created by the cutting process.

To Crimp the Ends of the Aluminum Cover Tubing:

Click to Enlarge

Step 1: Insert the jig into the end of the tubing so that the engraving faces outward. The lip of the jig should be pushed up against the dust cover tubing.

Click to Enlarge

Step 2: Using the soft jaw pliers supplied in the kit, squeeze the dust cover so that the two sides of the tubing make contact with the jig. The force applied by the pliers should be over the jig to ensure that the tubing is not deformed.

Click to Enlarge

Step 3: The end of the lens tube cover tubing is now crimped and will have a light press fit with all Thorlabs SM1 series lens tubes.

| Posted Comments: | |

jrameau

(posted 2016-12-09 14:46:39.52) Actually, I was hoping you had a version for your 2" lens tubes. It would be useful to couple a lamp to a UHV chamber where I need to be able to move the lamp around a bit while purging the beam path with N2. tfrisch

(posted 2016-12-15 02:54:30.0) Hello,thank you for contacting Thorlabs. Unfortunately, the SM1B3 is rubber and should not be used in Ultra High Vacuum as it will out-gas. I apologize for the inconvenience. ludoangot

(posted 2016-02-03 19:09:13.317) A below that fits over SM2 tubes would be much welcome (an SM2 version of your SM1B3). besembeson

(posted 2016-02-04 10:56:01.0) Response from Bweh at Thorlabs USA: Thanks for your feedback. We will look into adding this as a stock item. I will contact you regarding offering a special version if the 2" clear aperture is important in your application. Otherwise, the SM1B3 with an adapter such as the SM1A2 and SM1M05 may work. michaelbellos

(posted 2015-06-18 18:54:56.213) I wish you carried the 2inch version of the lens tubes in both anodized and, especially, non-anodized Aluminum. Also, the 2inch version of the flexure campling coupler (SM1CPL) would be great. Please let me know when these items come out. besembeson

(posted 2015-09-21 12:33:08.0) Response from Bweh at Thorlabs USA: Thanks for the feedback. We can provide these as special items for now and will follow with you regarding quoting these. hha07

(posted 2015-02-10 19:01:16.327) This product would be very useful in a Ø2" version for use with the lens tube of this type. Is it possible to order that?

Best wishes,

Hans Andersen

Aarhus University cdaly

(posted 2015-02-12 03:26:08.0) Response from Chris at Thorlabs: We do currently offer the 2" diameter lens tube cover SC2L24. If it is the bellows instead you are requesting, I'm afraid, at this time, we cannot offer an SM2 compatible version as a custom. |

Click to Enlarge

SM1CPL Holding Two Ø1" Lens Tubes. A rubber gasket makes the coupler light tight.

Click to Enlarge

Lens Tubes Are Secured by Tightening Two 5/64" Hex Screws

- Flexure Design Clamps Onto Lens Tubes

- RTV103 Black Silicone Gasket Provides Light-Tight Coupling

- Lens Tubes can be Positioned Along the Entire Length, Facing Either Direction

These Lens Tube Couplers are flexure-clamping sleeves that couple lens tubes. Each coupler features a black silicone gasket along the clamping section to provide light-tight coupling of lens tubes (see photos to the right). A lens tube can be slid into each end of the coupler and secured by tightening the two 5/64" (2 mm) hex screws on the side of the sleeve. The coupled lens tubes may be clamped with either the internal or external threads facing out and can be mounted at any position along the length of the coupler as long as there is at least 6 mm of the tube inside the clamp.

The SM1CPL Flexure Sleeve Couplers can hold any Ø1" lens tube, C-Mount extension tube, or other Ø1.2" outer diameter cylindrical object, and are available in lengths of 0.5", 1.0", and 3.0". The SM2CPL Flexure Sleeve Couplers can hold any SM2 lens tube or other Ø2.2" outer diameter cylindrical object.

Click to Enlarge

Secure lens tube connections with hose clamps for long-term stability.

Click for Details

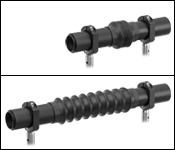

The SM1B3 bellows contracts and expands from 1.50" to 8.66" long.

- Light-Tight Rubber Bellows with Slip Cover Design

- SM1B3: Fits Over Ø1" Lens Tubes, C-Mount Extension Tubes, or Other 1.2" Outer Diameter Objects

- Adjustable in Length from 1.50" to 8.66" (38.0 - 220.0 mm)

- SM2B45: Fits Over Ø2" Lens Tubes or Other 2.2" Outer Diameter Objects

- Adjustable in Length from 1.26" to 4.92" (32.0 - 125.0 mm)

The SM1B3 and SM2B45 nitrile rubber bellows are designed to seal the gap between Ø1" and Ø2" lens tubes, respectively, and maintain a light-tight path. The SM1B3 features a 1.06" inner diameter that stretches over Ø1" lens tubes with either internal or external threads, and is adjustable in length from 1.50" to 8.66". The SM2B45 features a 2.05" inner diameter that stretches over Ø2" lens tubes with either internal or external threads, and is adjustable in length from 1.26" to 4.92". The stiff rubber construction ensures that the bellows do not reduce the clear aperture of the lens tube system while being compressed or stretched. These bellows can be used in temperatures from -30 to 100 °C.

Note: While soap and water is recommended to clean the SM1B3 and SM2B45, isopropyl alcohol may be used in moderate amounts as a cleaning agent. Acetone is not recommended, as it will cause damage to the nitrile rubber.

Click for Details

The KF25 flange is compatible with our SM1CH coupler clamp and coupling adapters (included in the SM1BTK Kit).

- Light-Tight PTFE Bellows with KF25 Flanges for Mounting

- Couples to Ø1" Lens Tubes Using Non-Rotating SM1 Couplers (Available Separately or in SM1BTK Kit)

- Adjustable in Length from 1.30" to 5.05" (33.0 mm to 128.3 mm)

- PTFE is Low Outgassing; is UV and Ozone Resistant; and has Minimal Sag and Low Deformation

- KF25 Flange for Robust Coupling to SM1-Threaded Components

- SM1BTK Kit Includes PTFE Bellows, Two SM1CH Coupling Clamps, One SM1CF Adapter, and One SM1CM Adapter

The SM1BT PTFE Bellows is designed to seal the gap between Ø1" lens tubes and maintain a light-tight path. The bellows features a KF25 flange that is compatible with our non-rotating SM1 lens tube couplers. The coupler clamp creates a connection between the bellows and Ø1" lens tubes with either internal or external threads, depending on the coupling adapters used. The stiff PTFE material ensures that the bellows do not reduce the clear aperture of the lens tube system while being compressed or stretched. Alternatively, the SM1TC clamp can mount onto the Ø1.2" smooth segments of the bellows; however, the lens tubes cannot be attached to the bellows when using this method. These bellows can be used in temperatures from -30 to 150 °C.

The SM1BTK Kit includes the PTFE bellows, two SM1CH Coupling Clamps, an SM1CF Adapter with Internal SM1 (1.035"-40) Threads, and an SM1CM Adapter with External SM1 Threads. This mounting hardware provides the bellows with internal SM1 threads on one side and external SM1 threads on the other end. For stable mounting and linear adjustability, see the video example above.

Click to Enlarge

A slip cover connecting a mirror mount and a detector. The app lists do not include the breadboard, BNC Cable, or screws.

- 24" Long Plastic Cover for Ø1/2", Ø1", or Ø2" Lens Tubes

- Easy to Slip On and Off

The SC05L24, SC1L24, and SC2L24 lens tube covers are designed to fit over SM05 (Ø1/2"), SM1 (Ø1"), and SM2 (Ø2") lens tubes, respectively. They can be used to span the gap between any two fixed lens tubes, thereby enclosing the light path in an optical setup. These plastic covers are easy to slip on and off and are sold in 24" lengths, which can be easily cut to the desired length by the end user. The SC05L24, SC1L24, and SC2L24 have outer diameters of 0.85", 1.35", and 2.35", respectively.

Please note that these lens tube covers are not light tight. Additionally, their plastic construction makes them unsuitable for high-power laser applications.

Click to Enlarge

SC600 Lens Tube Cover with SM1 Lens Tube Mounted in C127TC Clamp

- Non-Flammable Lens Tube Covers

- Raw Tubing Available in 6' (1828.8 mm) Length

- Anodized Tubing Available in 2' (609.6 mm) Length

- Fit Over Ø1" Lens Tubes, C-Mount Extension Tubes, or Other 1.2" Outer Diameter Objects

- Aluminum Dust Cover Kit Contains Tools for Cutting and Crimping Aluminum Lens Tube Covers

- 1.27" Outer Diameter

The SC600 and SC1800RL Aluminum Lens Tube Covers are designed to fit over SM1 (Ø1") lens tubes and are made from anodized and unanodized aluminum, respectively. These non-flammable covers can be easily cut to custom lengths using our SC1K Tool Kit. This kit contains a tubing cutter and de-burring tool, jig, and pliers, allowing the user to cut the aluminum covers and then crimp the edges to form a light press fit. For instructions on how to use these tools to cut and crimp the tubing to the desired length, please see the Cutting Tutorial tab at the top of the page.

These tube covers can be post-mounted using our C127RC(/M) Slip Ring or C127TC Tube Clamp. It is also possible to mount these to 30 mm cage components with 4-40 mounting taps using our C128CC Adapter Clamp (each sold below).

| Item # | Compatible Components | Inner Diameter | Locking Screw Hex |

|---|---|---|---|

| C127RC(/M) | Ø1.27" Components Such as Aluminum Lens Tube Covers |

1.27" (32.3 mm) | 9/64" (3.0 mm) |

| C127TC | 5/64" (2.0 mm) | ||

| C128CC | 1.28" (32.6 mm) |

Click to Enlarge

SC600 Lens Tube Cover with SM1 Lens Tube Mounted in a C127TC Clamp

Click for Details

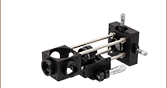

The C128CC can be mounted onto any 30 mm cage-compatible component with 4-40 cage rod mounting holes.

Click to Enlarge

Two C128CC clamps are being used to secure an SC600 Lens Tube Cover between two KCB1 mounts to cover the beam path.

- Easily Secure Ø1.27" Cylindrical Components

- Ideal for Use with Aluminum Lens Tube Covers

- Enclose Optical Path Between Two Components

These slip rings and clamps are designed to enable easy placement and removal of aluminum lens tube covers in optical systems. Ø1.27 mm aluminum lens tube covers and other cylindrical components can be mounted into a slip ring by passing them through the ring’s clear aperture and securing the flexure lock. To remove the cover on a clamp, simply unscrew the clamping screw(s), open the mount, and lift the tube out. This feature is useful for users who do not have the room to slide the entire cover out of a mount due to tight space constraints or are concerned with disturbing the rest of the system.

The C127RC(/M) Slip Ring has flat sides that are designed to conserve space in a system. A 9/64” (3.0 mm) locking screw is located along the top flat surface of the mount for easy access. This mount also includes a 8-32 (M4) tap for mounting onto our Ø1/2” posts.

The C127TC incorporates a hinge design that utilizes one 5/64" (2.0 mm) locking cap screw. The hinged clamp supplies the mounting force needed to secure the component in place. The C127TC can be mounted directly to any of our posts using the #8 (M4) counterbore on the bottom of the clamp.

Alternatively, the C128CC is a two piece design that utilizes two captive 5/64" (2.0 mm) cap screws to connect the two pieces. A 5/64" (2.0 mm) locking setscrew is included to provide the mounting force needed to secure the component in place. Two #4 counterbores, spaced 30 mm apart, on the front of the clamp are included to attach the C128CC directly to any 30 mm cage component with 4-40 mounting taps. This allows for the creation of an enclosed optical path between two 30 mm cage accessories using our aluminum lens tube covers, as shown in the photo to the right and above. The two piece design allows the cover to be easily removed to verify or correct alignment issues. Two 4-40 cap screws with a 5/64" (2.0 mm) hex are included to mount the clamp. The C128CC is also available in a pack of four, item # C128CC-P4.

Products Home

Products Home

Zoom

Zoom

Lens Tube Covers

Lens Tube Covers